-

Posts

6,642 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by wefalck

-

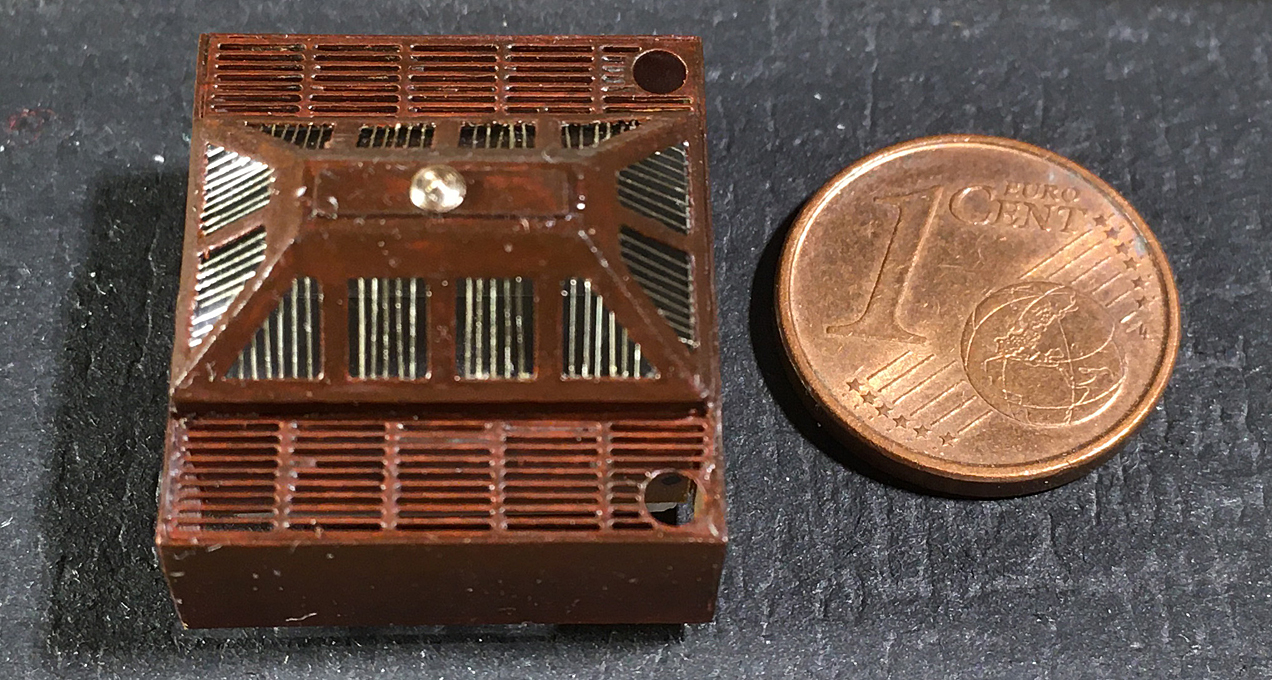

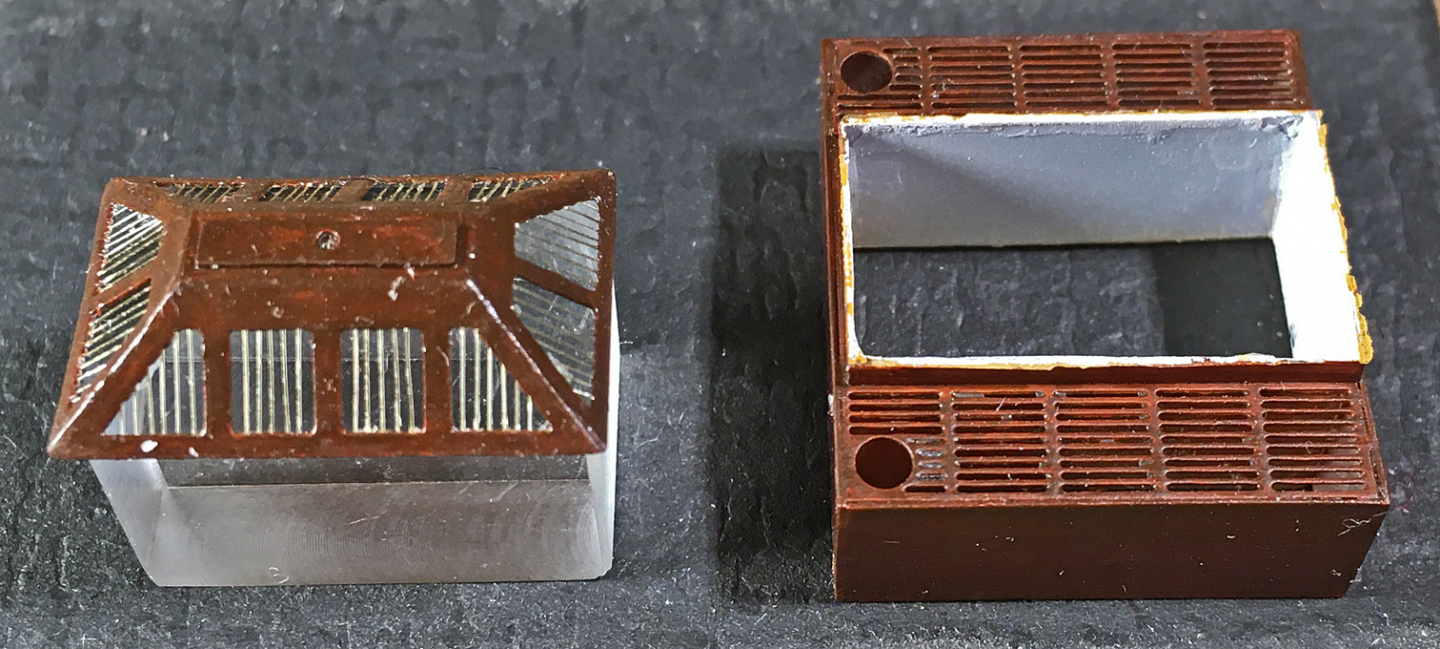

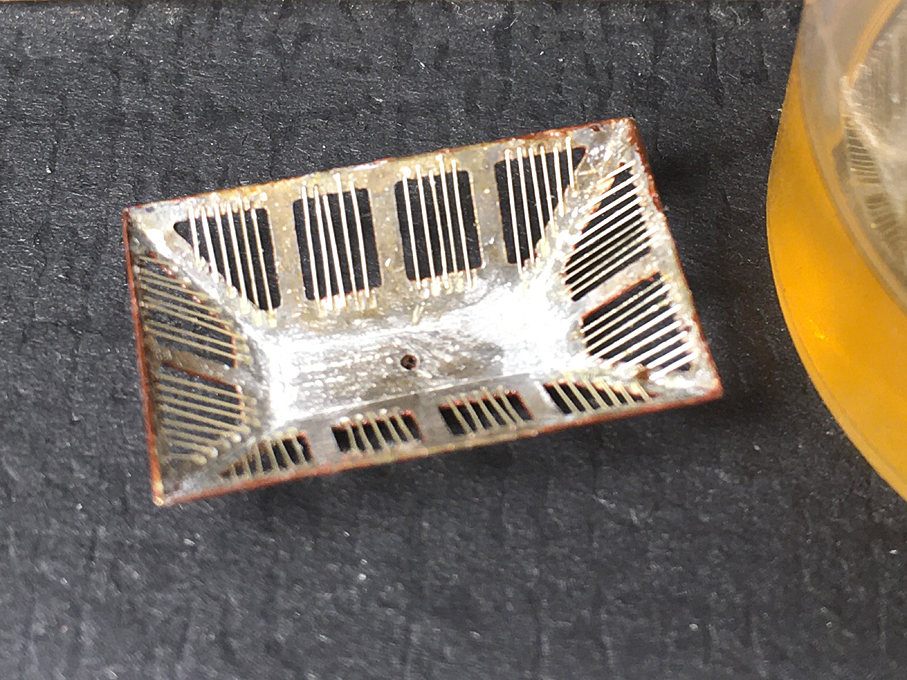

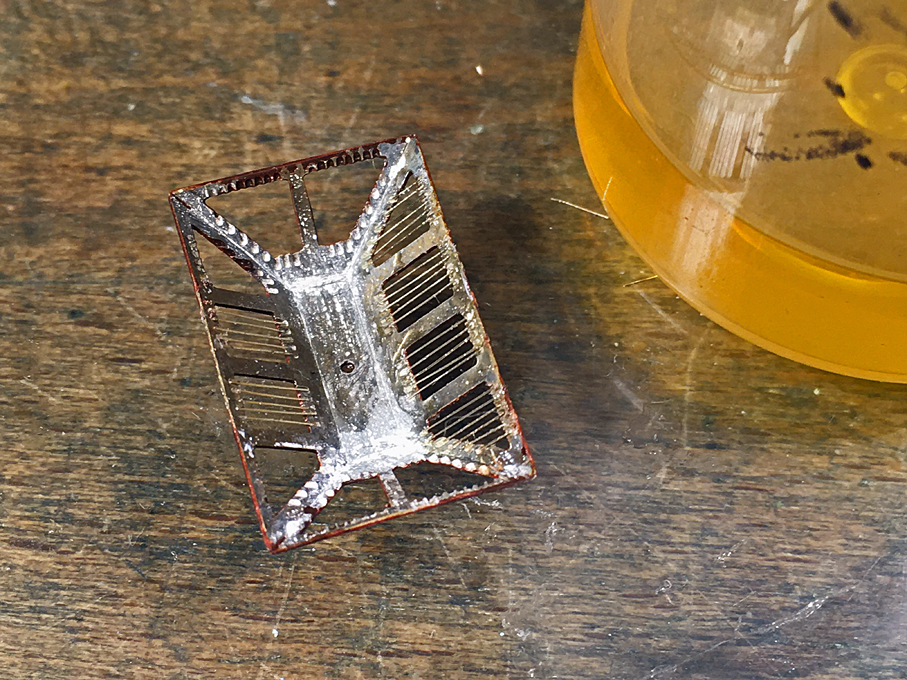

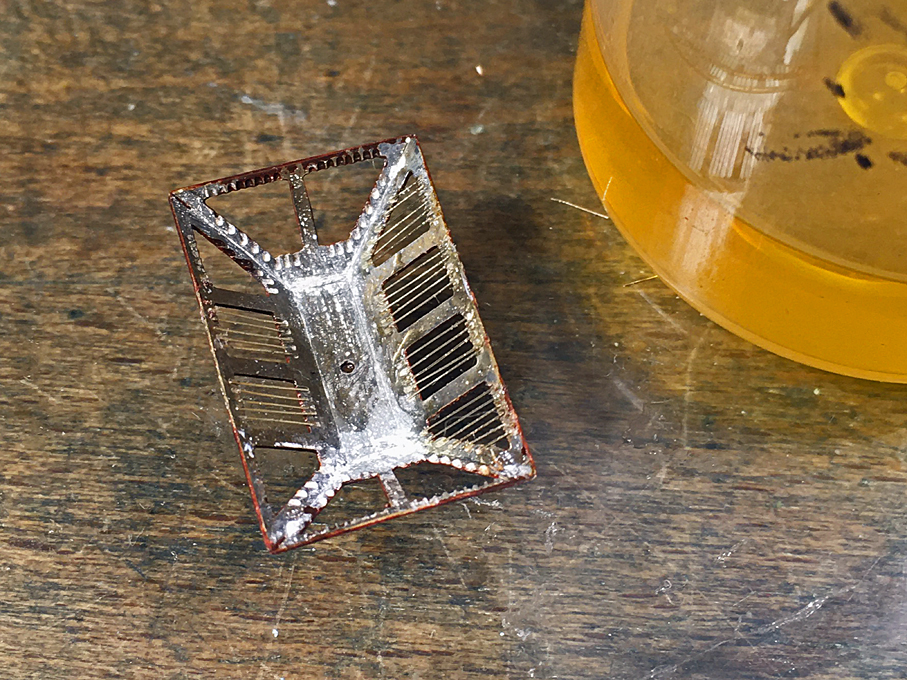

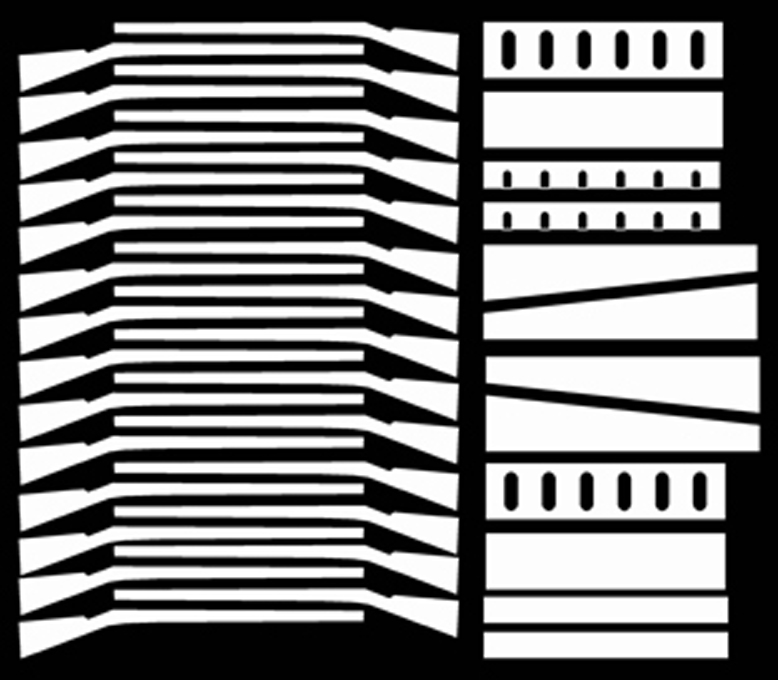

Keith, these wires are nearly ten times the size I needed ************************************************* Completing the skylights 1 The basic structures of the skylights had been produced a long time ago, but completion was delayed until the painting stage and just before fitting onto the model, as many of the details are very delicate and could be easily damaged during storage. The large engine-room skylight had been constructed from etched brass and bakelite paper parts over a Plexiglas plug milled from the solid. After the different parts had been painted it remained to insert