-

Posts

6,476 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Keith Black

-

Any and everyone. It's merely a statement of non importance on how I feel about trying to build something when lacking what I feel to be adequate information.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

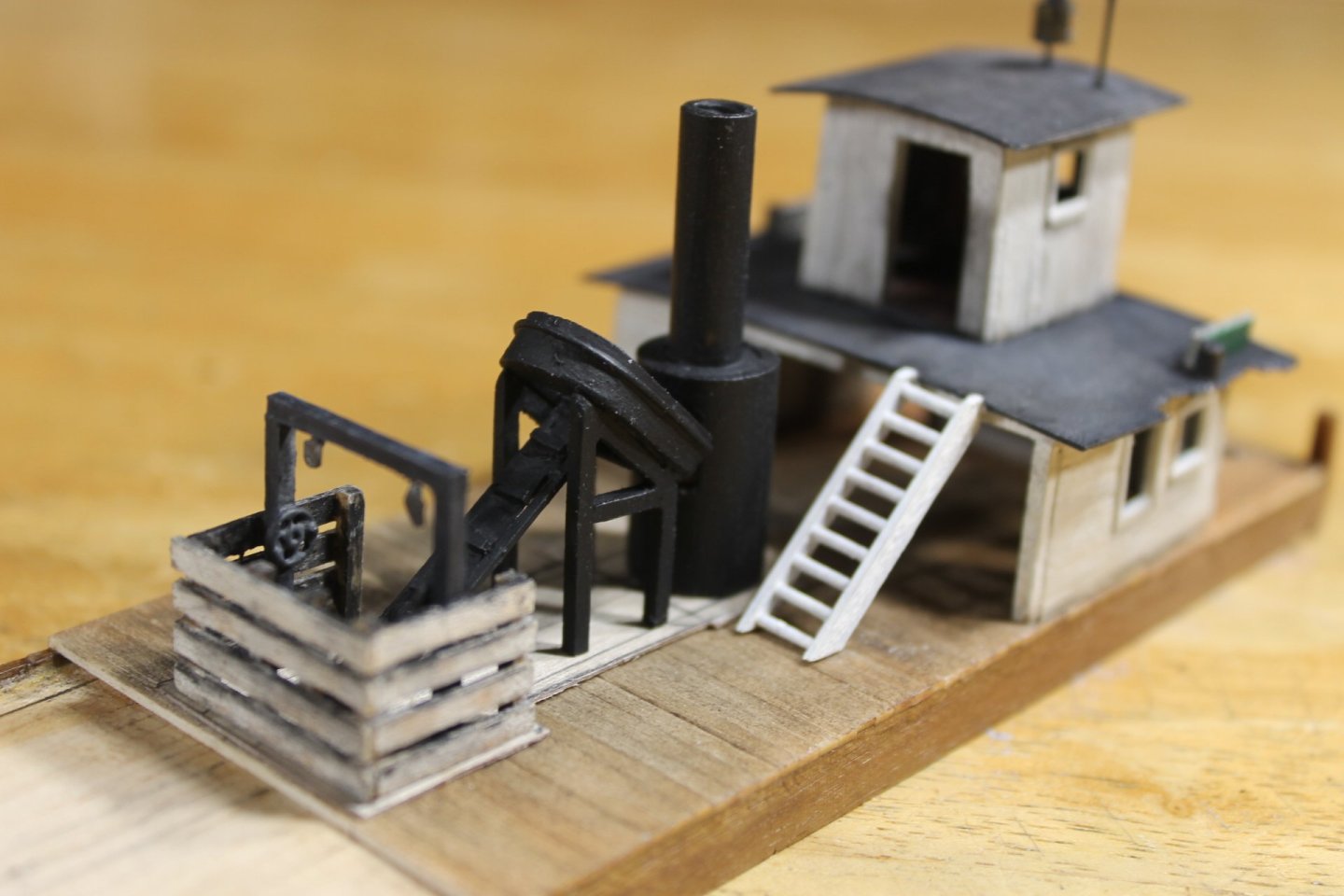

Eberhard, thank you for your kind comment regarding my health. Regarding the stoking system, I wasn't able to find anything on this type of system. I had to rely solely on photographic evidence and clues. I detest ambiguities when trying to replicate a thing as it always takes three to four times longer to build rather than the simple monkey see, monkey do.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Welcome to MSW. Glad to have you aboard.

