src

Members-

Posts

2,300 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by src

-

Robbyn, Looking great. Havent been comentig much anywhere cause of work but I have been dropping in nightly. Dont you just love it when that light bulb goes off in your head and you go "OH!" For me at least those are the bits of knowledge that stick. Sam

- 234 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Slog, nice save and it looks like you might have a way of making sheaves too. 0.8mm slices on the rod/tube...hmm perhaps mark and spin it on your drill/dremel/drill press? Maybe using a razor saw as it spins? I have the same challenges coming up, kind of brain storming on your build..... On your ring situation if low temp electrical solder doesnt work or isnt strong enough there are these tweezers I have been eyeballing myself at Micro Mark, I wonder if they might work for you. http://www.micromark.com/heat-sink-soldering-tweezer,7064.html sam

-

Got the parts blackened, although I may try to get them a little darker, once I rubbed at them they looked a bit more brown than black. This will most likely be my last post for a while, work is getting more and more demanding. I was supposed to be off today and have spent almost the entire day on the phone. Who said working from home is more productive?? sam

-

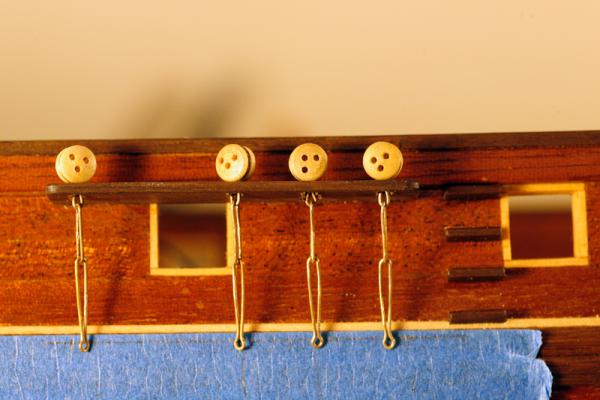

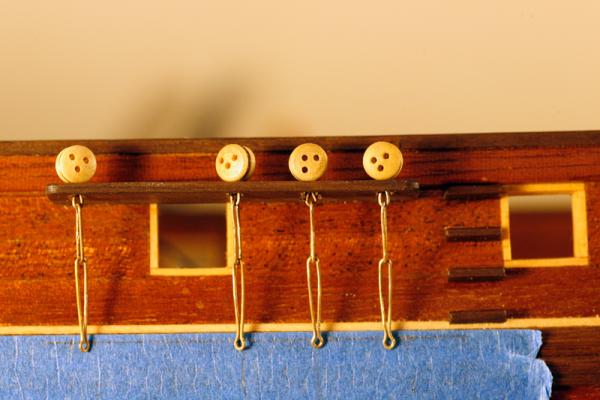

That four lettered word WORK has reared its ugly head again... I have had very little time to play in the last couple of weeks so building has slowed to a crawl. Finished manufacturing my chain plates and if my crews will leave me alone this morning I plan to blacken them today. I made a rough template out of card stock to determine the approximate location and rake, once the masts are in place and I can finalize their locations I will pin them in place. My rope came in a few days a ago from Chucks Syren company. Too lazy to go back over my posts but if I didnt mention it earlier he delivered several days before he promised them. I think I actually received them the day before he told me they would ship! Thanks Chuck!! Thursday night I tried tying on the rope to the stern gun ports, a knot looked horrible so I tried seizing them with 2 lb fishing leader, looks better than the knot but still not "right". Theoretically I will get over to a fabric store today and pick up some dark brown thread and see how that looks. I can see already I have complicated my life by not doing this on the bench before installing the transom. Oh well, live and learn! Sam

-

Very nice Slog!! I learn something virtually every time I visit. Your sheave looks perfect to me since it will be mostly hidden. You have the wheels in my scull turning though. There have been a few times at work where I have had to turn a screw head down for one reason or another, I have done it by chucking the screw up in a cordless drill and spinning it against a running belt sander. I wonder if something similar could be done to make a small sheave? Perhaps soft solder a rod to the sheave hole and spin it the same way then unsolder it? Just a thought. Sam

