-

Posts

132 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Gaffrig

-

-

Hi all!

Just a small update today..

With the keel, stem and sternpost mounted, I planked the transom with the same 0.5x4mm materials that I used on the deck.

I used the gorilla wood glue for this.

After cutting of the excess material and some sanding...

Starting to look more and more like a boat!

Also got some primer on the dinghy.

Those brushstrokes really show up in the pictures!

I guess some sanding is in order before painting!

Thanks to everyone for stopping by and reading my log.

Also for taking the time to comment and like! It is really appreciated!

Gaffrig.

- GrandpaPhil, RichardG, Arjan and 6 others

-

9

9

-

Thank you!

I was a little worried during the planking, but it sanded out pretty good.

Gaffrig.

-

Thank you!

I had to think a little about how to do the clamping.

It worked great with rubberbands.

Gaffrig.

-

Hello all!

Been away at a holiday for a week, but now I'm back at it!

Tompslattery, Thank you. Yes the brass parts look nice. The gun sleds are just two lasercut plywood parts glued on top of each other.

I was looking through your buildlog and it looks like you have an older version of the kit.

Great work on it, your model is coming along nicely! 👍

Rick01, Thanks for the tip. I did use a drill to line up the holes. I used a brass wire for the bars instead of the steel supplied. I left this untreated. But the trick with heating is a good one!

I've decided to leave the transom and the "bench" in the stern off until I fit the caprails, rubrails and rudder. I think this approach will be easier than following the sequence in the instructions.

After sanding the hull, I prepared to fit the keel, stem and sternpost.

This meant cutting a groove in the bow and opening up between the garboard planks to make the pieces fit in.

First the keel..

And then the stem. I used a razor saw and a scalpel with a new blade to do this. I found it a little tricky to get it straight and nice but it ended up ok.

I think it would have been easier to fit the stem and keel before planking, and make a rabbet to fit the planks in.

With the keel, stem and sternpost dryfitted I glued it all in place.

So, when the glue dries, more sanding, some filler and more sanding! 🙂

I've also made some progress on the dinghy, finishing the hull planking. My little changes to the sheer and transom made it so the lasercut keel/stem piece didn't fit.

So I made a new one out of some scrapwood I had lying around.

And after some shaping...

A bit more sanding and some paint, I think it will look good!

That's it for now!

Gaffrig.

-

Thank you for your kind comment.

This model has only one layer of planking, so I tried to make it as nice as I could!

It’s been a little tricky at times, since the planking is 2mm thick.

But with soaking and heating and patience I got there in the end!

Gaffrig.

-

So, now that the whiskey and glue has dried, time for some sanding!

Done on one side. Sanded first with 120 grit and then 240 grit.

Sitting out on the porch for this..

Both sides sanded. Looks pretty good, if I may say so myself!

I wanted to do most of the sanding before attaching the keel, stem and sternpost.

These are up next, and then a little filler before the final sanding with 320 grit or so.

Gaffrig.

-

-

Hello everyone.

The planking of my Le Renard build is now finished!

The gap for the last plank on one side ended up at 6mm and the planks beeing only 5mm this presented a small challenge.

I ended up gluing two planks together and that way I could make the plank to fit nicely.

That's it!

The whiskyplank is in! 🤪😝👍

Now time to sand when the glue (and whiskey) dries..

Work on the dinghy continues, and it seems like I will end up with the same amount of planks from stem to stern.

Here I have sanded lightly to see how it will look when finished, and so far I'm pleased with the result!

That's it for now.

Gaffrig.

- BenD, GrandpaPhil, Dutchman and 2 others

-

5

5

-

The strangest thing has happened... We've had several days of clear blue sky and warm weather! 😎

How enjoyable as this may be, it does cut into the time spent at the building table...

