-

Posts

685 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by captain_hook

-

Very nice! You‘re approaching the finish line. Keep up the good work!

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Very nice! I like the „painting with wood“ and your clean and crisp work.

- 143 replies

-

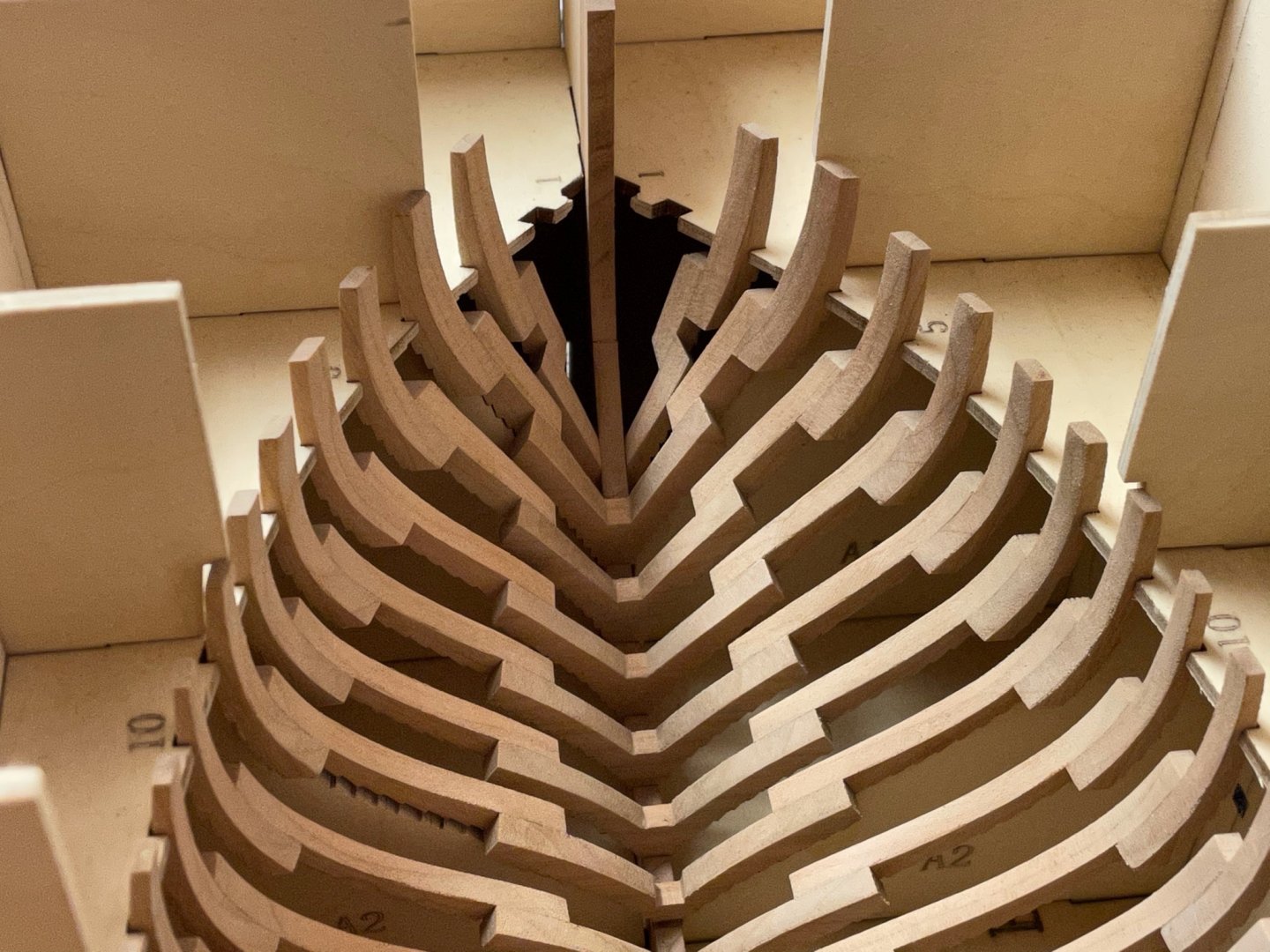

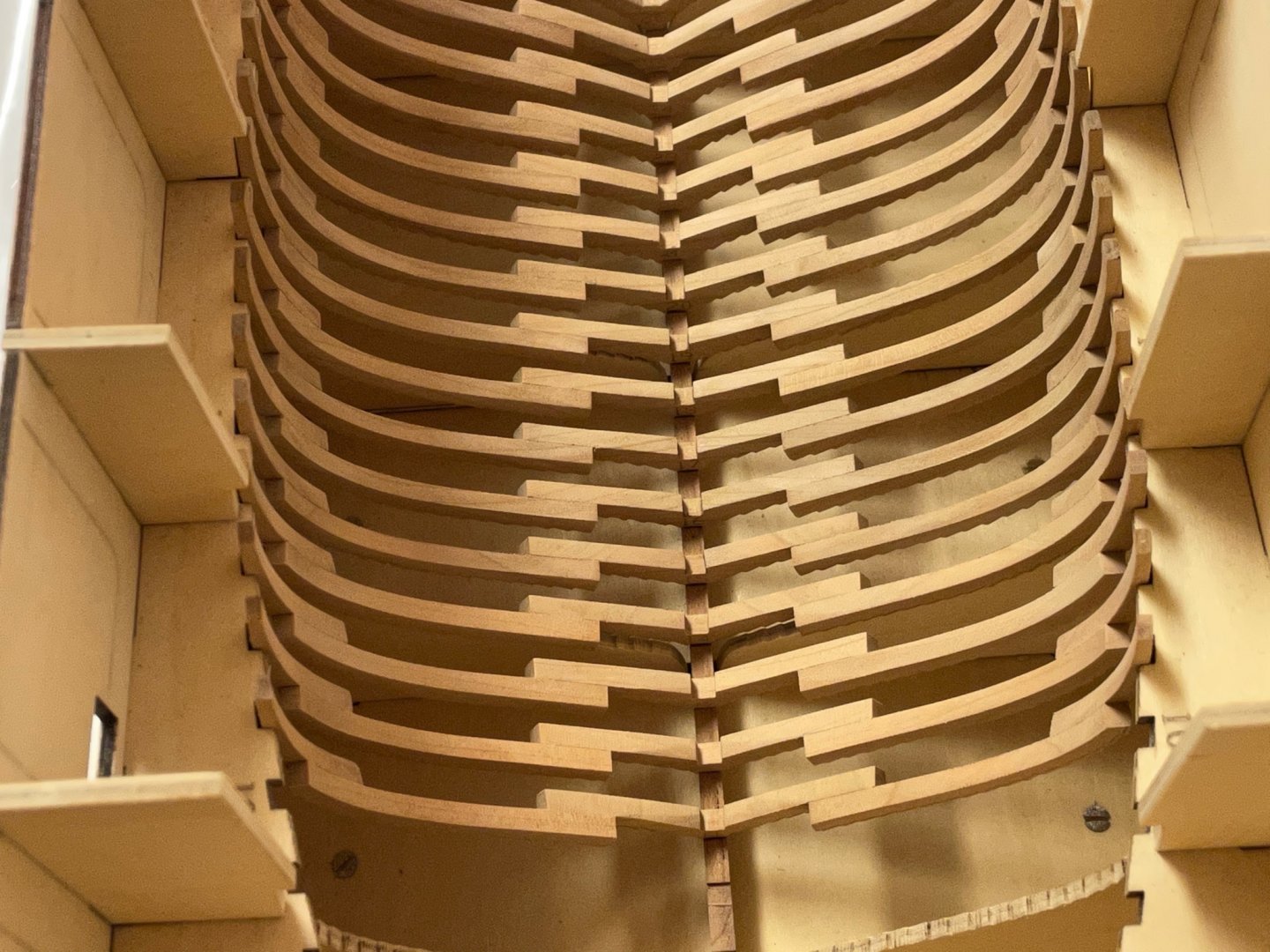

Finally found the time to correct the jig. The side-parts A1 - 7 have sawtooth pattern cut out to match the related frames but I had some difficulties to fit the frames in. So I deconstructed the jig (it wasn’t glued) and corrected all side parts basically by sanding off about 2 millimeters of substance. As the position of the frames is determined by the horizontal jig and the keel anyway changing the side-parts doesn‘t affect the geometry of the hull. Now all frames are aligned properly but still only dry-fitted. I have to enlarge some frame-slots to fit in the keelson next. Then I will be able to show something new instead of frames all the time. Stay tuned .. and save. Andreas

