-

Posts

308 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by RossR

-

Nice work. Looks great. I struggled with the pin rail in front of the windlass on my Beagle. Yours looks really good.

-

.thumb.jpeg.ffac2f8a24d212961a83eab4efb06a6c.jpeg)

Frigate Diana by RossR - OcCre - 1:85

RossR replied to RossR's topic in - Kit build logs for subjects built from 1751 - 1800

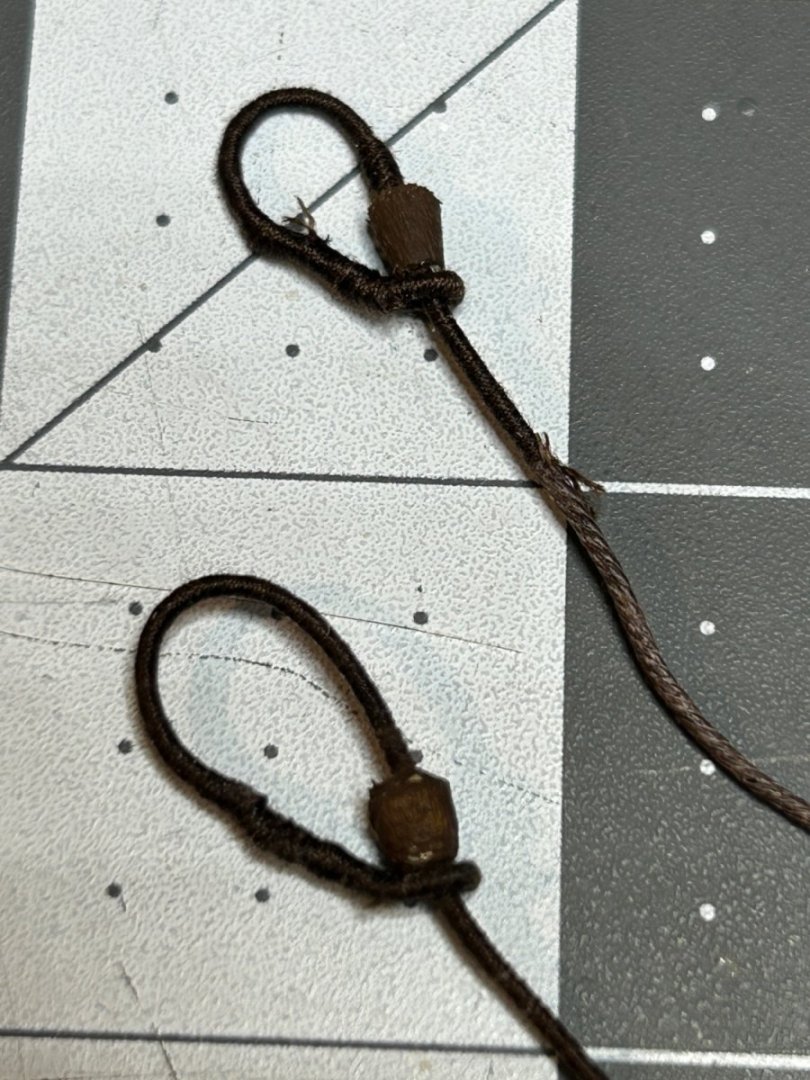

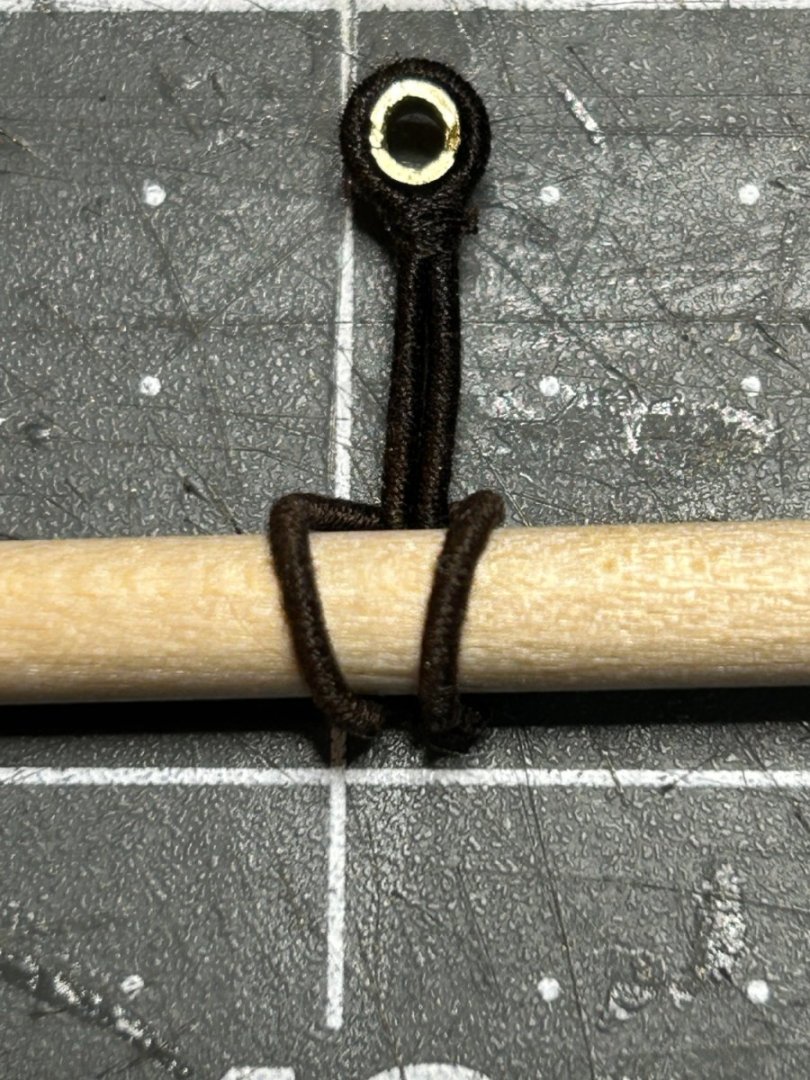

I haven’t made much progress on the ship. Fall projects and my daughter’s soccer season have kept me busy. When I have had time to get in the shipyard, I have been practicing some of the new skills I want to use in rigging the ship. Spent time practicing serving with my Serv-O-Magic and working on seizing the shrouds around the masts, putting together the slings for the yards and figuring out how I wanted to fabricate a mouse. The following pictures are of some of my practice attempts. I used the rope that came with the kit for practice. The fixed rigging on my model will use rope purchased from Syren. This is my attempt at serving the top portion of the shrouds. I will serve the entire length of the first should on each mast, the other shrouds will be served to just above the futtock stave. I need to work on cleaner knots where my serving ends, but am pretty happy with the results. next is a couple of attempts at a mouse. The loop that would wrap around the mast is too small on these attempts, but pretty happy with my progress on