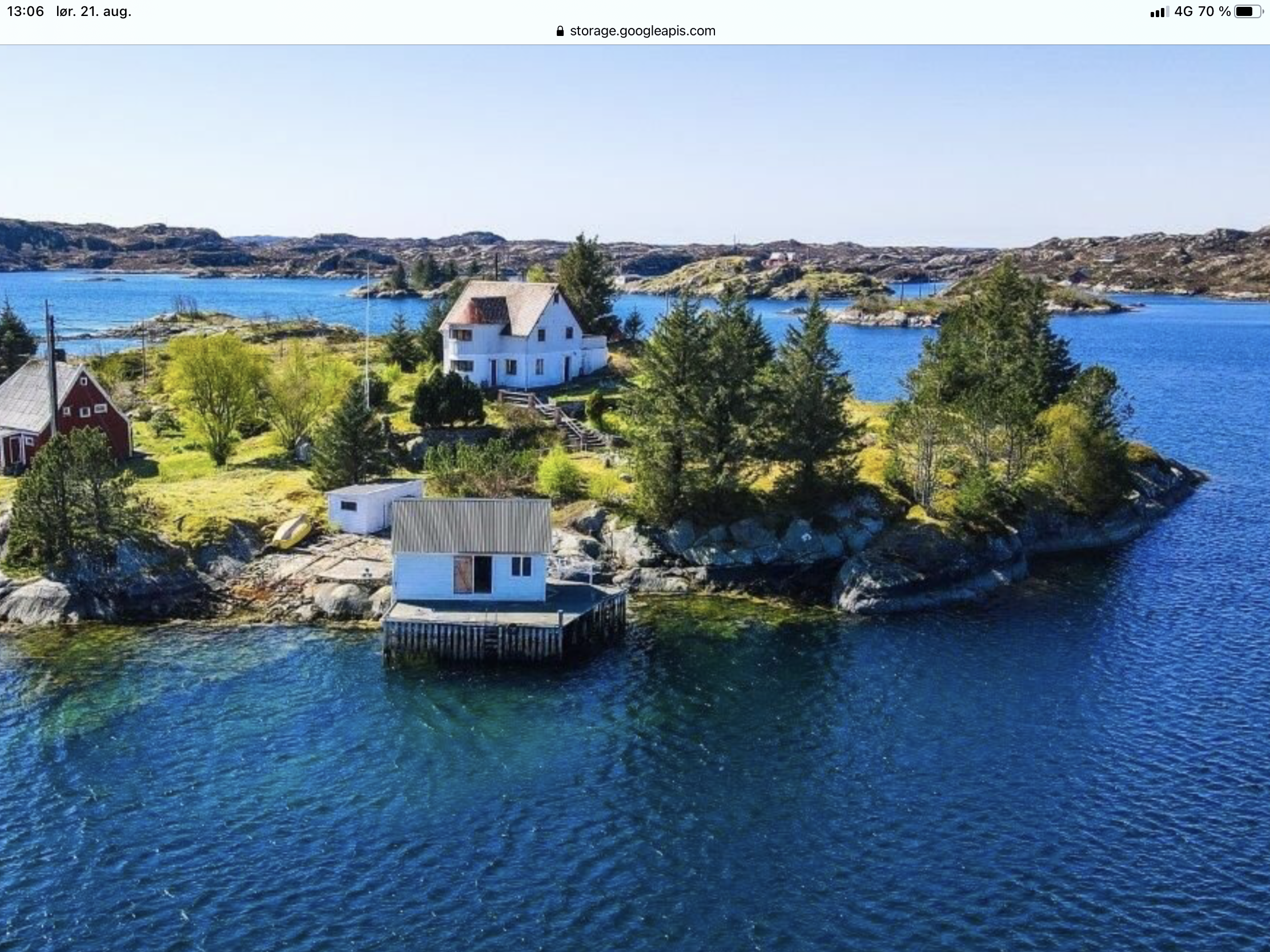

The good thing is that the time not spent at the buildtable is spent aboard the 1:1 scale pilotcutter!

Nice to get some work done there too.

Some progress has been made though, the planking continues and is close to finished.

The planking has started on the dinghy.

A few more planks, and I'm ready to start sanding. There is a few dumps and humps, but hopefully it will sand out smooth. If not, then I have a can of woodfiller!

The dinghy was (According to the instructions) to be planked with the same 4mm x 0,6mm material as the deck.

I found this to be a little wide for such a small boat, so i decided to use the 0,7mm x 3mm mahogany that I'm not using for the bluenose.

I tapered the planks "by eye" and felt my way as I went. The planks were then soaked and dried to shape on the jig.

Once the planks had dried, I glued them on with CA glue.

It shall be interesting to see how I end up with my "tapering by the eye" approach!

That's it for now!

Gaffrig.

- GrandpaPhil, Dutchman, Ryland Craze and 2 others

-

5

5

-

On 5/29/2020 at 12:11 PM, Arjan said:

I prefer building models of boats that either exist as replicas or are well-documented. There are loads of detail pics of the le Renard replica to be found on the internet. I'm currently building BB's Regina Yacht and to my dismay I haven't been able to find any reference material on this particular ship type , even though BB claim this was a common 19th century Baltic sailing vessel .....

Regards,

Arjan

You may not know of the "Treskibssammensluttningen" which is a organisation for traditional vessels in denmark. A lot of info at their site, (Mostly in danish, unfortunately) but also among their members. You might try them for specific questions you may have. www.ts-skib.dk

On 6/1/2020 at 3:47 AM, Rick01 said:Don't know if you've found this site http://renard.dechorgnat.com/index.html which covers some of the errors that appear in both the Soclaine and AL kits. Also there is no windlass and the anchor cable appears to go into the hull rather than onto the deck then down to the rope locker via a windlass. There wouldn't be room for a windlass below decks on a cutter so hoisting the anchor via a windlass or by hand appear to be the only option. Another possible error is with the siting of the various deck furnishings. Coming forward from the stern there's an item that may or may not be the binnacle housing for the compass almost directly after that is a companionway. These are sited so close together on the plan that you would not be able to open the doors on the companionway fully, in addition the binnacle is fixed to the deck but my understanding is that it would be lashed down and could then be stored below decks during any action.

