src

Members-

Posts

2,300 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by src

-

Vivian, Thats frustrating, but its how we learn - well at least it how I learn... sort of, I usually have to make the same mistake 2 or 3 times first . I have a similar problem with my build IE; holes in the decking, perhaps you can employ some of the same fixes I am planing - ropes, buckets mops? There is a thread here in the decking forum that may help. http://modelshipworld.com/index.php?/topic/4526-on-deck-brick-a-brack/ Shes looking good though, you will work through it And yes there are some great build/tutorials here. Sam

- 188 replies

-

- latin caravel

- artesania latina

-

(and 1 more)

Tagged with:

-

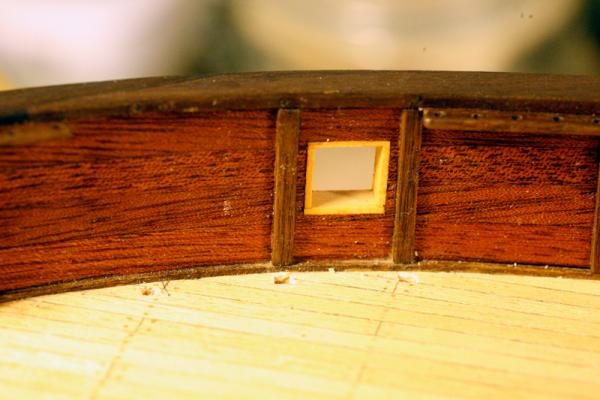

Robbyn, Most likely it will be ropes and buckets, but, I posted a question in the deck fittings forum and got some great ideas. One is a gun repair scenario that has me really intrigued. I dont know if where the third hole is will lend itself to that or not but it bears looking into I think. I tore out the offending timber heads, they came out disturbingly easy. Minimal damage to the deck and cap rail. The cap rail re-stained well; you can barely tell its been touched up. Some plugs in the deck and I can move on. I am using the old timber heads over since there is nothing wrong with the caps, just needed some tenons cut into them with the router. Looks like I need a new bit though, not a very clean cut. It should clean up with a file ok. I finished installing the pin rails and started in on the hatch coamings. I used the table saw for the rabbet but chose the dremel router for the lap joints. I have not made a sled for the saw yet and have found the miter attachment is not very stable; there is a bit a play to it. This is where she site today, a little different that the last full hull shot in September, not much but a bit. Sam

-

Sjors, at least you caught it now instead of later. Much easier to fix now I imagine. Take your time, make it right. Taps foot impatiently waiting for pictures........ Sam

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

Vivian, Looks good! Where are the mismatched pieces of wood you are talking about? Sam

- 188 replies

-

- latin caravel

- artesania latina

-

(and 1 more)

Tagged with:

-

Household Ammonia

src replied to Q A's Revenge's topic in Building, Framing, Planking and plating a ships hull and deck

Jan, Nice bend. It made the walnut brittle, interesting, I wonder if it is oxidizing the wood. There are a couple of chemist here, hopefully one of them will have something to say. Sam -

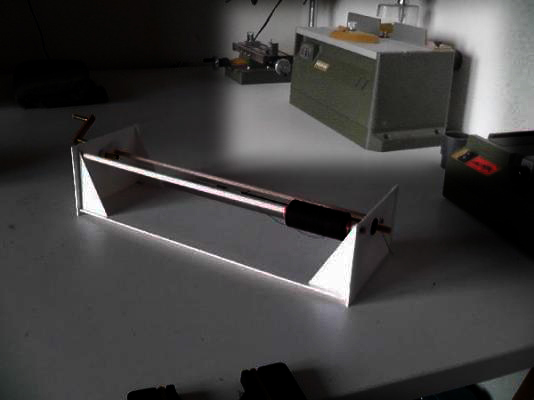

Very nice Sjors! I dont see any gears on your serving machine, I seem to be missing something, how does your work? Most of the pictures and plans I have seen there are gears and such. Hhhhmmmm a serving machine, does that mean Anja doesnt have to cook or clean anymore? Sam

