-

Posts

892 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by GGibson

-

Very sharp looking Bluenose, Gary! 👍🏆

- 88 replies

-

- Muscongus Bay Lobster Smack

- Finished

-

(and 1 more)

Tagged with:

-

Great start, Gary! Will be following from now on. 👍

- 88 replies

-

- Muscongus Bay Lobster Smack

- Finished

-

(and 1 more)

Tagged with:

-

It looks sharp, Eric! Congrats! All three boats look outstanding together. 👍🏆 No rest for the weary, which one is next?!? 😁

- 61 replies

-

- Muscongus Bay Lobster Smack

- Model Shipways

-

(and 1 more)

Tagged with:

-

Hi Eric - Looks really good. Yes, as I recall, the rigging on the Lobster Smack was a bit easier, especially after having one under your belt. 👍 You mentioned initially having difficulty with the tight rigging lines, and see that you have similar clamps to what I have, as well. My experience, probably like yours, was that the clamps weighed down the line too much. I had great success in simply using some smaller alligator clips as I tugged on the line taut, and that worked well for me. Looking sharp! Very close to done!

- 61 replies

-

- Muscongus Bay Lobster Smack

- Model Shipways

-

(and 1 more)

Tagged with:

-

Eric, I was wondering if the dam (or just being farther upstream) had an effect on the increased recreational use. Appreciate the input from someone who would know! Been loving watching your work. 👍🏆

- 392 replies

-

Your Peerless looks great, Eric! I've always found it interesting that, up in Sioux City, IA where I grew up, the Missouri River is truly a recreational river. I learned to ski on the Missouri when I was a teenager! And, in a recent visit to Sioux City this summer, I saw that the river is still very recreational, with boats and jet skis going up and down, and marinas on both the IA and NE sides. However, not sure I have ever seen any boats in the river in Kansas City or even in Omaha. Seeing even a canoe in the water here in Kansas City would be a rare sight! Sounds like an awesome adventure, Eric! 👍

- 392 replies

-

USS Constitution by mtbediz - 1:76

GGibson replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Really sharp, Mustafa! I am assuming that, in addition to securing the pins into the bulwarks, you are using some kind of PVA on the bottom of the wheels to secure to the deck? 👍 -

Welcome, Tim! Looking forward to seeing your Mayflower build log! This is a great group and awesome resource with a wealth of knowledge and advice. Enjoy!

-

USS Constitution by mtbediz - 1:76

GGibson replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Really awesome, meticulous work, Mustafa! Very impressive! I'm lovin' watching both of your build logs! The Constitution may still be on my "add to the shipyard" wish list, so I am enjoying reading your build logs and learning so much! And as I have said both publicly and to myself countless times as I slowly work on my own Bluenose and see others working ahead of me, it's not a race, but it's all about the journey! 👍🏆 -

Very nice looking, Eric! As I recall, I was able to find the right size parrel beads in either WalMart or Michaels. They come in a small plastic cylinder that (if you do comparable scale ships in the future) will last you forever! <shrug> 🤣👍 Carry on! Almost finished!

- 61 replies

-

- Muscongus Bay Lobster Smack

- Model Shipways

-

(and 1 more)

Tagged with:

-

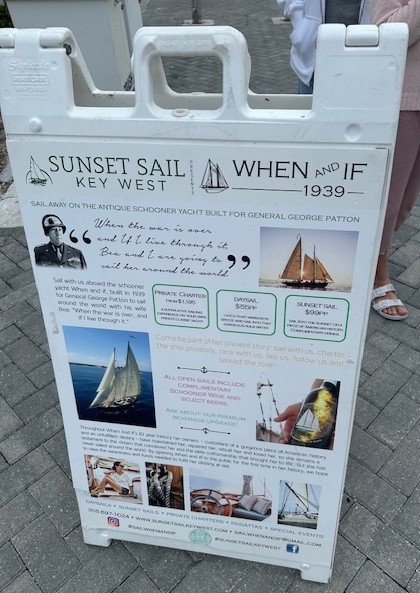

We were just in Key West last week and I noticed a sign for tours on the When and If, which was built in 1939 for General George S. Patton, When and If was commissioned by Patton himself from naval architect John Alden, and built by FF Pendleton in Wiscasset, ME. The boat was out of the marina on a cruise when I saw this sign where it is docked. We will be back down in Key West in May, though, and hopefully it is still there and I will try to take a close look at the ship and take pictures. From their website, it appears the ship is in Key West during the winter and Salem, MA in the summer. We have family down there, so if it's not there in May, there will be another time, I hope! Anyone familiar with this schooner of Patton's? Interesting history. Might be an interesting model.

