-

Posts

7,417 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

Thank you very much Gerhard, Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

thank you very much Patrick and Piet, and all the "likes" for looking in.... many thanks for your appreciations Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

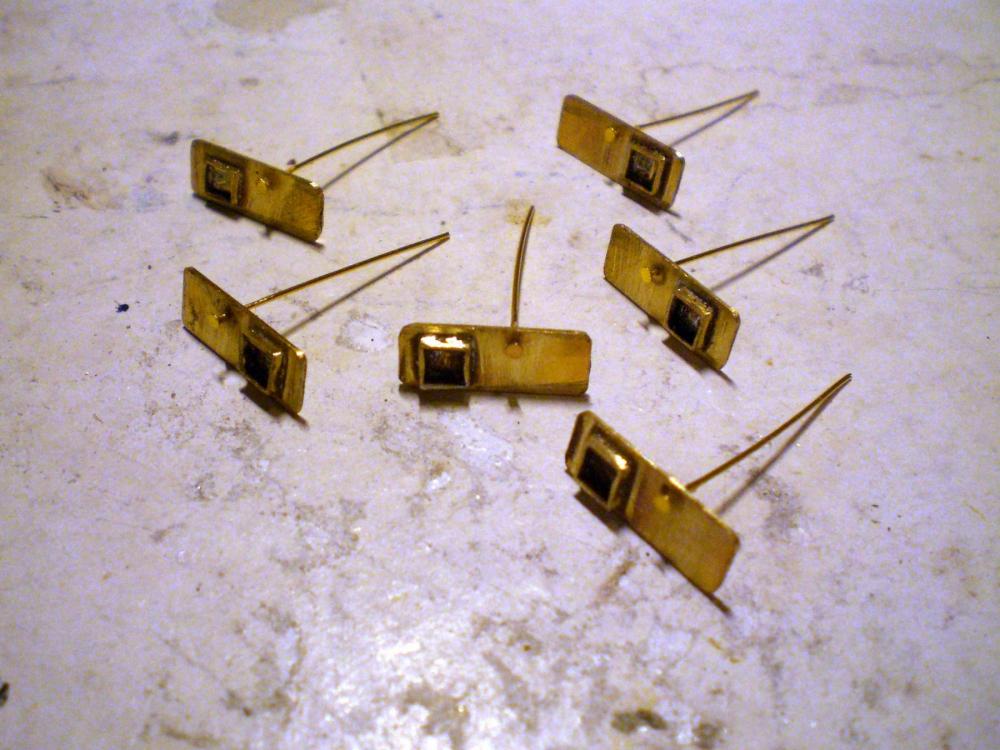

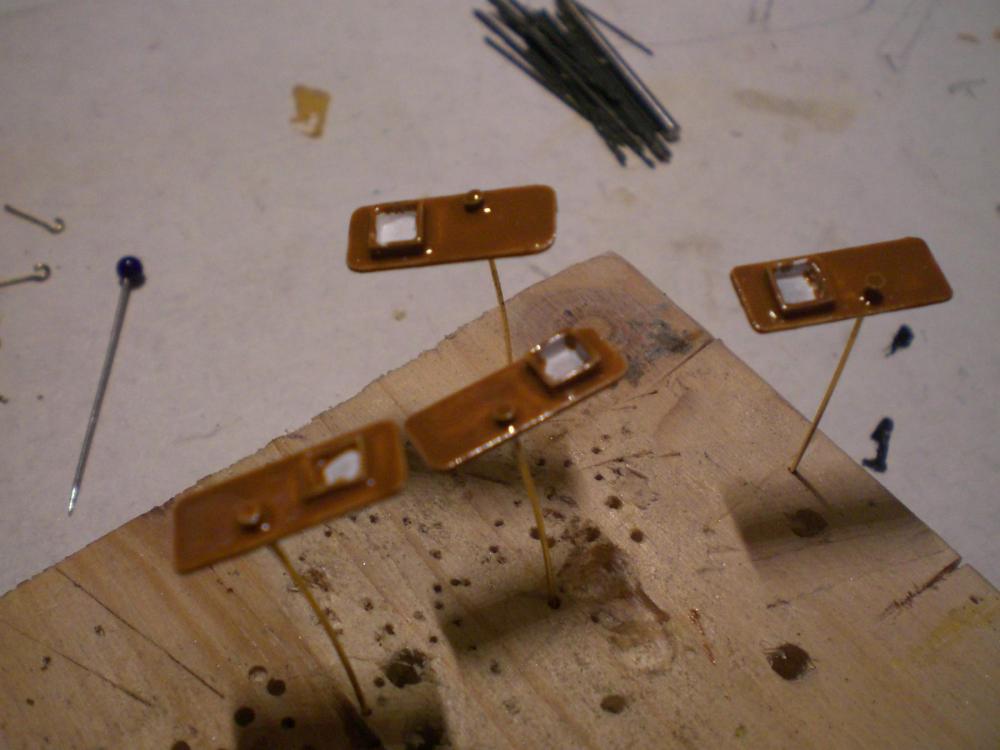

