-

Posts

1,735 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by flying_dutchman2

-

-

Mike,

Love these boats as well. My next boat is the Boyer, one of the 17th century merchant boats. Picked this as it is a large model so I can add lots of details and it has a beautiful looking stern.

Piet

Thanks for the info. Found lots of Utrecht pictures on Google.nl.

My first attempt to do the figurehead in sculpey. Made a piece of 3 x 1 x 1 inches. Backed it at 275F for 30 minutes. Glued a picture on it and rough carving with an xacto knife.

Marcus

-

Canon holes have been filled out and painted on the inside with medium cadmium red which is the same color as the inside of the railing. Still need to do the final coat of the cadmium red and the outside in cobalt blue. Transom is cut out and painted as well. Inside is Prussian blue and outside is cobalt blue.

Created a carving peg board. Took a piece of pine board and drilled 1/4" holes every 1/2" and every 1" all over the board. Took birch and left over cherry dowels and cut them in 3 and 4 cm lengths. The piece that is in between the pegs is the River God carving. I cut it out with a hand jigsaw and added pencil marks which will be carved out and painted yellow ochre.

The pieces on the blue cover still need to be carved. The red is cherry and the white is maple.

-

So instead of the carving the canon wreaths, I am replacing those with port hole covers. Will file them down somewhat, paint them yellow ochre and, voila, done.

This Wednesday I will meet a member from the north west Indiana woodworkers Association (a club I joined recently) and go through his stash of wood cut offs. There is a lot of basswood and balsa that I know of. Also, brass, copper, stainless steel, aluminum and other metals in strips and wire in various thicknesses. At the last club meeting I mentioned that I can use any cut offs that anyone wants to part with. After the meeting several members came to me and asked if I can use cherry, ash, alder and apple. I said yes, and I will have it in the December meeting.

-

-

I went to Google.nl and searched for statenjacht Utrecht and came up with all types of pictures. Areas that need to be painted a total different color. Also found additional items that are not included in the plans. As I am going to model it like the replica, I am going to omit the canons.

Marcus

-

Question for the Dutch members who have seen the replica of the Utrecht more than once.

The lion is holding a shield with his front paws, what are the two colors? Top color and the bottom color.

Nowhere in the Hoving book is their a picture depicting this and I have scoured the Net of Utrecht images.

This would be much appreciated.

Thanks

Marcus

-

- GrantGoodale, Elijah, Piet and 6 others

-

9

9

-

1 hour ago, *Hans* said:

If you want to make extra pieces of ornamentation you can take a medium thin thread (0,5 mm or so), make it stiff with some glue (white glue f.i.) and paint it afterwards in a gold or black or so. In this way you can add extra lines and so.

Thanks Hans, that is an excellent idea

Marcus

-

Piet, Patrick, Hans, and cog, thank you for your encouraging words. I can put a long post together of all the mistakes I have made, but this one is a "Big One".

If I am off by a few mm than I can adjust it but if it is more than 5 mm, and I try to adjust it, it won't look right and at the scale of 1-50 cm it gets out of whack fast.

The problem:

The bottom of the Stern windows need to match up with the side windows and they didn't. The bottom of the side windows compared to the bottom of the Stern windows are 5 mm to high. So I am leaving the side windows as is (instead of redoing that as well) and raising the area above the Stern windows by 5 mm. I don't want to widen the 45 degree area where the top of the rudder is. That looks weird (I tried that as well).

The carvings will be as is and where there are gaps, I will add filler pieces.

The carvings are going to be cherry. This wood carves nice. I am also keeping it simple. Non of the frilly stuff. I have broken many pieces by putting in too much detail and the piece I kept simple, looks good. All of these pieces will be painted Yellow Ochre.

Below is a piece that goes on the top of the Stern. Still needs to be sanded.

