russ

Members-

Posts

3,086 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by russ

-

I have made gratings in that same method and they looked very good. Mine were at 1/48 scale so your smaller scale results are certainly impressive. I used a slitting saw blade, probably about 1/32" saw kerf when slicing them off on my 4 inch table saw. I had a few break, but not many. Yours look very good. Nice work. Russ

-

Ron: Nice details. I like the edge detail on the seat. Your use of hand tools always gets me thinking. As for the mast step, I would go ahead and make a new one. You might find the other one, but it would take longer than it would to make a new most likely. That is how these things always work for me. Russ

-

The stirrups are those vertical lines that hold the foot ropes (the lines that hang below the yards) to the yard. Lashing the heels of the booms means simply wrapping the thread around the inboard ends of the studding sail booms (parts 165, 167,169) and the yards so that the booms do not move. Russ

-

That photo was in Plank on Frame Models and I recall Underhill writing that it was taken very late in her life and that she had spars that were too long in the photo. Russ

- 108 replies

-

- leon

- brigantine

-

(and 1 more)

Tagged with:

-

Check out the photo of Ed's model of the Young America. He whipped the lanyards to the shrouds. I would think that would be the way to do it. Click on the link and scroll down the page to see photos. Russ

-

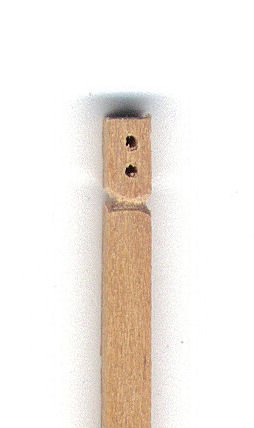

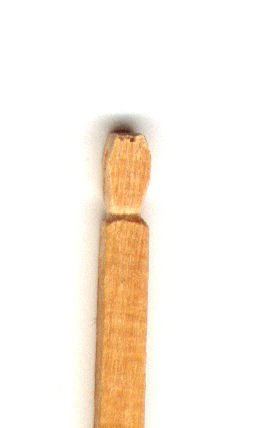

I am not sure if there is a tutorial, but I make small scale blocks by carving and shaping them on the end of a strip of boxwood. I layout the length of the block and then drill holes for the sheave with a drill bit in a pin vise. I use a variety of 4 inch jeweler's files to shape the block and details before cutting if off using a small razor saw in a hobby knife handle. The razor saw blade is shaped like a typical number 11 blade except it has saw teeth. Go slowly cutting the block off the stick. Too much pressure will send the block flying into the next dimension, never to be found. This method is much like what Harold Underhill described in Plank on Frame Models. It takes some practice, but once you get the hang of it, you can make several blocks in one sitting. Not long before you have several small jars filled with enough blocks to rig a model. Russ

-

The straight strips in a kit can be spiled and tapered a bit to get a solid and good looking planking job. I am currently restoring/repairing a model of a Baltimore Clipper from a kit that was built about 30-35 years ago. Everything was glued with some sort of cyanoacrylate, probably a gel type glue. It had the thin veneer strips over the plywood surface on the bulwarks. They were laid on straight with no tapering or spiling. The result was awful with raised edges everywhere. Add to that the CA had failed almost everywhere. I am replacing the veneer strips with similar strips I have collected over the years. I am spiling the edges to create a smooth planed surface along the bulwarks. I am also tapering as needed to make everything fit better and look neater. These strips are your typical kit veneers, about .020" thick. I am using a sanding stick to spile and taper, but emory boards could be used. It is not a quick process, but the results, while not great, are gratifying. Here are some shots where you can see a little of the original planking (it came off in my hands) and some of the work I am doing to replace it. I am using carpenter's glue rather than CA. The first and last photos show my work while the second and third are of the original planking. Russ

-

Tools, tools and more tools....

russ replied to CPDDET's topic in Modeling tools and Workshop Equipment

Exactly. -

Ken: Your model looks great. Nice work turning it into something special. For my part, I vote for fully rigged, but then....I always vote for fully rigged. Russ