the brass protecting bars. For these, notches had been etched into the underside of the frames to ensure the equidistant positioning of the bars. The bars were cut from 0.1 mm brass-plated copper wire. A diameter of 0.1 mm is equivalent to 16 mm in reality, which is probably too heavy for such bars, but this was the thinnest brass-coloured wire I could find. I have also dark-brass coloured molybdenum in smaller diameters, but it proofed too difficult to cut to exact dimensions in such short lengths due to its hardness. The etched fret for the engine-room skylight The wires were cemented using shellac. To this end I made myself a solution of shellac in alcohol with a consistency of thick honey. This solution is very tacky and stays so for an hour or so – plenty of time to position the short lengths of wire and enough time to cut new ones, if they should jump off your tweezers. A drop of alcohol will also redissolve the shellac should further adjustments be needed. The process of cementing the protective bars with shellac Installation of the bars complete Outside view of skylight cap The skylight received a base-coat of Prince August ‘wood’, followed by a wash of ‘transparent mahogany’. To give this mahogany simulation some ‘depth’ a couple of coats of Vallejo ‘satin varnish’ were added before the bars were installed. Finally, the frame, the Plexiglas plug and the skylight cap were assembled. A small turned brass button was added to simulate the vent – the actual look is conjectural, as it is barely visible only on the very first photograph that was taken of SMS WESPE. The skylight cap fitted to the Plexiglas-plug The two holes in the grille will eventually receive two cowl-vents, but these will be installed later in the process, as their handles are very flimsy. The assembled engine room skylight (I have to take some pictures in diffuse light with the DSLR – these iPhone close-up snaps under the bench-light emphasise all the imperfections …) To be continued ....

-

Nice job on the cleats ! How will they be attached, with brass pins ?

- 153 replies

-

- Ancre

- Bruno Orsel

-

(and 2 more)

Tagged with:

-

SMS Karlsruhe by Wreck1919 - 1/100

wefalck replied to Wreck1919's topic in - Build logs for subjects built 1901 - Present Day

Another project that I had missed so far, perhaps because it is somewhat outside my 'time-frame' (19th century). Very nice work on the slip-hook. Are the pieces for the shackles etched or stamped ? Talking about the slip-hook: are you sure that it is attached that way to the anchor-chain ? I thought these slip-hooks were used at the end of chain-stoppers (short chains or wire-strops), hooked with the opening part into the anchor-chain, while the other end was shackled to an eyebolt on deck. -

