-

Posts

2,535 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rustyj

-

Hi Ben, I pulled my boxwood down to a # 28 on the draw plate and a # 69 drill bit. That was a real snug fit so you might want to try a # 68 bit too. Enjoy!

- 147 replies

-

Well done Ben. Those are very good joints and nice looking frames!

- 147 replies

-

Echo by jml1083 - cross-section

Rustyj replied to jml1083's topic in - Build logs for subjects built 1751 - 1800

Looking great Jim. Thanks for all of the great guidance! -

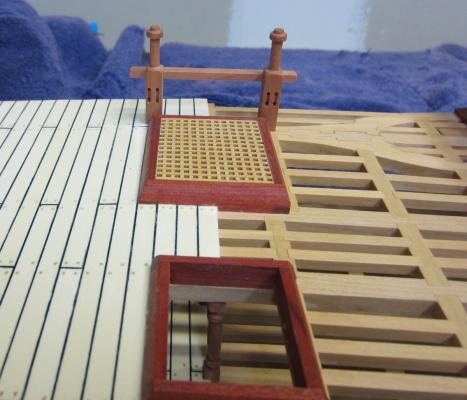

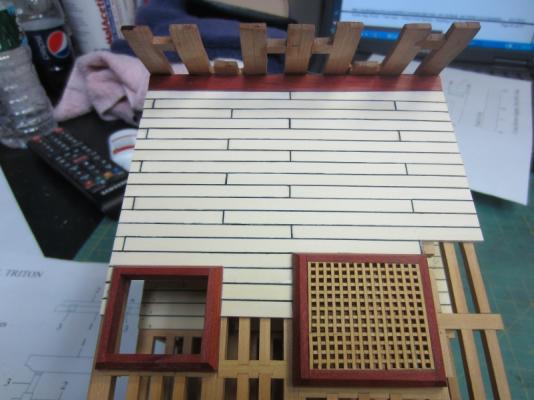

Hi all, Thank you for all the kind words. It is very much appreciated. Well after making the bits and gallows I installed just the bits and cross piece. I left the gallows off for now as I still had to add a few pieces of planking and treenail. I didn’t want to damage the gallows with my ham fist hands. For the deck treenails I used boxwood. They stand out a little more than some will like but I kind of liked the contrast. Next I will start framing in the gun ports and continue planking the exterior of the hull. That is if the summer activates will allow me sometime to do so.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

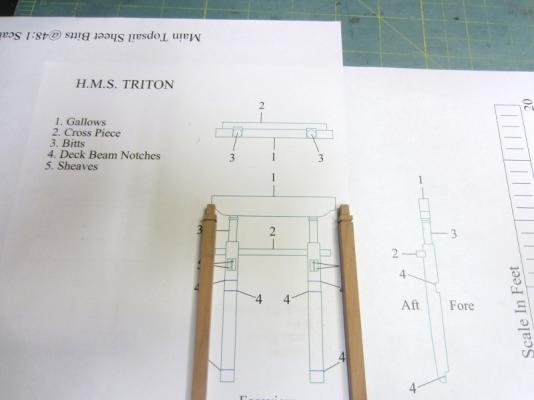

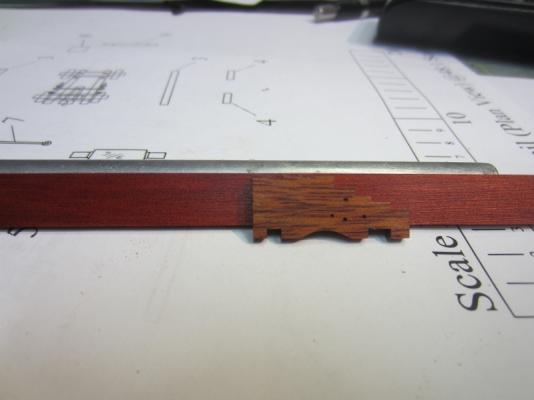

Next I focused on the Gallows. The plans called for them to look like this. I saw some other builds where people got a little creative with the gallows and I liked the look and figured I’d give it a try. First I cut the gallows as per the plans. After cutting the gallows from the plans I decided on a style I like, traced it on the wood. I then using a ¼” dremel sanding drum, files and sand paper I created the shape. Here it is semi sanded to the desired shape. I don’t know if it is historically accurate but I’ve heard the captain can us his prerogative while building his ship.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Thanks Russ. Yes they are a bit off plus the angle of the camera makes it worse. Once I glue them in place hopefully they will sit straight.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

