Roger Pellett

NRG Member-

Posts

4,519 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Roger Pellett

-

boom rigging on a ship's launch boat

Roger Pellett replied to Peanut6's topic in Masting, rigging and sails

Kev, Unfortunately, you’re in no mans land. Saying that rigging details for Eighteenth Century warships Boats is sketchy is an understatement. Steele gives extensive rigging details for cutters then says that “sloops are rigged like cutters except lighter.” For sloop rigged ships boats he says, “what little rigging they have is like that for a sloop.” Not very helpful. May’s book, The Boats of Men of War includes an Admiralty Draught of a rigged Longboat. The draught is undated but the boat appears to be early, mid Eighteenth Century. I have concluded that there there were three gaff sloop rigs employed for Royal Navy Ships Boats: Earliest- Short Gaff, No Boom Early to Mid Eighteenth Century- Short Gaff, Boom and loose footed sail. Mid Eighteenth Century and Later- Long Gaff with sail fastened to boom. The loose footed rig required a block and tackle purchase on the boom for the outhaul. This, by necessity would have to be belayed on the boom, most likely with a cleat. With the sail fastened to the boom (the long gaff rig). It is possible to secure the clew of the sail to the end of the boom without an adjustable outhaul, hence no cleat. I don’t know if this was actually done. Roger -

Oxy/Butane Micro Torch Kit

Roger Pellett replied to Boccherini's topic in Modeling tools and Workshop Equipment

My recent experience with cheap gas torches is bad. The valves leak. -

What Glue is Best for Rigging Ropes?

Roger Pellett replied to Bill Jackson's topic in Masting, rigging and sails

Lacquer type clear nail polish. Cheap, quick drying, convenient, easy to find. Does not leave a residue. CA- Ditto to popeye’s post above. Roger -

If you need a more technical approach than the Mark I eyeball, Eric Ronnberg published a well researched article about early Nineteenth Century paint colors in the NRJ, maybe 1989. An abridged version of this article is included in Volume II of the Guild’s Shop Notes (Support the owners of this forum, buy a, copy ). The color chips from this article are on the Guild’s website. Roger

-

Model shop bandsaw choice?

Roger Pellett replied to tooter's topic in Modeling tools and Workshop Equipment

Do not overlook full sized old tools. IMHO they are preferable to new ones for several reasons: First, sturdy construction. They have more machined cast iron and little or no plastic. Belt driven. Motors are easily replaced or switched to high HP if you decide to do so. Fewer propriety parts. Replacements like threaded fasteners can be found at the local Hardware store. Availability of a wide variety of locally sourced blades. A 14in bandsaw uses a standard 93-3/4in blade. My 14in bandsaw is 45 years old and still going strong. I have added a more powerful motor (belt driven) and have replaced the tires, tension spring and guide blocks, all with generic aftermarket parts. I also replaced all adjustment thumb screws with socket head cap screws. I doubt if any of the new small 9in saws will still be providing like new performance after 45 years of use. Roger -

Sand the hull before glassing it. Sanding should be to give the hull a nice fair smooth shape. Final sanding with very fine sandpaper is not necessary or desirable as some “tooth” on the sanded surface is a good idea. Any localized wood filling necessary to produce a fair surface should be done prior to glassing, but do not use sanding sealers, primers or other paint type coatings before glassing. Assuming that the resin that you are using is a two component mix, take care to mix it in the correct proportions. Adding additional hardener will not make the resin cure faster but it can prevent it from completely curing completely resulting in a sticky mess. Do not try to glue the cloth to the resin coated hull. Instead drape the dry cloth over the hull and pour the resin on to it. Then using a plastic squeegee spread out the resin working it into the weave to wet out the cloth. More than one application of resin will probably be required to completely fill the weave. Some resins produce an “Amine Blush” on the cured surface that can interfere with paint. This can be removed with detergent and water. I would then sand the hull to provide a finished surface for painting. Roger

-

A great job on a difficult subject with those tiny frames. Roger

- 153 replies

-

- Ancre

- Bruno Orsel

-

(and 2 more)

Tagged with:

-

Vlad, Following others on this forum can be both inspiring and discouraging. It is easy to become inspired by other’s precise clean work and discouraged by our inability to achieve it. Keep in in mind that it’s the final result that matters. Don’t hesitate to redo work that doesn’t satisfy you but when you feel that you have done your best, move on. I’m sure that your final result will be excellent. Roger