Me too, I somehow missed this project so far ... I have been pondering something along these lines for several years - having been impressed by the phantastic models of early iron-clad battleships, for instance in the Musée de la Marine in Paris (https://www.maritima-et-mechanika.org/maritime/paris/frenchironclads.html), the Museo de Storico Navale in Venice (https://www.maritima-et-mechanika.org/maritime/venezia/museonavalevenezia-1.html), or Museo Naval in Madrid (https://www.maritima-et-mechanika.org/maritime/madrid/madrid.html). Though on the real ship the armour belts would have been painted, on these models the steel is left visible, making a nice contrast with the copper-sheathing (the ships were wood or composite-built) and stem/stern posts and rams in bronze. Steel as a model-building material is discouraged by conservators (see article here on MSW on this subject), due to its susceptibility to rust. A few weeks ago I happened to participate in a restauration seminar of the Musée de la Marine and asked them, how they conserve these iron-clad models. Apparently they treat corrosion with a rust-converter, that is a phosporic acid solution (as you would use on your car), to solidify the rust and turn it black, followed by a coating in 'Renaissance Wax'. Looking forward to more updates here ...

-

Realistic Water

wefalck replied to taylormade's topic in Painting, finishing and weathering products and techniques

As matter of fact, the miniaturis McCaffery describes in his book also, how he carves the seas from a block of wood. This requires, however, to have a big chunck of suitable wood - unless you really work in very small scale. -

Realistic Water

wefalck replied to taylormade's topic in Painting, finishing and weathering products and techniques

Here is a text I wrote some years ago on the topic: https://www.maritima-et-mechanika.org/maritime/tips/makingwaves.html, with links to examples. Using epoxi-resins to imbed plastic models can be dangerous, as the curing reaction is exothermic and can melt down your model ... Personally, I tend to go down the plaster-road (traditional plaster-of-Paris or the modern acrylic-based repair plasters). You can shape it wet and carve it dry. When completely(!) dry, give it a good coat or two in sanding filler to close the pores and you are ready for painting. Wave crests and likes are build from acrylic gel to which one can add 'micro-balloons' for volume. Note that some areas the water may have a glossy appearance, while the surface in other areas is disturbed by gusts of wind. I give the whole surface a good and wet coating of glossy acrylic varnish. The disturbed areas are indicated by stippling on acrylic varnish with stiff bristle-brush. -

Roger, this is indeed another possibility - in principle. I doubt, that say 0.05 mm thick brass or even steel sheet would be stiff enough for the process of photoetching. At least not under artisanal conditions at home. There are photoetched seat-belts for aircraft models that look very good, with buckles and everything.

-

Thanks again, gentlemen, for your kind words ! There are a couple of (semi-)commercial sources of flat wire: it seems that certain guitar strings are wound with flat brass-wire, which could be one source. The other one are NiCr-wires used in various heating devices, which not only use round wires, such as in toasters, but flat ones as well. In Vienna we had a supplier that catered for the repaired trade and had all sorts of such flat wires - they should exist in other parts of the world as well. Apart from rolling with a steel bar on a flat, hard surface, short lengths of a defined thickness I can also produce with my horological jewelling press (that I got cheaply of ebay, because no tools came with it), for which I made custom anvils.

-

Probably true, but the Navy handled things differently from the Army. It seems that only the side-arms have been personal weapons.

-

Thanks for the kind words, gentlement ! Roger, the rifles were not kept in the barbette for storage, but only when 'battle ready'. There is a storage area in the rear of the deck-house, away from the seamen's quarters for a total of 36 rifles. So basically every crew-member could be issued with a rifle. I don't know, whether the seamen were issued 'personal' rifles in the Kaiserliche Marine, or whether the rifles were assigned to the ship. One thing I wondered though was, whether the rifles were supplied with (leather) muzzle covers. So far I have not found any information on this. Certain cleaning and maintenance utensils were not issued per rifle, but for groups of rifles - there are old records available on the delivery of the rifles from the factories to the Navy that indicate this.

