src

Members-

Posts

2,300 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by src

-

Steve, Not exactly. Something big going in one of the very local theme parks near you. For the leather around the bowsprit, it sounds like it was a relatively close fit on the real item? Sam

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Steve, I don't know what time off is at the moment. 12+ hour days 7 days a week since mid Nov until December 22! Enjoy your time off, I am envious. Yes, I think this drought is going to end in a big way. Will continue yo live vicariously through yours and other builds!! Sam

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Steve, She is looking great. Can't wait to see her on a real monitor - I am limited to cell phone access A.T.M. Stay dry today. Sam

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Augie Looks great as always. As far as display, tell your admiral if she got rid of some shoes you could turn HER closet into a display cabinet. May I suggest Kevlar before you tell her this though? Sam

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Robyn, Great to see you back!!! That plane is an ibex finger plane. They come in various sizes and shapes. My computer died on Monday so I can't access my hardrives or backup drive at the moment. With my work schedule at the moment it's going to be a few days till all that is resolved so I can't give you a link where I bought it. The best I can tell you is it was a luthier website. Good luck looking forward to seeing more of you around here. Sam

-

Rich, If it works and you like it it looks, do as you will. If it doesn't then there are tried and proven ways to fall back on. We would be hunting with rocks if somebody hadn't said,"there has to be a better way" Carry on. Sam

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Rich, What are the purple handled plier in post 1325 above? They look like a flat jawed box joint plier. Do to they have a groove for wire or just a flat face? Sam

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

David, the Scary Sharp system Pat refers to is really popular with some people. One advantage is your not limited to the size of your oil stone so flattening out large chisels or plane soles is relatively easy. Its also very inexpensive compared to water or oil stones. Regarding new chisels, other than some Stubai carving chisels I have yet to buy something that didnt need some attention. My Pfiel chisels all required honing and if I recall so did my Two Cherries chisels. For me at least its part of buying a new chisel, plane or plane iron. The sole or back needs to be flattened and then the cutting edge needs attention. Thats just me, a couple of the guys I work with are happy with their Buck Bros tools right out of the blister pack. Sam

-

When I have a lot of sharpening to do - which is less and less now that I sit at a desk at work - I use a Tormek. Even with that if I have a really dinged up chisel or plane iron I start out with a slow dry grinder. If its one or two items a wet stone is usually easier and faster for me. Sam

-

Rich, looking forward to that factory picture. sam

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

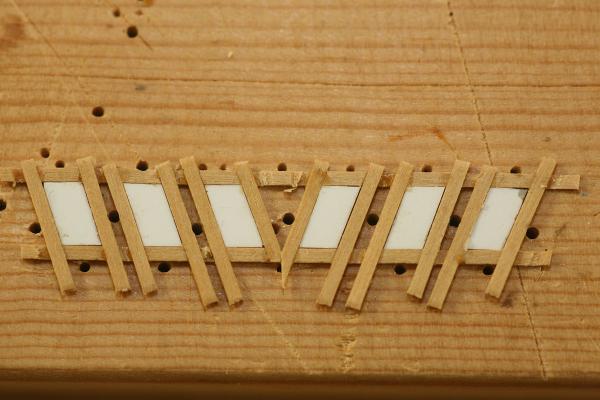

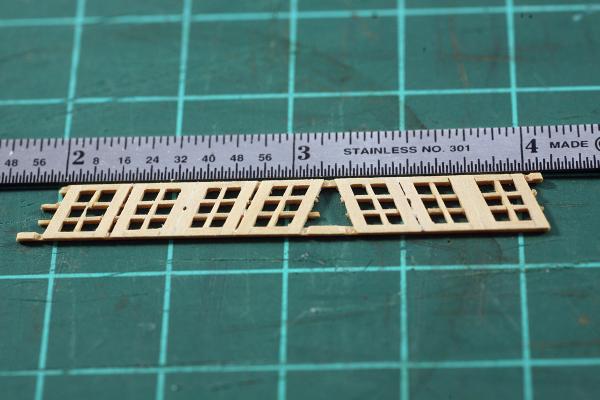

Very nice Sjors! What did you use for your window glazing? Sam

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Pat, Thank you!! I will check that out. sam

-

Joe, thank you for the compliment on the windows. I had not thought about backing up and then the MM product. Certainly cheaper than a $30.00 kit that I ma never use again - another reason for using a few grams of existing stock from work. I may just go that rout. The MM product does look good, I used some on one of my frames that was too big. I just wasnt sure how long it would hold up its so soft and thin. Hornet, there is a tackle shop around the corner from my work that sells rod blanks I am sure they would have the epoxy you are referring to. If it is water clear, that would be another option. Ulises, I agree, even before I began this build it seemed my work life was one huge experiment! Thanks for all the advice. sam

-

Tom, Joe, It doesnt HAVE to be castible, it is just the direction I was going. My frames are certainly not complex; small parallelograms really. http://modelshipworld.com/index.php/topic/113-enterprise-by-src-constructo-151-or-lessons-in-adapt-improvise-and-overcome/page-29?hl=+enterprise%20+src I made them thick to simplify construction so glass or plastic feels like it will be too far back. Certainly an option though. Mark, any idea of how the Micro Mark product holds up over time? Joe, casting under a vacuum or just degassing with vacuum? I have never left a casting to sit under vacuum while it kicks. One of the first times I degassed a mix I left it under vacuum to long and ended up with a deli cup full of hardened foam, an interesting look but not the crystal clear I was shooting for. I have heard of curing under pressure but have never tried it.

