-

Posts

6,586 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Keith Black

-

Not an issue, Eberhard. I just liked the look of the linoleum, it's been discarded.

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

Thank you, Eric. Spittoons, geez, every pilothouse seems to have had one. How bout i use one of the several buckets I have instead of a spittoon? I sanded and poly coated the wood flooring last night. I really did like the look of the linoleum, it's a shame it doesn't fit into Lula's timeframe.

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

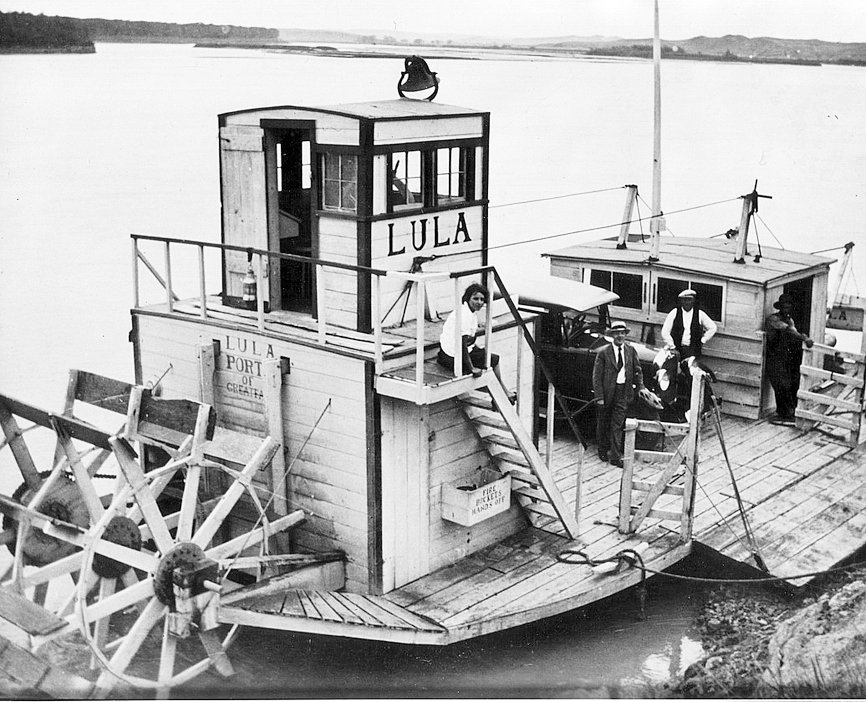

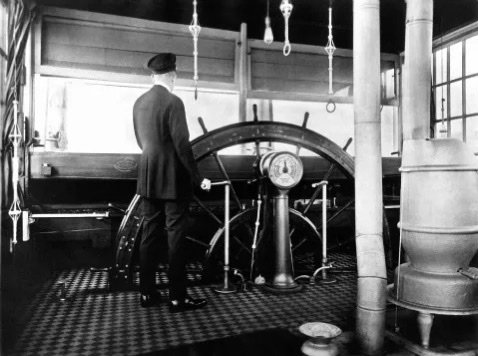

Eberhard, thank you taking the time to explain. I thought I could shoehorn linoleum into Lula's time period but I can now see that's not the case. Okay, okay, wood flooring it is. But I did quite like the linoleum, Tom......from your girlyman brother. Tom and Pat. Unlike the majority of steam vessels Lula's pilothouse sits right on top of the engine room. In fact, if there was a hole in the pilothouse floor the captain/pilot could reach through and strike the engines with his cane. I'm going to portray Lula's engines being controlled from the pilothouse without the aid of someone in the engine room. If there are those that feel this is impractical, I have two EOT's, I could add on in the engine room and one in the pilothouse. But in the below photo I posted earlier, isn't that what's being shown regardless of the EOT? Oh, I'll also be adding a steam whistle and also keeping the bell.

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

Doug, welcome to MSW. Glad to have you aboard.

-

I'm tryin' to quit, I'm down to a tenth of inch a day. Eberhard, I searched Mr Google for a dark antique linoleum and this is the best that Mr Google came up with. If in your travels you find something that looks more manly please post the photo and I'll scale it and print it and see how it looks. I like the linoleum look but I'm not 100% sold on this pattern.