In fact the AL kit seems to be a copy of the replica with its amendments to comply with current regulations not of the original.

Rick

I looked a little at the site, (thank you for pointing it out to me) but my french is not very good. I could not find a language setting.

I think you are quite right that the Artesania Latina kit is a model of the replica, rather than the original.

The item that may or may not be the binnacle is very close to both the main companionway and the tiller. I think it may be a housing for modern navigation electronics. There is also what appears to be ventilation "pillars" four places around the deck.

As for the windlass situation, it may be that the replica has a modern electric or hydraulic windlass mounted below deck, and the anchor rode coming out of the hull.

I got the kit at a discount, as something to build while waiting for materials for the Bluenose.

I'll probably build the kit more or less as is, rather than going for historical accuracy.

About building the kit.. Here's a little update.

The planking continues, slowly but steadily.

Got a few more "laps" done during the weekend.

I have a little clinker effect going on in the bow, but I think it will smooth out with sanding.

While waiting for the glue to dry, I got bored and started another kit... 😎

It was in the same box though!

And if I do it right it should be the dinghy.

Got the parts out of their sheet, these are small, brittle parts.

-And started building the jig.

I just had to make some small adjustments... I gave the transom an angle and I cut away from the frames to give it more sheer.

We'll see how this turns out.

That's it for now.

Gaffrig.

- Ryland Craze, Dutchman, GrandpaPhil and 2 others

-

5

5

-

Ok.

Will contact via pm.

Good thing I asked first!

Gaffrig.

- mtaylor and pythagoras

-

2

2

-

1 hour ago, Major said:

Nice one mate. Would you be able to take photographs of instructions for Hannah and send them to me? I want to finish mine, but lost instructions.

cheers.

If you send me your email in a private message, I can send it to you.

Posting it publicly is not a good idea. (Either the instructions or the email)

-

Ok.

Thank you for your answers. It’s just the instructions as there is no drawings for this kit.

I guess that sharing the instructions with this member in private should be fine, as he already has the kit but has lost the instructions. Apparantly they are not available at the website.

Gaffrig.

-

It would be the whole instruction booklet.

The kit in question is the hannah ship in a bottle kit from amati.

Gaffrig.

-

Hello.

Just got asked by another member about instructions for a kit I have built.

Would it be allowed to post this in the forum?

I don’t want to do anything wrong, and reading the thread about pirated kits, posting instructions might not be the smartest?

Hope someone who knows the in’s and out’s of this can advise.

Gaffrig.

-

Hello.

Yes, I can do that. If it’s allowed, I’ll post them here. If not I can send them to you privately.

Gaffrig.

-

The planking continues..

Got four more planks on both sides. Eight in total.

It's going slow but steady!

Not the prettiest planking, but I think it will smooth out when sanded. The camera seems to highlight all the bumps and edges...

In between waiting for the planks and the glue to dry I've continued on the cannons. Or carronades?

There is some photoetched brackets that I cut loose from the sheet and "folded" and blackened.

The little crosses are the back supports/adjusters to hold the backend of the barrel to the carriage.

I'm not too sure I like those..

When mounting the gun barrel to the bracket I got a problem with the gunbarrel tab being too wide to fit..

So I have to file down the sides of the tab on my newly painted barrels.. 😟

Oh well. It's one of those little setbacks that's a part of the hobby I guess!

12 hours ago, Arjan said:I have also recently bought the AL Renard kit so I'm following this thread with interest. Looking good so far ! My intention is to scale up the kit parts to 1/25 (simply a matter of enlarging them by 200 % ) and I may not even build the original 1/50 kit.

Regards,

Arjan

That sounds like an interresting scratch build project! It will be a big model!

Between planking and guns I also started at the deckhouses/skylights. These are pretty simple affairs of lasercut plywood that fits together pretty well.

I'm jumping a little back and forth in the manual, but it's all gonna be done at one time or another.

The main deckhouse is all that got captured on "film" 😆

That's it for now.

Next update coming soon!

Gaffrig.

- Ryland Craze, coxswain, GrandpaPhil and 4 others

-

7

7

-

Hello.

That’s a good idea to use the glue. That would mean no pin holes in the planks. And it’s probably faster to plank that way.

I’m a newbie at this so I like to take the plank off after it has dried to shape and sand a bevel so it fits against the previous plank as best I can.

