-

Posts

13,368 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

Maury: The are chemicals specifically for 'antiquing' brass and copper. These create a brown rather than black patina. There are other chemicals that give different color finishes. For example: https://jaxchemical.com/product-category/colorants/

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Slow and neatly does it! You're off to a good start.

- 70 replies

-

- Lowell Grand Banks Dory

- Finished

-

(and 1 more)

Tagged with:

-

Um, wish I could take credit for the technique, but I saw this some time ago on MSW: another benefit of belonging to this wonderful forum!

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

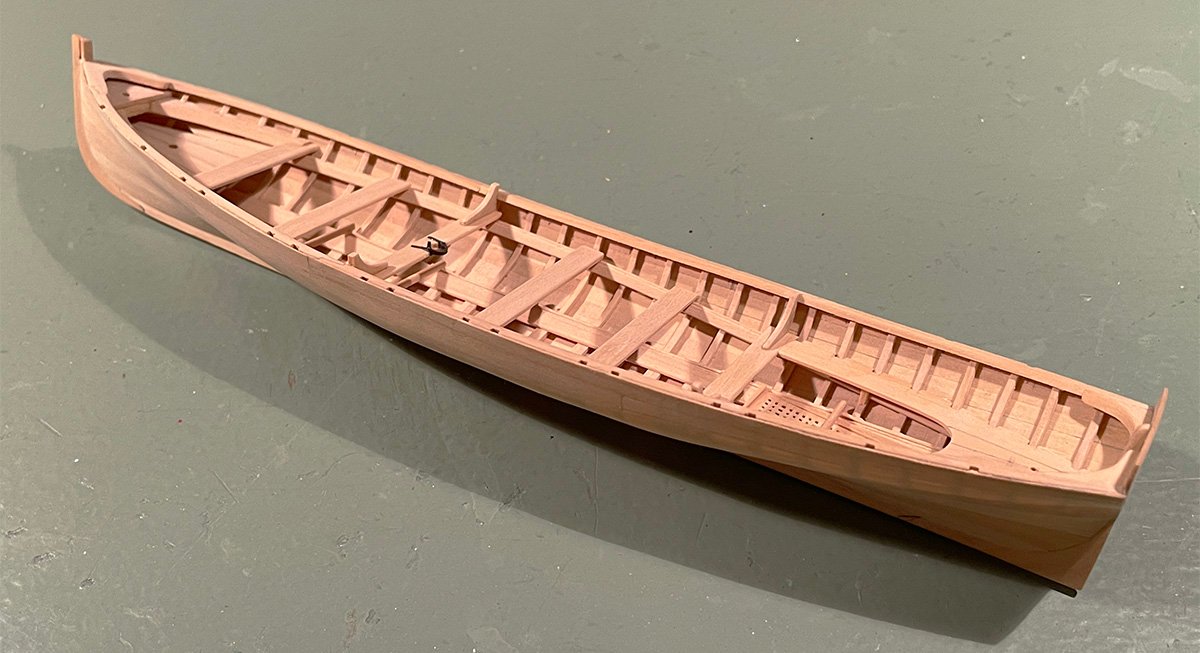

Moving on, all the standards (inverted knees) have been added to the thwarts and the model removed from the 'girdle'. As the standards are so small, I've found it easier to install them oversize and then reduce them to final dimension when firmly glued in. You can see some 'as installed' ones and other standards finished. To shape them, I use micro chisels and a custom sandpaper stick. Next are the pillars under the thwarts. To turn such thin pieces, it is necessary to support them. I cut down a piece of brass tube and fixed in in the tailstock so that the stock can revolve freely in it. Notches mark the main dimensions of the baluster so that I can replicate the turning.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

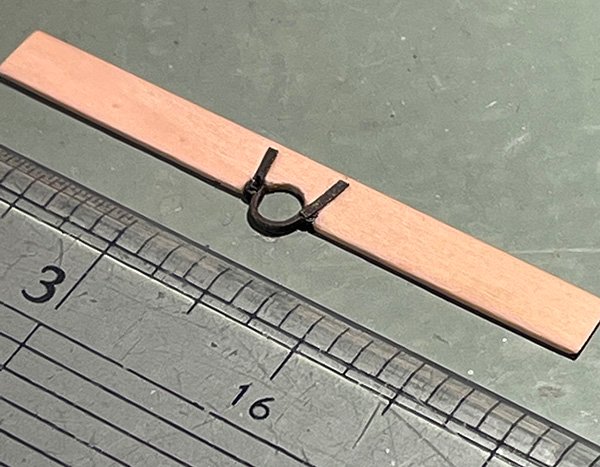

Thanks for looking in and the compliments. Moving on, the thwarts are in and the hull now fixed to within an inch of spec'd beam. A little miniature metalwork produced the clasp for the mast. It was fabricated from brass, silver soldered and then chemically darkened rather than blackened. I felt black would have been a little too much contrast to the wood color.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Coming along nicely, Bob. Some filler is inevitable, so don't sweat over a less than perfect planking job. Each model you build will improve your skills with the experience that you gain.