-

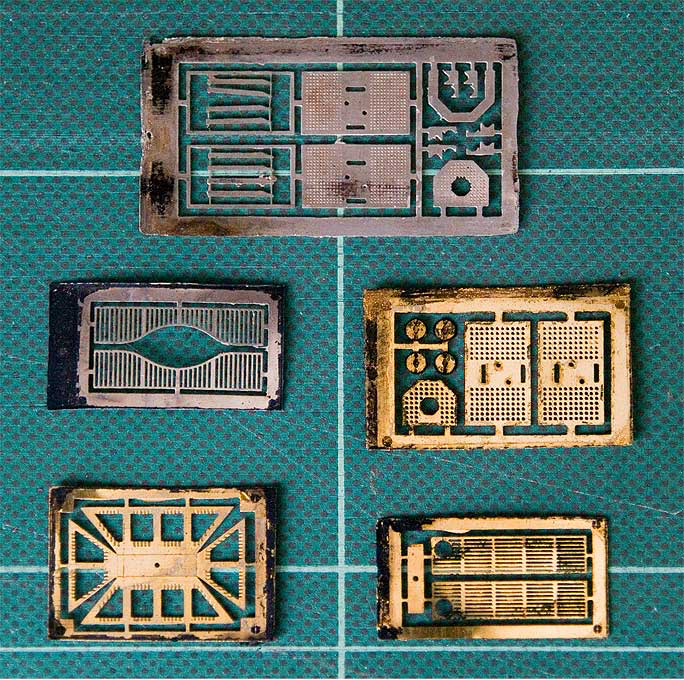

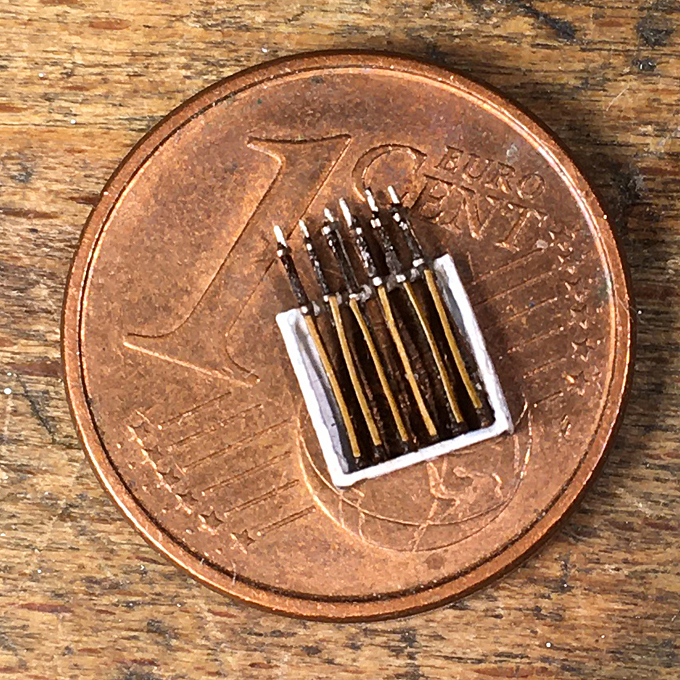

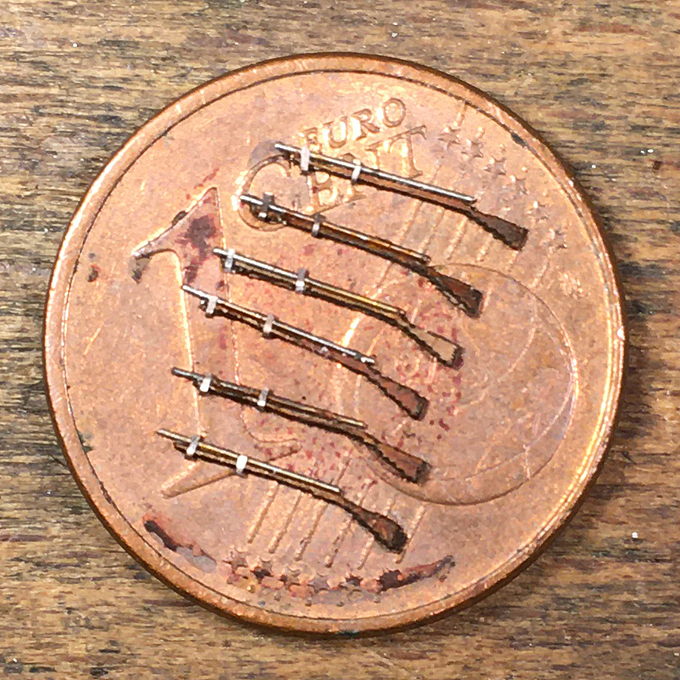

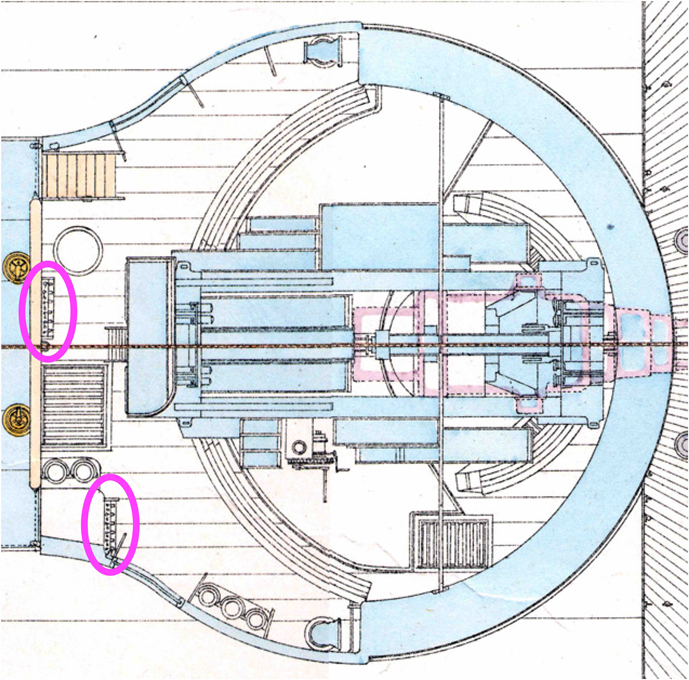

An enigmatic feature in the barbette On the plan view of the original drawings from the mid-1880s two enigmatic features appear, but they are not represented in the cross-sections, which could have provided further insight. These featured have puzzled me for a while until I realised that the oval shaped items look like the cross-section of a rifle-butt – we are looking down onto two rifle-racks. This interpretation was confirmed, when I came across a later drawing that showed the same feature, but with an annotation. Enigmatic feature in the barbette Warships at all times were provided with some small arms to fend off boarding-parties, or to form boarding- or landing-parties themselves. According to RECKENDORF (1983) ships of the Imperial German Navy at that time in question were provided with the Jägerbüchse 71 and the appropriate side arm. The Jägerbüchse 71 is a refined version of the Gewehr 71 that was introduced after the Franco-German War 1870/71 to replace the famous ‘Zündnadelgewehr’. Jäger stands for hunter and Büchse for rifle. Compared to the standard infantry weapon Gewehr 71, the Jägerbüchse was more precisely manufactured/inspected and had a finer trigger, as the Jäger-batallions received better gun training and a good proportion recruited from the hunting and forestry professions. Both weapons were still single-loaders, chambered for metal cartridges. In the cited book and on the Internet I found good photographs of the rifle. At 1:160 scale it is only 7.8 mm long, so requires considerable simplification. I drew the stock to be cut from two layers of 0.2 mm thick Canson-paper using the laser-cutter. At the same time, I drew my interpretation of what the rifle-rack might have looked like, as I only had