Marcus

-

-

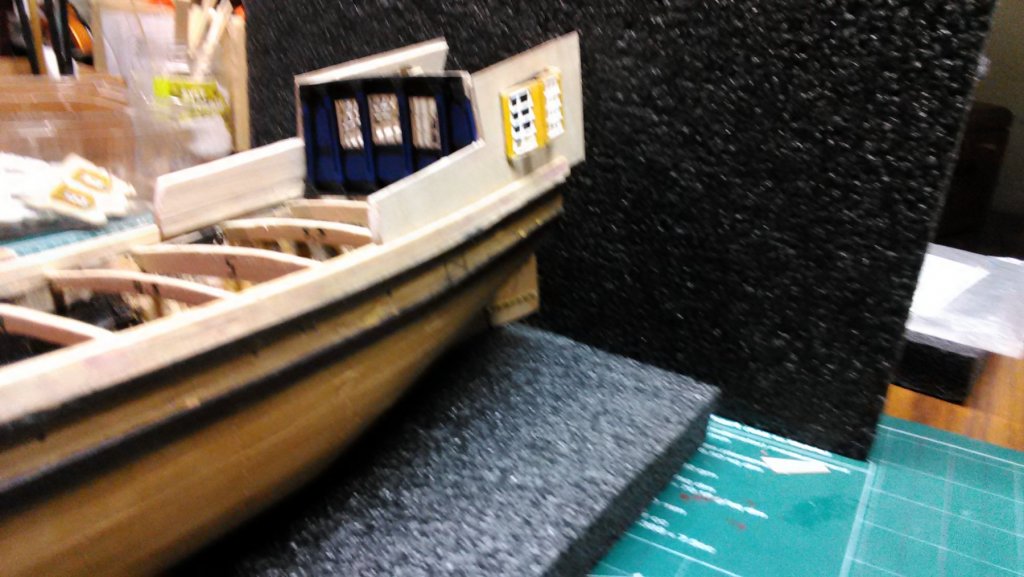

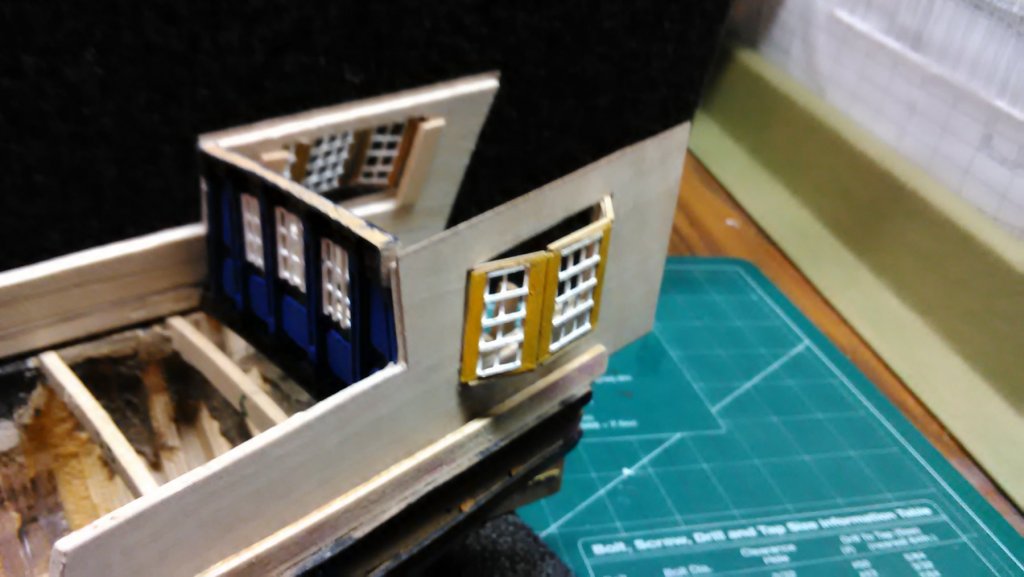

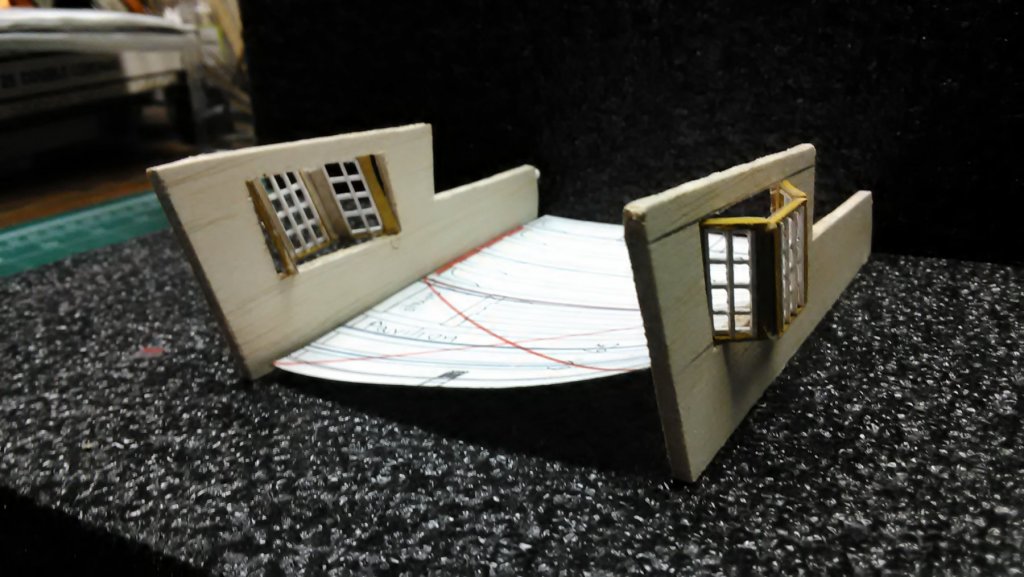

Glued the two sides and the front of the pavilion together. Most of the pavilion wall areas will be covered with carvings

Paint color:

Pavilion outside is cobalt blue.

