-

Posts

6,652 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by wefalck

-

Thank you very much for the friendly comments ! Well, G.L., that's an interesting question I have asked myself and various colleagues very knowledgable on the German navies, but no one could come up with a conclusive answer. It is drawn on the existing plans. One of my guesses was that it might have been for holding the lanyard to the steam-whistle, but at that stage no steam-whistle was fitted. Perhaps it was for a kind of course-indicator for the helmsmen ? It will remain an enigma. Keith, the WESPE-class gunboat had two steering positions, one on the bridge and one in the stern. Both where equipped with binnacles, but only the one on the bridge was equipped with engine-telegraphs. The stern one also had poor forward visibility. I gather it was meant only for emergency situations or perhaps when backing up. Pat, you are so lucky to have all these specifications. In comparison, very little is known about such details on German ships say before the 1890s. A good deal of the records have been lost during WW2, or rather in the chaotic weeks after 8 May 1945, when war-time storage places were either looted or the contents taken away as war-booty. Some archival material was returned from St. Petersburg in 1990, but even during the intermediate storage in the military archives in Potsdam material was stolen and popped up later on ebay et al. A group of volunteers from my association reviewed and catalogued in Potsdam the material returned from Russia in the early 1990s and found that in between visits material had disappeared, drawings cut out of bound material etc. At least sometimes such material did not disappear in someone's private archives, but was made available to others - I assume that the drawings on www.dreadnought.org might have been acquired in that way.

-

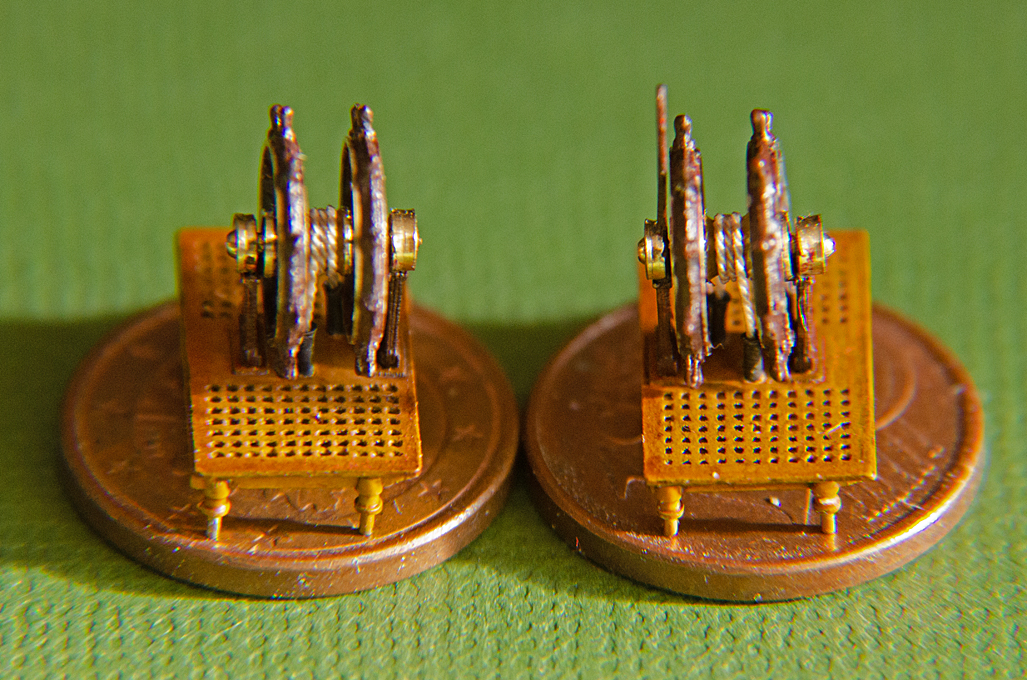

Assembly of the steering-stands Progress has been slowed down somewhat due to travels and bread-winning work … Much time has been spent painting various details, often beginning with a basic layer applied by airbrush and then detailing with a hairbrush. In many cases several coats of paints and washes are needed. In particular parts that are meant to resemble varnished or oiled wood will need a base-coat followed by washes of darker paint and again followed by several coats of varnish to increase the ‘depth’ of the colour. ‘Oiled’ wood is finished off with Vallejo satin varnish, while ‘varnished’ wood is finished off with a 1:1 mixture of Vallejo gloss and satin varnish. The satin varnish is not glossy enough to simulate varnished wood. Below are a couple of shots of the assembly of the two steering stands from the laser-cut parts produced earlier. The steering wheels and the brackets are painted in Prince August (Vallejo) transparent ‘mahogany’, while the gratings were given a base-coat of Prince August (Vallejo) ‘wood’, followed by washes of Schmincke ‘ochre’ to simulate teak. I have to take some better close-up shots, but the steering-rope leads into flared down-pipes fashion from 0.6 mm OD/0.4 mm ID brass tubes by widening one end. BTW, the steering rope looks a bit like an anachronism in 1876, when steering chains and even steam-steering was available. However, it seems that warships have retained this simple mechanisms for a while, presumably because it was easier to repair battle damage off-shore. To be continued ....