-

I dont know if this is the correct forum for this question, if not will one of the mods please move it? I am looking for a water clear casting epoxy or rigid polyurethane for my quarter badge windows. I had intended to use a product from BJB Enterprises because we had some at work and I have experience with it; WC784: http://www.bjbenterprises.com/polyurethanes/castable/rigid/water-clear/ Unfortunately it didnt get stored properly and we wont be buying any in the foreseeable future. At $65.00 a quart I cant justify buying for what amounts to about 0.5cu inches of product . I did a search online and found something from Smooth-On Corp. I dont have any direct hands on experience with their products except their So Strong tints (great stuff by the way). Has anybody used either the EpoxACast690: http://www.smooth-on.com/Castable-Epoxy-Res/c1295_1377/index.html Or the Tarbender encapsulant? http://www.smooth-on.com/Castable-Epoxy-Res/c1295_1395/index.html I can get a sample of either for about $30.00 which is easier to justify in my mind, still a lot of money for 6 windows. I have some Micro Crystal Klear but it dries pretty flexible and I dont know how long it will hold up over the years. Any advice or recommendations for a castable product that wont break the bank would be appreciated. Thanks Sam

-

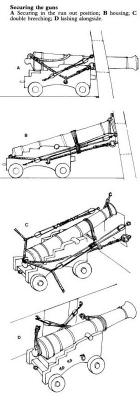

Sjors, thank you, I will move the breaching bolts farther out from the gun ports. Thats what i love about this site, everybody has your back covered. Regarding the lashing, the second drawing below is what I am aiming for (sorry no pun intended this time) Rather than a 'run in" or "run out" look I am going for a lashed to the bulwarks display. As you can see in the drawings the breach rope is terminated at the ring so I dont know where the extra would go. somehow lashed out of the way. My two chase guns I intend to lash like the bottom drawing to hide my decking disaster. Sam

-

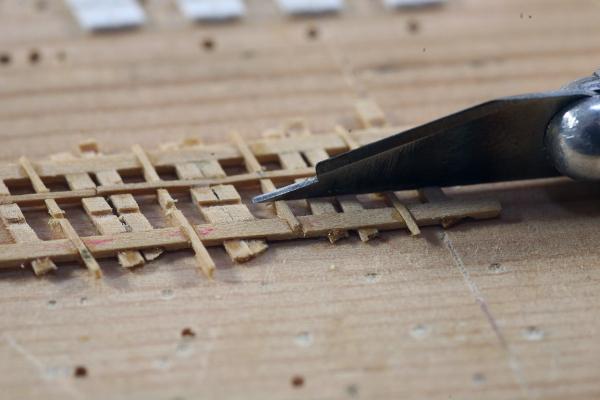

This is most likely my last post till after christmas. Other than the last two days we have been on 12 hour days 7 days a week for the last three weeks and will pretty much continue until the 20th. So, very minimal build time for me. My bank account (and the IRS) are loving the double time though! Who needs sleep or hobbies? There is coffee and dreaming while awake! Just before the insanity started at work I was working on my quarter badge window frames as my sciatica eased up. I finished my first set only to find I made my jig wrong. I had thought I allowed for a small amount of trimming top and bottom but ended up making them so big by the time I trimed them down there wasnt enough frame left to hold everything together! Dohh!! Looks OK Too big! DOH!!! So I made a new jig and built some new frames. When I made my dados for the mullions I cut just a tad too deep and ended up wit numerous match sticks......Doh-dohh!! Somewhere in all this there were a couple more screw ups that required starting over. All told I think I made these 5 times before I got something I felt was workable. I wan to get over to a place called SilPak and buy some casting epoxy for my glazing. I have several failed attempts at frames so I will experiment with that. If it doesnt work out I have some micro crystal clear I can use. My only concern is it dries so soft. we will see. Several attempts later. While glue was drying on the frames I continued stropping blocks for the gun carriages and ordered some 0.025 rope from Chuck for my breaching ropes. Tonight i was able to rig one carriage - took me most of two hours to do. There is still room for improvement but I am mostly OK with my first attempt. Not sure how much breaching rope I should have and how it would terminate on a lashing like this, so far I have not found a picture or drawing that shows the and of the breaching rope. All the drawings I have seen the rope is cut off at the ring, I assume for clarity. I havent trimmed the lropes yet as I may still play with them or redo them as I gain experience. Not sure how much of the breaching rope to leave, leaning toward the left side. Hope everybody has a great holiday season. Till then , sam

-

More importantly, did they get paid Grog and a half? Sam

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Sjors, Thank you for the warning, no broken bones for me. Racing over to aggie to stake a corner out. Sam

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

Outstanding work sjors!!! Happy klompen dance!!!!! Sam

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.