Inside is Prussian blue.

Pavilion front is Prussian blue and the molding is cobalt blue.

All window are titanium white.

The window frames are yellow ochre.

Inside of the railing is cadmium red, medium.

Marcus

-

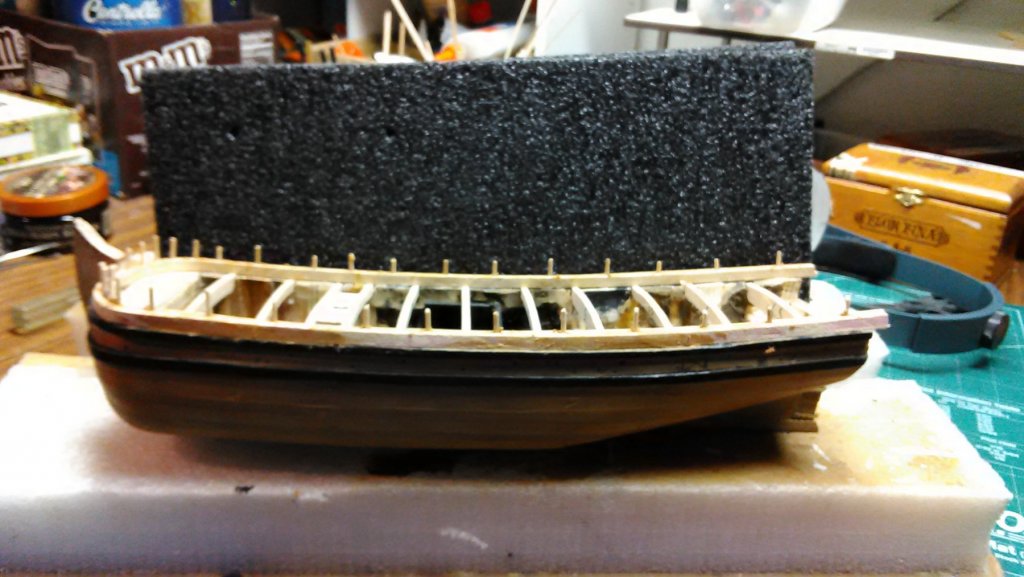

Discarded the walnut and created the railing with poplar strips.