-

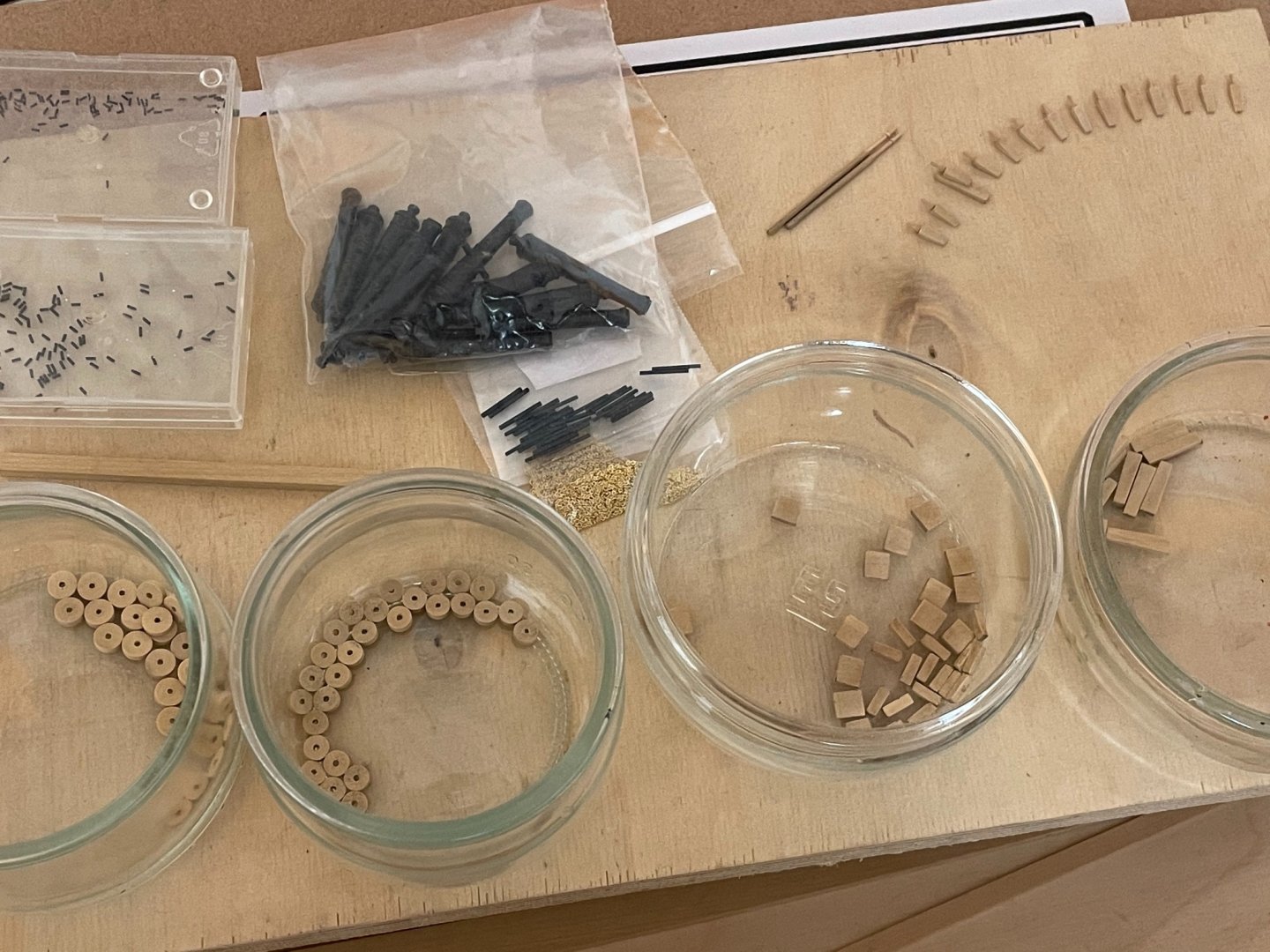

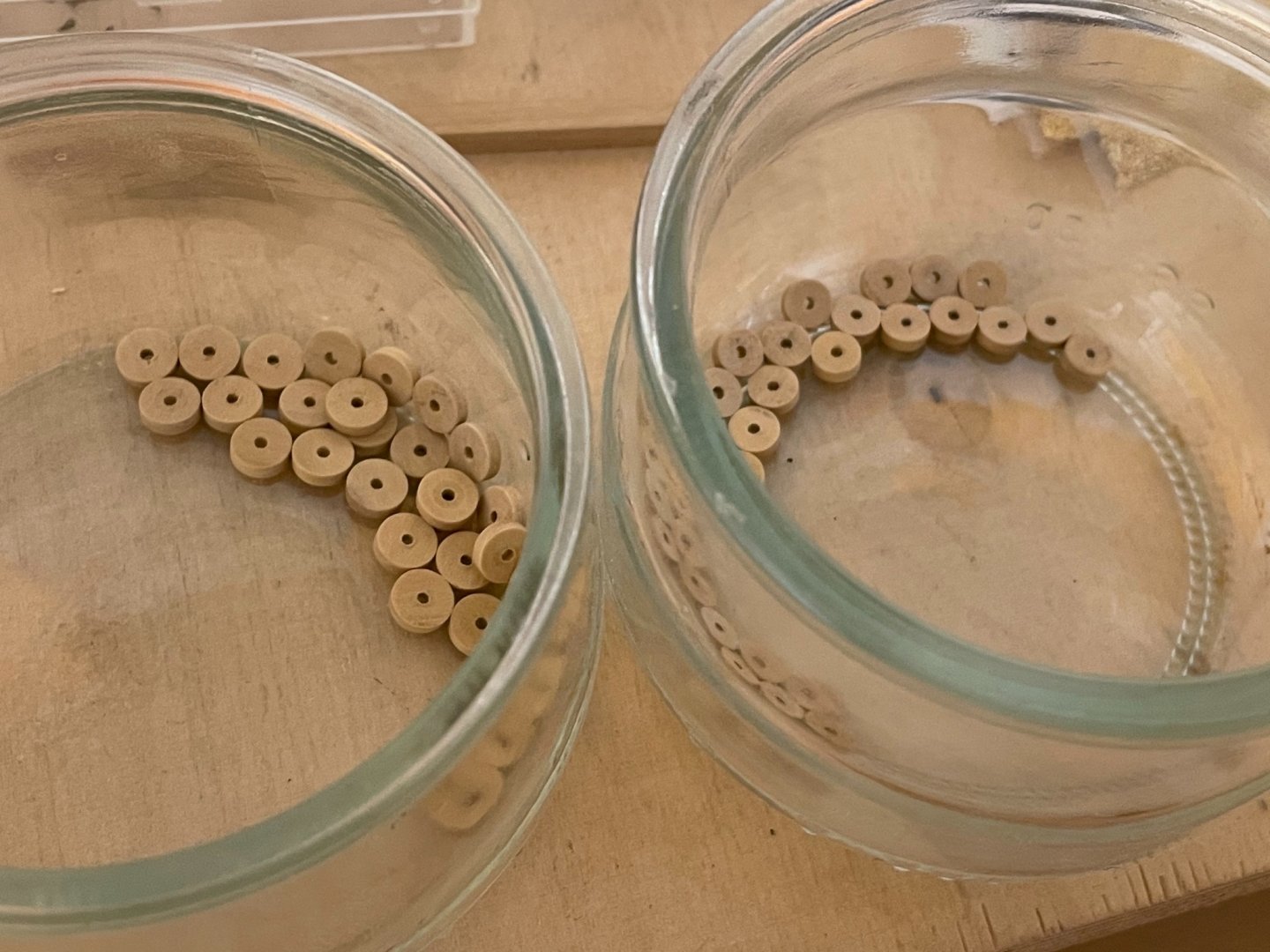

The Coureur is having my full attention, so I have to switch between both projects for a while. But I found some time to make more cannon parts. As I don’t own a lathe, I made myself some little tools to make the wheels by using a regular bench drill. They‘re made of stainless steel tube with a thread (cut off from of a 1,2mm diameter screw) soldered into it. The wheels are drawn with a pencil using a template, a 1,2mm central hole is drilled and then they are roughly cut off from 1/16‘‘ sheet boxwood. The tool can be used to turn the wheels in my bench drill using spacers and a micro nut to lock the boxwood part. I use these tools for turning small parts like wheels. The wheel is made by using sanding paper and a file, two wheels can be made at one. The diameter is checked by an electronic measuring stick several times until the desired diameter is reached. And I managed to do all front and rear wheels at once, 48 pieces. Now only the axles and the side parts are missing. Stay tuned .. and save. Andreas