-

Vlad, You are doing a great job building a model of a handsome ship. If I may, I would like to weigh in on the paint/ natural wood subject. In my opinion different finishes look better on different types of models. For example, a clear wood finish definitely is a must for a 17th-18th Century Dockyard Model. Likewise, Ed Tosti’s exposed framing with it’s natural wood finish produced striking results for his Young America model. On the other hand, I believe that fully planked models of these large mid Nineteenth Century sailing vessels look much better painted. The sailing ships built during the last 75 or so years of the age of sail were powerful vessels that made fast passages by their ability to carry sail in a blow. An unpainted models these can look like toys instead of miniatures of powerful sailing vessels. OK, enough of my opinion. You’re the master shipwright here. Enjoy what you are doing, and I’m sure that you will achieve stunning results. Roger

-

Trumpeter Scharnhorst Battlecruiser 1/200 is coming soon.

Roger Pellett replied to yvesvidal's topic in Plastic model kits

Chris, Maybe you can build the Scharnhorst kit in your spare time. A Busman’s Holiday!😁 -

Doors

Roger Pellett replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

Yes, and water depths in feet, not fathoms. -

Doors

Roger Pellett replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

Chuck, Here on the Great Lakes, we have our own nomenclature. Ships regardless of their size, including the thirteen 1000 footers in the fleet are called boats. Or more commonly “Ore Boats.” The speed at which they travel is measured in Miles Per Hour and they do have windows as well as round portholes. Roger -

Doors

Roger Pellett replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

Back in the day when Officers using US Navy Officer’s Clubs could just sign their drink tabs and be billed later, a famous alias used by deadbeats was “WT Door.” Ships were built by Shipwrights. After launch they were towed to the outfitting pier to be finished by jointers, a different trade. To find details about internal fitting out of ships you will need to look beyond Steele. The best reference that I know of is Lavery’s Arming and Fitting of English Ships of War. Roger -

A year or so, forum member and master modeler Michael Mott posted a series of Blogs about his restoration of one of these Shipbuilder Models. I don’t remember the name of the ship but you should find this on the forum. He did a wonderful job that included matching old finishes. Prewar modelers sometimes mixed their own paints from “Japan Colors.” Volume I of the NRJ’s. Ship Modeler’s Shop Notes includes instructions for mixing these colors. Forum member Bob Cleek has also posted about using Japan Colors. Roger

