-

Posts

3,498 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by captainbob

-

Yes, RC and scale can go together. When I was with the Indy Admirals RC Club in Indianapolis they would have an annual get together of RC’ers from all over the country. One of the competitions was the best detailed scale boat. There are some fine boats out there. Bob

-

Walt, yes it’s too bad we can’t build all the time but the rest of life needs to be taken care of also. I just started a Friendship sloop (click below). Take care and keep in touch my friend. Bob

- 208 replies

-

- meridea

- repair ship

-

(and 1 more)

Tagged with:

-

I have to agree about the R C forum but a book for beginning I like this one. "Working scale model Merchant Ships" by Tom Gorman Published by Naval Institute Press. http://www.amazon.com/s/ref=nb_sb_noss?url=search-alias%3Dstripbooks&field-keywords=working+scale+model+merchant+ships Bob

-

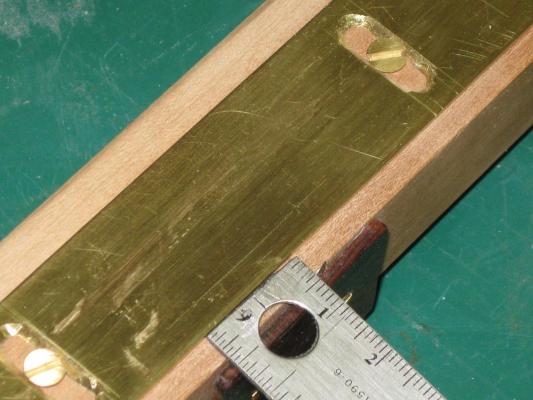

I thought others might like to see this. On a build log someone showed a strip cutter made out of black plastic with a slot to hold an Exacto knife. Someone else asked if they work. This was my response. Yes, it is used for cutting strips of wood from a sheet. The idea is good but this tool is not that accurate so I made my own. I made it longer to ride against the sheet better and I mounted the blade more securely so that it did not wobble in the holder. I use mine all the time for soft wood like poplar. I have cut strips as thin as .015 inch. Bob Someone then asked how it is used. First loosen the screws with the knobs on top. Adjust the plate on the bottom to the width of strip you want. Place cutter on sheet with edge of strip pressed against plate. Slide cutter along sheet. Bob

-

Nice movement of the sails, looks like a winner. Bob

- 366 replies

-

Can i live without a BYRNES TABLE SAW

captainbob replied to shihawk's topic in Modeling tools and Workshop Equipment

Or mill bitt. Bob -

Now you can see those beautiful lines. Bob

- 112 replies

-

- buzzards bay

- herreshoff

-

(and 1 more)

Tagged with:

-

Fine job, she looks great, you should be proud. Bob

- 26 replies

-

- louise

- constructo

-

(and 1 more)

Tagged with:

-

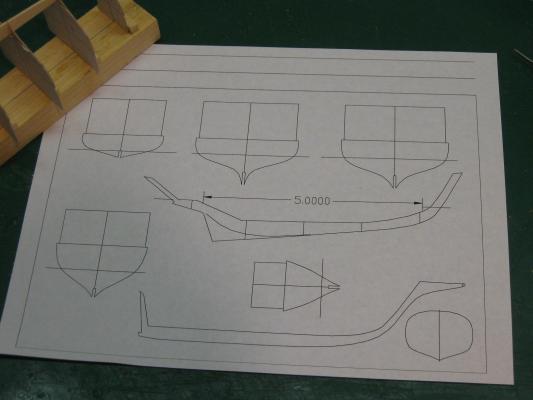

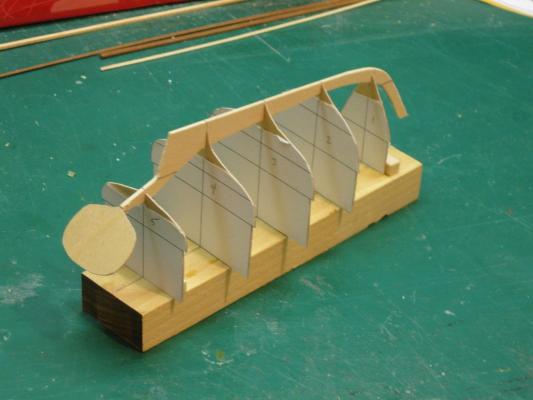

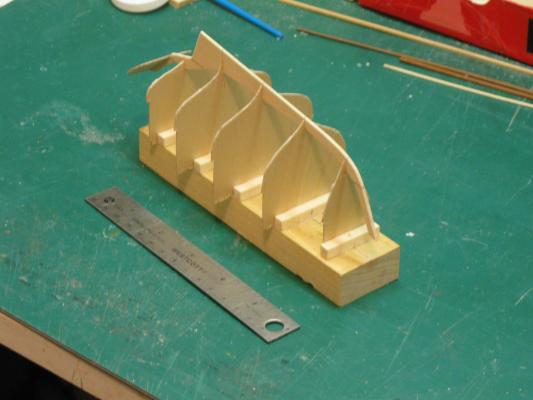

Twister, Frank, Harvey, all are welcome aboard. Come join the party on this first day of 2015. The building has begun but there’s still a long way to go. Harvey my boat is based on those drawings but instead of 25 feet mine will be 30 feet (7.5 inches) on deck and 10 feet (2.5 inches) in breadth. Also as mentioned earlier the cabin and cockpit will change. Bob

-

Well it’s time to start building again. I’ve been working on the plans for an early friendship sloop. The friendship sloop was originally a fishing boat similar to the Muscongus Bay lobster smack, but since it did not have a centerboard it became popular with the cursing and day sailing crowd. That is the way I plan to build this one. Start with the plans drawn by Chapelle, remove the fish well and enlarge the cabin. I plan to hold to Chapelle’s sail plan with two head sails no shrouds and no topsail. First I scanned Chapelle’s plans into the computer and drew the keel parts and bulkheads. After planking the bulkheads will be removed except for the lower portions which will become the floors. Now it’s time to slice up some wood for the planking. Bob

-

Beautiful woodwork, your detail work is fantastic. Bob

- 26 replies

-

- louise

- constructo

-

(and 1 more)

Tagged with:

-

A very long extension cord. Bob

- 176 replies

-

- muscongus bay lobster smack

- Midwest Products

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.