- 64 replies

-

- badger

- caldercraft

-

(and 1 more)

Tagged with:

-

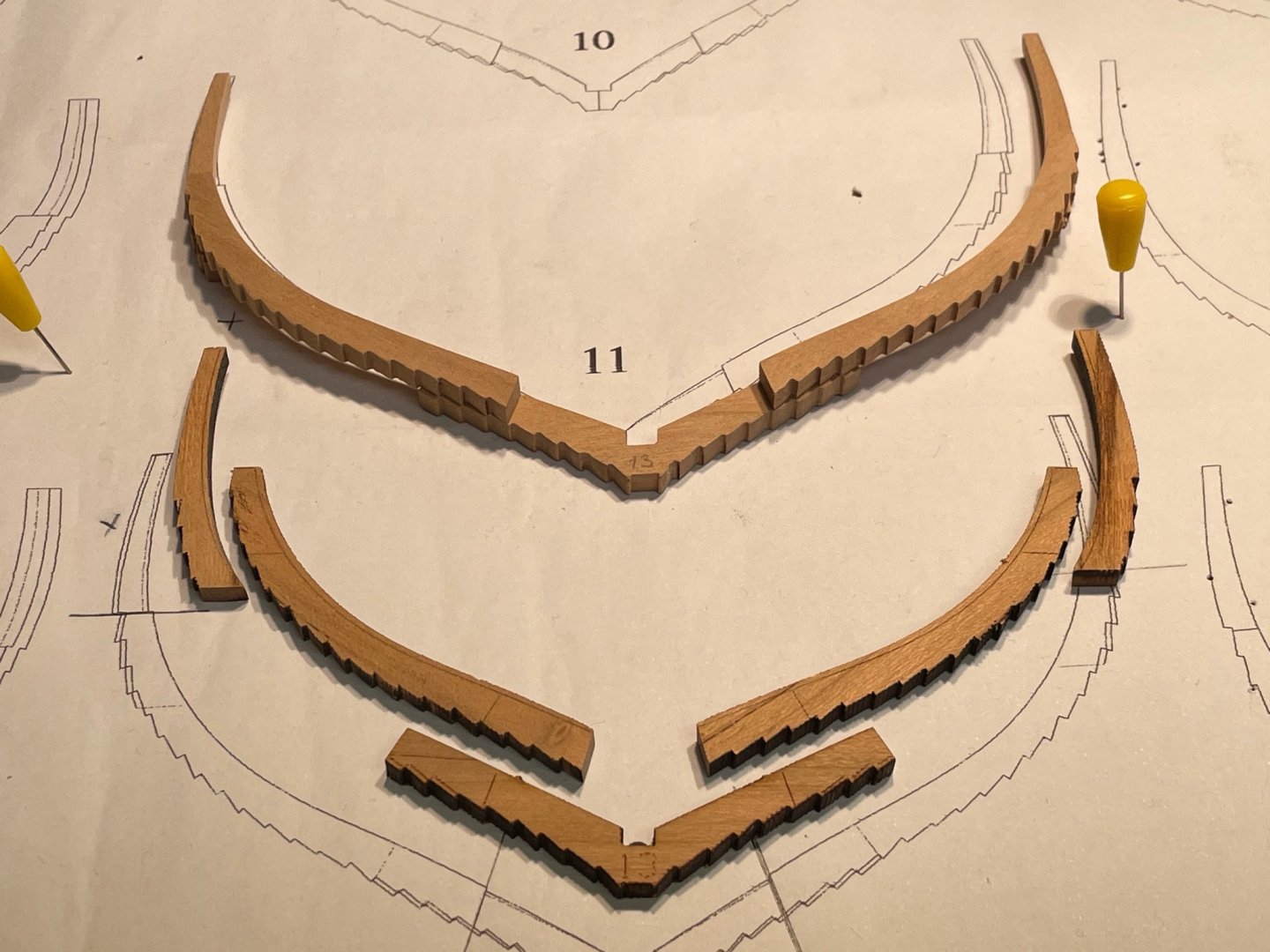

I did the last multi-part frame today, No. 3. It is actually tapered on almost all heads, so I checked the plan multiple times to get it into the correct shape. As all the other frames it is just dry-fitted into the jig. Next thing will be to disassemble the jig and correct all vertical plywood parts so all frames that interfere with the jig can be aligned properly on the keel. As the cant frames are to be attached after installing the keelson I will do them later. Stepstone reached .. jippie. Stay tuned .. and save. Andreas

-

Very nice. I like your idea of substituting the supplied wood with pear - it has a beautiful colour.