Glued in the deck beams, redrilled the holes in the hull and jammed toothpicks with a bit of glue in them.

Laminated 2 strips (1x6mm) of poplar together and glued on the outside of the toothpicks and 1 of the same strip on the inside of the toothpicks. Added scrap wood to fill in the gaps between the strips.

It will be finished off with 2 x 2mm strips laminated on top totalling 8mm in height. Cut out the strips on the inside including the toothpicks where the pavilion sides are glued in.

Out of 3mm thick balsa cut out the pavilion sides and laminated 1/64" veneer to the front of it. Dry fitted the sides and the windows and the front.

My overall width of the boat is 6mm too narrow, so I had to sand down the sides of the pavilion front. Furthermore, my Stern piece is going to be a little higher than what the plans show.

Now that this is all done, I will be working on the deck. The pavilion floor will be a couple of mm higher than the deck as the tiller goes between it. This is what the plans show.

Marcus

- Omega1234, cog, kees de mol and 4 others

-

7

7

-

On 11/2/2017 at 4:29 PM, cog said:

Walnut is a b*tch to bend, even wet. You have to bend it further than the required bend to have it come close to the curvature you want. I had the same problem on the Dolphyn

I was going to use the walnut as it is the correct width (6mm ) plus a 2mm square dowel to make a total of 8 mm high railing. I am now going to use 4 x 2mm strips and veneer it on both sides. It will be painted Prussian blue.

I can also pin down the walnut with the smallest insect pins I have and glue a 2 x 2mm strip on top of it. I have so much walnut in my possession.

Marcus

-

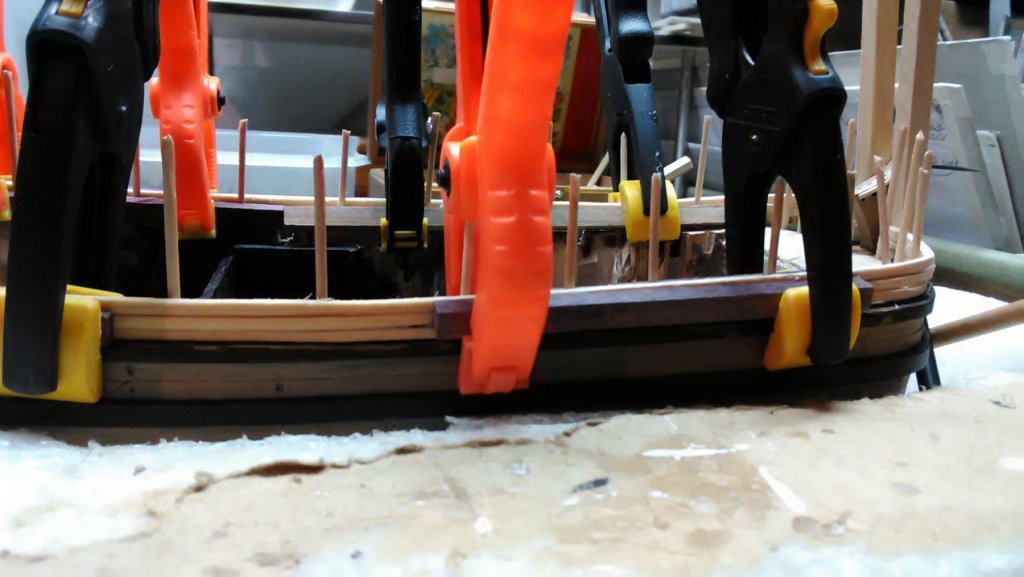

I had to rethink the railing. First time I soaked 2x6mm walnut and tried to bend it along the curve of the boat and ended up with a clamp forrest (Cog's definition). After the planks were dry they didn't keep their curve.