-

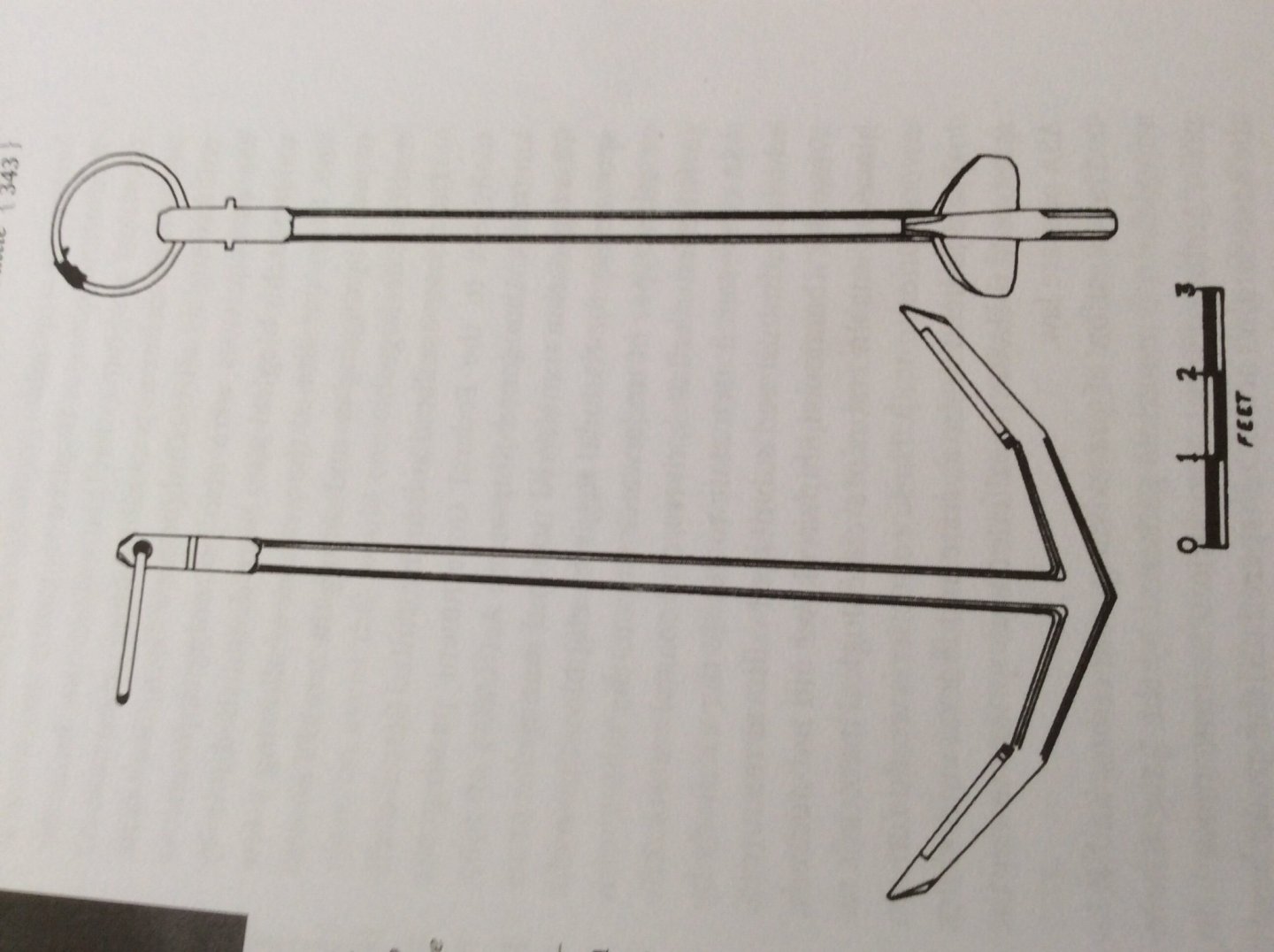

Complicating matters is the fact that Eagle was built in a very short period of time, less than a month? Transporting an anchor from civilization on the East Coast would take time, so maybe they used what they had on hand. In 1776, ironwork for Benedict Arnold’s gunboats was forged on site at Skenesboro so if this capacity still existed anchors might have been forged on site. An old style anchor works by hooking the bottom and the resistance to pulling loose is a function of the angle that the anchor rode makes with the anchor shank or in nautical terms, it’s scope. You are therefore, correct, that all other factors being equal the anchor will have more holding power in shallow water. And finally, two anchors have been recovered by divers from the Plattsburgh battle site. One has British markings, the other is unmarked. The unmarked anchor measures 12ft-1in from crown to head, and 7ft-1in between the tips of the flukes. The ring had an outside diameter of 24in. The anchor shank had broken 2ft below the ring. Eagle’s log records that “the small anchor broke off the shank” during the battle. They also left at least one more anchor on the bottom after cutting the cable to move the ship during the battle. Here is a drawing of the anchor:

-

La Couronne by GP-SAV - 1:100

Roger Pellett replied to GP-SAV's topic in - Build logs for subjects built 1501 - 1750

While Woods like mahogany and walnut are the staple of European POB kits they are not good modeling Woods. The grain is too coarse. Fortunately, our American Black Walnut is Superior to other walnut type species provided in kits. I have some Mahogany in my stash that was salvaged from an old chair that is beautiful stuff that I would not hesitate to use in a model. It is probably the true Honduras variety. On the other hand, the other woods sold as Mahogany today can be nasty stuff with a stringy grain, unsuitable for models. American Hard Maple can be an excellent modeling wood, if you can find straight grained material. In the long run, you’ll get better results using solids Woods than veneers. Most veneers sold today are “rotary cut,” in other words, peeled from logs. This process can cause tiny tears in the wood that would be invisible in veneered cabinetry but are causing the ragged appearance that is concerning you. Roger -

My modeling and my wife’s kitchen activities have resulted in trips to the Emergency Room to stitch up cut hands. On two occasions the Doctor asked if I was a fly fisherman. When I replied that I built ship models he gave me the tweezers and forceps and said, “We just throw them out.” They seem to be nice quality. Roger

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.