-

Posts

7,410 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

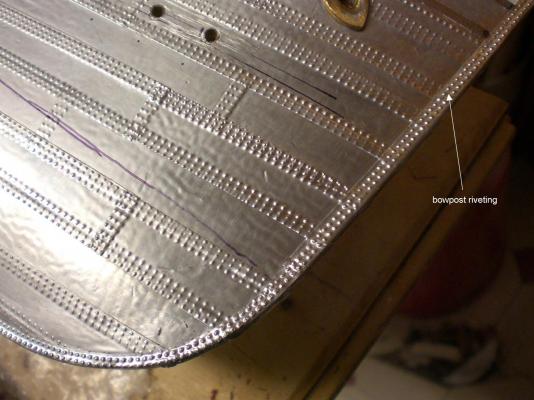

little update.. - a look into the hull - a trial for painting the hull - the "riveting" of the bowpost - "glassing" the porthhole inserts (procedure) Nils here a dive deep down into the ship`s belly aft section with the two drive shafts coming to the inside this is the tape I intend to use for taping the painting borderline (not pleased with it yet), will have to improve the technique. Also the black color should be more dull, will do next trial with dull black oven-paint. The critical part is to get a good tape contact over the rivet rows, so that the paint does`nt creep under the tape. The red paint is RAL 3000, silk-surface glaze, when drying bowpost "riveting" is done around the bend Am quite pleased with the result.... here using trimming line for grass-cutter for the "glassing" of the portholes Cutting off a length ready for final trimming cut off directly at the porthole insert. "Glass" surface will be sunk in appr. 0,6 mm afterwards into the tube

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Dankeschön Dimitris, Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you very much Patrick and Grant, and all the "likes" for you nice appreciative words Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you David, your comment is very much appreciated.., I`m also quite happy with the Project so far. Presume that doing the superstructure will be far more ambitious... Nils Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

wonderful, those steamengine cast parts Steve, Nils

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

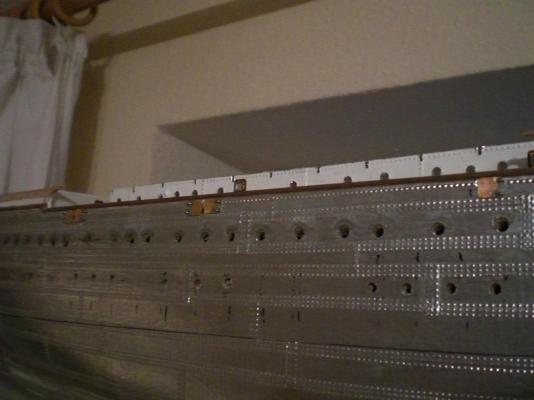

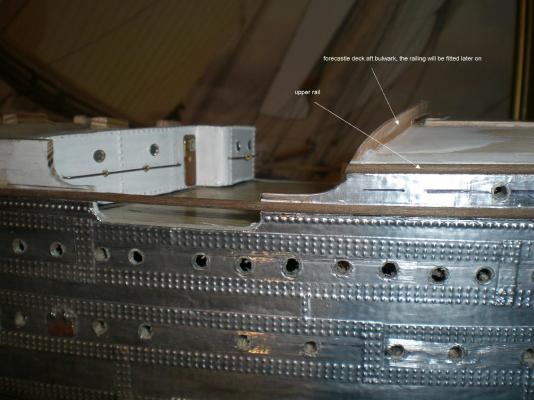

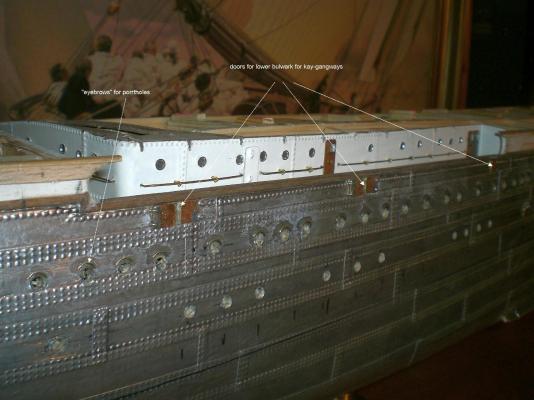

Build log part 23 little update not much this time, but it keeps the wheel turning... Nils in this lower deck area there are the bulwark doors for the kay gangways mended two misalignment portholes with wooden dowels and drilled new... upper forecasle side-rail, and aft forecastle-deck bulwark

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you very much Dimitris, Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

The anchors, found these good looking and scaled heavy metal anchors, in nostagic design of 1900 in a Hamburg based modeling web shob. The parts are of castings and have to be deburred, the vertical bar and the hole in the spike-base have to be reworked a little larger, I`m glad I found them, love that nostalgic look with the long spikes. Two will go at the bow, one at stern and two in the spare anchor supports on the forecastle deck Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you Nenad, you`re right with the hinges, they are made from 0,6mm brass wire, and soldered in 0,6mm drilled holes, the plates are 6 x 5 mm and 0,5 mm thick brass plates Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Bill, that really is a very impressive model, and the sideboard below is just long enough for the distribution glass-case, Well done Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you Denis, Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

A nice Illustration, many thanks Crackers, all people seem to be happy about dad`s b-day event... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

HI David, the hull above the waterline will be in dull black resp. anthrazit (charcoal, dark Grey), including These doors.. Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

phantastic Work Albert, like a visit in the 1797 shipyard. Your framing and joining work is 1A, and the wooden composition (tones) of decks and timber work is super Well done Nils

-

only a small update today... soldering the 14 ea. port side coalport doors, the starboard ones are already mounted... Nils the holding device is of good help when soldering with the flame clean surfaces, the right amount of flux and careful, steady heating up provides a good joint all 14 doors done, a cleaning with aceton shall follow next

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you very much Bob, for your comments, I`m glad you like it... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you very much Bob, Dimitris and Dan, For appreciations and comments as well as all the "likes"... Bob, thanks Bob, there are some mis-alignment borings, that moved out a bit, which were obviously not able to be prevented whilst drilling (except with a not existing jig tool). Hopefully I`ll do better on the other hull side Dimitris, I also used RB portholes on my Pamir and Gorch Fock, a good source choise. They shall look fine on your AV Dan, with Jan`s help (identifying one of the appropriate Frames, showing the way of opening for the coalports) I could put the hinges on the top side. Yes, the "hinges" are soft soldered, and then glued on to the hull skin Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.