-

Trying to understand white balance

wefalck replied to Gaetan Bordeleau's topic in Photographing your work. How to do this.

Yes, a lot of lumen are important, in particular when one's eyes get older ... As I said in an earlier post I prefer to build in a light colour in which my models are likely to be seen in the future and this is likely around 3600 K. A temperature of 4500 K might be a good compromise between incandescent light temperature and daylight. -

Well, as I said earlier, in a POB construction or similar, where the interior of the hull is not visible, one can make the deck as thick as is practicable. Of course, one would need to make the bulkhead correspondingly lower and the waterways would need to be correspondingly thicker so that their difference(!) in thickness is to scale. I would advise against using coloured cardboard, as very few such materials are really light-fast. Also, it is rather difficult to get a clean sharp edge onto the cardboard, so that it butts cleanly against the waterway. I have been tossing for some time also with another idea, facing a similar problem as you, namely to print the pattern of the seams onto a decal sheet and apply this to an appropriately prepared piece of wood. Not sure, how well such a large decal would handle. Decal sheets are available for laser- and ink-jet-printers. Both need to be sealed e.g. with acrylic varnish. In my case I did not follow the idea through because I had to deal with a pattern of radiant planks and could not find any wood with a suitable grain.

-

Trying to understand white balance

wefalck replied to Gaetan Bordeleau's topic in Photographing your work. How to do this.

I have replace in our home almost everywhere the traditional incandescent bulbs with warm-white (3600 K) LED-bulbs, including the lighting in my workshop area. Currently, there are no LEDs that emit light of this temperature, so 'white' LEDs that emit at around 5550 K are covered with a yellow lacquer. Although this results in about 10% absorption losses, from the psychological point of view I find their light more pleasing and less factory- or hospital-like. In consequence, I also take my workshop photographs at this light and did not experience any problems with the white balance. However, different LED-bulbs or -lights (I also have a 3600 K indoor LED-floodlight in my workshop) may have slightly different light temperatures. -

Thanks for the praise, Bob ... ☺️ Sawn veneer is available down to 0.4 mm thickness, I believe, but rather expensive due to the waste generated during its production. There are sheets of low-grain veneers available in Europe for WW1 1:32 scale air-craft models, which are meant to be laminated onto styrene or polyurethane fuselages, that may be worthwhile looking into. However, the thicknes of the material is inconsequential in a scratch-built model, as one can account for it in the design. Say, sawn veneers 1 mm thick tend to be relatively cheaper than thinner veneers.

-

I have been using spotters for some years now. Interesting to know, that they also come in angled form - could be useful for touching up on the model. I also use this kind of paint-brush soap, but don't dip the brush into, but rather take some on my index finger and gently move the brush on the finger - you don't want to stub the delicate brush down onto a firm surface in order not to break the hairs.

-

This may be a sacrileg here on this forum, but at a 1:96 scale it may worthwhile to look into alternatives to actually planking the deck. One option could be to look for a piece of veneer or thin plywood with very little graining or virtually no graining, sand and dedust this carefully and then using a method called thermo-transfer to 'print' on the pattern of seams. There special thermo-transfer papers for laser-printers. The print-out is then put face down onto the wood and the pattern is iron-on - much like what the T-shirt guys do. So far, I have not done this myself for decks, but I used the technique to transfer drawings onto heat-resistant materials.