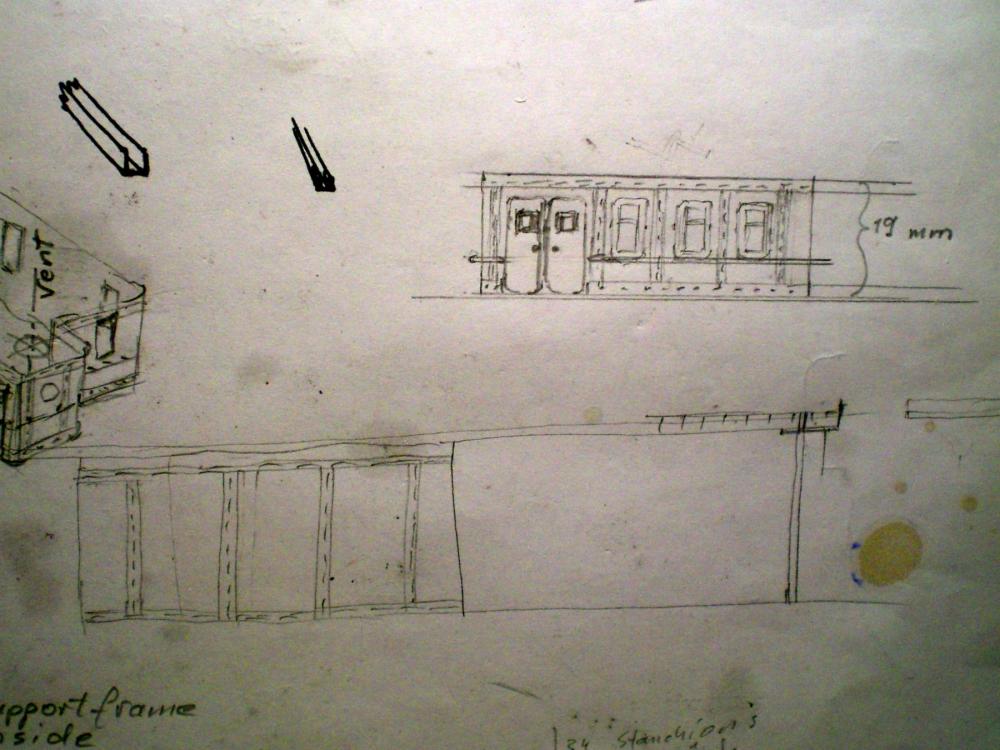

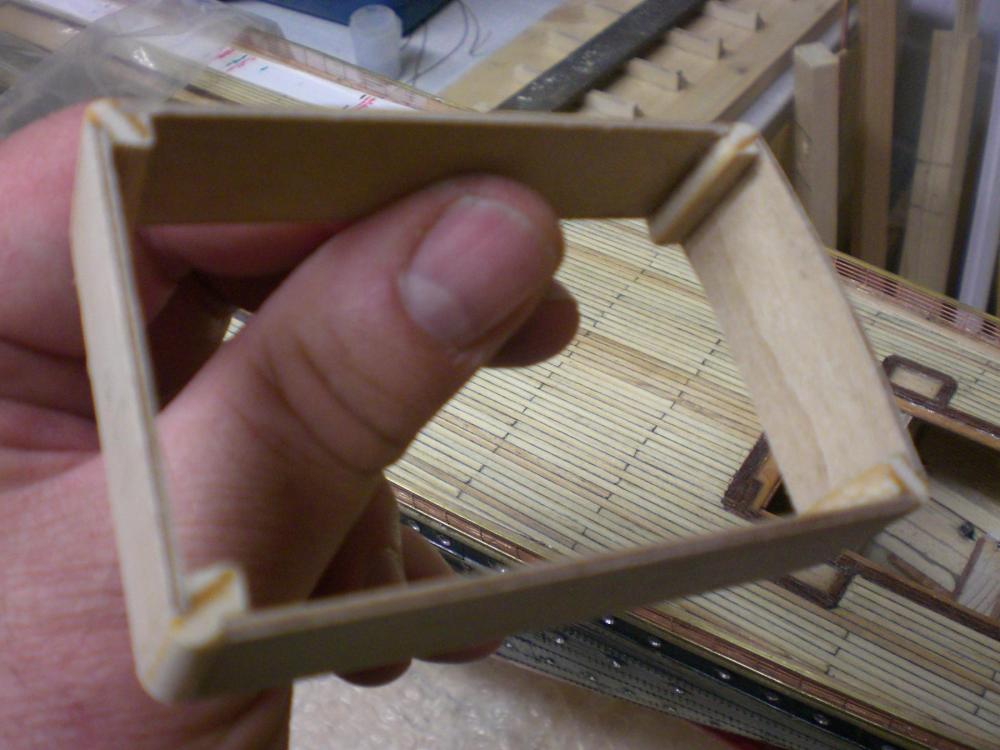

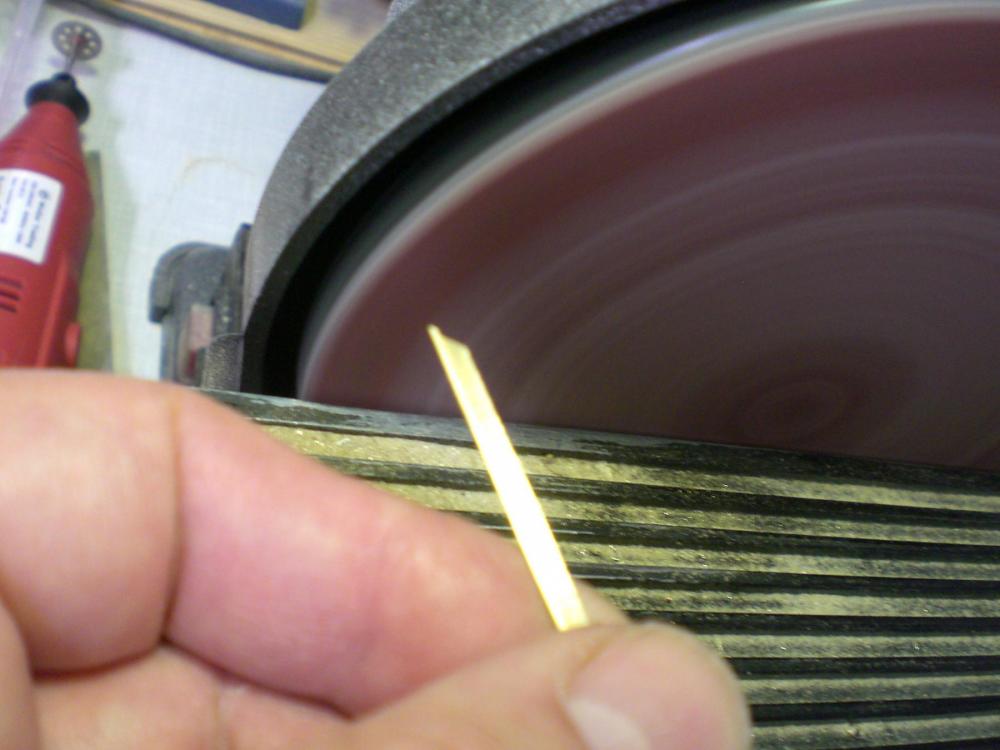

Update only a small update today...... priming, painting doors and cabin walls, making stanchions for handrails.... This relatively small aft cabin is a test for making the extensive promenade deck cabins in the same way Nils the holes for tht handrails are brought in already raw doors with window frames and knob handles, need 5, one is spare as sample for later on... the pins, surplus material from the knobs will be clipped off flush with the rear doorside first paint coat, needs some touch up stanchion holders for the handrails, the loops will be closed when the rail is in position test sample piece for handrail making

