-

Posts

2,535 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rustyj

-

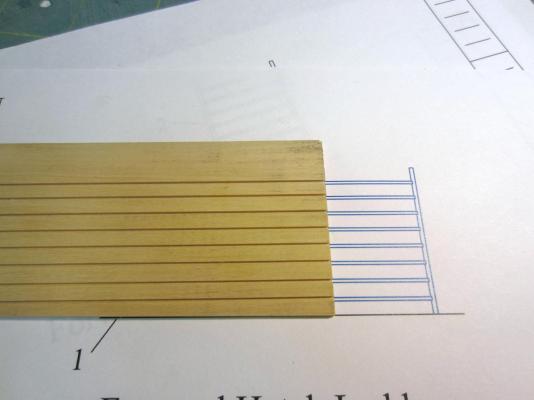

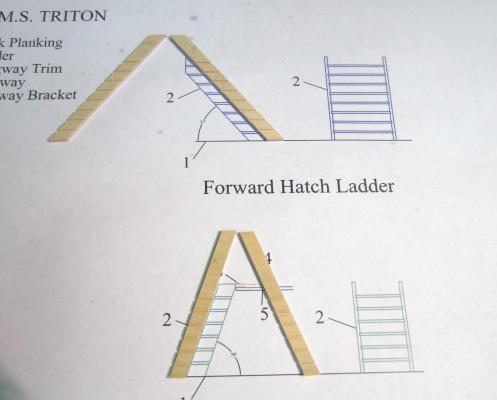

Well I’ve started to make the ladders. I transferred the lines from the plans to the wood, cut the slots for the treads with the table saw and then cut the side pieces to the angle dictated on the plans remembering to make a mirror of each one cut out. Hopefully I’ll assemble them today.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Thank you all for your very kind words. Russ, I was pleased with the way the colors came out. I wasn’t really certain how it would all look once completed. Antony, As far as the case goes I’m going to semi cheat and get a premade plexiglas box and just make the base for it to sit on. I thought about making my own plexiglas box but I didn’t want to get into that yet.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Thank you Ron, Grant and Kevin. Well the other gangway has been installed and the skid beams added. Gotta make some ladders and the top rails then a case and I should be wrapping her up by next weekend. Just in time for the hectic end of August when I don’t have time for any modeling.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

You'll be fishing, we'll be modeling and the pages keep turning. What a great day!

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Hey Augie, Once a page you have to mention the case you are building just to meet you know who's standard!

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Thank you Paddy. Hi Pete. No bevel on the trim. The individual piece still has the pencil lines on it and may give it a beveled look.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Hi Russ, I wish I could take credit for great planning, but it looked ok and was what I had on hand. Sometimes it just works out ok in the end. I am using holly to make the gangways. I measured the length and glued them together and then used a dremel drum sander to rough in the shape and sandpaper to finish it. I used a little strange way to make the trim molding. It’s made out of pear. I cut the straight top piece and then traced the shape for the two curves, cut it out and sanded it to shape. I wasn’t having a lot of luck making individual pieces to fit the curve and for some reason a whole piece was easier. Not the strangest thing I’ve done. And here is the first one in place. I'm getting there slow but sure.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Scratch building the Syren using the kit's plans

Rustyj replied to rtropp's topic in Wood ship model kits

Hi Richard, No one simple answer. It depended on the parts needed but generally speaking I used a scroll saw to cut out most parts. I would cut out and paste the plans on the wood using temporary paper cement and cut them out using the scroll saw. Some parts were cut using a razor saw or xacto blades. Sometimes I would cut them larger then needed and then sand to the correct shape. The better the wood, the nicer the piece produced. This is what works for me and trust me there were many a piece that went into the scrap bin. The hardest thing for me to learn was throw it in the bin and do it again. I hope this helps. -

Hi Augie, I know many of our friends here will send along a well deserved “Well Done!” on a truly wonderful build and a riot of a build log. Having built her too I fully understand the sense of accomplishment and pride you have and it is well deserved. Great choice in the Confederacy and I eagerly await the fun to start again when you get to it. Enjoy your time fishing, travelling and building the case. I look forward to seeing ya building back here soon. Again great job!

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Well Done! Oh by the way today is the tomorrow you mentioned yesterday! Pictures pictures pictures!

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Scratch building the Syren using the kit's plans

Rustyj replied to rtropp's topic in Wood ship model kits

Hi Richard, The Syren was my first adventure to the "dark side" of scratch building and was a wonderful experience. As Chuck said "Go for it"! -

Very nice job on what I consider a difficult part. Well done!

- 122 replies

-

- bellerophon

- victory models

-

(and 1 more)

Tagged with:

-

Hi Russ, I used some .028” line I had for the breeching rope. It was the closest I had on hand. Thanks on the colors. I’m real pleased with how they came out. Hi Ben, Have you still got that spy hidden in my shop? I started dusting the Echo off just last night!

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.