-

Welcome to MSW. Glad to have you aboard.

-

Rick, Gary, and Eric, thank you so very much for your kind comments.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

What little I've done altering 3D printed resin figures, I've found it pretty easy to remove unwanted features using an X-Acto # 11 blade. Micro Master products are great but expensive. You might try purchasing a inexpensive piece and see if you can alter it as I suggested. Then you'll have a pretty good idea of the difficulty involved.

-

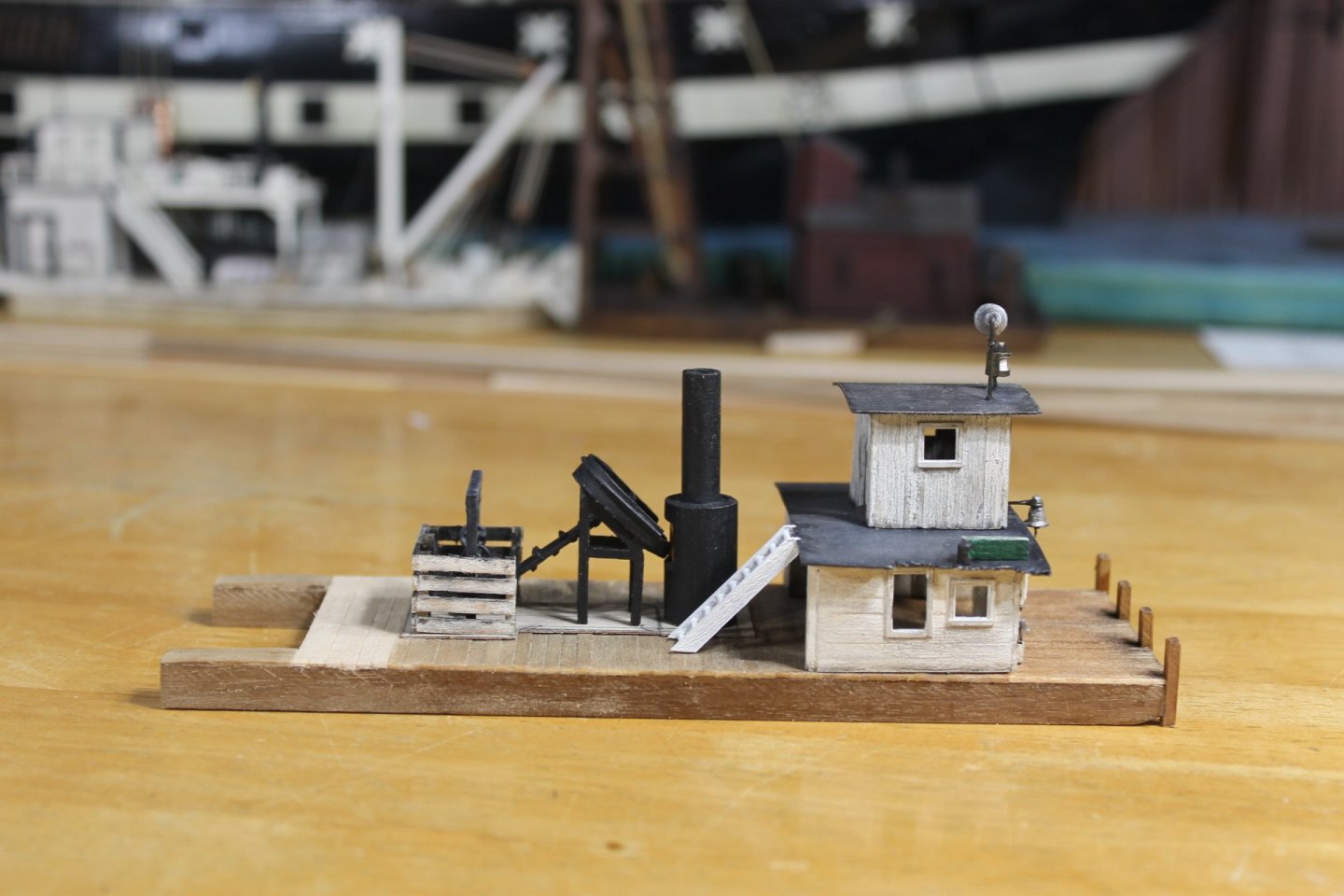

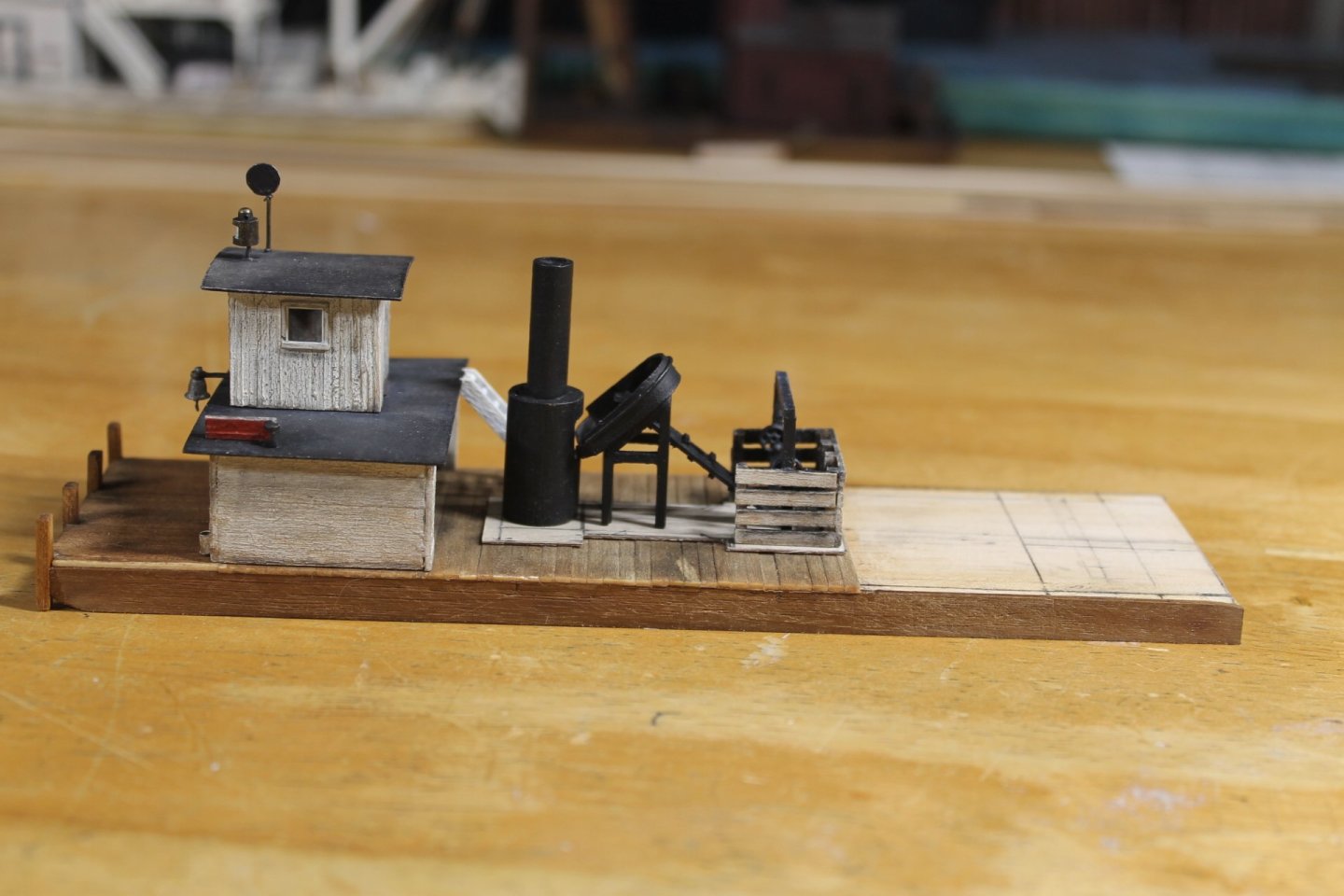

Thank you my MSW family for your kind support, it warms the cockles of this old man's heart. A quick update. After what seems forever we finally have a hull. The length is 63 feet. I'll create an access hatch for the rudder chain and shaft tunnel aft of the coal crib. The pace should quicken a wee bit getting the knows made and placed. The wheels will take some time but I look forward to getting them made and installed making this look the proper towboat. Thank you everyone for your support, the likes, and for being part of the journey. Keith

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Glen, Grant, Bob, and Ken, thank you so very much for your kind comments. Your kindness is a gift I will always treasure.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

That's the great thing about MSW. The willingness of of nearly everyone to share information with one another. We are the Collective.

- 257 replies

-

Jacques, Steve, Kurt, John, Paul, Keith, Craig, and LJP, thank you so very much for your comments. Your kindness touches my heart.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

