GrandpaPhil

NRG Member-

Posts

6,112 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by GrandpaPhil

-

Anyone out there working on a card model?

GrandpaPhil replied to gagliano1770's topic in Card and Paper Models

Seahorse makes some amazing stuff! I ended up buying most of the base kits off their website. The Seahorse Zeven Provincien is one of my bucket list builds, built to 1/64 scale to match my Revenge. -

Welcome!

-

Welcome!

-

I use the Folk Art Clear Primer and brush both sides, even after laminating pieces. It helps prevent (or at least reduce) delamination when cutting small pieces out. If they still delaminate, I just clue them back together with PVA (Mont Marte to be exact). I apply the CA after cutting small pieces out to reinforce them. It essentially plasticizes them. That’s how I got my davits to retain their shape, and be functional, on my model of the Solferino.

- 106 replies

-

- digital navy

- v108

-

(and 3 more)

Tagged with:

-

For really thin pieces, pre sealing both sides, and scalpels are your best friends. Then, if the pieces are super thin, I add CA to the cut edges to stiffen them up. It works quite well.

- 106 replies

-

- digital navy

- v108

-

(and 3 more)

Tagged with:

-

I would also likely be interested if they have something in my area of interest. I like predreadnought era battle wagons personally, although I would also love to get ahold of a card kit of the Akagi.

- 106 replies

-

- digital navy

- v108

-

(and 3 more)

Tagged with:

-

I will, I need to finish my other projects first though. I’m going to enlarge it to 1/64 when I build, so it matches the scale of two of my other models.

- 12 replies

-

- Le Coureur

- Shipyard

-

(and 1 more)

Tagged with:

-

Clare, Looking forward to seeing this model as a build log! I have Shipyard’s 1/96 scale version of this kit.

- 12 replies

-

- Le Coureur

- Shipyard

-

(and 1 more)

Tagged with:

