-

Posts

2,441 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rustyj

-

Echo by Rustyj - 1:48 - cross-section

Rustyj replied to Rustyj's topic in - Build logs for subjects built 1751 - 1800

Pete, That's what keeps me out of trouble. Idle time tends to be bad for me. Thanks Mario. Greg. Great tip. They are always appreciated. -

Echo by Maury S - FINISHED - Cross-Section

Rustyj replied to Maury S's topic in - Build logs for subjects built 1751 - 1800

Hi Maury, She's looking great. That's the way I'm thinking of doing it when I get to that point. Keep up the good work!- 324 replies

-

Hee Hee. I see you've joined the club of three at once! Nice start and though the Jim saw makes it easier there's no reason you can't achieve great results with hand tools. Yes the tree nails are seen on both sides. The hardest part, for me, is getting a straight drill through. I’ve been known to mark both sides and drill each side and meet in the middle just to be safe. You’re off to a great start.

- 147 replies

-

Echo by Rustyj - 1:48 - cross-section

Rustyj replied to Rustyj's topic in - Build logs for subjects built 1751 - 1800

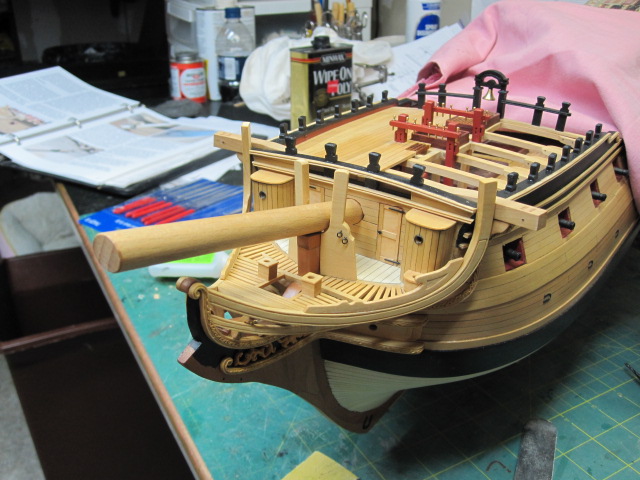

Thank you all. Well I'm really only working on 2 right now. You know the Bomb Vessel is only in the "set up" stage. With this type of build it's not too hard to do. I have enough room for all three although at 1:24 the bomb vessel is pushing it. Like last night I worked on the Triton deck beams after assembling part of the frames for the Echo and they were drying. Then I'll add some chocks let them dry and work on the deck beams again. So switching back and forth is not bad. Also they each are so different it's easy to remember where I'm at. Now if I could only remember where my work shop is I’d be all set! -

USF Confederacy by Rustyj - FINISHED

Rustyj replied to Rustyj's topic in - Build logs for subjects built 1751 - 1800

And more of the walk ways and skid beams etc. Also I included a big oops. This walk way was reversed. Must have been looking in a mirror while I built it. So I took it apart and redid it the correct way.- 149 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

USF Confederacy by Rustyj - FINISHED

Rustyj replied to Rustyj's topic in - Build logs for subjects built 1751 - 1800

Thank you all very much. Here are more of the chain plates and the knees for the walkways and stairs.- 149 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Echo by Rustyj - 1:48 - cross-section

Rustyj replied to Rustyj's topic in - Build logs for subjects built 1751 - 1800

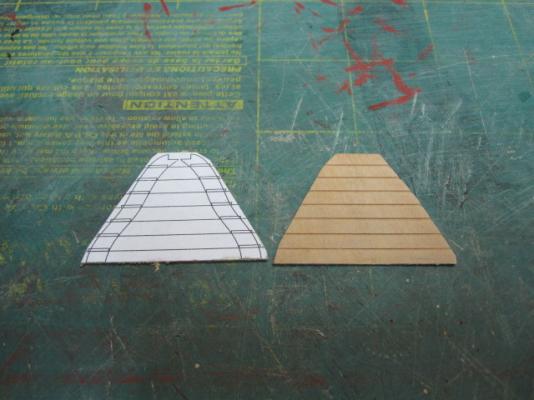

Hi all, Still plugging away here. So far I’ve completed the first seven frames and I’m working on the eighth (3 aft). Here a couple of frames set in place just to see them there. This one has a top timber that really has a curve to it. Here is another top timber with a much more subtle shift. Greg recommended aliening it on the plans as shown. It really helped with getting the shift right. Only had to throw around three away. Here is a frame being assembled. I placed handi wrap over the first plans so the glue wouldn't stick to the plans. Once I get all of the frames completed I’ll then start to raise them. -