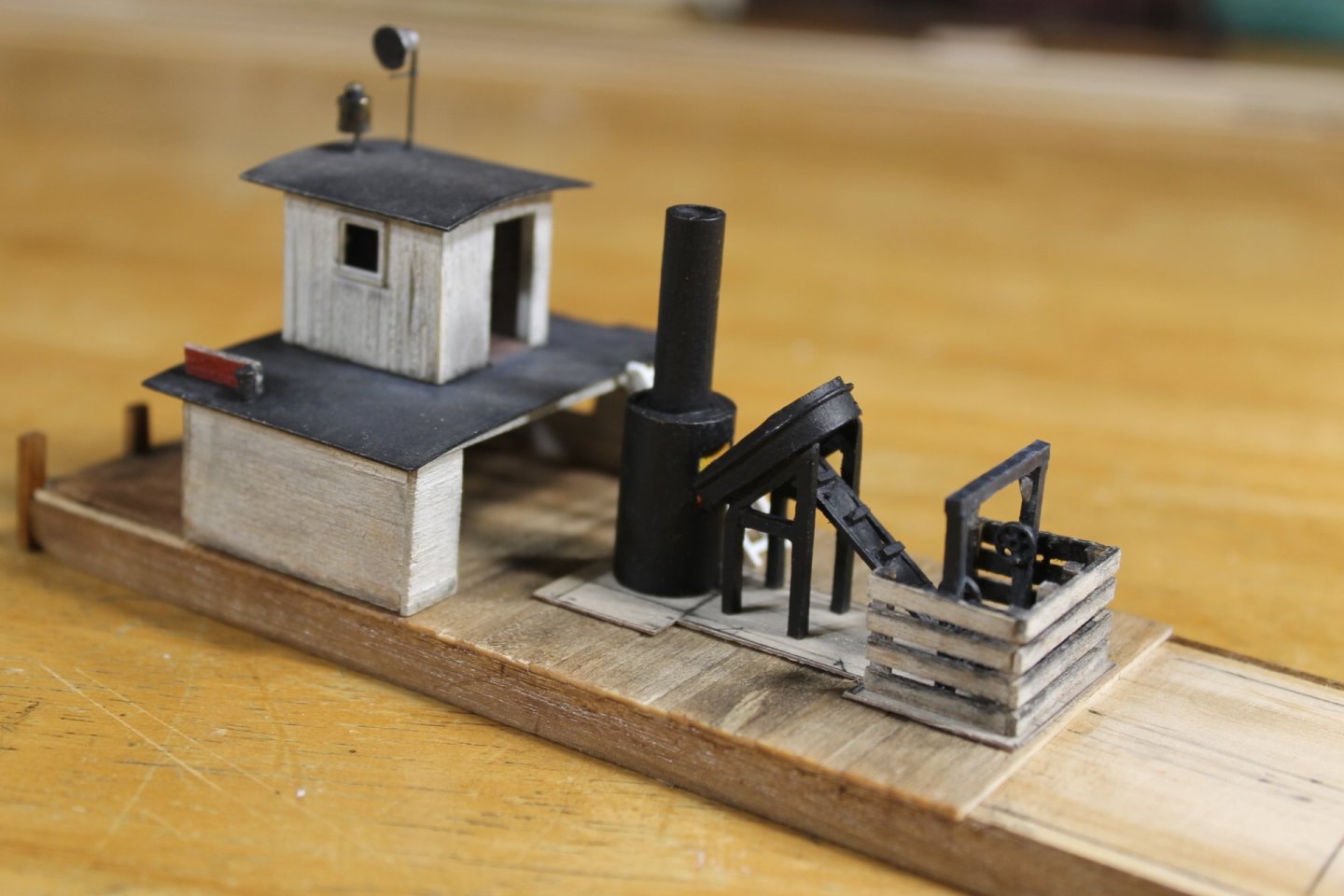

Thank you to everyone for your comments and likes. The coal feeder body is done, sorry I just realized I didn't add a photo of the table throat. I still need to add lever, gears, rig the lines to conveyor tail, and put coal on the conveyer. There is a sequential gluing order to that list and I'm still trying to figure out the best way to do that. Once I have the boiler's port side fire and clean out doors added I can the glue the boiler to the steel plate. I can add coal to the conveyer at any time but the trick is adding coal to the coal crib without the crib being glued into place because I need to be able to lift the crib to rig the blocks to the conveyer tail. It's kinda like needing three hands to do something. As you can see in this photo I got the boiler lit. I'm going to add five feet of deck space (0.5 inches) aft of the coal crib and then make the wheel's cutouts. Once the cutouts are made she should start looking more like a towboat. View as seen in the original from aft photo. Thoughts The steam engine is directly underneath the pilothouse in the engine room. This allows the Skipper to control the engine without need of an engineer to do so. This means the shaft ran below the boiler, coal feeder and coal crib in the rudder chain tunnel. The deckhand's bluejeans, teeshirt, and baseball cap wasn't normal work clothes till the late forties early fifties. The photos show a vessel with antiquated machinery in a general rundown condition. Had this ole gal been pushing barges for twenty/twenty five years? Other than electricity, what other "modern" updates had been added through the years? I am fairly certain there was a water tank connected to the boiler on the port side up next