- 370 replies

-

- Model Shipways

- Confederacy

-

(and 1 more)

Tagged with:

-

Today frame no. 4 has been assembled. It is the smallest full frame and required a lot of tapering. It looks like a baby-frame compared to a midship frame. So there is only one multi-part frame left. But I have to repair a frame after that because I did slightly too much tapering 🤔. And some jig-parts have to be modified so all frames fit nicely into the keel. Anyway only 3 frames until I reach the bow. Stay tuned .. and save. Andreas

-

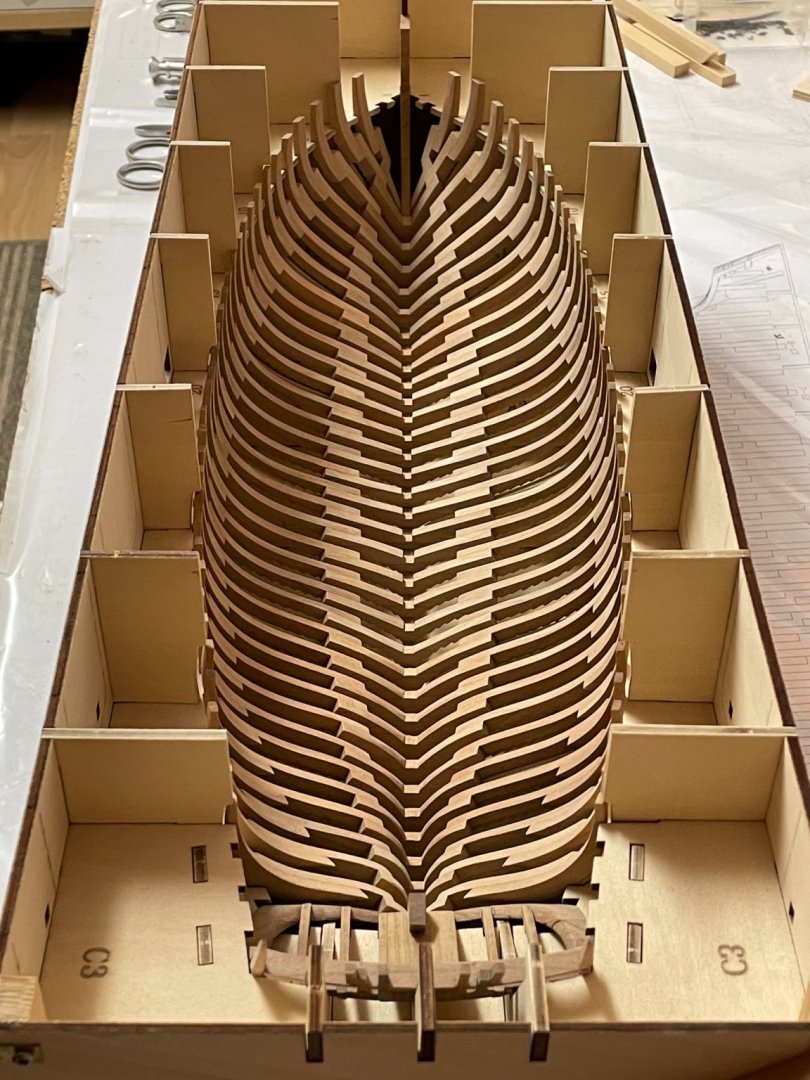

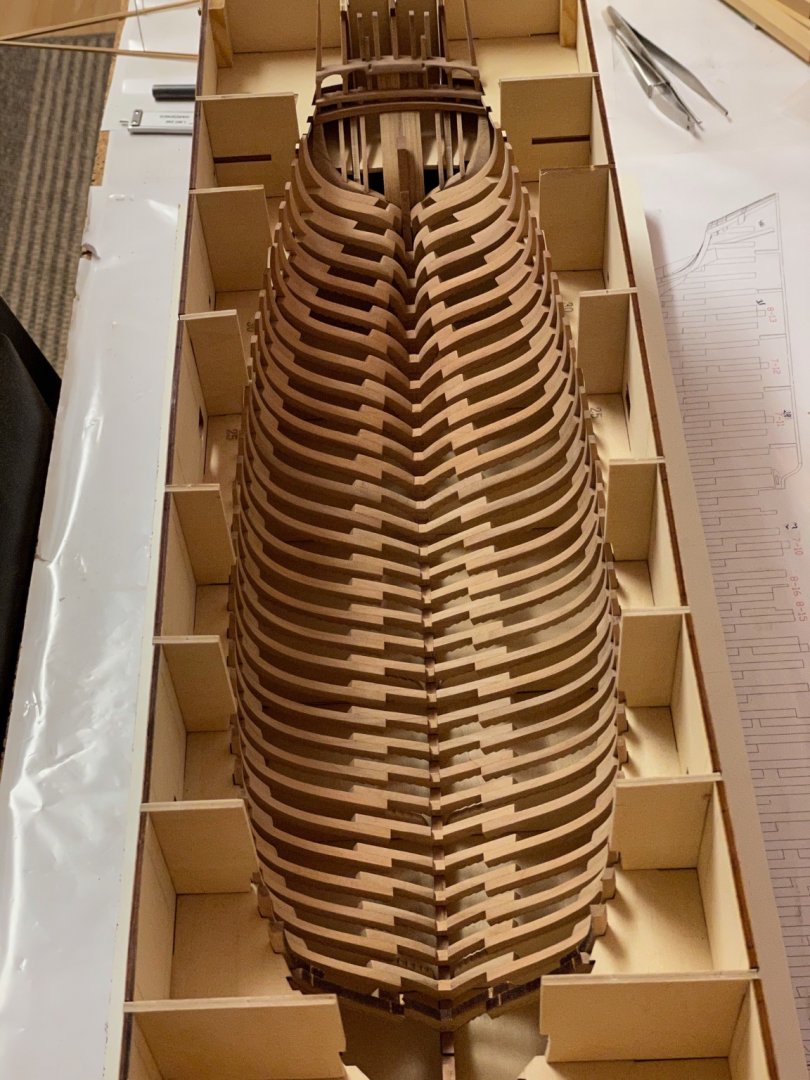

Almost there. One concern about the kit: Almost every cherry sheet that contain the frame parts seems to be from a different wood source. So the completed frames vary in colour, grain pattern and hardness. Most sheets were very clean and of good quality while a few had some very ugly black wood defects that were to be seen after removing the laser char. So I had to make several replacements. But the cherry wood will eventually darken over time and that might compensate the colour differences. The last frames require quite a lot of tapering and I will do them tomorrow. The frames 1 and 2 are just single futtocks but they have to be tapered from several angles to fit the keel and planking run. I will eventually show them in detail later. Stay tuned and save. Andreas

-