- 122 replies

-

- independence

- privateer

-

(and 1 more)

Tagged with:

-

Tools, tools and more tools....

russ replied to CPDDET's topic in Modeling tools and Workshop Equipment

Sometimes it is something even simpler, just a quick jig for a simple task that I can make myself in a few minutes. Nothing to wonder at, but it beats spending the money and then waiting for it arrive. Problem solving is one of the things I like about modeling. Russ -

Mike: Have fun. She looks great and I look forward to seeing more progress. Russ

- 150 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

I totally agree with what has been suggested. If that is the finished garboard, it extends too far up the stem. You will run out of room for the rest of the planks to fit at the bow. I strongly suggest you take it off and give it another go with the end of the garboard sitting much further down. Good luck. Russ

-

Duplicating Garboard Strake

russ replied to frankwil's topic in Building, Framing, Planking and plating a ships hull and deck

Ideally, that would be the way to do it. However, please check the other side against your pattern to make sure it is exactly the same. It would not be unusual for there to be some differences from starboard to port. If your garboard pattern works for both sides, you are doing excellent work. Russ -

Tools, tools and more tools....

russ replied to CPDDET's topic in Modeling tools and Workshop Equipment

Dave: When I get the Micromark catalog, I sometimes find something to order from them. But, often times, I see something that gives me some inspiration for a simple shop tool/jig I can make myself. Russ -

Depth of rabbet cut.....??

russ replied to CPDDET's topic in Building, Framing, Planking and plating a ships hull and deck

Dave: Each of us has a comfort zone for this type of situation. Feeling confident in my ability to make a small slice, I would cut the rabbet a shade deeper. However, Mark is right about sanding. That would also address the situation. You could even sand the end of the plank before gluing. Just hold it flat on the bench and use a sanding stick to dress the end of the plank slightly before gluing. The question is, with which option do you feel more comfortable? Answer that, and you will know what to do. Good luck with your model. Russ -

Your dead eyes look pretty good. I would not go any larger, though. Nice work. Russ

- 360 replies

-

- sultana

- model shipways

-

(and 1 more)

Tagged with:

-

Your model is coming along very well. Nice work. On the deadeyes, please proceed carefully. The kit supplied deadeyes are probably very close to scale. The 3 mm deadeyes you bought might work, but keep in mind, the larger the diameter, the more difficult it will be to get the required number of deadeyes to fit into the space provided. The deadeyes on a ship this small would not be very large. The 3 mm diameter would be equal to about 9 inches on the actual ship. That is bordering on out of scale. I hope it works for you. It is a nice looking model. Russ

- 360 replies

-

- sultana

- model shipways

-

(and 1 more)

Tagged with:

-

Gene Hunt practicum.????

russ replied to CPDDET's topic in Building, Framing, Planking and plating a ships hull and deck

There is also John Earl's Bluenose II practicum. It was the Artesania Latina kit, as I recall, but his methods are well worth looking at. I do not have his website handy, but it was free to look at. Russ -

Dave: Another good method would to use a tick strip. Just a piece of paper or cardboard where you can mark reference lines. Lay the strip onto your plan and transfer the top of the profile former (for instance) onto the strip and then transfer the reference line at one of the frame locations. Now, lay the strip onto the profile former piece, lining it up with the same frame location and the line for the top of the profile former aligned with the top of the profile former piece. You can then transfer the reference line mark onto the profile former. Repeat at several frame locations and you will have marks through you can strike a line for the reference line. This is easier to do than to explain and it is very accurate, provided you take the time to accurately transfer the marks. make sure your pencil is SHARP. Russ

-

Here on the Gulf Coast, there would have been a rod bolted to the upper aft end of the board and led through the deck. To the upper end of the rod was attached a block and tackle, the upper block of which was secured to a pendant that led to the main mast head. The tackle was handled from the deck. The centerboard tender would control the board per the captain's orders. Here is a crop from a 1920s photograph that shows the typical centerboard arrangement. Russ

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.