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

Rich, good to hear. THat sucks about your heater. I used to have to travel back East for work. Most trips they would bring a car up from Richmond VA to whatever city I was working in. One trip somebody forgot to drain the water or add a different windshield cleaner to the windshield wiper reservoir...in December. I got about halfway between Philly and Bethlaham when everything started icing over. I am a west coast boy, didnt realize what was happening right away. Here in LA you can just hit the ice with your cleaner for the wipers. Not a good idea when the ambient temp is below 20 IIRC and your driving 65!! HA! Good times!! From the sound of it your Niagara arrived ok then? Sam

-

On Deck "Brick-A-Brack

src replied to src's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

So many great ideas! Hmmm RUM Kegs, nice! Too bad tequila is inappropriate. Mark, the cannon idea crossed my mind last night although I didnt think of the wheel to cover the hole. Liking the sail idea too, may have to wait till I get further along to decide and see how much room I am going to have. Both holes are fairly far forward and the gun barrel will come into play also. I will try to get a picture up in the morning to give an idea. Thanks everybody, Sam -

Household Ammonia

src replied to Q A's Revenge's topic in Building, Framing, Planking and plating a ships hull and deck

Brian, what does ammonia do to the ebony? Simply lighten it or?? Sam -

Meredith, Meredith, Meredith! Really?!?! The Future Admiral is SO going to hate you!! This place looks better than Japanwoodwrker.com, I see a whole lot purchases from Germany in my future. Thanks(?) Sam

-

On Deck "Brick-A-Brack

src replied to src's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

No problem Larry, I appreciate the input, its something I wouldnt have thought of. Sam -

On Deck "Brick-A-Brack

src replied to src's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Thanks everybody, some great ideas. Thats one of the things I love about this site; ask a question and you get way more than you ever expected. Larry, as Russ pointed out the area in question is too far forward and I have already added in drainage. I had originally considered the bucket and or mop. I had posted this to find out what else might be on deck and wasnt disappointed. Mark, I am really liking the spliced rope idea, it gives the rope a reason to be laying out on deck. Maybe with a little three cornered stool for my non existent deck hand to sit on. Sam -

Sjors, Thanks. Wacko is correct in english its called a shaper. I see where confusion can come in with translation. In a wood shop we will frequently run material through a planer, joiner or shaper and call it milling. Its all good. To me Klomping is a slang to describe a "stomping" kind of walk, but from you I learn Klompen is something somewhat different. No wonder there are still wars. Looking forward to more pictures. Sam

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

On Deck "Brick-A-Brack

src replied to src's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Was it common for rope coils to be "laying about"? -

I have a couple of ooppses in my decking that need to covered up/hidden. My instructions called for the timber-heads to penetrate the deck just inboard of the hull. I foolishly followed the instructions and questioned it after I installed them! The more I think /dwell on it the more I want to correct it. The problem is, I morticed them into the deck and now I will have 6 .125" holes to patch and hide. I can hide four of the patches with gun carriages, the other two will be in plain sight. What items would normally be found on deck in a non combat, day to day setting? Buckets, brooms and mops come to mind. Coils of rope perhaps? Anything else? Thanks in advance, Sam