-

How to rotate photographs

GGibson replied to wmherbert's topic in How to use the MSW forum - **NO MODELING CONTENT**

Thanks, James, for this available solution reminder! 👍 Hi Bill - On my Windows 11 Home OS laptop, when I open the Pictures app in preparation to post a picture in MSW, I have simply "spun" the picture 360 degrees and then cropped it to just show what I am featuring (trying to take out background objects, etc.). In times where I have not "spun" the picture in order to set it, the picture has posted sideways, upside down, etc., so it seems like the "spin" option has worked pretty simply and effectively for me. <shrug> 👍 -

Nice work on the standing rigging, Tim! Looks really good. And, good thinking on using the R/C fuel tubing for the clip covers! I bought a bunch of clip covers from Amazon for like $5.00. I'm finding they get a little gunky with glue, etc. after a bit, so I replace them as needed. The tubing idea, though, is great. Keep the extra tubing handy just in case! Your Bluenose is shaping up very well, sir! Carry on!

- 145 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

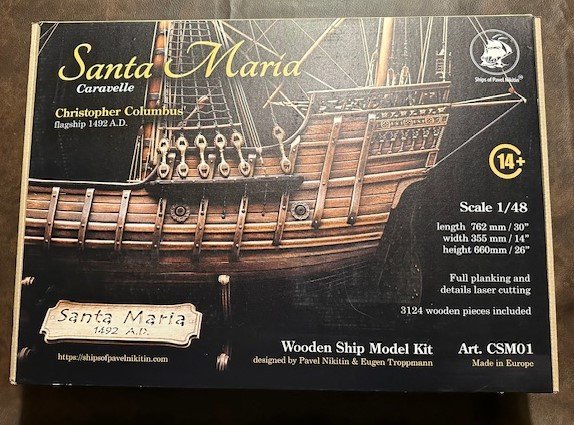

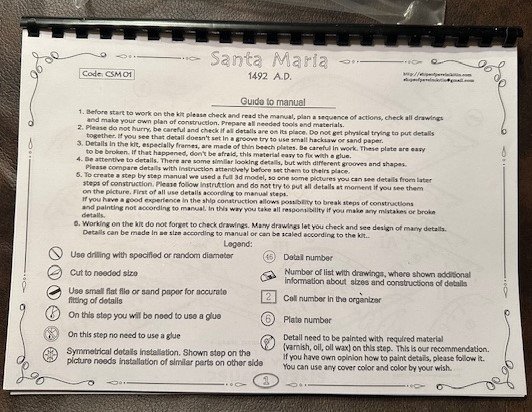

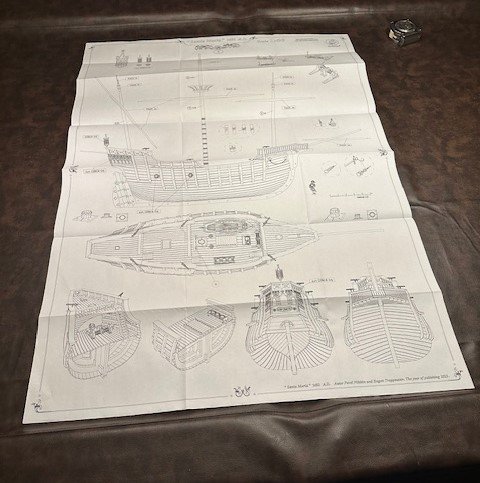

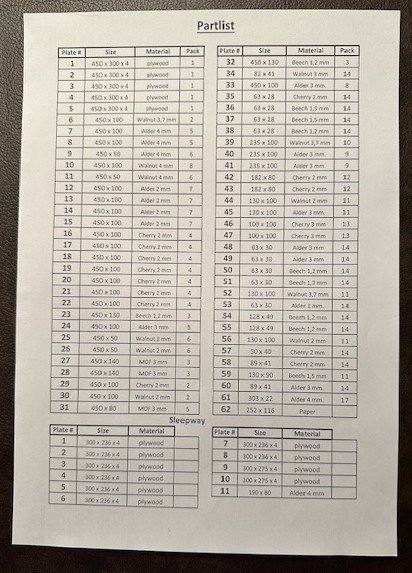

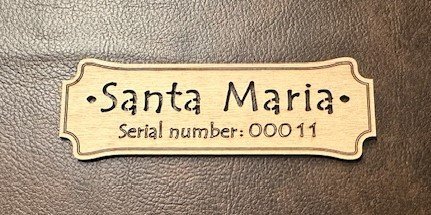

AN ABBREVIATED "UNBOX" INTRO - I was recently internet surfing and looking at Olha Batchvarov's work again (I really enjoy reading her posts and watching her videos, and often pull up her work to get "re-inspired"). In a recent post, she mentioned working with Pavel Nikitin, so I found his website shipsofpavelnikitin.com, and saw the release of his version of the Santa Maria. I then saw that Model Expo was distributing his Santa Maria in the US, and had to add it to my shipyard. I know there is much discussion about the accuracy/authentication of the Santa Maria models and the caravelle vs. nao discussion. As one of those "casual modelers", though, I am happy to work on something as historical as the Santa Maria, and Pavel Nikitin's reputation is exceptional, so I am absolutely