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

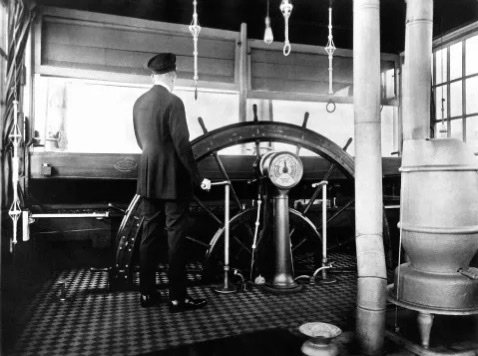

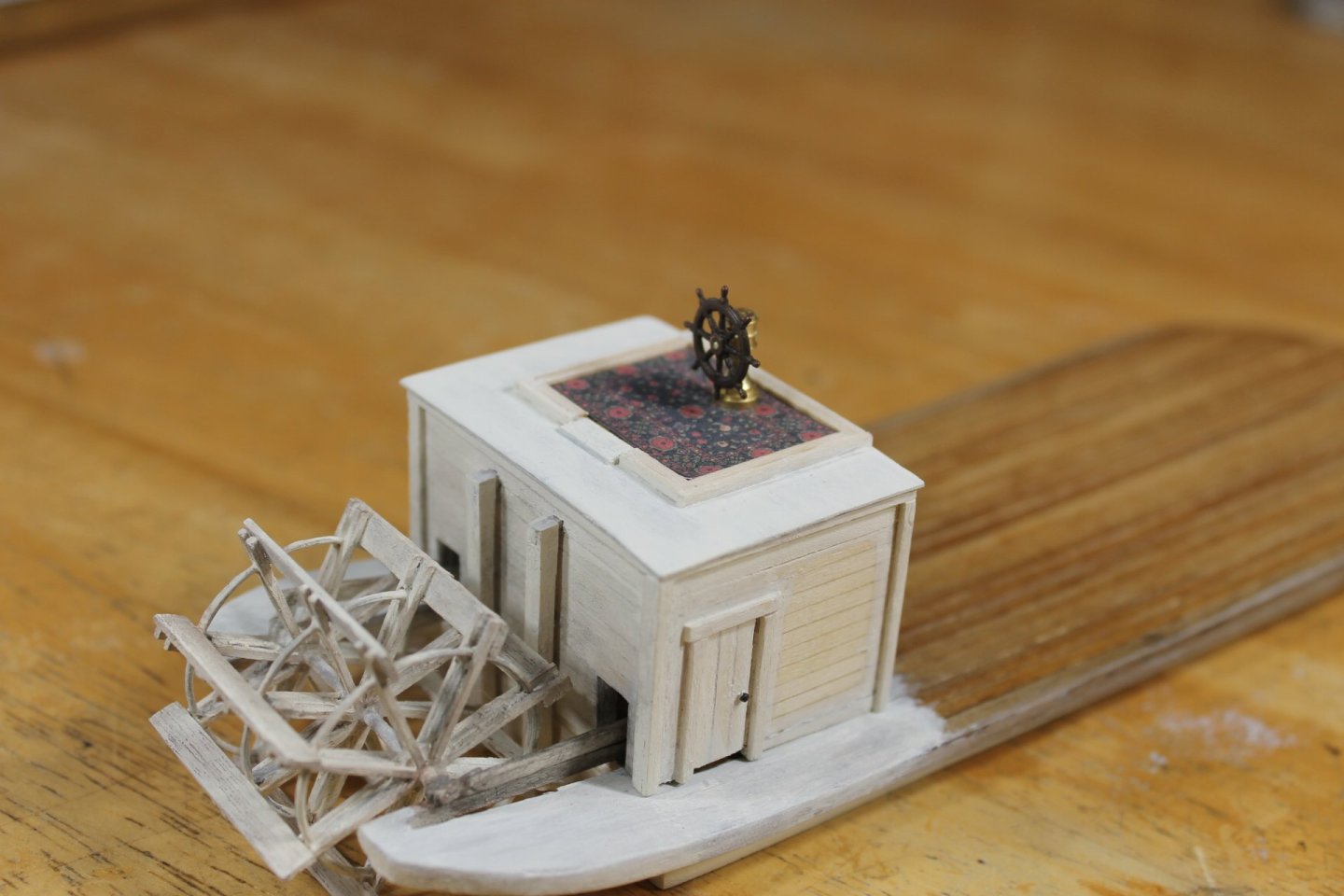

Thank you to everyone for your comments and likes. After the potbelly stove debacle it's great to be back on track making progress. Because the engine room's roof is convex I laid down the pilothouse floor plates and bottom siding boards and sanded them level. This allows bringing up the walls without having to make a bunch of wonky cuts. After the floor plates and threshold were done the pilothouse flooring was added. The ships wheel is unattached and raw at this point which still needs to be addressed. If there was any elegance to Lula it would have been inside the pilothouse. Looking through the aft door, the floor is dark after the white threshold so the the floor doesn't look like it's painted white. The chart desk/table is white but the walls don't appear to be white suggesting they may have been paneled? One can also see a four legged stool with a backrest and then the wheel. That's all we can see for certain, anything else I may add and the interior treatment is conjecture on my part. Pilothouses seemed to be comfortable with a certain amount of beauty. This pilothouse interior is what I'll use as a templet for Lula less the engine telegraph. I could sand the flooring I added and give it a poly coat or... I could add linoleum which was a traditional flooring treatment. I think this looks pretty stinkin' hot. I like it but it's so different and out of character, it'd take some getting used to. I was going to add doors on the port and starboard walls but I need wall space plus the single aft door keeps the original Lula look intact. Thank you for your support and for following along. Keith

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

The water turned out great, Bob.

- 87 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Compared to the amount of time I spent trying to make one it's dirt cheap. At a tenth of an inch I'd do better trying to shape the solder blob with a jewelers file. As long as a turning is simple or an object is straight lines I can get objects made that measure between .03 and .04 with moderate success. I've had enough time in the saddle in the 1:120 world to know that a tenth of an inch object is beyond my meager skills.

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

