-

Posts

2,932 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rafine

-

I've been out of touch for a while, but just got a look at your progress, Augie. It's simply great. Into the homestretch! Bob

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

I've completed the interior planking up to the lower deck clamps. I've also done the treenailing up to that point. Lastly, I put on one coat of Wipe-on Poly for some protection. I will do additional finish coats later. Next up will be the wales and the exterior planking from the keel up to the wales. With the frames now quite rigid with the addition of the interior planking, I will do some more fairing on the exterior before doing the planking. Bob

-

Wow. You guys are much too kind. I really enjoyed reliving the build through the reposting and I'm delighted that others got some enjoyment as well. I have no other photos, Christian. Brian, when has any modeler not believed that they could have done better. Bob

- 81 replies

-

- kingfisher

- lauck street shipyard

-

(and 1 more)

Tagged with:

-

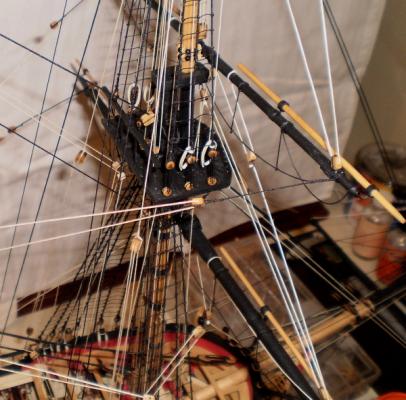

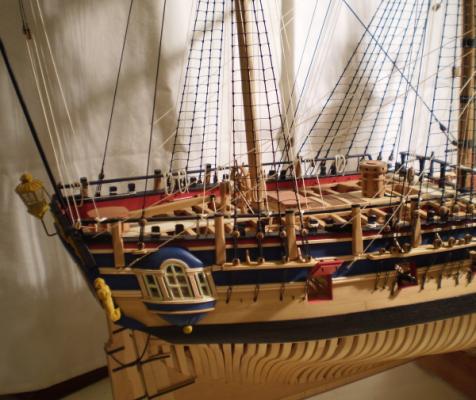

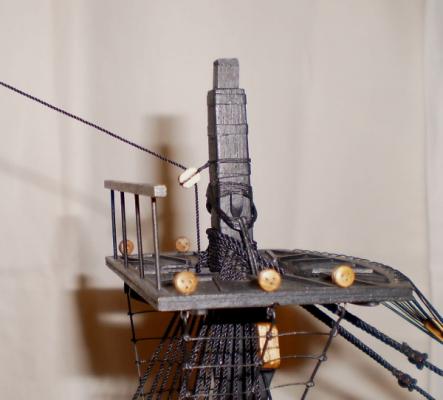

Final installment on the rebuilt log. The yards and running rigging and the final details: The yards, like the masts, were made from dowels with the eight sided sections built up. The blocks were commercial items with some shaping. Specialized blocks such as long tackle blocks were made from strip wood. The rigging line is tan linen line that I have had for some years. The sequence of construction and rigging was fore to aft ( opposite to how I do the standing rigging, but also to give the greatest access), and lower to upper on each mast. The most difficult task was running the main jeers through the jeer bitt sheaves and attaching to the bitts. In hindsight, it wold have been much better to have made that attachment at a much earlier stage of construction before the bitts became very difficult to reach. The final details included the anchors and their bouys and rigging, the entry ropes and the installation of the swivel guns and the elm tree pumps. In summary, this kit, although it had numerous shortcomings, provided a unique opportunity to build a fully framed boxwood model without the necessity of cutting all of the framing. For me, without power tools, that was a critical plus factor. Bob

- 81 replies

-

- kingfisher

- lauck street shipyard

-

(and 1 more)

Tagged with:

-

Great work Len and great to see the log back. Bob

- 122 replies

-

- bellerophon

- victory models

-

(and 1 more)

Tagged with:

-

Thanks to all. Christian and Grant, I had already come to that conclusion and had done the lower deck clamps before continuing with the planking. The result is that I will only have to adjust one plank up to that point. The bad news, Paddy is that there are lots of treenails. The good news is that you lern some tricks to make it easier as you go along. Very much like ratlines. Bob

-

Thanks, Mark. I don't remember how long it took me to do the ratlines on this one, but I'm sure that I was glad to be done with them. Bob

- 81 replies

-

- kingfisher

- lauck street shipyard

-

(and 1 more)

Tagged with:

-

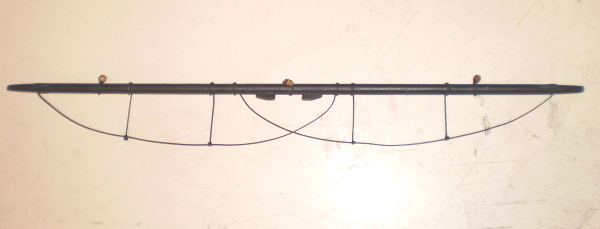

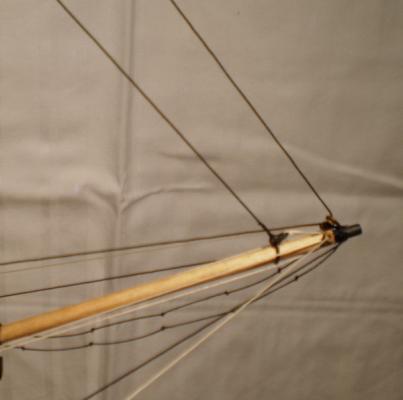

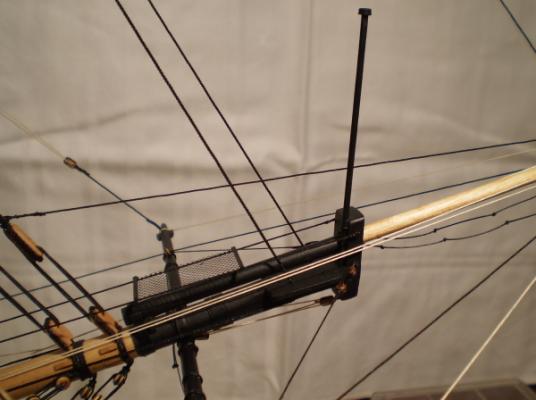

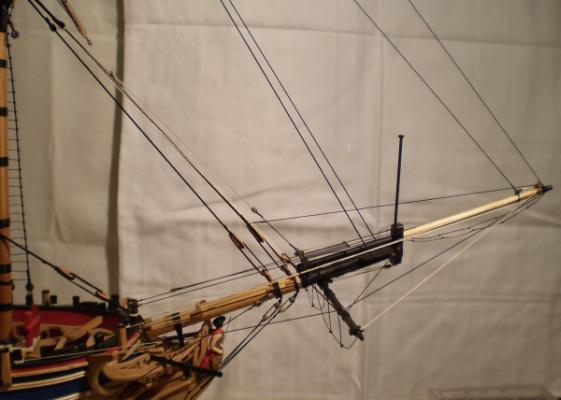

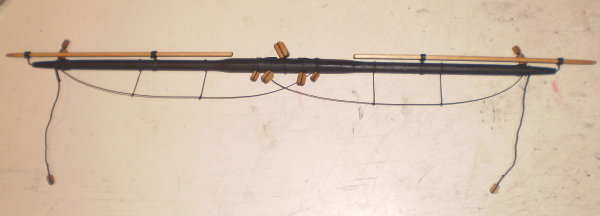

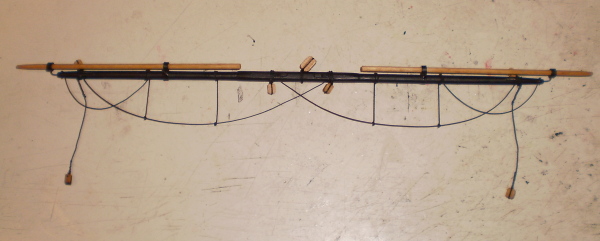

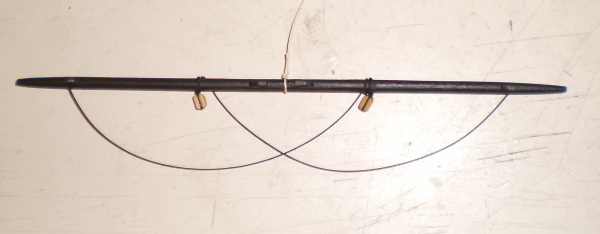

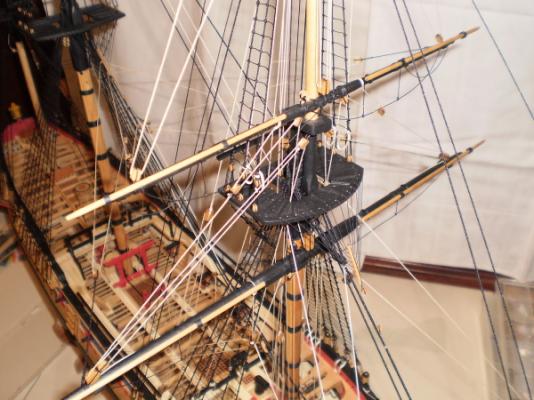

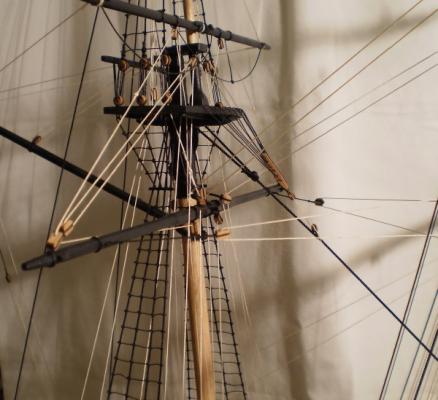

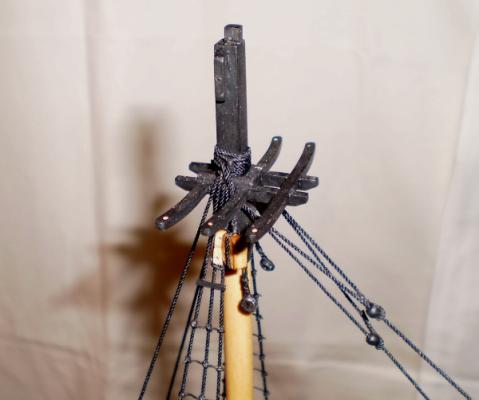

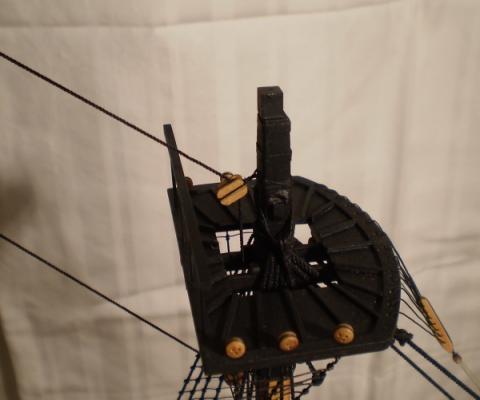

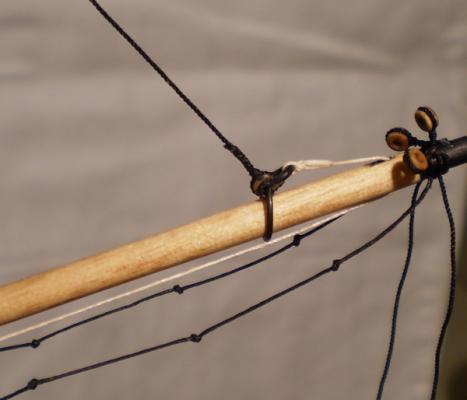

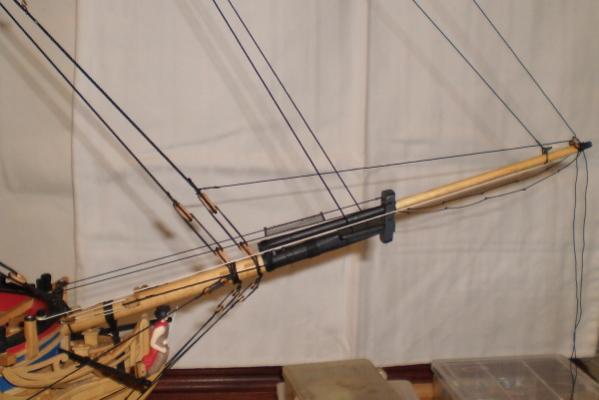

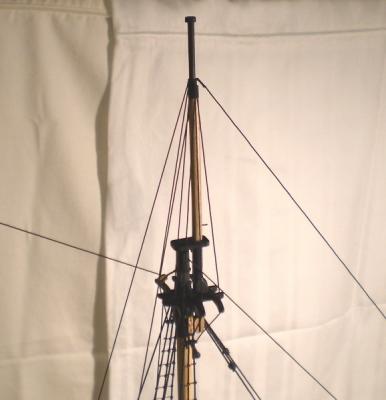

This installment covers the completion of the mast installation and standing rigging.This work began with the installation of the topmasts and their pendants, shrouds, ratlines,stays and backstays .It continued with the jibboom with it's horses, thimbles and traveler and also the bowsprit horses and netting. It finished with the topgallant masts and their shrouds, stays and backstays. As with the lower masts, the work proceeded from the mizzen forward. The last photo shows the model with the masting and standing rigging complete. Bob

- 81 replies

-

- kingfisher

- lauck street shipyard

-

(and 1 more)

Tagged with:

-

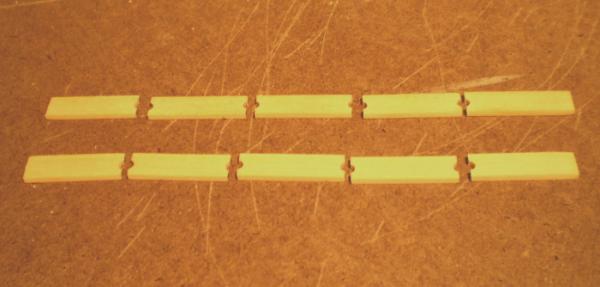

Planking is now underway. I began by installing the keelson and then did the limber strakes and limber boards. I also did the ceiling out to the first thickstuff. All of the planking was done with boxwood. After installing and trimming the planking, I treenailed it, using bamboo skewers and a Byrnes drawplate. I found the hardest thing to do was to split the bamboo skewers into pieces small enough to go through the drawplate. The treenails will show better when finish is applied to the planking. Interior planking will now continue out to the lower deck clamps. Bob

-

Seeing your beautiful work with the red heart is making me rethink my wood choices for work down the road. Bob

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.