pleased. Placed the order and shipping was handled very quickly by Model Expo. Kudos to them! I have promised myself that I would not start the Santa Maria until I finish my Bluenose, but I had to open the box when I got it. Right?!? So, here are a few observations... First thing you notice right away, the box is H-E-A-V-Y!!! Lots of parts! Box Cover Box Contents Upon Opening 92-page Manual (all diagrams, no text) Five (5) - 33"x46" Plan Sheets Parts List (some info on backside, too) Wooden Nameplate - Serial #11 Well, there it is! Putting it up on the shipyard shelf for now. It looks like there are no less than twelve (12) current or finished MSW build logs of the Santa Maria from various kits and in various scales, so there will be no lack of research support from previous builders. I thank you all in advance! And, looking forward to see if anyone else builds this Pavel Nikitin version (other than hopefully @shipphotographer.com Olha Batchvarov, once she completes the handful of ships ahead of this one in her queue). I assume that at least serial numbers 2-10 are out there somewhere! OK, back to my Bluenose so I can get to this build.

- 56 replies

-

- Santa Maria

- Ships of Pavel Nikitin

-

(and 1 more)

Tagged with:

-

Ummm, apparently you were!! 🤣🤣 Nice work on shrouds, John! I am not a knot expert, but is there a discernable difference in strength and appearance between a half hitch and clove hitch? As I recall on my Ballahoo, I used clove hitches on the rat lines, and used clove hitches again when I tied the stirrups to the footropes on the Bluenose bowsprit. At this scale, probably makes little difference. Either method, as you pointed out, is being secured by a touch of CA glue, anyways. Looking great overall, John! Envious of how far you have gotten so well. Carry on, sir! 👍

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

Santa Maria 1492 - Ships of Pavel Nikitin - 1:48 - UNBOXING/RAFFLE

GGibson replied to a topic in REVIEWS: Model kits

Will Olha be building this Santa Maria? Love her work!- 3 replies

-

- Ships of Pavel Nikitin

- santa maria

-

(and 3 more)

Tagged with:

-

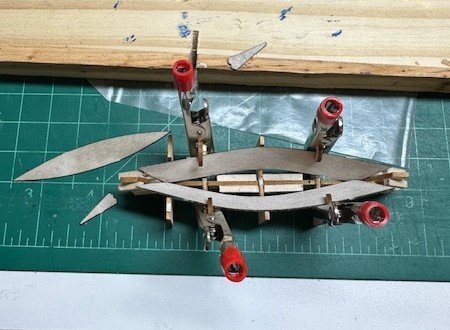

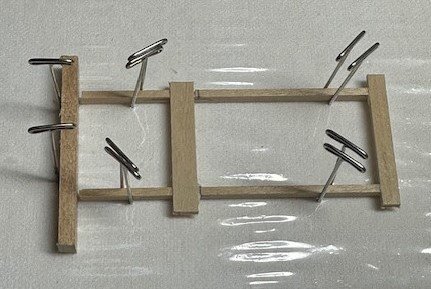

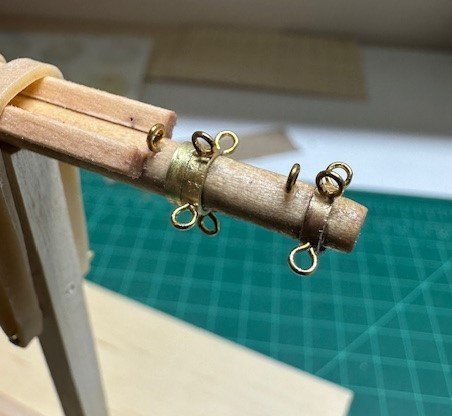

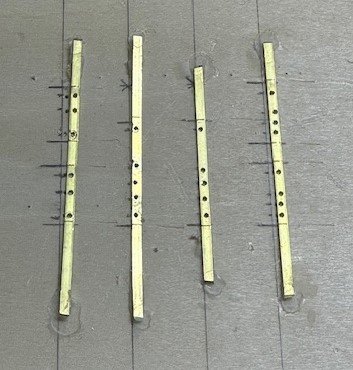

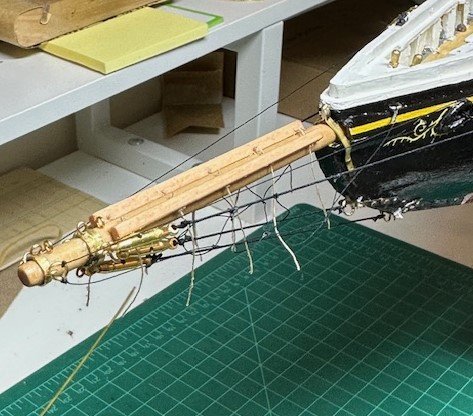

An update on progress... (or lack thereof)... It was a bit frustrating in the shipyard these past few weeks. Besides the fact that I had several travels that interrupted shipyard time (spending some great time over the various holidays with family, though, so it was totally worth it despite the shipyard absence), my time in the shipyard was a struggle completing some things successfully. Guess it is all a part of the build journey and learning along the way. Wanted to start working on the dories and tried to use the supplied pieces in the kit. The dory sides were difficult to shape properly, so built a little jig to hold them after wetting, shaping and drying. That helped some but I still found it incredibly difficult to shape them and build them using the kit-supplied brackets. So, after visiting with another local builder who gave me some alternative options, I decided to shelve the dories project for a little bit. Hopefully, I should be able to finish some dories in the coming weeks, so... perhaps an update on those in my next post. I did, though, work on the dory kids that the boats will sit on while stored on the Bluenose deck. Measured, cut, fitted and glued the small wood strips. Set them aside for now waiting on what I finish with the dories. Time to work on the bowsprit. Shaped it to the measurement needed at certain points on the 1/4" dowel. Started at first using my small handheld planer, then went to various grit sandpaper. Squared off the aft end that fits into the bits and added a small brass rod to fit in the hole I had placed in the samson post. After it was shaped, it was time to add bands... after soldering some type of rings to the bands for the various backropes, footropes, and stays. Uggghhh.... I am still not very good at soldering. Getting better with some practice, but I was not able to duplicate the band rings I have seen on other build logs. So... I settled for using brass hooks placed through holes drilled in the brass strips. I also needed to determine how I was going to simulate the turnbuckles. Without a milling machine (yet), I didn't really know how to duplicate. Got online and found a company that had small model turnbuckles that looked the best (these are 16mm x 2.5mm), and decided to use those. Another "settle for" on this bowsprit. Worked on the gammon iron, the guy plates and the bobstay plates. The Proxxon drill again became useful for that operation. Completed, then, all of the rigging from the bowsprit to the bobstay plates and to the guy plates, and also ran the rope for the backropes and footropes and tying those together at three intervals along the bowsprit. Finally, ran the jibstops through the holes in the bowsprit strips. Not my most exciting work to-date on my Bluenose, but I'll get better. I'll definitely have to, though, as I look ahead to the next huge task, which is the mast work. Lots of detailed soldering work will be needed there, as I have looked at other build logs and the awesome work they have done on the mast caps, spring stay bails, shoulder bands, etc. Taking another quick trip to watch a granddaughter in her "senior day" basketball game, and then the hard shipyard work will start again. Appreciate all the guidance many have provided as I look at other build logs. Thanks!

- 184 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

USS Constitution by mtbediz - 1:76

GGibson replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Ahh, sure, of course! Dowels make sense. Sometimes I forget the scale we are working with when I see certain wood pieces. They look bigger in pictures! <doh> 🤣👍 -

USS Constitution by mtbediz - 1:76

GGibson replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Nice work, Mustafa! How did you make the wheels and axles? -

USS Constitution by mtbediz - 1:76

GGibson replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Yep, that's the one I have read about most and am seriously looking at getting it. Thanks for sharing what it can do! 👍

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.