I agree, thank you, John. Thank you, Lynn. Lynn and Tom, a coffee pot to scale would be about 0.10 inches. I don't have the equipment to make things that small. Thank you, Pat

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

New here, checking the place out

Keith Black replied to jbassett's topic in New member Introductions

John, welcome to MSW. Glad to have you aboard. -

After a day's effort of trying to make a potbelly stove I've raised the white flag. I take defeat hard but I need to move forward with positive progress. I've ordered a potbelly stove from All Scale Miniatures., see the link below. https://www.allscaleminiatures.com/miniature-gallery/stove-potbelly-w-chimney-single

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

John, welcome to MSW. Congratulations on completing your model, so many come excited to start and never finish which is so sad. I look at making mistakes as a learning experience. Learning what not to do next time, learning how to make it better in the future, and most importantly, learning how to have more fun. Glad to have you aboard.

-

Wolle, welcome to MSW. Glad to have you aboard.

-

Thank you, Keith, you are most kind. The difficulty in turning a potbelly stove is the size, 0.30 H X 0.21 W at the base and trying to show detail. I may waste some time in the effort but in material, not so much. John, I absolutely agree.

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

Thank you for your input, Bob. Thank you, LJP Thank you, Keith. Thank you, Eric. You're correct, there wouldn't have been any smoke or fumes coming up from the engine room. And you're also correct for the need to turn it off come summer. I'm of two minds, floor registers or potbelly stove. Floor registers keeps the look of the original Lula but a potbelly stove is traditional. Plus, where the heck would the crew have put on a pot of coffee? Without a stove in the pilothouse there wouldn't be one. With a stove in the pilothouse, one could argue that was where the coffee was made. I'm going to get out my 1/2 inch cordless lathe and see if I can successfully turn a potbelly stove. If I'm able to, Lula gets a stove, if not, then I'm going with floor registers though neither registers nor radiated heat plumbing would hardly be seen at this scale. No real progress to note in the below photo, it's just a fun photo of Lula and the pile driver. Thank you to everyone for your comments, likes, and for being part of the journey. Keith

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.