But it’s definetly a good idea that I’ll put in my toolbox fore future use!

Gaffrig.

-

Thank you all who have been reading the log and giving it a thumbs up!

On with the planking.

The kit supplied materials are 2 x 5 mm battens of what I think is limewood. They are a lot stiffer than the ones supplied in my Bluenose kit, and since this boat has a bow that's a lot more blunt than the Bluenose I think I will need to soak and heat the planks for this build. This was not necessary on the Bluenose.

Le Renard has a single planked hull, as did the Bluenose.

So I measured the bulkheads, and divided so I ended up with 16 planks. This gave me a taper from 5 down to 3,2 mm in the bow, and nothing in the stern.

I tapered the first two, soaked them for about 15 to 30 minutes and bent them roughly in shape with the electric plank bender from amati.

Then I clamped them on the hull and left them to dry.

Once dry I took them off and gave them some fine adjustments and glued them on with the same gorilla wood I used before.

I keep forgetting to take pictures once I get going, but here I have two planks on both sides glued on.

I've sanded the keel to imitate a rabbet and have glued on the garboard strakes. There will be cut a grove in the garboards later to accommodate the keel.

Now it's "taper, soak, heat, shape, dry, glue and repeat" for a few days, and hopefully I'll end up with a planked hull!

Take care!

Gaffrig.

-

-

Onwards with planking.

In preparation for planking I faired/beveled all the bulkheads using one of the hull planks as I went to see that it would lie nice and snug on every bulkhead.

I marked the bulkheads with a permanent marker first, to ensure that I didn't take off too much.

I used a scalpel to take the most of it and then sanded.

I decided to use filler blocks in the bow between the stem and the first bulkhead. I didn't have any balsa, so I used a piece of cedar for this.

Both the trick with permanent marker and filler blocks is something I have picked up here at this wonderful forum! 👍

Before I start the planking the instructions say to mount the plywood bulwarks. This because the bulwarks go past the deck and down on the bulkheads by 4-5 mm.

Then the planking starts from the bulwarks.

Dryfitting of the bulwarks.

These are made from 2 mm plywood and was surprisingly easy to bend. No soaking needed, just bend around the hull and clamp.

There is a second inner bulwark of the same 2 mm plywood that is glued to the inside later. This is first clamped to the outer one with the top flush, and a line is drawn on the outer one so you have a line to follow along the deck when mounting it to the boat to get the correct height. (hope this makes sense)

I'm using push pins to hold it in place.

Once I'm satisfied with the placement I'll remove them and glue them on with wood glue.

Looks pretty nice and straight, I was a little worried about this step as there are no tabs sticking up from the bulwarks to help me keep them in the right place.

Time for glue!

Gaffrig.

- Dutchman, Ryland Craze, Edwardkenway and 1 other

-

4

4

-

No, I just removed the picture from the text, and clicked save.

Clicking the little trashcan did the trick!

thank you!

-

I seem to be getting a picture or two at the end of each post that shouldn't be there...

When I try to remove by editing the post, it keeps reappearing...

Anyone know why this is?

-

Time for the deck.

When the glue for the plywood subdeck had dried, I started laying the deck planks that I had prepared.

I started with one plank along the centerline as the kit suggests, and worked from this and outwards on both sides.

I decided to make "frames" around the hatches/skylights as I think this will look good.

I had a little problem as the instructions didn't give a exact measurement of where the forward companionway hatch should be.

But looking at pictures throughout the manual I could guesstimate by measuring from other things. This is where I would really like to have a fullsize plan...

I cut the deck planks at a length of 120mm as this would be 6 m in fullsize at 1:50 scale.

I am using zap a gap ca glue to glue to the subdeck.

I don't know if this is the best glue for this, but it seems to work ok.

I am putting the butt joints at places where there would be deck beams on the real boat. Like fore and aft of hatches, the mast and so on.

Done planking!

The charcoal dust gets everywhere, next time I'll probably use a regular pencil instead for the caulking.

Hopefully it will clean up in the sanding..

Edges trimmed away and ready for sanding.

After sanding, and it looks a lot better!

Got rid of most of the charcoal dust!

After sanding I gave it a thin coat of linseed oil. Haven't decided yet if this will be the final finish, or if I should go for a flat varnish of some sort.

Not perfect by a long stretch, but acceptable for my first try!

Next step, planking... 😎

Gaffrig.

Le Renard by Gaffrig - FINISHED - Artesania Latina - Scale 1:50

in - Kit build logs for subjects built from 1801 - 1850

Posted

Wow!

That looks great!

Yes, it appears that the two benches fore and aft of the main hatch are lifebelt boxes on the replica.

there is also what seems to be ventilation «ducts» on either side of the main and fore companionways.

I think these can be omitted for the better.

Gaffrig.