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

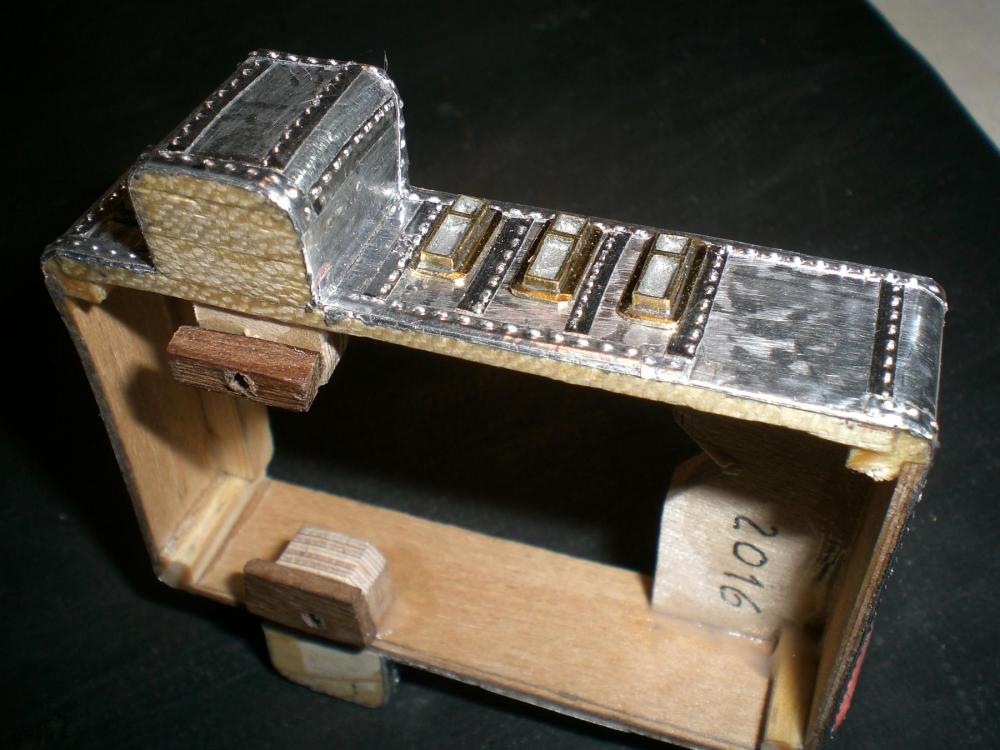

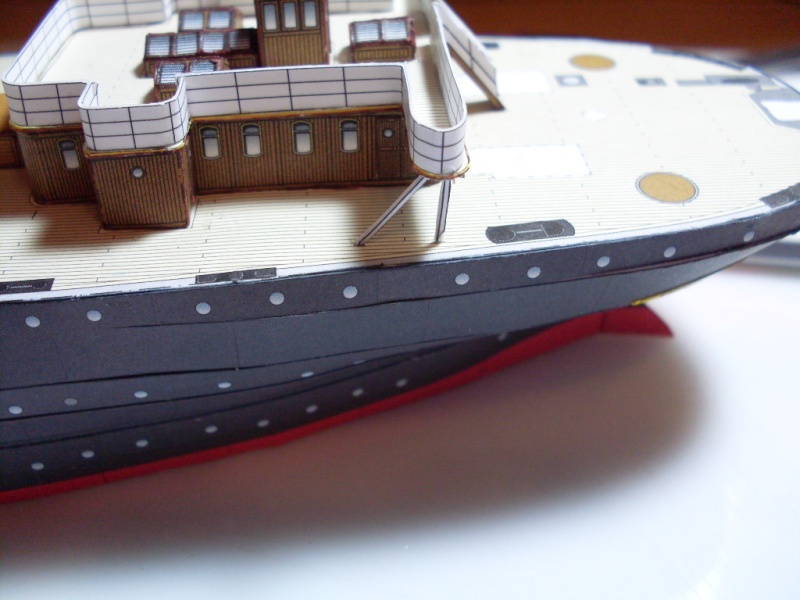

Many thanks Albert, today I tried a sample of structuring the aft cabin walls, double story windows only dry fitted...., doors and handrails not made yet... The riveting is slightly overscaled, but I wanted it to be this way and visible also for the viewer`s eye in 1 m distance Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Greg, thank you very much for your nice compliment, much appreciated... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Steve, yep, that`s right, intension is to make it look like the scetch in my post # 1202, and painted white, that shall match the main deckhousings of this deck later on. Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Schreiber 1/200 scale Titanic railings and ventilators