creating the small loop with a false splice. the mouse is build from a bit of basswood. The one on top turned out better. Again the knots need to be a little neater. Next is my attempt at a sling. The splice on the part that wraps around the yard is not very good, but I can hide it between the yard and the mast. The thimbles will be blackened on the model. overall pretty happy with my progress developing some better rigging skills. -

Any chance you would offer it as POB and POF. At my current skill level I would be interested in POB, but I wouldn’t be up for the cost of POF. I hope you do get enough interest in the POF to move forward with the project. I think the hobby is better off with high end offerings like you are putting together. Good luck and I hope we see this model in some form soon. and following the build logs will be enjoyable and educational.

-

There is a free online book available on the Modelexpo web site, How to Build First-Rate Model Ships. It has a drawing of how to cut down a regular sized sail if you are going to furl it.

-

.thumb.jpeg.ffac2f8a24d212961a83eab4efb06a6c.jpeg)

Ships at Trafalgar - what kits are available?

RossR replied to bruce d's topic in Wood ship model kits

No model kits of French ship at Trafalgar are available? Seems like an opportunity for Syren or Vanguard. -

.thumb.jpeg.ffac2f8a24d212961a83eab4efb06a6c.jpeg)

Frigate Diana by RossR - OcCre - 1:85

RossR replied to RossR's topic in - Kit build logs for subjects built from 1751 - 1800