Thanks Grant. As you know “set up” can be endless. Ben, I just wish my brother hadn’t retired as a machinist. He once made a working cannon. Pete, I hope you plan on it taking a while! You know “set up” takes forever. Mark, As long as you haven’t applied a sealer or Poly it could be considered “set up”.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

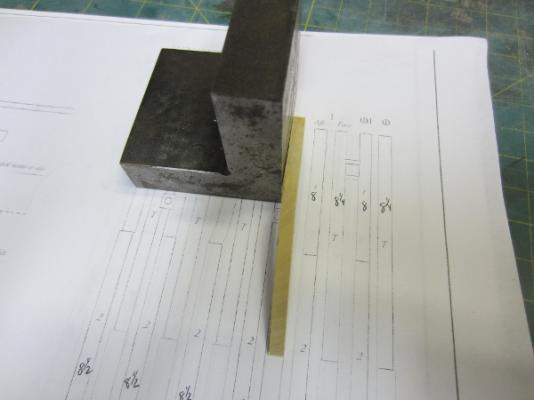

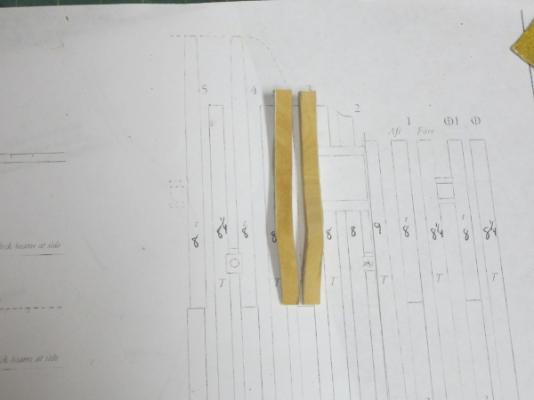

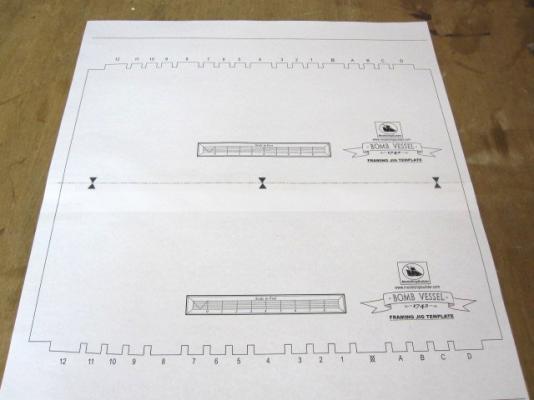

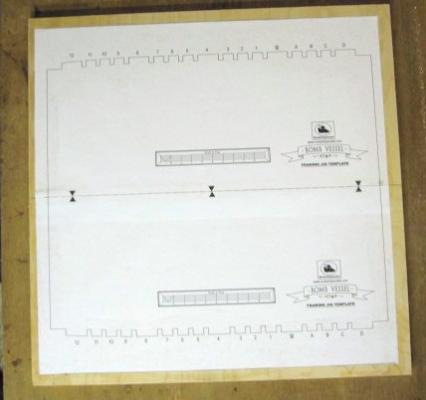

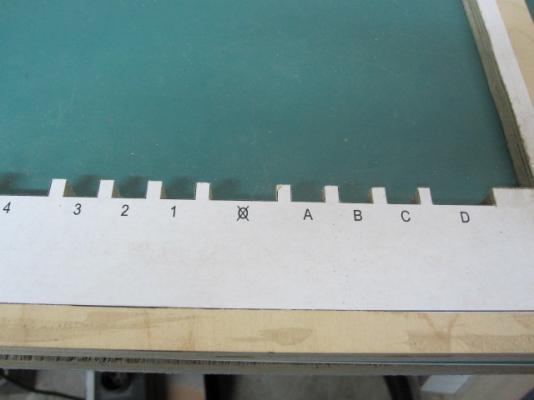

Hey Ben, Already way down that rabbit hole my friend! Rice n beans again for dinner. Thanks Pete it may take awhile but should be fun. I’ve continued on with the now infamous “Set Up” work. Quiet Mark! Here I’ve constructed the jig that will hold the set up keel and frames in the correct position. The bottom board is some ¾” ash that I had left over and the top piece is ½’ beech plywood that is eight ply and very solid. I glued the plans to the plywood and then cut it out using the scroll saw. After it was done I placed it evenly on top of the bottom piece, clamped it and drilled 6 holes for the bolts. This way I was pretty sure the top and bottom would stay square to each other. Once the bolts were installed it was a simple matter of adjusting the nuts until the correct height was archived. Here’s the Triton Cross Section placed in side for another size reference. As I complete more “Set Up” work I’ll let you know.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