Mirabell61 replied to Edubarca's topic in Card and Paper Models

Hi Edubarca, here`s a German source`s web shop from Hamburg (excellent quality), it might help....for 1:200 railings http://www.shop.modelltechnik-hamburg.de/epages/ModelltechnikHamburg.sf/de_DE/?ObjectPath=/Shops/ModelltechnikHamburg/Categories/Modellschiffbauteile/Reling__Gelaender/Reling_1200 Nils -

thank you very much Bob, the rough fitting of the aft deckhousing is done, I`ll leave it removeable (two screws holding down), until it is ready for attaching of details, deck, docking bridge and railings for final mounting.... Nils the 5,5 mm thick piece of ply inforcement will give secure hold for the vent-shaft borings

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

unbeleaveable Robert, what you`re doing with those bone-deadeye chain links They look so fragile, hope you do`nt do too much for the bin.... Nils

- 241 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

many thanks for yor compliments Kees and Nenad Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you very much Geoff, your compliment is much appreciated Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

beautiful rigging on your cutter Tony, it looks super with your sails set, the way you did it..... Nils

- 269 replies

-

- Caldercraft

- First build

-

(and 3 more)

Tagged with:

-

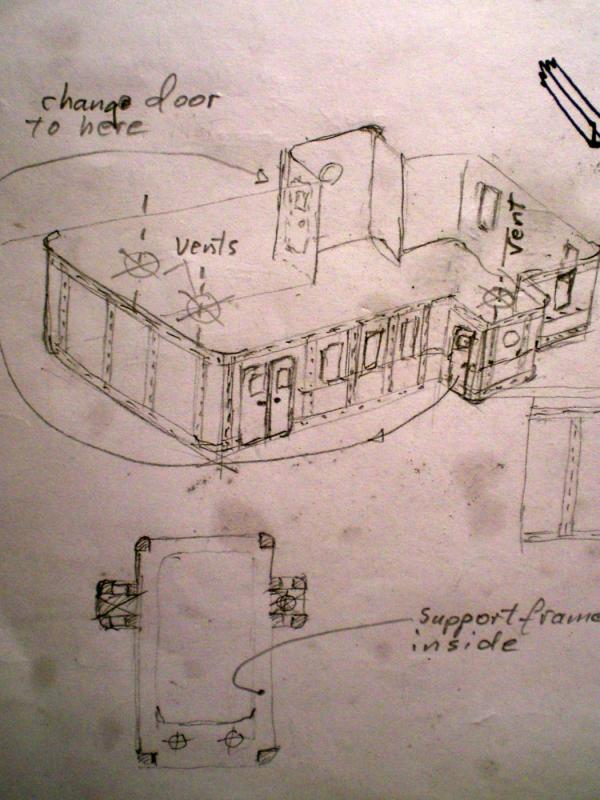

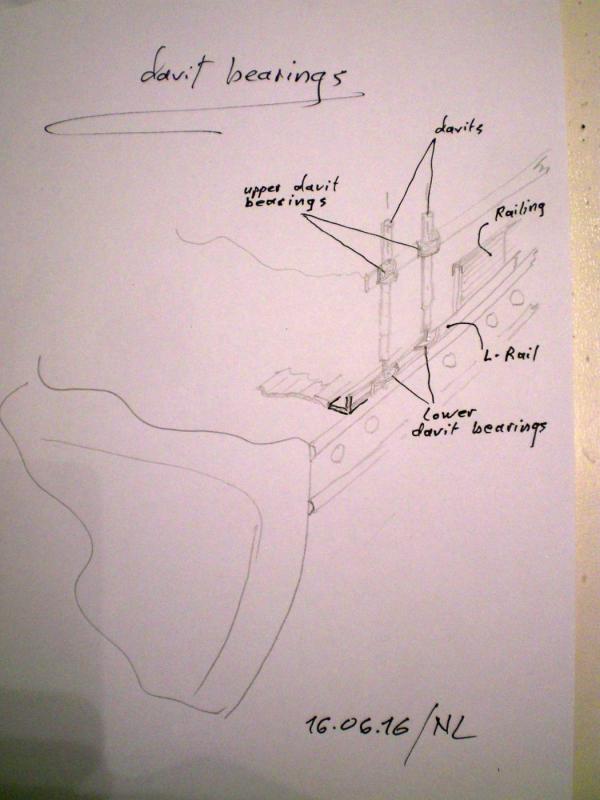

Hi Bob, thanks for your comment the parts are only small, but quite easy makeable. All 40 bearing parts are done and 20 of them mounted on the port side already. If the CA glued joint holds well, it will be an alternative to soldering. I was afraid to solder so near to the railing. For the deck housing I`m starting with the aft cabin section, in order to get a feeling for the matching of doors, windows, handrails, etc. Also I´m intendind to do some structuring and metal plating. The housings arre from 1,5 mm ply, with rounded corners (like shown in an earlier post of this thread). To suit the decks curvature the fore- and aft plates have concave resp. convex curvature. For the first study, there is again an obligatory hand scetch, so that alterations / improvements can be implemented easily Nils This is a view on a card built (not completed) model, borrowed from the web

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

THE 74-GUN SHIP by Jeronimo

Mirabell61 replied to Jeronimo's topic in - Build logs for subjects built 1751 - 1800

Fantastic work Karl, and a wonderful ship section. The gun-rigging and -arrangement looks very realistic.... Nils- 194 replies

-