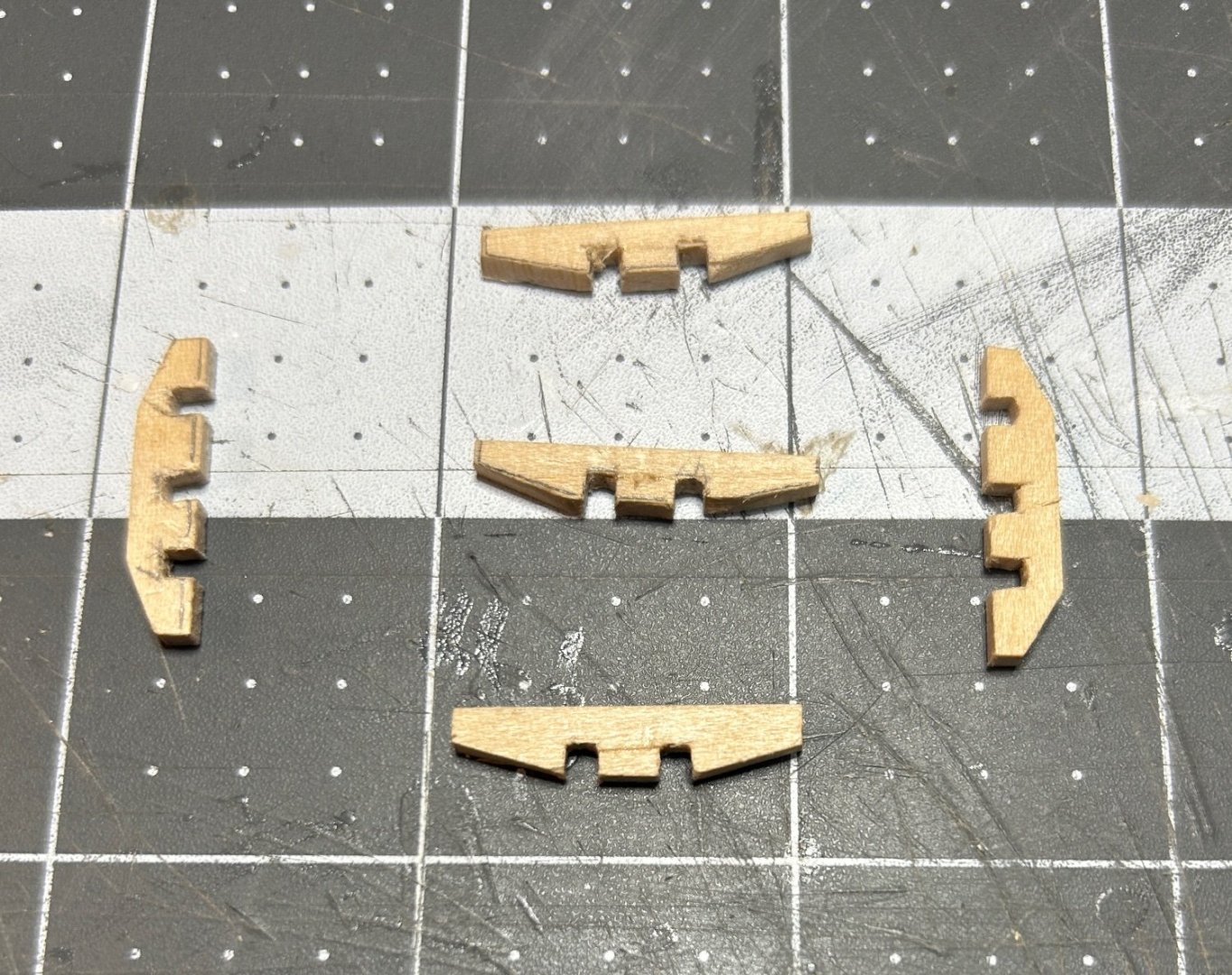

Sometimes mistakes create opportunities. I have been posting details of my build as items have been attached to the model. Sometimes I have build certain items weeks or months before I post about them. Even though I haven’t posted about it I have been busy fabricating the components of the fore mast assembly. This morning I put the final coat of paint on the cross tree for the transition from the fore top mast to the fore top gallant mast. At some point in the day I accidentally knocked the cross tree on the floor without realizing it. Later I must have rolled over it with my chair. Occre would gladly send me replacement parts, but I didn’t want to wait. So I decided this was an opportunity to fabricate a new cross tree from scratch. I used the plywood sheet that the laser cut pieces were cut from as the pattern and traced the pieces onto some 2mm x 5mm lime wood left over from the first layer of planking. I need to do a little more sanding and then paint and glue the pieces together, but I am pretty happy with the results. -

.thumb.jpeg.ffac2f8a24d212961a83eab4efb06a6c.jpeg)

Frigate Diana by RossR - OcCre - 1:85

RossR replied to RossR's topic in - Kit build logs for subjects built from 1751 - 1800

David Thank you. Your HMS Diana build has been a great resource for me. Fantastic job. A different Diana than I am building but similar era. I have a note to myself to look at your anchors when I get to that step on my build. -

.thumb.jpeg.ffac2f8a24d212961a83eab4efb06a6c.jpeg)

Frigate Diana by RossR - OcCre - 1:85

RossR replied to RossR's topic in - Kit build logs for subjects built from 1751 - 1800