-

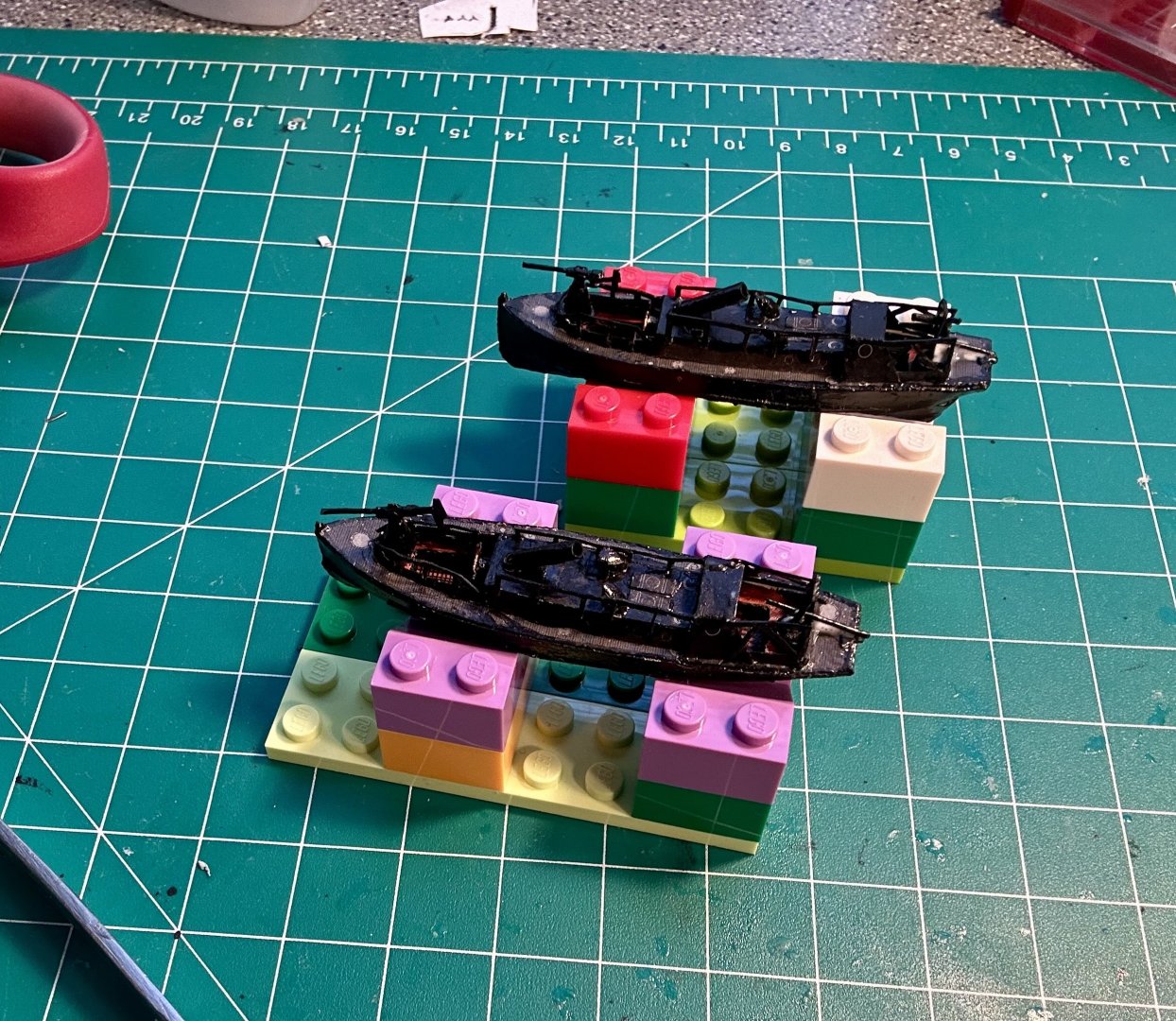

Here are the 40’ mine launches ready for installation: Here are the first of the rowed launches in progress:

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

Glen, Thank you very much! I found out about that trick on this forum. Legos make excellent quick customizable jigs and temporary cradles. I bought a box of 1000 bricks and then a couple of those small suitcase type starter sets from Walmart when they went on various pre-Christmas/Easter sales. They have been immensely useful on several different projects. Also, they make a great square for traditional POB construction. They are 90 degrees, especially when built into a block and can be clamped into place, thus ensuring square construction of a POB hull. OC, Thank you very much!

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

The railings and other small pieces are made and installed on the mine launches: The rudder structure shown in the instructions/plans won’t fit on the boat in the cradle. I cut that structure off once I realized. Once the boats dry I will paint and seal them. Then, I’ll make the flag masts for them and lay them down in a storage configuration. After that it’ll be time for the rowed ship’s boats. Then I’ll finish painting the cradles and get the rest of the yards and running rigging installed.

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

Welcome!

-

Orel, HMV and Schreiber kits are still available on Amazon. Hopefully the other card kit sellers figure out the tariff situation and adjust their shipping policies/prices accordingly.

- 106 replies

-

- digital navy

- v108

-

(and 3 more)

Tagged with:

-

Lol! @ccoyle was one of the significant influences to my getting into card kits!

-

Ages of Sail has Shipyard’s full line.

-

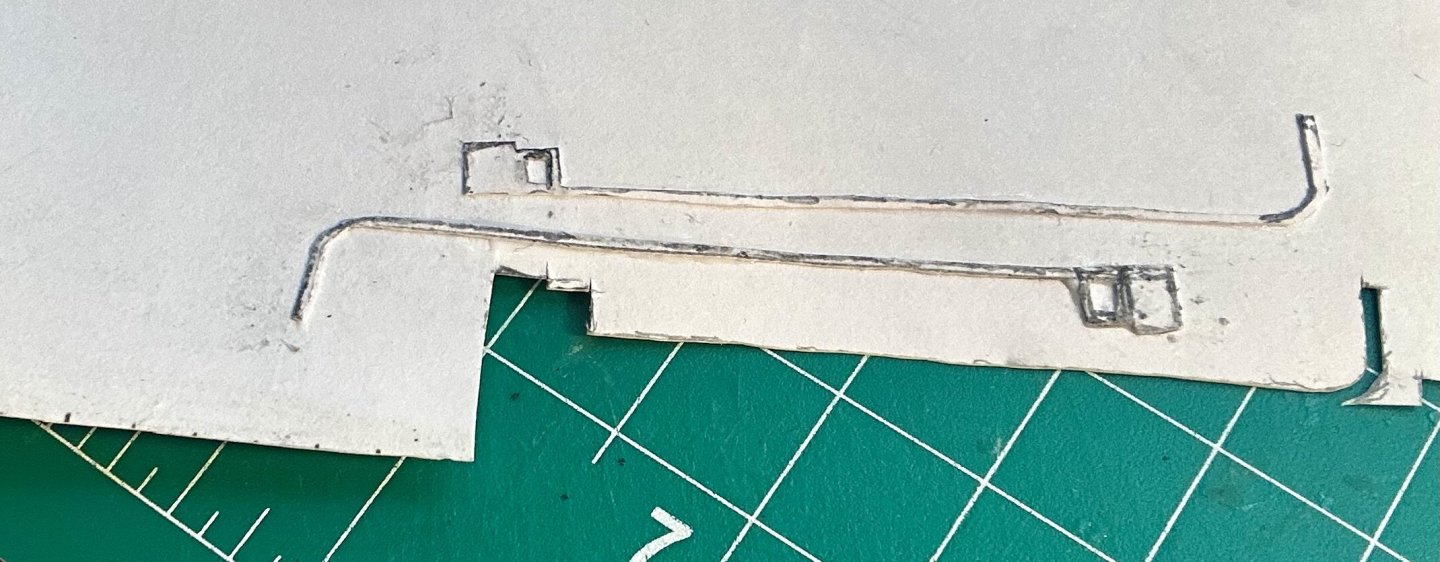

Making good progress on the 40’ mine launches: It didn’t come with the keels/rudder assemblies, so I just made my own: I still need to make the bilge keels and a bunch of railings. Maybe I’ll make a couple of quick three bladed props while I’m at it.

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

Welcome!

-

Welcome!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.