Thank you very much John, its great that certain small profiles are available in these small dimensions as semi material. The ideas come when seeing the profile variety Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Update.... today started with the lower davit-bearings. There will be 10 boat stations on each side, calling for 40 turnable (360°) davits in total. The davits will be looking like prototype one shown in my post # 1124, slightly modified. The lower bearings I intend to glue against the promenade deck L- rail that already is present for mounting the railing to. The upper double-bearings shall be fastened to the brass framing of the boats deck....., reference is taken to enclosed scetch.... Nils taping the deck for finding and marking (transfer to the sides) the correct davit positions, red markings

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Many thanks Martin, By switching the camera`s pic quality from "high" to "economy", wich is still sufficiant, I can get 7 pics out instead of only 4 from the built in memory capacity In the meentime I have received the 0,6 x 1,5 mini mahagoni strips. They will be glued to the painted railing later on, trust that will provide a nice nostalgic looking handrail. Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Carl, Thanks for your comment...... you`re so right with the use of the cable. If I would have done so from begin on, I could have simply left the card in the camera. Actualy since i`m posting in MSW the card was put in and out every time, and so a matter of wear, when the contacts giv e up their life. The new ( 8GB) card was only 5,99 EURO, I`ll save it up till I have a new camera, where it may fit. The railing looks quite good, although its so fragile and takes so much care to get it / keep it straking, when the handrail is glued on (need to get the CA into the 0,5 mm wide slot) Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Giampiero, your model is a delight to see, I also love the way you incorporated the unplanked deck halves into the overall impression ! Nils

-

Many thanks to - Mark(taylor) - Carl - John - Bob(rafine) - Piet -Greg(peg leg sailor) - Nenad, For the nice comments and appreciations, much appreciated and all the "likes" for looking in.... Mark, that could be the reason, the new card is 8GB (gigabyte), from the outside it looks like the old (2 GB) one, I`ll have to looking out for a new camera. Carl, you`re right, made the check, and the PC does not recognise the new card as a storage card (wasted the money on that investment ) . The old card is still recognised by the PC though John, I`m pleased you like it .... Bob, its of course different to the wooden squareriggers, but I love the technique involved with these oldtimer steamers Piet, yes a relief after all, its good I did`nt rip away the old shrouds while I was still frustrated.... Greg, thanks for your suggestion, I tried it, but no reaction there either... Nenad, thanks for your comment, am pleased you like it.... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.