I have my bowsprit mostly assembled and have started attaching the various rigging components. I am pretty happy with how it is coming together for the most part. One area where I am not satisfied is on the jib boom. I tried to create a closed loop of served rope that would be seized to a block and the jib boom to attach the block. I struggled creating the splice. As an alternative I used a section of served rope and created an S shape with one loop of the S around the block and the other loop around the boom. I then seized the ends of each loop along with the middle section of the S between the block and the boom. I am not happy with the result. The section where the rope is seized looks clunky and not very clean. I will likely look to replace these blocks before the rigging begins. Hopefully I can get better at the splice needed to create the closed loop, or I may try using the technique illustrated on post #2111 and #2113 of Archjofo's build log for his La Creole French Corvette. His rigging is stunning. I doubt I will ever produce results as good, but his work provides something to strive for. -

If planking your model the way an actual ship was planked is not the most important thing to you on a first model, consider looking at Occre. I built their HMS Beagle as my first model and am happy with the results. They may not be the most historically accurate models when it comes down to the finer details, but they can be built with minimal tools and no prior experience. For the Beagle and I think the Polaris, they have a series of about 100 short YouTube videos to help step by step. If planking in the historically correct way is a goal on your first model I would go with something other than Occre. Good luck.

-

Great work on the bow. I struggled with that on mine. Yours looks fantastic. I remember being short on one size of wood on my Beagle, I think it was the 2x4 mm sapelli and Occre sent more no questions asked. I made a mistake on my Diana and they even replaced those parts. It does take 2-3 weeks to get the replacement/missing items shipped from Spain to the US, so be ready for the wait if you are in the US.

-

I received my Half Hull kit last week. I have about a year before I finish my current build, then I will start the Half Hull. Looking forward to following your build in the meantime. Good luck.

- 17 replies

-

.thumb.jpeg.ffac2f8a24d212961a83eab4efb06a6c.jpeg)

Frigate Diana by RossR - OcCre - 1:85

RossR replied to RossR's topic in - Kit build logs for subjects built from 1751 - 1800

Here is my attempt at scratch building the gallery. I did use the brass provided by the kit for the dividers between the pains of glass. -

.thumb.jpeg.ffac2f8a24d212961a83eab4efb06a6c.jpeg)

Frigate Diana by RossR - OcCre - 1:85

RossR replied to RossR's topic in - Kit build logs for subjects built from 1751 - 1800

