-

Posts

7,418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

Thank you John, that explains nicely the pointing of the rudder blades (steering oar in the dark, etc...) Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thanks very much for your kind comment John, Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Peter, nice final photos of both ships, congrats to the two beautiful looking models... Nils

-

Hi Rob, you are absolutely right, N scale (1:160) is adequate and is bringing her to live....., for the passengers on the decks, they will be N scale in period fashions, I did`nt put them on yet... For crew and machinists I use regular N scale and also scale 1:144 (like for instance from "North Star" marine crews) Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Good work Danny ! as the card models are most in a rather small scale, in my opinion these are much more difficult to make, require utmost attention and precise joining, glueing and fitting. You are doing an excellent job ! Nils

- 193 replies

-

- cerberus

- paper shipwright

-

(and 1 more)

Tagged with:

-

Thank you so much Greg and Piet, for your nice words... Greg, Thanks for looking in regulary, am pleased you like the ship. On 26th May it was 2 years since keellaying, estimated was 2,5 years to complete, guess it will not be earlier.... Piet, lovely to have these romantic emotions, I often have same thoughts when trying to implement mental ideas into a model.... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Martin, I would like to thank you for your kind book tip recommendation, after a web research at the master-site of book antiquariates, I am now holding a wonderful copy of the 50th aniversary edition of this publication, at a bargain price, and I must say you have not promissed too little......, boy, its a real treasure !! Nils

-

Doris, I thank you for your kind compliment with this build, much appreciated... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Awesome work Doris !! it looks so clean and accurate, also the warm "wooden" planking tone matches good with the black hull portions... Nils

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Many thanks for your nice compliment MD... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Danke, for your nice compliment Johann, much appreciated.. Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

thank you very much Christos, well, I have to be patient, considering that it takes me round 1 hour to do the lifelines on a single lifeboat..... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Many thanks to Keith, Nick, John and Christos, for your nice comments, and thanks to all the "likes".... Keith, thanks for taking a mental look around on board....., for display I am looking for a suitable side-table to put the glass casing on, besides that I need to deal with my admiral for an ideal place in our home, up to now the agreement is, no models in the living area of the house Nick, pleased you like the overall shots, sometimes not easy with the small digital camera... John, blades pointing forward (was just luck in this case...), but thanks for that input, I`ll be aware of this now. Do you know what is the reason, is it easier to put the oars into the rowlocks ? Christos, for the figurines I chose scale N gauge (1:160) make "Preiser". It was a process of watching out in Ebay auctions, and the web over weeks and months for figures offered in (around 1900) fashions Preiser unfortunately does not produce these in this scale in "around turn of the century fashions" any more, but with some luck I was able to achieve quite some good ones. They are not all placed on the decks yet. Four figurines (custom made in scale 1:144) I am very thankful for, came as a greatful gift from a fellow MSW modeler including the captain of the ship.

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

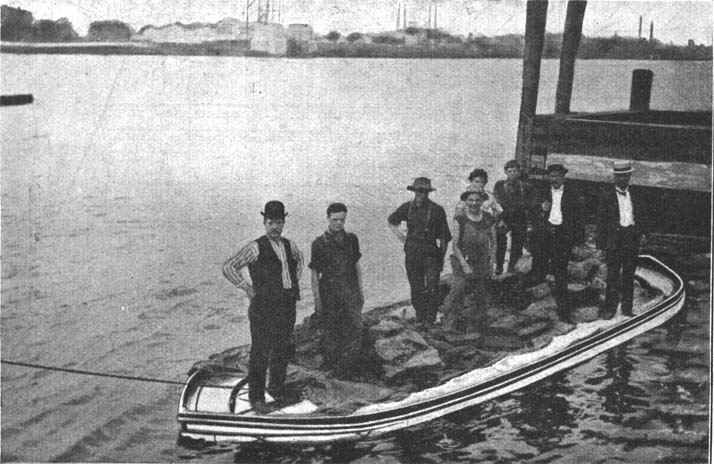

B.E., excellent work, one really gets tempted to build that pinnace. The kit looks like very good quality , it seems fun and joy you`re experiencing at this phase... Question : are you leaving the plank edges free of glue due to the caulking you show ? Nils

- 156 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

Build log part 59... Update : for those fellow builders who frequently catching up on the status,.... I put in some overall shots.... The 4 open lifeboats are rigged, they are also equiped with oars (only rudderblades still missing). The two smaller boats will be in the same paint scheme, but without lifelines, as that is too much straining for eyes and hands. The remaining closed boats are waiting for the lifelines to be attached, refer to the pic for one first sample. I decided not to lash on seperate protection covers (canvas) Nils the oars are stored on the oposite side to where passengers would step into the boats The two open boats on the left of the pic have appr. 5 mm less length and a lower sheerboard, they will match in color scheme The "hard cover" shown here on the sample "closed boat" will be the protection canvas, no seperate lashings under and around the boat. these are the two smaller (shorter) open, also clinkered double ender boats, that fit into the row of 10 boats per ships side with the others. These boats claim to be 1:144 scale, the figurines are 1:160, but I feel they match together perfectly

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Very nice work Frank, your framing and joining looks excellent. Will that centerboard later on be swivable with a pivot point ? Nils

-

Piet, thank you very much, am pleased you like it... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Martin, love the lines of your cutter "Vanity" they are resembling the yachting era of those British "deep and narrow" ships, or also nick-named "plank on edge"... I might myself be considering one day to build a scratch model of the racing cutter "Genesta". these ships really have class indeed ! (fell in love with the lines, here a beautiful built example of which I unfortunately do`nt remember the modeling builder, pic from the web) Nils

-

Many thanks John, Michael and Greg, for your nice comments... also thanks to the "likes"... John, again a new term, thanks a lot.. Michael, I`m just trying to implement the pictures I have in mind.. Greg, yes, agree, they look quite flimsy, but in worst case, anybody would be happy to get a place on those collapsibles.. Thanks for catching up with your recent looking in... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Rob, thank you for your fine comment, I`m very pleased you like the boat outcome, as you have recently been engaged with many good ideas and suggestions. Now its just the mass of repeatable work to be done to get all the boats in following the first sample ones.... The colapsible boats I have`nt begun yet, but my mind is thinking in this direction..(I borrowed some pics from the web, may be for Titanic or so...) Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.410ea5b87d7db5bfe23f71a3a396cbf5.jpg)