USF Confederacy by Rustyj - FINISHED

Rustyj replied to Rustyj's topic in - Build logs for subjects built 1751 - 1800

- 149 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

USF Confederacy by Rustyj - FINISHED

Rustyj replied to Rustyj's topic in - Build logs for subjects built 1751 - 1800

It will be no surprise to anyone that Chuck generously supplied me with one of the original resin castings of the figurehead which I painted and dry brushed to look like the boxwood.- 149 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Hi Bob, Thanks for reposting your build log. I'm looking forward to seeing your great workmanship all over again.

- 31 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Hi Pete and Ben. There’s nothing special I do. I just make sure that the paper is completely glued on both sides. I only leave about 1/32” excess on the topside and none on the bottom. Once dry I sand with 150 then 220 then 400 grit sand paper. I sometimes I will scrap it too with a single edged razor blade. I’ve only tried this on hardwoods like holly, boxwood and par marfin. I hope this helps. Hi Bob, Thanks’ and the chisel’s I use are the small and mini palm chisels from U.J. Ramelson. Thanks Russ. Doing them really makes me want to get a lathe! Thanks Paddy. I wish I hadn’t lost the pictures though. Thanks Bob. I was pleased with the contrast with the planking, paper and treenails. Hi Daniel. I just use a strip of wood cut to the desired width and lay it on the beam and mark each plank prior to drilling. Thanks Mark. Much appreciated.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

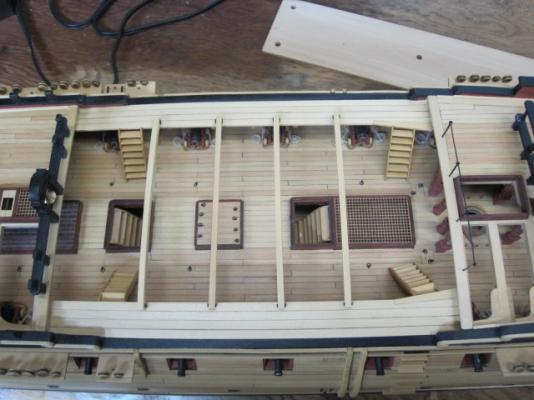

Hi All, Sorry all but the camera decided to hack up the hair ball. I was taking pictures thinking all was good. I pulled the memory card to download the pictures and nada, zip, zero nothing. Put the card back in, took some more pictures. Nope. I replaced the card and still nothing. You would think that a $100 camera would last longer then 6 years of being covered in dust in a work shop and repeatedly knocked on the floor. So anyway, I stole the Admirals camera to take some pictures to bring us up to date. The decking was completed and I used Holly treenails with the black construction paper for the caulking. For the support beams I used some Swiss Pear and using a xacto and files. I then went on to framing in the gun deck with the boxwood which the main beams are almost done and then I’ll start on the carlings ledges and knees. That's were I'm at right now!

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

USF Confederacy by Rustyj - FINISHED

Rustyj replied to Rustyj's topic in - Build logs for subjects built 1751 - 1800

- 149 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

USF Confederacy by Rustyj - FINISHED

Rustyj replied to Rustyj's topic in - Build logs for subjects built 1751 - 1800

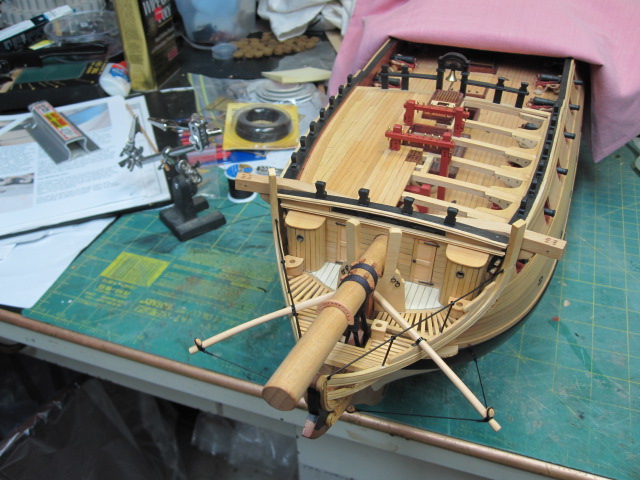

Hi 42Rocker, Popeye, John and Dirk. Thanks for joining me on the trip down memory lane. Funny thing looking at the pictures is my desk still looks like the same mess just a different build sitting on it! Well here are yet more pictures of the head rails.- 149 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.