-

Posts

3,498 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by captainbob

-

Michael, I agree. If you can't find the tool you need, you need to make it, That's what builders used to do. Bob

-

Martin, thanks for looking in and the comments. Yves, this will be the admiral’s boat. But I like the older wooden workboats and fishing boats. I’ll let the others play with their guns and square sails while sit back and admire their skills. PopJack, I enjoy working with brass. This is .005” thick and the mast where it is fixed is .125” - .156” diameter. I think that is a little small to solder. The solder would fill the .025” holes for the lines, so it is crimped and glued. I recently modified a set of new pliers to help in the brass work. I bought bent long nose pliers because they did not have the box joint and then ground off the ends leaving only about 1/4” of grip. I use these to crimp the brass around the mast with sharp corners and also to flatten the end of a wire as a stop or to drill a hole through it. Bob

-

Thanks Popeye, it had to be. Jay. Thanks and yes I couldn’t make the turnbuckles that small so I used brass tubing. Thanks John. Bob

-

Thanks, JMaitri and Lawrence, for stopping by. And now it’s time to start the rigging. I would like to be able to write all kinds of words to describe the rigging but I think the pictures can say it much better than words. So here is a start on the standing rigging of the main mast. More later. Bob

-

Interesting method and looking good. I'll have to watch this one. Bob

- 553 replies

-

- sloop of war

- constellation

-

(and 3 more)

Tagged with:

-

Thanks, Piet, I understand the matter of economics. Swiss pear, cherry, maple or boxwood, I’ll have to see about getting some. I also like to make all things on the boat work but it gets more difficult as the scale gets smaller. You’re doing great. Bob

- 102 replies

-

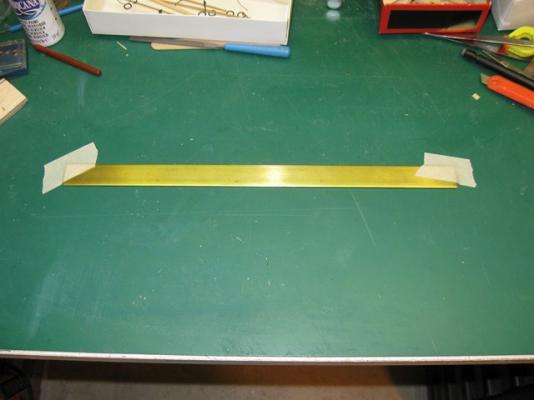

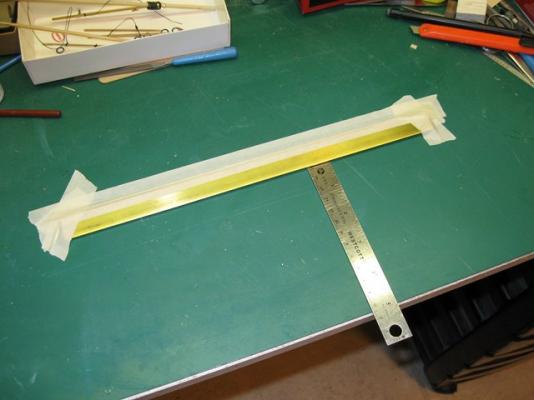

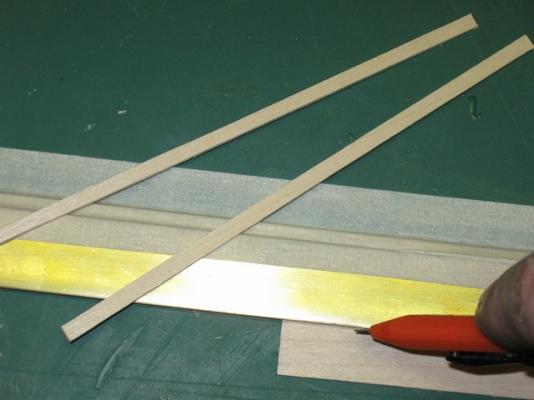

I always cut my planking from 3 or 4 inch wide sheet. If the planks are from a 1/32" thick sheet, I tape a brass bar 1/32" thick by 3/4" or 1" wide to my table, leaving the front edge of the brass without tape. I then use another brass bar on top, overlapping the first by as wide as I want the plank. Now I can slid the wood under the upper piece of brass until it rests against the lower piece of brass and I have an edge to run my blade against. With this setup I can cut as many planks as I need. Bob

-

Piet, Given a choice, what wood would you have used instead of Poplar? I've always worked in poplar or bass wood but I'm thinking of trying some other woods. Bob

- 102 replies

-

Walter, I've missed your entries. Glad to see you're still building. Bob

- 208 replies

-

- meridea

- repair ship

-

(and 1 more)

Tagged with:

-

The mounting look great for such a fine ship. Good job, congratulations. Bob

- 125 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

-

Dee Dee it's looking better all the time. I've missed you and your build. Glad you are still building. Bob

- 89 replies

-

- muscongus bay lobster smack

- midwest products

-

(and 1 more)

Tagged with:

-

Moving along nicely. No need to hurry. Bob

- 97 replies

-

- Willie L Bennett

- SkipJack

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.