-

Sjors, Very nice! Dave explained OSHA quite well for you/me. And yes it was very tongue in cheek. Except for the Beaurocratic nightmare part, the regs are there for very important reasons but dealing directly with the people there can be a test of patience and logic. Now, back to ship building. May I ask what your method is for seizing lines? I just tried my first ever last night, and the results were less than I hoped for. You seem to have a love for busses? Sam

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

Sjors, 2.7 meter ceilings are energy efficient? What am I missing, 2.7 meters is close to 9 american feet wouldnt lower ceilings be more energy efficient, less space to heat/cool? Not that I begrudge you tall ceilings, your builds need them. I am still trying to figure out what kind of fall protection your going to need to safely rig those tall masts! On that note can you imagine if OSHA existed in the 17-18 centuries? "All ratline shall have a certified fall arrest anchor point rated at 5000lb for each swashbuckler engaged in said swashbuckling. 10,000lbs if saving a damsel in distress" FYI for those outside of the US, OSHA is the beuarocratic nightmare forced upon those of us engaged in any kind of business here in the states. Sam

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

-

Hey all thanks!! I have a similar solder here. I am amazed at just how little it takes! So far I have all my deadeyes stropped and the first chain attached. Yesterday I stared in on the second chain that gets bolts/nailed to the hull and plate. Off to work at the moment, I will get a picture up this evening. Thanks Sam

-

Robbyn, Looking good. I see you are applying lessons learned from the SF, IE your deeper tenon. Metal work looks good too, isnt soldering fun once you start to get the hang of it? Next thing you and hubby will be welding up your own bike frames!! Sam

- 234 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

She is a very impressive lady Sjors! Nice little cart she is on too. Please tell me you dont sit and ride her around the house singing French sailing songs!! Andy will be visiting you with his duct tape.... Sam

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

Druxy, that is some beautifully clean work! Maybe this should be a separate topic, I dont want to steal this thread, if so I will happily delete this and repost, cause now I am curious. In your picture this tuck rail appears to be an applied molding, is it simply to hide the transition from the transom to the planking or is there more going on on a real ship? Sam

-

Sjors, OK I will learn patience and wait for pictures. Work is really busy right now into December so I have to get my fix vicariously. Andy, Popeyes singing cant be worse than mine, when I sing angels cry out in agony. Sam

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

I can say make the "J" sound just fine. Jay! see! I am a "yeenius" (Thats genius for those who cant say the "G" sound correct..... ) Ummmmm progress pictures Mr SeeYours?? Sam

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

-

Wow Rich, no pets? what about the cats and dogs? Ahhh big block engines in the living room!! Never did that but my last place, where I lived alone, my dining room had two rolling tool chests, a couple of rolling tool boxes and the wash room in addition to the washer and dryer had tool cases; routers, drills etc in it. The work table was in the living room. Land lord used to call it the Hobby House. He was pretty cool as long as I paid rent and didnt destroy things. Too bad he doesnt have places in Virginia for you. Good luck with everything. Sam

-

Robbyn, None of the solutions seem to have harmed the deadeyes. The black you see on the two on the left are from my torch. No matter how i set up the flame or shielded them they scorched. Russ pointed out that he solders and shapes his and then lips them over the deadeyes, presumably after blackening. I was trying to fit, shape and solder everything on the deadeye and was creating little lumps of pre-diamonds. Now that they have dried they are very close to the same color as the parts fresh out of the kit. As far as ordering, order away, but I need to direct you to my earlier post about a fireplace mantle started in high school..... Sam

-

Sjors, no problem. I was just curious. So then we can call you anything except "Late for dinner?" Sam

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

Sjors, masts look great! Hhhhmmmm perhaps we can call you the Sjorserers Aprentice? Which brings up another question, how do you pronounce your name? In my head I hear it as "Syours." Sam

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.