-

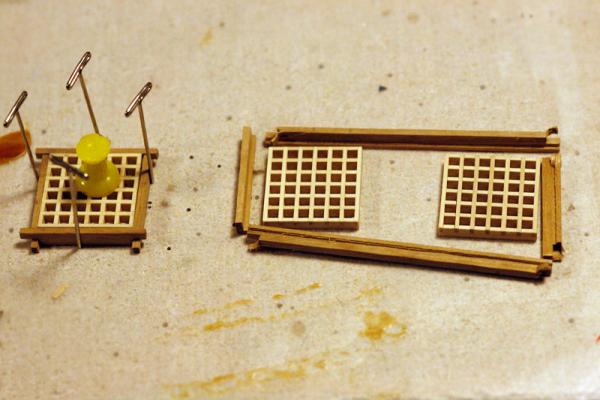

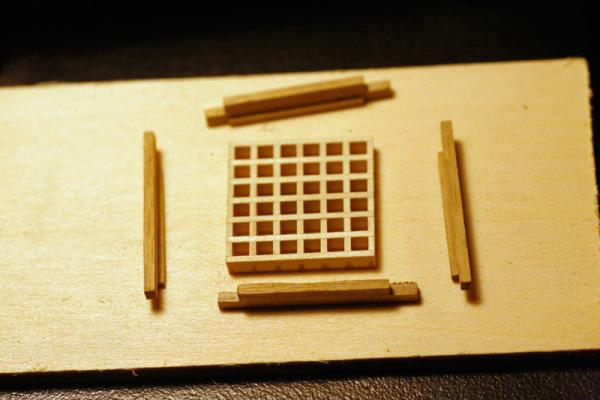

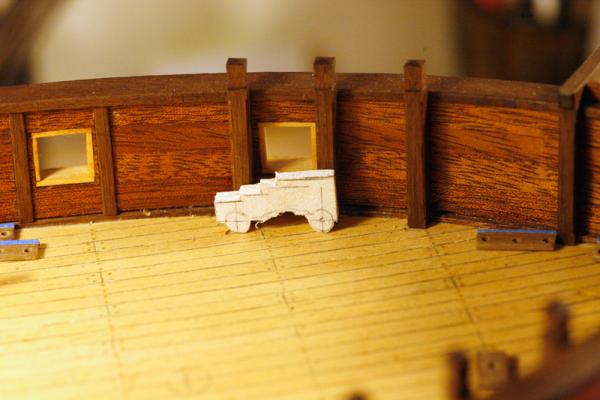

The Gremlin has been sitting on my shoulder and grumbling about the timber head locations. I may have found a work around to shut him up. Since I bought correct cannon barrels for this ship I have been planning on lashing them sideways instead of the more common run out position. It hit me suddenly that I might be able to hide four of the mortices with the carriages so I made a very crude carriage mock up based on the plans in the database here. If I can remove the timber heads reasonably cleanly it looks like it will work. I can cover the forward most hole with a bucket or broom or something. Restaining the cap rail could be problematic, got some 'speramentin' to do. Stupid Gremlin wins again! Sam

-

Popeyes right, where are the Bits -O-Wood and string and such? Are you slacking off on us? Its good to have friend like Mobbsie. Is that a Proxxon shaper I see in the back ground? You likey? Sam

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

Robbyn Thanks. I have reached the point I no longer trust the instructions or the pre-fabed parts. I went through the "Fully Framed" series, "Masting and Rigging" as well as a couple of other books looking for dimensions. Either I am not qualified to to research this or the information isnt in those books. Most likely me as I have found other information I have searched for at a later date. I may need to make a trip to the hobby store and find me a 1/48 scale period sailor figure and do like other builders do; use the figure as a reference and check. A 1:48 figure will be a tad large for 1:51. A five foot sailer is 1-11/64" at 1:51 scale and 1-1/4" at 1:48 scale, only a 1/64" difference. Sam

-

Robbyn, I cant say why the kits have us do this for sure. After surfing and lurking here for a while I have seen several Constructo kits, they have similar premade parts like the pintles and gudgeons, belay pins thread etc. I get from a manufacturers point of view that is a lot of parts to keep in stock. As far as the bits timberheads I think its lazyness or lack of research. If it wasnt for MSW I would never know they were wrong - I also wouldnt have the build I have today. I also would be done with this build, either as a completed model or in the trash bin, not sure which. The FA went away for T-day and left me to my own devices, Foolish Mortal! I spent part of the day working on my pin rails and have the Starboard side ready to glue on. Now of course after all that work I am wondering if the pins are a little out of scale, they look kinda beefy to me. They measure out at 0.399 long - about 20" the fattest point is 0.0895" - about 4.5" Dia. That doesnt seem unreasonable in my mind, they just look a bit big, I have nothing to compare to though. Sam

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.