-

Certainly. There is currently a project going on here: http://www.shipmodels.info/mws_forum/viewtopic.php?f=13&t=314249 Back in the 1960s at least the German model supplier Graupner offered styrofoam hulls and they offered a special primer (no water-based acrylics yet) that would not eat into it. They were discontinued after a few years in favour of vacuum-formed hulls made from ABS. Event with paint on, they would have dented relatively easily. My very first model had such hull. Some 35 years ago I devised a POB construction for an iron tug by which I cut the bulkheads from 0.25 mm thick brass sheet, the keel from 0.5 mm brass sheet and filled the spaces with a special hard foam, which is essentially foamed-up Plexiglas. Very good material to work with, but difficult to get - at that time I had easy access, as my father worked for one of the daughter companies of the Plexiglas-manufacturers. The hull then was plated with copper-foil to imitate the rivetted iron plating. The reason for choosing these somewhat unorthodox materials was, that I wanted to make the bulwark-stanchions of this flush-decked tug in one piece with the bulkheads and at scale-thickness. For my next project I will probably use a similar technique, but use 1 mm Plexiglass for the bulkheads and the keel-piece. The spaces will then be filled with this acrylic foam to prevent the thin styrene planking from sagging. The reasons is again, that this going to be a flush-decked sailing ship and I would like to make make the bulwark-stanchions in one piece with the bulkheads for easy definition of the hull shape.

-

Trying to understand white balance

wefalck replied to Gaetan Bordeleau's topic in Photographing your work. How to do this.

I am very well aware of the storage space issue, but by not saving the RAW-image one looses a huge amount of prosessable information and effective resolution. In RAW the original sensor information is saved pixel by pixel, while in JPG more or less severe interpolation and averaging between pixels is used in order to compress the amount of information. This results in a loss of colour resolution, sharpness, and overall effective resolution of the image, even though the number of pixels has not changed. Watching myself, I noted that in many, if not most cases, the first shot of a series is the one I retain ... -

Trying to understand white balance

wefalck replied to Gaetan Bordeleau's topic in Photographing your work. How to do this.

Yes, but one can/has to convert them in to JPG at home, in the digital lab. So, I never clogged up the memory cards with these, even though all of my digital DSLRs had the possibility to save both formats at the same time. -

Trying to understand white balance

wefalck replied to Gaetan Bordeleau's topic in Photographing your work. How to do this.

You must have been a very observing child ! I remember that my father told me about the colours of shadows etc. and he also had various books, some of them dating back to the 1940s, on colour photography that I read in my teenage years and that I still have. I never had the possibility to set up a colour lab, so I never had the possibility to manipulate prints, but it was always on my mind how to change this or that on the image. When reasonably priced slide scanners came onto the market, this opened up this possibility and over the last 15 years or so, of course digital photography. And I agree, the function in Adobe Photoshop to manipulate 'highlights and shadow' is very useful and I use it frequently to make up for less than ideal lighting. This is a situation one frequently encounters during travelling, when there is no time to wait for different light/weather, or in museums, where one depends on what light is put there. I find Photoshop particularly useful to manipulate images taken in museums for information purposes, not to make 'nice' or technically 'correct' photographs. In these 'technical' photographs it is important (for me) to be able to identify details, even on the expense of 'white noise', when light levels are low. As I always shoot in RAW, I can also adjust the white balance, if needed. Again, using the RAW-format to save the primary image gives one the possibility to adjust e.g. the white balance or tonality of an image in order to achieve the desired effect. I often have a specific 'picture' in mind when taking a photograph, but not always the primary image comes out like that, so the image processing software provides the tool to create this 'picture' by post-processing: http://www.imago-orbis.org -

Trying to understand white balance

wefalck replied to Gaetan Bordeleau's topic in Photographing your work. How to do this.

... and LEDs don't give off kilowatts of heat, as the halogen studio lamps do - guess how I learned this already in my teenage years Another plus is that you can choose LEDs of your preferred light temperature range. -

Pizza- or baking oven ?

-

Trying to understand white balance

wefalck replied to Gaetan Bordeleau's topic in Photographing your work. How to do this.

What you are talking about is a too high contrast in the image. Like in the old days the film, today the camera sensors can only handle a certain contrast ratio. The consequence is that 'lights' 'burn out' and 'shadows' become 'blackened out'. With post-processing, e.g. Adobe Photoshop, you can increase the apparent dynamic range, but it will increase the white noise usually. However, the colour of white or black pixels cannot be changed. In the 'studio' you can reduce the contrast by illuminating dark areas and by using e.g. a less stark background, say grey or green instead of white or black. When I am photographing parts for my building logs, I use a sheet of medium green paper as background. The rationale is that it provides a medium contrast, green is a less frequent colour on (my) models, so there is a good colour contrast, and a medium green is perceived by most people a soothing to the eyes (which is why we have green leather desktops, writing mats, etc.). It is an old wisdom among photographers (knowledegeable hobbyist and professionals alike), that a a blue sky with nice white cumulus clouds is the the best light conditions, as it provides lots of lumens of diffuse white light. In consequence it is common mistake modellers make to drag their models out to the terrace or balcony on a bright sunny day without clouds. For the same reason professional photographers doing e.g. fashion shots have an army of assistants running around with diffusing reflectors on tripods - to reduce the contrast and light up dark areas. -

