-

Posts

3,867 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by KeithAug

-

Wonderful project Andy. It will be a pleasure to watch the model come to life.

- 174 replies

-

- Vigilance

- Sailing Trawler

-

(and 1 more)

Tagged with:

-

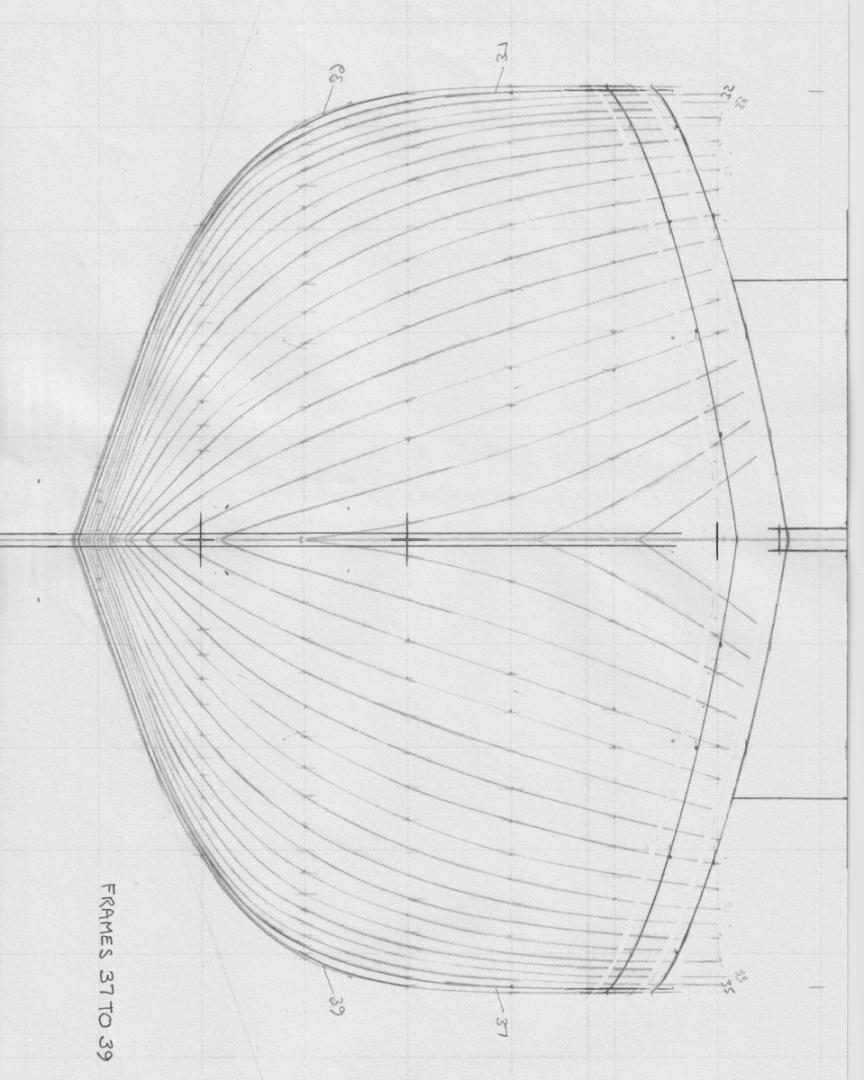

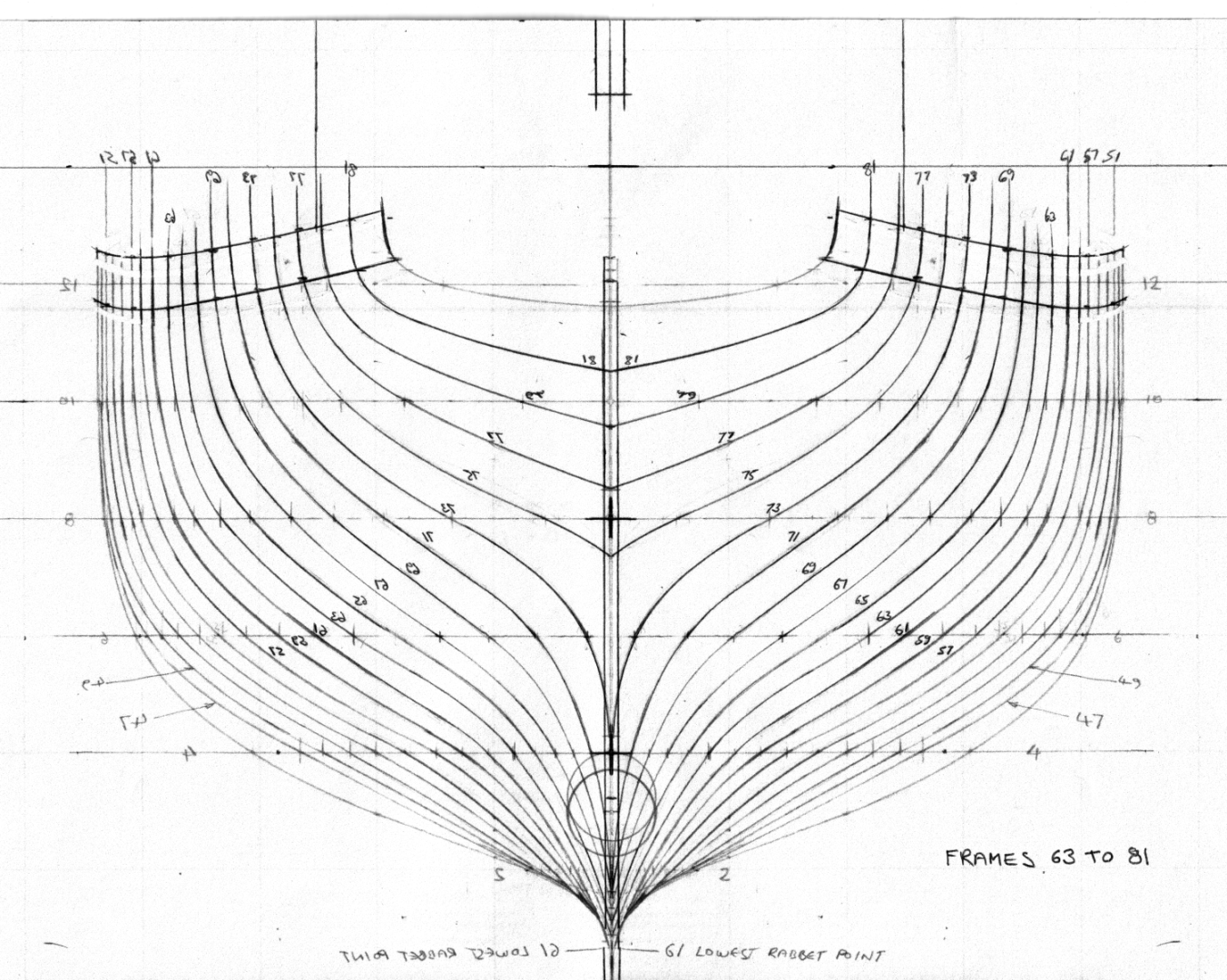

On 13 May I commented "i can start generating the hull transverse sections corresponding to the frames on Cangarda". Somehow we are now at the the last day of August and I have just completed the task. My productivity is sadly lacking, Cangarda has frames on a 18" pitch or 3/4" at model scale. The pitch is a bit over the top for model purposes so I plan to make every 2nd frame giving a frame spacing of 1.5". I have kept the numbering as per the plans supplied by Tr1-Costal Marine so every second section is missing. I took a lot of care with plotting (using the pencil, dividers and french curve method). I then spent some time reviewing the nested section to identify and obvious glitches. Generally the nested lines seem to have turned out reasonably well. I have included all the drawings as PDF files in the event that others want to have a go at building Cangarda. Full frames 01 to 35.pdf Full frames 01 to 37 to 39.pdf Full frames 41 to 45.pdf Full frames 47 to 61.pdf Full frames 63 to 81.pdf

-

Hello friends. Just touching base to confirm that I am still in the world of the living. Sorry about the absence. Lots of family duties got in the way of ship building and the workshop has been collecting cobwebs for most of the summer. The geriatric members of the family (my age) seem to have accumulated various degrees of serious illness necessitating ongoing visits. Meanwhile my son and daughters house moves respectively have provided a string of opportunities from simple decorating up to patio construction and garden re-modelling. Grandparental duties are also likely to be in sharp focus for a number of months - grandchild number 2 (boy) arrives next Friday. In my day the sex and the arrival time were a mystery but it seems that in our modern word all uncertainties have been removed 🤞. I hope to get back onto a bit of modelling in the autumn as the weather deteriorates. In the mean time I will try to catch up with all your build logs. Best wishes.

-

Valeriy, Te hull seems to have lines running along its length. I think this is to represent the steel plates that the hull was constructed from (presumably the plates were riveted together). My question was how did you simulate the these on the hull. Thank you for the details of the power plant - it looks like triple expansion steam engine. The stokers must have had a difficult life - very cramped space, lots of coal dust, lots of heat. It must have been hell.

-

Ah! Maybe in need an upgrade. There is not a lot wrong with me that a whole body transplant wouldn't fix - or maybe all I need is a better computer.

