-

Posts

2,932 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rafine

-

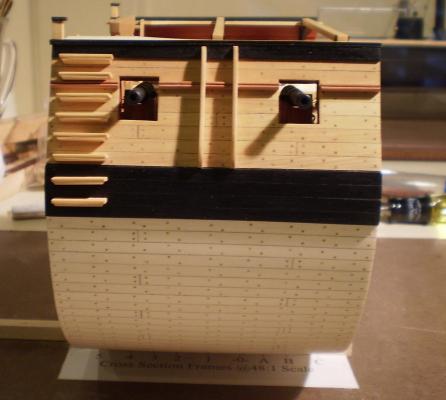

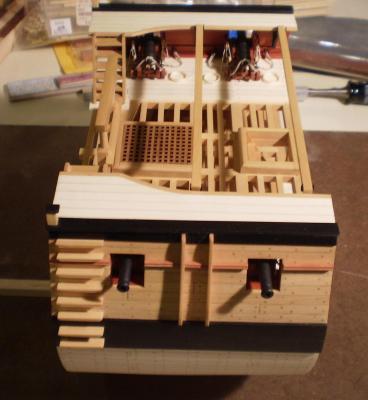

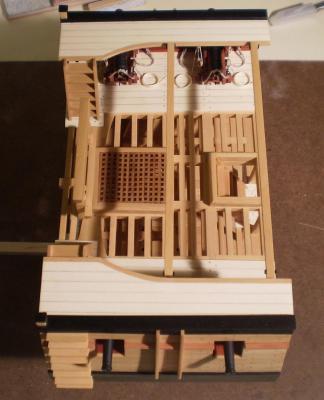

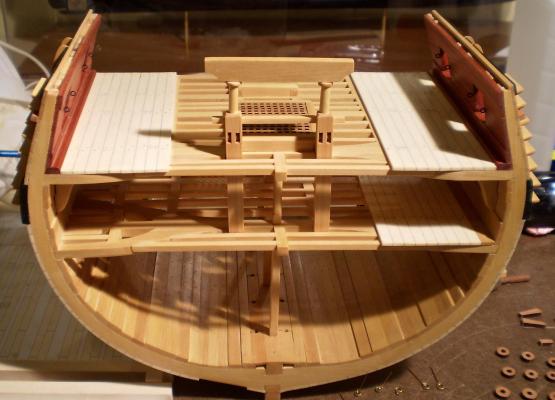

As indicated earlier today, attached are the final photos of the cross section build. This was a really fun build, made even more so by being part of a great group of talented builders and warm, encouraging and helpful friends. As with all builds the end is bittersweet -- nice to be done and looking forward to the next, but sad to part with a "member of the family". This was also a learning experience for me. I learned that it was possible for me to do a framed scratch build with only hand tools, including tools like chisels, which I had never used before. On the other hand, I learned that it is highly unlikely that I will ever attempt a full framed ship -- simply too much time and effort at my age (I might consider another cross section at some point). I'm happy to be looking forward to a return to kitbashing (or kit enhancement as B.E. calls it). Essex is sitting here waiting and I'm starting to figure out how I'll "enhance" it. Thanks again to all who have followed and supported this build. Bob

-

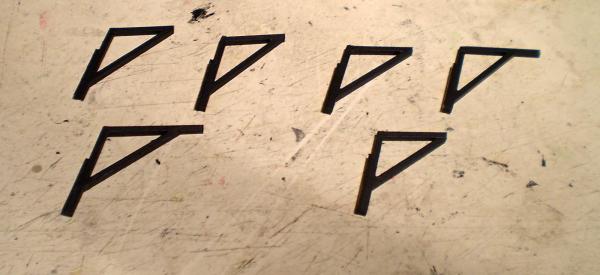

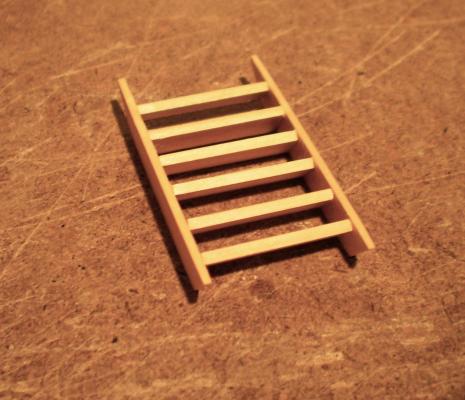

In a burst of activity over the last few days, I completed all of the remaining work on the cross section. This included making and installing the gangway brackets, the gangways, the cap rails, the ladders, bits of deck planking for the gangway ladder landings, the skid beams and the tiny slivers of the quarter deck rail. Because of my fear and loathing of working with metal, I made the brackets from wood, with the exception of the skid beam crutches, which are brass. The gangways were done with holly, with boxwood trim. The skid beams are boxwood, as are the ladders. The cap rails were made from laminations of ebony, sanded to create a molded outer edge. The fussiest part of this work was mounting the brackets so that they aligned properly and were level for the installation of the gangway. It required a lot of time and even more bad language. Later today, I will post photos of the fully completed model and my thoughts about the project. Bob

-

It's looking very good Ken. You're off to a very nice start. Bob

- 455 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

It's looking very nice Ed. The filler should be put in the holes before any finish is applied to the deck and then the deck can be sanded and/or scraped. You could still possibly fill the holes and then sand and refinish the deck. Bob

- 42 replies

-

- fair american

- model shipways

-

(and 1 more)

Tagged with:

-

Nice job with the ebony Mark. Nothing really beats the look of it if you can make it work. Bob

-

As they say Ken, "no good deed goes unpunished". Just kidding. All of the work at the head was done with laminations -- I find it very difficult to do accurate scoring. I know that others use homemade scrapers to do this work. The stern moldings and those on the outside of the sheer rail were done with double bead molding from Northeastern Scale Lumber. I have no memory of doing the "ball". Bob i

-

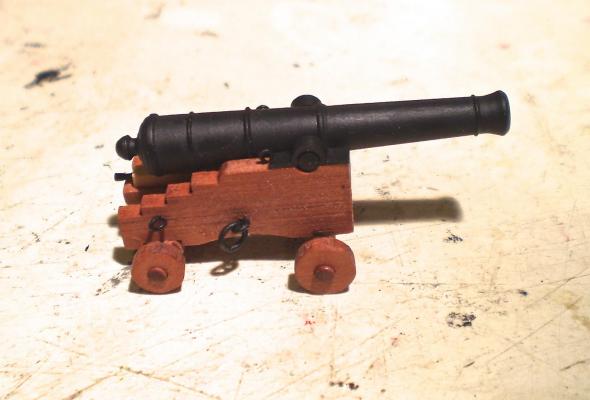

Thanks Mark and Russ. The Lumberyard acrylic barrels are very nice. They also have cast metal barrels, which are not nearly as good (but considerably cheaper). The carriage parts really require little more than removal of the laser char, rounding of the axles and a little filing. I've used their guns before and like them. Bob

-

Thanks Thomas. The guns have now been made up. As I previously indicated when I did deck planking on both sides of the gun deck, my choice was to do all four guns. The guns are my next departure from true scratch building. Without a lathe, I simply did not want to try turning the cannon barrels, although I suspect that given enough time and effort they could have been done from wood. I bought acrylic gun barrels from The Lumberyard that fit the plan dimensions almost exactly. I also chose to buy a sheet of their laser cut pear carriage parts. After assembling the parts, I made and added various eye and ring bolts, the quoins and the cap squares and their hinges. Next, the guns will be mounted and rigged. Bob

-

US Brig Syren by Gahm - Model Shipways

rafine replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

It's coming along beautifully, Thomas. Bob -

Ken: I didn't change the angle of either mast. I used the slots in the center keel. There seemed to be no reason to make a change. Ed: I changed what is shown on the plans, following the ideas of Pete Jaquith, whose log appeared on the old site. I don't recall the exact reasoning, but he had substituted a waterway and margin planks for the coverboard arrangement shown on the plans. As you can see from my photos, the waterway butts against the frames and the margin planks butt against the waterway, laying on the tops of the bulkheads and level with the deck planking. I believe that I cut the margin planks to a width of 3/16". which matches the width of my deck planks. I'm happy to be of any help to both of you. Bob

-

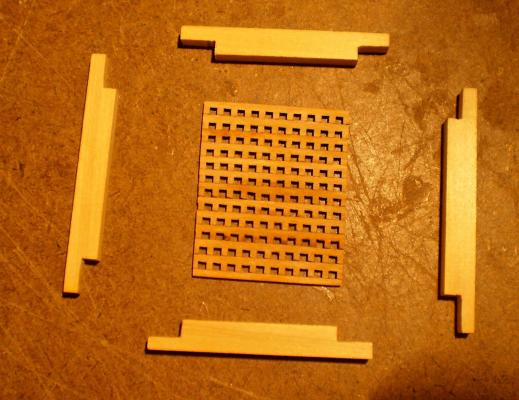

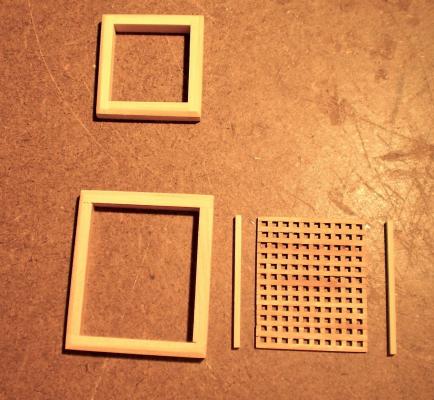

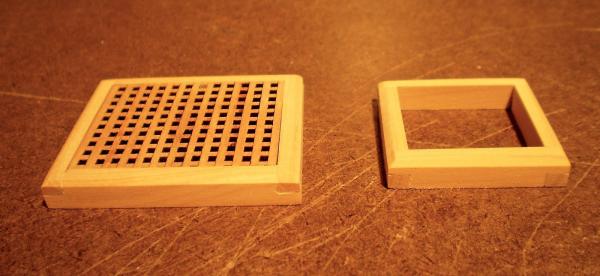

I've done the hatches and bitts. The hatch coamings are made from boxwood strip with lapped ends cut in. The gratings were my first ( but not last) concession to lack of power tools. Although I'm sure that there's a way to cut them by hand, I opted to use Model Expo cherry grating strips. The bitts are also made from boxwood.The bitt pins are laminated strips to create the sheave openings. I've never had much luck cutting slots in solid pieces. The sheaves are slices of walnut dowel. The round portion at the top of the pins was done by hand sanding square boxwood strip. The gallows was cut from boxwood sheet. I also drilled the holes for the eyebolts and ringbolts in the bulwarks and installed the eyebolts at this point. Next up are the guns. Bob

-

Your usual beautiful work, Rusty. It's going to look great in the case. Is it going to be Echo or the bomb vessel section that gets your attention next? Bob

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.