to the pilothouse. Water would be pumped to the tank and from tank to boiler. With that setup there would always be water available for boiler startup without the need to start a pump as the boiler water on startup would have been gravity feed. Health update. Months ago in my Lula log I mentioned i might have an aorta aneurysm stent endoleak that would require surgery. I could never get an answer from my then healthcare provider's vascular department so I changed healthcare providers and, I'm good. I have an area of concern that we need to monitor closely but I'm not about to blow, surgery is not required at this time. This is an answer to prayer that allows me to get on with my life and continue my care for Maggie. For those of you who have prayed for me and for those who have kept me in your thoughts, from the bottom of my heart, thank you. Thank you everybody for your support and for following along. Keith

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

You too? I restored a 37 MGTA, 60 MGA, 59 TR3A, 58 Morris convertible, and various American iron. Pre war MGs are my favorite cars and as goofy as the TA engineering was, it is the car I remember most fondly. I still have my collection of car badges, golly knows what I'll ever do with them?

-

Rick, welcome to MSW. Glad to have you aboard.

-

As well you should be, Phil. She's turning into a gem of a build. 👍

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

Congratulations on completing a fine looking model, David. 👍

- 114 replies

-

- Cutty Sark

- plastic

-

(and 4 more)

Tagged with:

-

Welome to MSW. Glad to have you aboard.

-

I guess saying you were displaying them in your half didn't work out?

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.