-

Posts

3,498 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by captainbob

-

Nice sails for a beautiful boat. Bob

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

plank steaming

captainbob replied to bigpav's topic in Building, Framing, Planking and plating a ships hull and deck

Ulises, Is the wood wet or dry? If wet, how long did you soak it? Bob -

Delftship question

captainbob replied to captainbob's topic in CAD and 3D Modelling/Drafting Plans with Software

Thanks Bob -

I see on the Delftship sight that you can design ship hulls, but I see nothing about using the program to develop frames, keels or other parts as 2D drawings. Is it possible with delftship or should I look for a different program? Bob

-

plank steaming

captainbob replied to bigpav's topic in Building, Framing, Planking and plating a ships hull and deck

Thanks, Looks like a good system. Now where is that tea kettle? Bob -

plank steaming

captainbob replied to bigpav's topic in Building, Framing, Planking and plating a ships hull and deck

Looks like nice tight bends. How about some scale. What size it the wood and what dia. is the bend? Bob -

Michael and John, Thanks for stopping by and your encouragement. I always try to make my builds fun. Bob

-

Oh Anja, Don't jinx me that way. No ! No ! I'll get it together. Thanks. It's all fun. Bob

-

plank steaming

captainbob replied to bigpav's topic in Building, Framing, Planking and plating a ships hull and deck

Thanks, RiverRat, That article is very informative. Thinking more about the steam box, wood is a better insulator than PVC and you need to hold as much heat as possible. And the time, He was bending 8.5mm wood and said he steamed it for one hour. Two boats from now I will need this information. Bob -

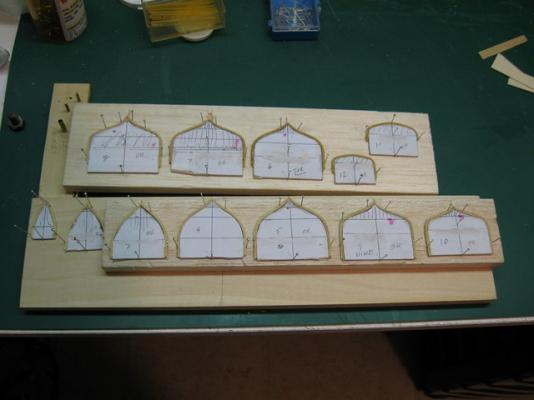

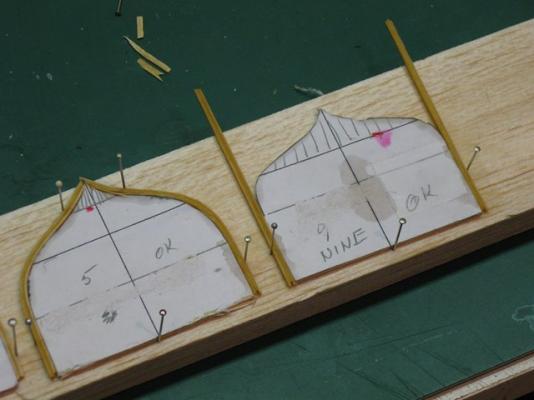

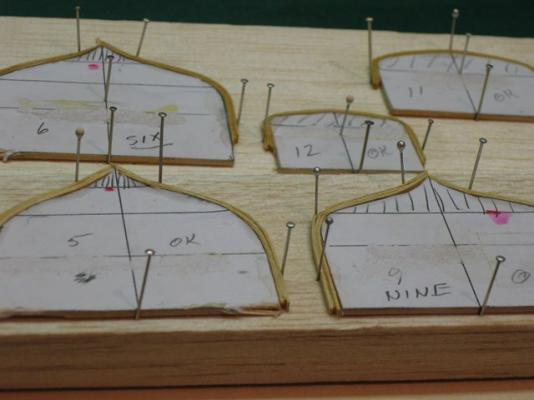

So here's what I did starting over. I took everything apart and after resizing the molds I decided to bend and dry the frames on the flat. It turned out to be a lot easier than when they were on the building board. Once again I cut the veneer into 1/16” strips and soaked them overnight. I bent three together and held them with pins. After they dry I will sand them and glue on the floor timbers before mounting them on the building board. For now they are drying. Bob The lower part that is hash marked is where the floor timbers go.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.