the plan-view. Template for laser-cutting the rifles and the rack The individual parts were laminated/glued together Zapon-varnish and painted using Vallejo acrylics. The rifles were fitted out with barrels from appropriate lengths of 0.2 mm tinned copper-wire. The rings that fix the barrel to the stock are flattened 0.1 mm tinned copper wire. As I still did not get around to build the miniature rolling mill for which I had drawn plans years ago, I flattened the wire by rolling a piece of round steel on a thick glass-plate. Jägerbüchse M71 in 1:160 scale As the tiny rifles are difficult to handle, they were glued into the already assembled rack at this stage using some satin acrylic varnish. Originally, I intended to complete them with trigger-guards made from 0.05 mm wire, but I did not manage to glue down the tiny 0.4 mm diameter rings, so I only added shoulder straps from rolled 0.1 mm wire that was painted in brown leather colour. These were also attached using satin acrylic varnish. Given the amount of work that went into constructing these tiny rifles, I decided to only equip the most visible rack with them. The completed rifle-rack To be continued ... ___________________________ RECKENDORF, H. (1983): Die Handwaffen der königlich preußischen und kaiserlichen Marine.- 172 p., plates, Dortmund (Eigenverlag).

-

What do you mean by 'anodised' steel wire ? Anodisation is normally a process that makes a metal corrosion resistant by kind of electroplating a dense layer of a defined oxide on it. It is mostly used on aluminium. In any case, an oxide layer is exactly what you don't want, when soldering, as you need the metal-metal contact. (Soft)soldering steel is possible, but usually requires a pretty strong acidic flux. So you need to clean the parts in an alkaline solution to neutralise the flux afterwards. Instead of steel, I would rather go for hard brass. Much easier to solder.