-

Barncave Shipyard by mbp521 - Scale 1:1

KeithAug replied to mbp521's topic in Non-ship/categorised builds

Very elaborate shed Brian. I think however you have missed the most important feature from your plans - the lost bits black hole! Also you seem to omitted the "where did I put that "xxxxxx" craft knife" desk. I hope you haven't got so far that you can't change the design! -

Planking the stern would have been difficult. I think your alternative plan is the right way to go

-

Keith - your interpretation of photos is impressive. I think my eyes need an overhaul.

-

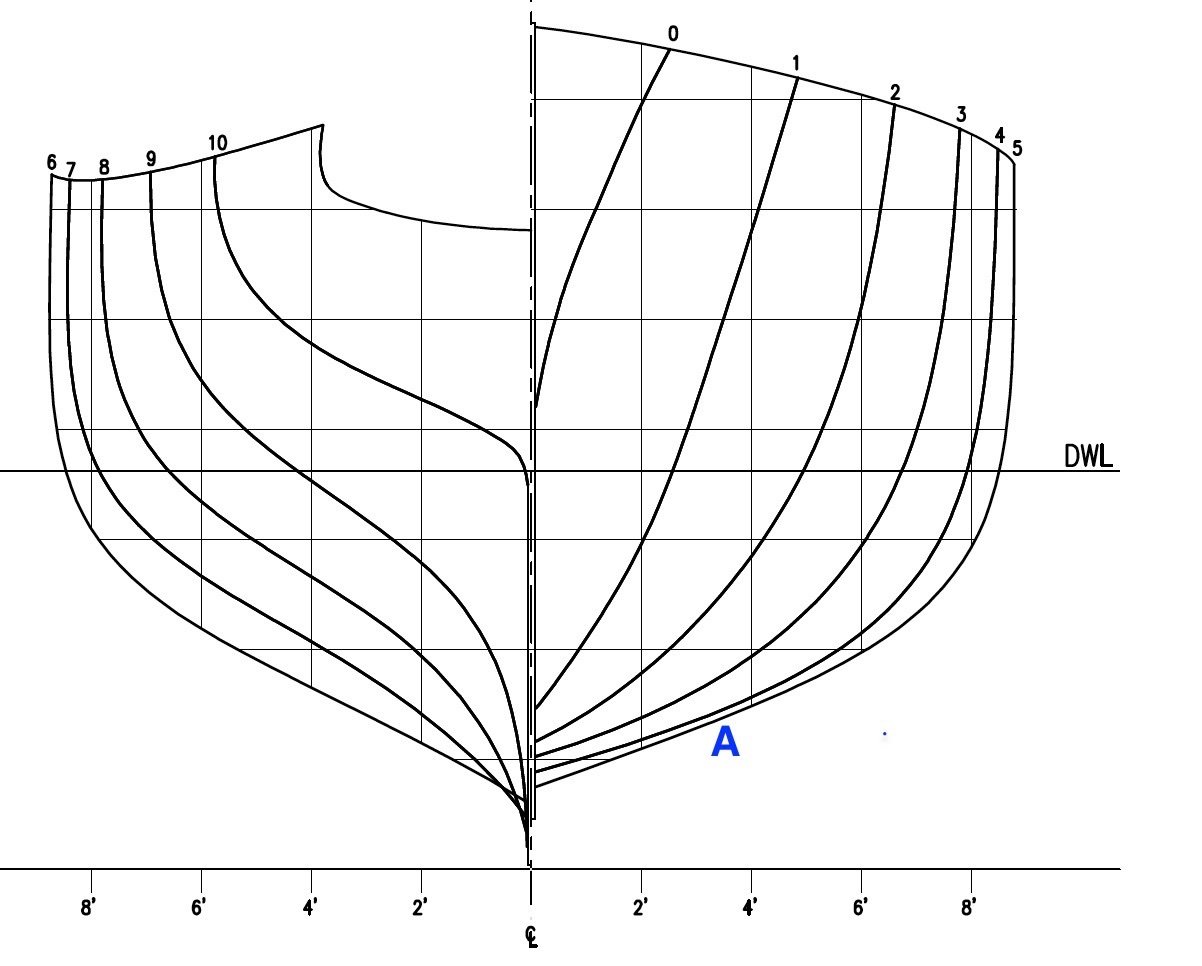

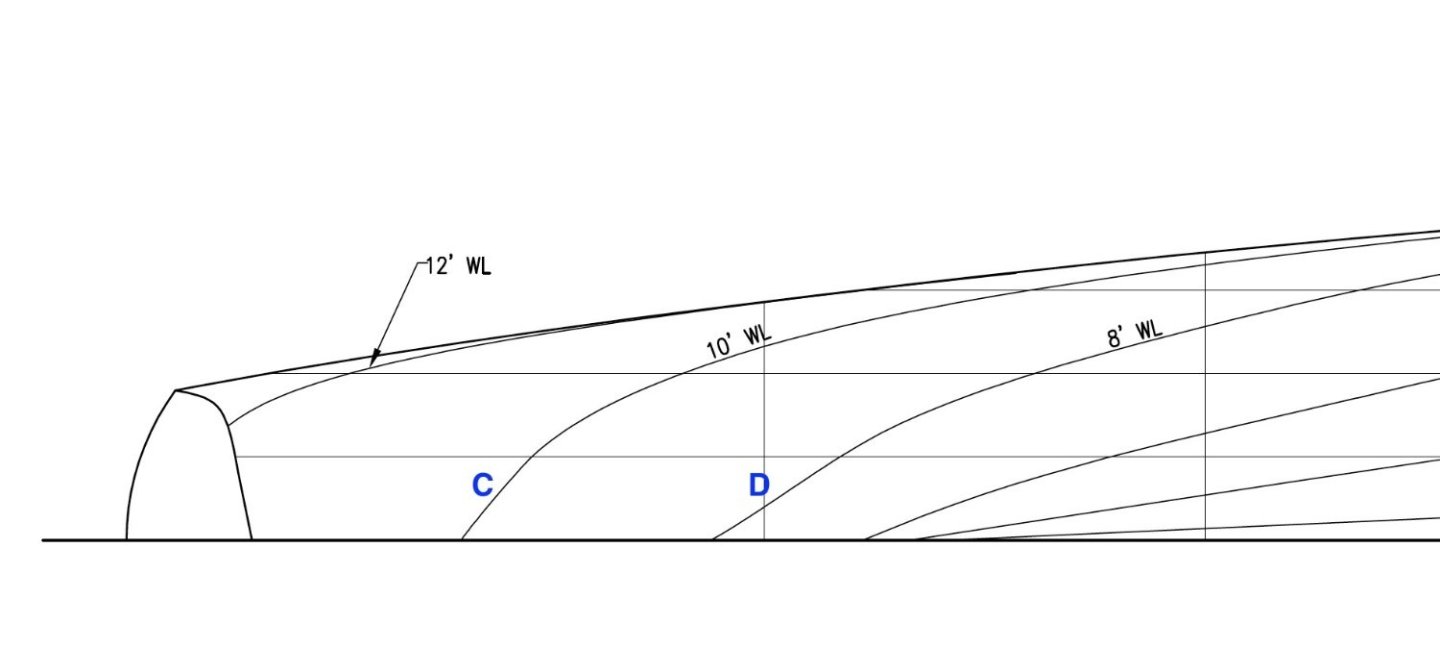

After a bit of a layoff I am back at it. Somehow I picked up an unusual lung bacterial infection that required 3 rounds of different antibiotics to knock it on the head. The last lot seemed to do the trick and i'm now on the mend. I have been doing a lot of work on the hull lines drawing. You will probably recall Mr Rutherfords comment to the effect that the original lines were not available and the lines drawing was produced from a scan of the hull. I don't know in detail how scans are done or indeed the details of the curve fitting programme used to generate the lines. Clearly though the small number of scan points has presented a challenge the curve fitting programme. Having printed out the the previously mentioned drawings at 1:24 scale on A4 sheets i joined them together paying particular attention to alignment and overall dimensions. The breakfast bar came in quite handy (despite some protests). I played the illness card which seemed to have the desired effect. Looking at the lines drawings prompted a few questions. On the transverse sections at section 4 near position "A" there is a slight curvature. On the various photos I have the hull seems quite flat at this position, much more like frame 5. On the horizontal sections near the stern the lines at points "C" and "D" seem to have odd local curvatures and I guessed that this was down to the curve fitting programme struggling with lack of data. Rather than accept the lines I decided to check the transverse, horizontal and longitudinal sections against one another starting by plotting the transverse section on top of the horizontal sections. This revealed a number of discrepancies. Near the stern the 4'WL plot deviated quite a lot from that line on the horizontal plan. The orange line below shows the original plot line while the new line below it is the line generated from plotting out the transverse sections. Smaller deviations were also revealed on the 6",8"and 10"WL plots, here again the orange lines are the original and the black lines are the projections from the transverse plots. There were similar (but smaller) discrepancies towards the bow. I then plotted the longitudinal section back on to the transverse sections which revealed discrepancies at the rail. The pencil lines show the runs of the rail and deck edge. While none of the discrepancies were major I decided the best way forward was to get the plan, side and frontal lie drawings in agreement before generating the hull sections for build purposes. This is now complete and i can start generating the hull transverse sections corresponding to the frames on Cangarda.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.