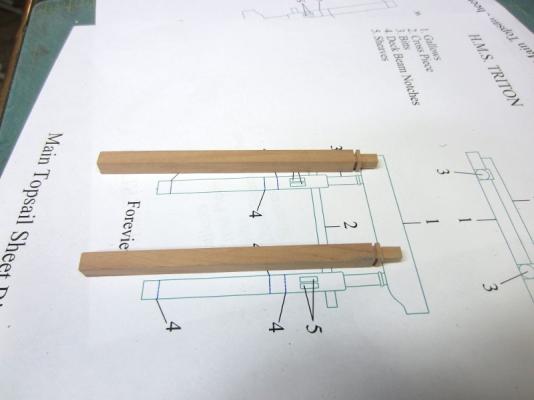

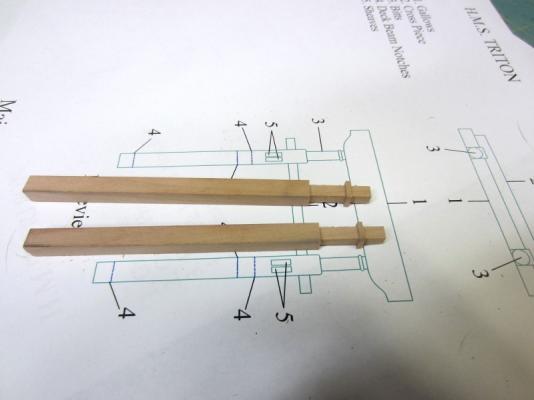

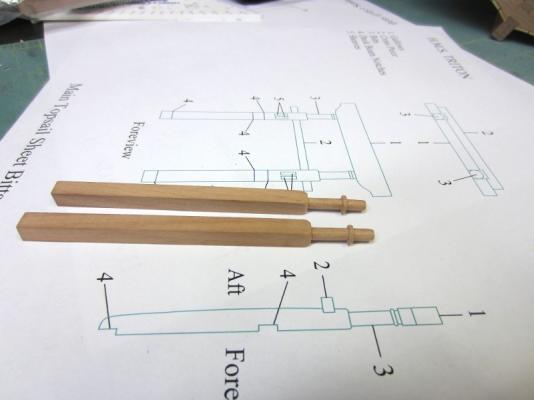

Hi all, Well I’ve been on a bit of a forced break. Our daughter went on a second honeymoon and we had the pleasure of watching three of our sweet but high maintenance grandkids. So needless to say I was lucky if I got to look longingly into the workshop yet not be able to step in and partake! It took one day to figure out where I left off and what to do next. Here are some things I had done prior to their arrival and since the departure. Seeing that I had planked the deck to the point that I needed to install the main topsail sheet bitts before I could continue I figured it was time to make them. I started at the tops, figured the depth I needed to cut them to and the cut away the extra with the table saw. After they were cut square I used a file to sand them down to a round shape. After that I used the table saw to cut the cross piece and deck beam notches. I then drilled the holes for the sheaves and shaped them with a file and xacto. Here they are set temporarily in place.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Hi Augie, that is one fine job of rigging you have done. You're making a complex process seem effortless. I always enjoy catching up on your build. Well done.

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Pete. Hi Grant. Yes the large piece is the redheart and the grain is nice and tight. The carriage is bloodwood and has a much more pronounced grain. Looking back I find I didn't explain it well. Sorry.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Thanks Pete. 42rocker, At the 4th plank the pattern repeats it’s self. I don’t remember if it’s called a 3 or 4 shift pattern. Speaking about gun carriages made me wander off and start cutting parts for them just to see how they look. I do that waaaaaayyyyy too much. I glued the plans to some bloodwood and used my table saw to cut it out. I increased the depth at each step. I repeated each cut on 4 more pieces before adjusting the depth. Good thing I did too becauase one broke while cutting out for the axles. Here is one with a plans in place and a second one cut out. And more And compared to a piece of redheart so you can see the differance in the two colors. You also can see how nice and tight the grain is. Now I'm trying to decide if I should continue on or get back on course.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Thanks Russ, Grant, Mark, Martin and texxn5. Ben, Thanks but it’s no real insight. I just like the colors and I love playing with different woods. Just to throw a curve I decided to make the gun carriages out of bloodwood. It will be interesting to see the contrast between the two. Joss, That’s why I stuck with paper on this one. I will try the stain sometime though. You and John0868 made it look so good. Most of the deck planking has been completed. I just have to make the bitts and plank around them, treenail it and sand away. With the way the time is going by it could take awhile.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.