Thank you for all the likes. Still nothing more to show than frames but I‘m approaching the bow. There are only 5 frames left to assemble, frame 1 and 2 are just single pieces. As I come closer to the bow every new frame needs more tapering than the one before. But the laser-engraved lines makes tapering rather easy. There is another assembled frame waiting for me to be cleaned and tapered. Another view from opposite direction. So maybe I am able to finish the last ones next weekend. Stay tuned and save.

-

Thank you, Brian. Some more replacements have slowed me down but I managed to complete more frames ... frames, just frames. Have the impression that I have done nothing else for months. But there are only 10 ones left.. Time to see a man about a dog .. wait, we‘re locked down. Ok, let‘s bring the dog to the man 🤗. Stay tuned and save. Andreas

-

Thank you very much, Yves. Thirteen is an unlucky number and indeed - frame no. 13 was kind of a mess. All parts have defects all over and a small edge broke off while releasing it from the sheet. After calming down I decided to replace all the parts. I scanned the plan, redraw all lines with Corel and printed the templates on adhesive paper. Cut all segments with templates on and used the existing parts for reference. Used the plan to complete the frame. Test-fit into the jig - passed. If I will do POF again, it definitely won‘t be a clinker-planked ship. Stay tuned and save. Andreas

-

Very beautiful work! I especially like the mix of painted structure with natural wooden accents.

- 140 replies

-

- benjamin w latham

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.