-

Not sure, whether I had posted this already, but some years ago I made myself a similar table on MS Excel. The formula to calculate the approximate diameter D in Millimetres from the tex-number I used is: D = =SQRT(tex/(Y*1000*100*PI))*10*Z where Y = density (g/cm^3) of the Material (for Polyester around 1.5 g/cm^3) Z = number of threads (ply) in the yarn The other numbers are derived from the definition for tex, wich is the weight of a defined unit of length of the yarn. The rest of the formula is the inverse formula to calculate the area of the cross-section from the diameter of a circle. Thus a two-ply Mara 220 of 13 tex does have indeed a diameter of SQRT(13 / (1.5*1000*100*3.1415))*10*2 mm = 0.105 mm

-

I don't know, whether the customs service at that time was associated with the navy, but it may be worthwhile to have word with the Brazilian Naval Museum in Rio de Janeiro: https://www.marinha.mil.br/dphdm/espaco-cultural-da-marinha I don't know how good the museum is, it seems to be relatively new, at least it did not seem to exist in the early 2000s, when I had been a couple of times down there.

-

Indeed, rubbing some graphite (soft pencil) over black give iron-work a sort of metallic feeling without looking too metallic. You could also rub some white and/or grey pastel onto the bottom of the hearth to simulate ash from wood/charcoal ...

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

As you have the mill, you fabricate an adapter for a hand-held drill that allows you to rise and lower it like on a drill press - the x-y-table than provides for co-ordinate drilling capability. Wasn't it Keith Aug on this forum, who showed some years ago such a gadget ? The hand-wheel on the y-column is not very conveniently located for drilling operations, put personally I like the screw-feed for drilling tiny, sub-millimetre, holes, as it results in less drill breakage.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

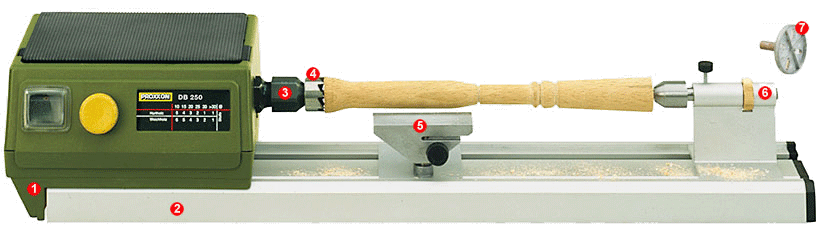

Joe Martin's book indeed is quite good, but is more or less written as a manual for Sherline machines (both lathes and milling machines). It should be easy to get in North America. In the UK there is a long tradition in writing such books, going back to the early 20th century. I found the older ones particularly useful, as they typically refer to simple techniques. It is difficult to name titles, but for instance this specialised on-line bookseller has a good selection in his catalogue: https://www.camdenmin.co.uk/collections/engineering-practice-skills. One may be able to get one or the other title in North America. As 'Clueless' was specifically referring to making masts and spars, there is a problem with many small metal lathes in the sense that their width between centres may be too small to handle such long parts. I gather one cannot have it all. For this kind of work perhaps the small Proxxon wood-lathe is a better and cheaper option (with the limitations of a wood-lathe, of course): https://www.proxxon.com/en/micromot/27020.php They offer also an extension bed that doubles the capacity to 500 mm between centres.

-

... one can argue about that.

-

An old rule is to buy a lathe with double the capacity (length between centres, swing) you think you'll need The main difference between a wood lathe and and a metal lathe is that on the latter the tool-bit is controlled by a cross-slide, while on the former it is guided by hand only. This means that only with a metal lathe you can produce objects with a well-defined geometry and dimension (unless you are really proficient in using hand-turning tools). Metal lathes also offer better and more varied options for holding parts to be machined. Apart from the common three- and four-jaw chucks, most small lathes also offer the option of using so-called collets, which are a more precise and safer option for small parts. Before buying any lathe, it would be probably advisable to read through a textbook on machining for modellers.

-

Nice metal work as always. Perhaps it is a question of perspective, but shouldn't the antenna sit in height more or less between the two rings to let the beam pass unobstructed ?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.