-

Posts

8,149 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by allanyed

-

Ed, Cudos continue from all of us, and justifiably so. In addition to the quality of the workmanship that you show, I really believe the step by step process you have taken the time to photograph and show has shown a lot of members it is not that hard to do. It takes a willingness to try, and the patience to try again and again at times. Broken down into each single step as you show on the hanging standards (I still think those are standards, not knees :>)) it takes the fear out of the process. Thanks again for sharing. There are a lot of great builders that are members here, but you are the teacher of the year as far I am concerned. I hope this is a lesson for others to try to share as much as you have. Allan

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Making small nails with round head

allanyed replied to Aleksei Domanov's topic in Metal Work, Soldering and Metal Fittings

Alexey, Simple, fast, easy, inexpensive, you gave us the complete package! Thank you very much for sharing. Allan -

Keith This subject got me doing some research. As you probably already found, the Harland book, Seamanship in the Age of Sail and the pages mentioned are on line from Google Books. I also found a very nice Texas A&M thesis on anchors by Harold Jobling that is wealth of information on anchors tehmselves from 1550 to 1850 and his research sources. Nautarch.tamu.edu/pdf-files/jobling-MA1993.pdf Allan

-

Making sails for HMS Victory

allanyed replied to rafterrat_2005's topic in Masting, rigging and sails

Having just seen Blue Ensigns photos, I humbly stand corrected as he has shown it can be done. Allan -

Making sails for HMS Victory

allanyed replied to rafterrat_2005's topic in Masting, rigging and sails

Frankie, I think the consensus is sails on a model at scales such as 1:98 look terrible. They are near impossible to make to scale regarding thickness and sewing pattern, they make rigging more difficult, and they cover from view a lot of the work that goes into the model. Allan -

Hi Hamilton When you say a fair run of the planks, what do you mean? I took it that you were talking about the width of the wales, not the thickness. The thickness did taper in order to seat into the rabbet as Druxey points out, but the width is another matter. The other planks taper in width as they approached the bow, so it is a fair question to ask if the wales also taper in width. Allan

-

Monello, Welcome to the club of redo, we all have a scrap box of mistakes. I don't know about others but from my experience, oak was not a friendly wood in terms of cutting, carving, or chiseling and the large grain is not attractive in most model scales. I know you have that lovely stack of dried timber, but this is something to consider and I for one would like to hear if anyone else has had bad experiences in using oak. Allan

-

Danny Wouldn't it have been quicker to order a piece of tubing and soldering than sanding and filling Disk sander or not, that is a LOT of material to remove. I must say they do look very very good. Allan

-

Naci Three sources are The Art of Ship Modeling, TFFM Vol. 2 and Euryalus 1803, Vol 2. Each is a bit different than the other, but all three work. My preference of course is the last, because it uses a single piece mold, not two part split mold, thus not parting line down the middle of the barrel. I am sure there are other viable sources that other members will hopefully post for you. Allan

-

Nacioffi, Further to Druxey's comment, if you do not have a lathe, purchase one of each size barrel, that you require and then cast your own in resin or pewter. It is not terribly difficult, it will save a lot of money, and it really is gratifying. Careful to get good quality, scale, proper era barrels in the right caliber. Allan

-

I thought to look at some contemporary models for an answer, but I am more confused. They all show natural ratlines, but the standing rigging is natural except on the Prince Frederick. The top photo is a 60 of 1705, the second is a 36 of 1780, the third is the Portland 1693 and the last is the Prince Frederick 1714 Not also that the lanyards for the deadeyes are natural in each case as well. Allan

-

Thoughts on standing after running rigging

allanyed replied to cwboland's topic in Masting, rigging and sails

Mike, When at all possible, work from the inside out and then the spars and running rigging. If you do not already have any, consider getting a rigging book or two. Volume 4 of TFFM by David Antscherl, James Lees Masting and Rigging are VERY good. The former explains how-to rig a sixth rate, but much of the information will serve you well for any vessel. The latter covers a range of vessel sizes from 1625 to 1860 in such a way that you can calculate mast, spar and rigging sizes. It is not so much a "how to" book but gives a wealth of information including where each piece of rigging starts and ends. It is laid out in pretty much the order you would do the rigging. There are a few others that many of the folks here like and can recommend. These two happen to be my personal favorites. Allan -

Mark, It may be easiest if you spile those last few. There is a lot information in the tutorials at MSW on spiling. It is easy to do and saves a lot of wood as you will get the shape using some card stock first versus your planking materials. Once you make the card stock plan you can trace it onto the wood. Or you can just get the card stock and trial and error until you get the exact shape, then trace this onto the wood. Allan

-

Steve, I went to the video and I must say, it was nicely done. For anyone that has not been using clove hitches, this video should convince them it is not only the easy, it duplicates real world practice. Allan

-

Rob, As the saying goes, necessity is the mother of invention. There is so much information out there that is simply too difficult or expensive for most of us to access so when this chance came up, I knew what I wanted to do and Bob Friedman was instrumental in making it happen, in spite of a lot of agida that came with the project. Allan

-

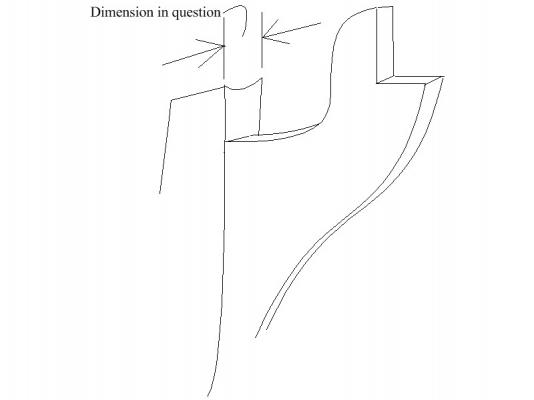

Rob, I am very happy that you like the book, I appreciate you taking time to post that. As to Q&A, I am always in the learning mode as well. I must admit I have no sure answer for you. The 1719 Establishment had a line that this dimension was the same bigness as the keel amidships. I merely copied the same dimensions from the appropriate line of dimensions. Unfortunately, as I was transcribing, I did not look at what many items actually are, but now I want to know as well. I have attached what MAY be the answer. I hope some of the more learned members kick in their two cents be my answer right or wrong, more likely the latter. Allan

-

Shihawk, If the guns were run out, they were there to be fired. If they were there to be fired, I bet no one was too concerned about making nice cheese rolls on the deck or worried about rot or much else. They just wanted to be sure they could cleanly move the lines so they could haul the gun into place with the barrel outside the hull before firing. Perhaps a neat but not perfect coil was used if only to minimize tripping hazards or kinked lines that would impair use of the lines when hauling or during recoil. If the ship was not engaged in battle or practice firing, the guns were secured inboard with the barrel up and tight against the inside of the hull, and the side running tackle ends frapped, not hitched or coiled on the deck. The tackle used to haul the piece inboard was removed when the piece was secured like this. Is that the only way it was done? I have no clue, but these are the methods I have seen decribed most often Allan

-

Gun Port Lids

allanyed replied to wq3296's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Regarding the red paint on ports and bulkwarks, the following are contemporary models in Rogers collection at the US Naval Academy Preble Hall museum. Most had red lids, but the upper bulwarks were sometimes red, sometimes left in the natural wood color. Allan

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.