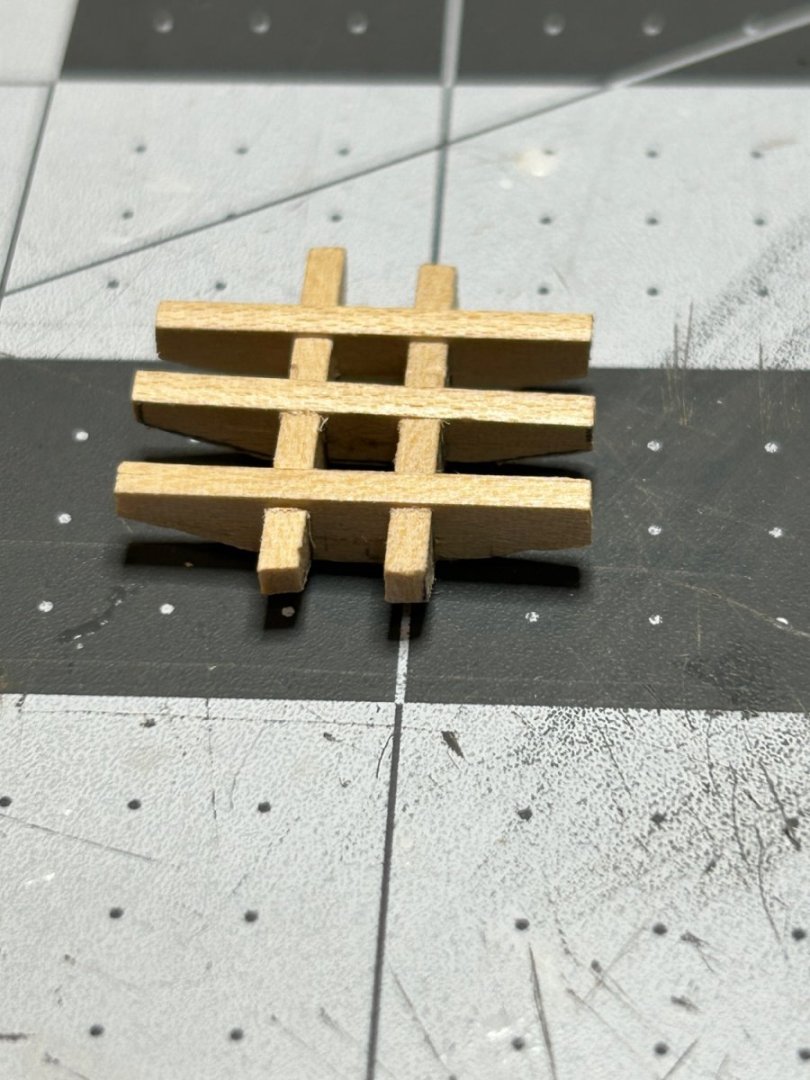

It has been awhile since my last update. I haven’t had much time in the shipyard lately. My daughter’s soccer season has keep us busy. I did have some time to start fabricating the galleries from scratch. I didn’t like the way the kit provided pieces fit. I built these new upper and bottom pieces by cutting pieces out of some thin basswood and glueing them together. A little filing and sanding and I am getting close. Hopefully I can finest these up in the next few days. -

Hard to believe you did all of this in a little over 3 months. Fantastic job.

- 233 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

.thumb.jpeg.ffac2f8a24d212961a83eab4efb06a6c.jpeg)

Planking Book?

RossR replied to BWDChris's topic in Building, Framing, Planking and plating a ships hull and deck

Just ordered it myself. -

.thumb.jpeg.ffac2f8a24d212961a83eab4efb06a6c.jpeg)

Planking Book?

RossR replied to BWDChris's topic in Building, Framing, Planking and plating a ships hull and deck

I am a fan of Occre. Building my second Occre ship right now. They are a great way to get started in the hobby, but they are not designed to be planked in the traditional way. The second layer of planking on the Occre models is very thin (about 0.5 mm). The bending or spiling that would traditionally be done really doesn't work with that material, and the bulkhead former (piece that the bulkheads attach to that runs the length of the ship) is not designed to have a rabbet cut into it. If you want to have fun building something and end up with something that looks good on your shelf, Occre is a great way to go. They have video series for some of their models and I would watch them and plank the model according to their instructions if you go with Occre even though it is not the traditional way to plank. If you really want to learn "the right way" to plank a ship, consider Allen's advice or maybe the half hull project from the NRG. I will be tackling that before building my US Brig Syren model that I have on the shelf. I would have failed at planking a ship in the traditional way on my first ship, but that's me. I get a little impatient. I have seen some first time modelers do a great job of planking on their first ship on MSW. Good luck. -

.thumb.jpeg.ffac2f8a24d212961a83eab4efb06a6c.jpeg)

Frigate Diana by RossR - OcCre - 1:85

RossR replied to RossR's topic in - Kit build logs for subjects built from 1751 - 1800

I spent quite a bit of time in the shipyard the last week. I finally finished putting together my Serv-O-Matic and started fooling around with that a little bit. I also started working on the chain plate. I don't care for the single brass wire that the kit came with for chain plate. I am going to use the instructions from my US Brig Syren that I have on the shelf as the basis for the chain plate on this model. I need to work out exactly how long the various components will be, but I started putting together some jigs for making various length components. I will be using dark annealed wire. Most of my time was spent working on the stern. The kit came with a large decorative piece of photo etched brass for the stern. I didn't like the look of that much brass on the ship. I decided to use some left over planking materials and the scrappers I purchased from Artesania Latina to make some trim for the lights on the stern. I added two other pieces of trim above and below the decorative scroll design on the photo etched brass piece. I still need to fill in a gap between the two trim pieces on the top, and touch up the paint after that. I am very happy with how this turned out. The bottom piece of trim is made 2mm x 5mm piece of basswood. To get that piece to match to curve of the stern I needed to pre-bend the piece. In the past I have struggled to successfully bend planks using heat. I think I haven't been patient enough. I didn't want to soak these because I thought it would distort the the grooves that I carved into the piece. I decided I needed to give using heat another try. I used a wood burning tool of my daughter's as the head source and took my time. I was able to match the curve of the stern without soaking the piece. I think this will give me confidence to start using heat more for bending planks. I will be continuing to work on the chain plate and finishing up the bowsprit in the next couple of weeks. I will also need to make some decisions on the gallery lights on the sides of the ship. I may attempt to build these from scratch instead of using the metal components that came with the kit. The way the stern has turned out gives me a little confidence in trying to build something myself.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.