So this morning pulled out the saw and cut 2x2mm strips from Poplar _ Tulip tree, to be exact. Made a lot of these as I am bound to break a few.

For the Utrecht I have been using a lot of Poplar. It has good bending characteristics, especially for bluff bows and it is cheap.

Marcus

-

-

-

-

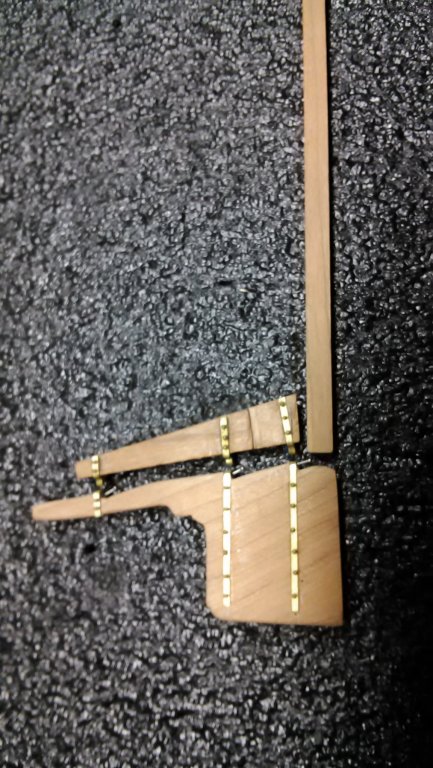

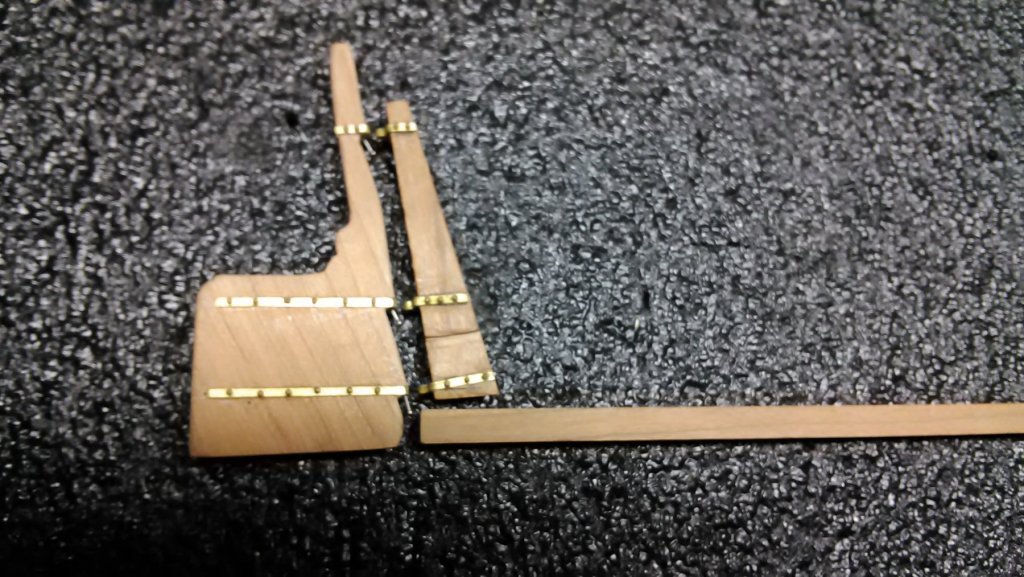

Finished the rudder and the post. Used cherry wood for both items and the brass pintels were attached with stainless steel insect pins cut to 3 mm in length.