Proxxon TSG 250/E disc sander

wefalck replied to DaveBaxt's topic in Modeling tools and Workshop Equipment

Actually, for a change it is not the Pandemic that is to blame. It's a development that began 15, 20 years ago. One factor was that due to the decreasing amount of snailmail with the advent of email, the postal services had to look for other revenue and increased the parcel prices. The second, transatlantic issue is that about 15 years ago the US postal service decided to discontinue 'surface mail' as an option, offering only the much more expensive air-mail option. If you didn't mind to wait for a couple of months, the 'surface' mail was a quite cost-effective option to get stuff over from the USA. I gather it works both ways. In addition, the EU has tightened the rules for imports this year, basically now you pay import duties (equal to the EU VAT = 19% in most Member States) from the first Euro of value (sales price plus shipping costs!). Previously this was levvied only on values above 40€ ... -

Proxxon TSG 250/E disc sander

wefalck replied to DaveBaxt's topic in Modeling tools and Workshop Equipment

Remember you US guys that American machinery, unless it is imported here in bulk, is just too expensive for us Europeans with the huge shipping costs and the customs duties (around 20% I think) on top of it ... A tilting table is very useful I think for working on longer pieces and for sanding compound angles with the aid of the adjustable fence. -

I seem to remember from my boyhood days when I was flicking through model suppliers catalogues that there were two weights of silk fabric and 'Japan' paper for covering airplane models. Another option (that I have not yet tried out myself) is serigraphy cloth that comes in many different weights/thread counts. You can get it on ebay.

-

I think your problem will be that a deck is actually curved in two directions, something that carbon-fibre sheets don't like too much I believe. Not sure, whether you actually would need the deck to add strength to the model, if the hull structure itself is already quite substantial as it seems. Maybe a sheet of 1 mm aluminium would be sufficient. It's relatively cheep and would not need a lot of surface preparation. In the old days aircraft models were built with a balsa-wood frame and silk-span (either silk fabric or 'Japan' paper) cover. It was attached with a fast-drying varnish that also shrunk during the drying process, thus producing a sort of 'pre-stressed' structure. It was also practice to not only cover the wings in this way, but the planked balsa-wood hull for added strength. However, such processes would require a lot of work to achieve a surface that can pass for sheet iron/steel.

-

Trying to understand white balance

wefalck replied to Gaetan Bordeleau's topic in Photographing your work. How to do this.

I was also puzzled how difficult it was to read the purple '5' on the blue Ishihara-plate, but both my MacBook Air and my iPhone SE displays look the same. It puzzled me, because, as noted earlier, I passed the blue-purple test under the supervision of a university ophtalmic hospital. -

Trying to understand white balance

wefalck replied to Gaetan Bordeleau's topic in Photographing your work. How to do this.

Well, some people don't seem to have much of a colour vision, my father was one of them. I remember that he asked me once to fetch a particular blue book from his study, but I had to return with empty hands, as I could not find the book at the indicated location. When he finally fished himself the book from the shelf, it turned out to be green He never wore coloured ties only silver ones - just to be on the safe side. -

In fiberglass reinforced resin, the fiberglass provides for tensile strength, not watertightness. The resin provides for compressive strength. The tensile strength is needed (probably) in RC models. Carbon fibre is probably going to be very expensive and likely to be an overkill for a static model, where the tensile strenght provided by carbon fibre is not needed. I would think carefully what you actually wanted to achieve with your layer of balsa-wood, what its intended function was. That then probably indicates what properties you are looking for in an alternative material. Is it supposed to be a structural material or just to provide a smooth surface.

-

Are you talking about the reefing points that dangle from the sails ? They would be on both sides. There are different ways of doing them in real life, but on a model they can be simulated by making a 'figure-of-eight' knot in the thread, pushing the rope through a pre-made hole and then making a second 'figure-of-eight' knot, which is pushed as close to the sail as you can. BTW, the holes in the sails for the reefing points and for lacing the sails to the mast and spars are protected by 'grommets'. These can be simulated by making dots with suitably tinted white glue that are pierced through after drying.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.