Glued the pintels with CA on the rudder and post, once dry, used a drill bit #79 (0.0145") to drill holes through the brass and partially through the wood. Then pressed the pins in. The pins are strong and they are great for this.

Marcus

- Geoff Matson, mtaylor, archjofo and 3 others

-

6

6

-

-

I am pulling up a chair as well. This looks like a great kit to build. Dutch kit made by Dutch company. You know it will be accurate. Hans (one of the owners) has built a fantastic model the Batavia.

Marcus

- Robin Lous, cog and Old Collingwood

-

3

3

-

-

Hi.

I have been procrastinating about this but it is time that I start this. The yacht Utrecht has many carvings. I have practiced some simple items from wood but with the many mistakes I have made I am no longer using wood.

Purchased 1 lbs. of Super Sculpey and I have the following questions.

Is it possible that I make, say a rectangle piece of clay 1/4" by 2" by 1", bake that, and after it is cooled, carve it?

As Chuck mentioned in an article in Ships and Scale is that you can bake a piece and keep adding to it.

Does the new clay adhere to the baked clay just like that or how is it done?

Thanks

Marcus

-

- Robin Lous, Omega1234, mtaylor and 2 others

-

5

5

-

45 minutes ago, cog said:

Overkill or not, it looks very good, Marcus

Thanks Carl.

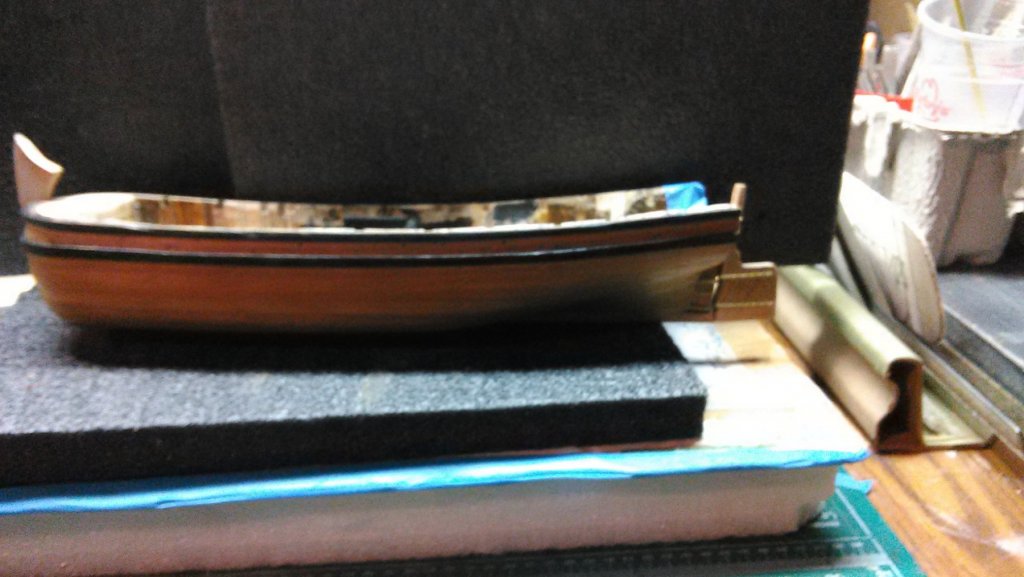

Finished the second layer of planking. I am pretty satisfied with it. Planking flows nicely towards the back and the bluff bow looks good as well.

The will sand it tomorrow, and upload some pictures.

Still haven't done any serious carving. I keep procrastinating on this, but will eventually have to do it.

Marcus

Utrecht 1746 by flying_dutchman2 - FINISHED - Scale 1:48 - Dutch Statenjacht

in - Build logs for subjects built 1501 - 1750

Posted

Comment for the Dutch members as they would understand the following statement.

The sculpey cuts and shaves like "Hele oude Leidse kaas". (very old Leiden cheese)

I wish I had some. Yumm.

Marcus