- 52 replies

-

- Model Shipways

- muscongus bay lobster smack

-

(and 1 more)

Tagged with:

-

Definitions

druxey replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

'Rotten to the core', Bob! -

Definitions

druxey replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

Harris cut is a straight diagonal cut for joining two pieces end on. The false keel it the usual application for this joint. Cyphered joints are longitudinal half- joints, edge on. See and read: https://books.google.com/books?id=TWsmw-QqvmAC -

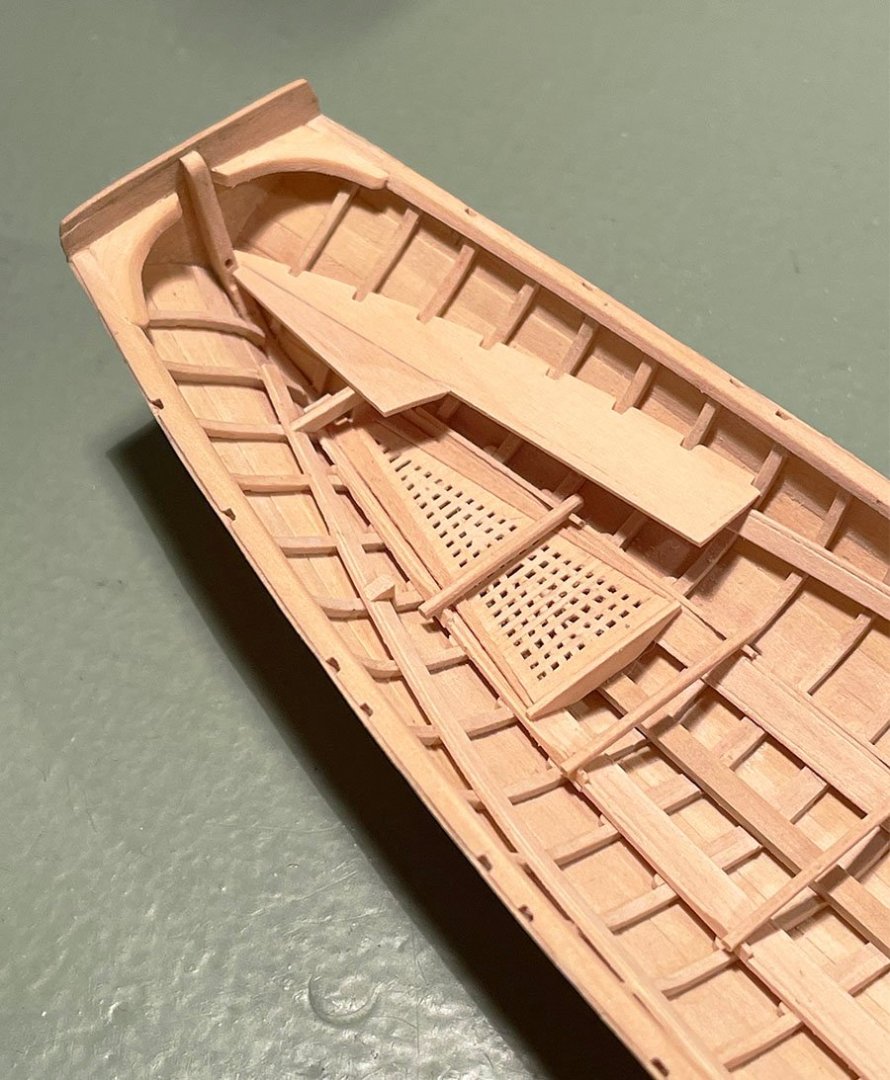

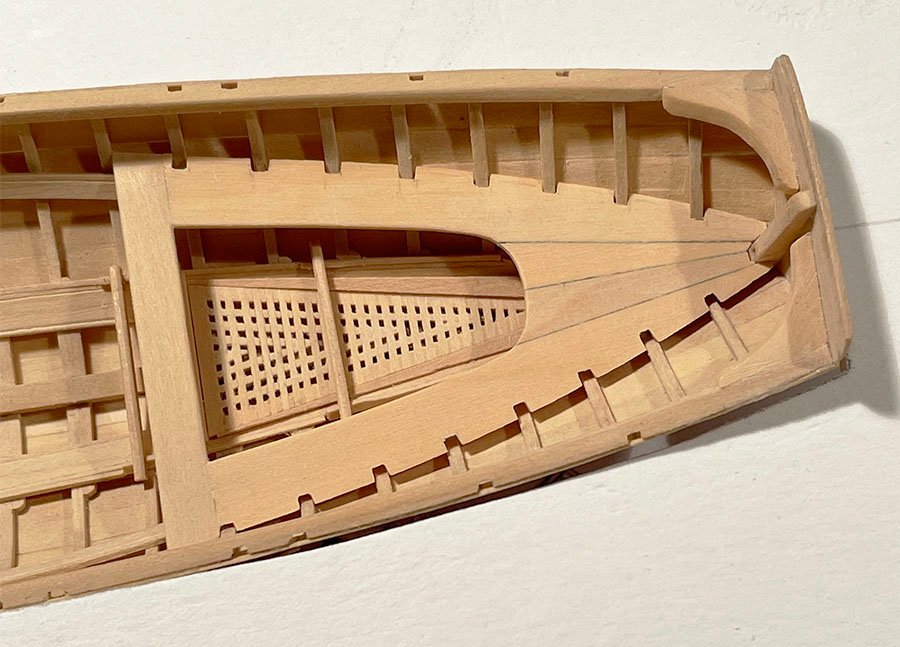

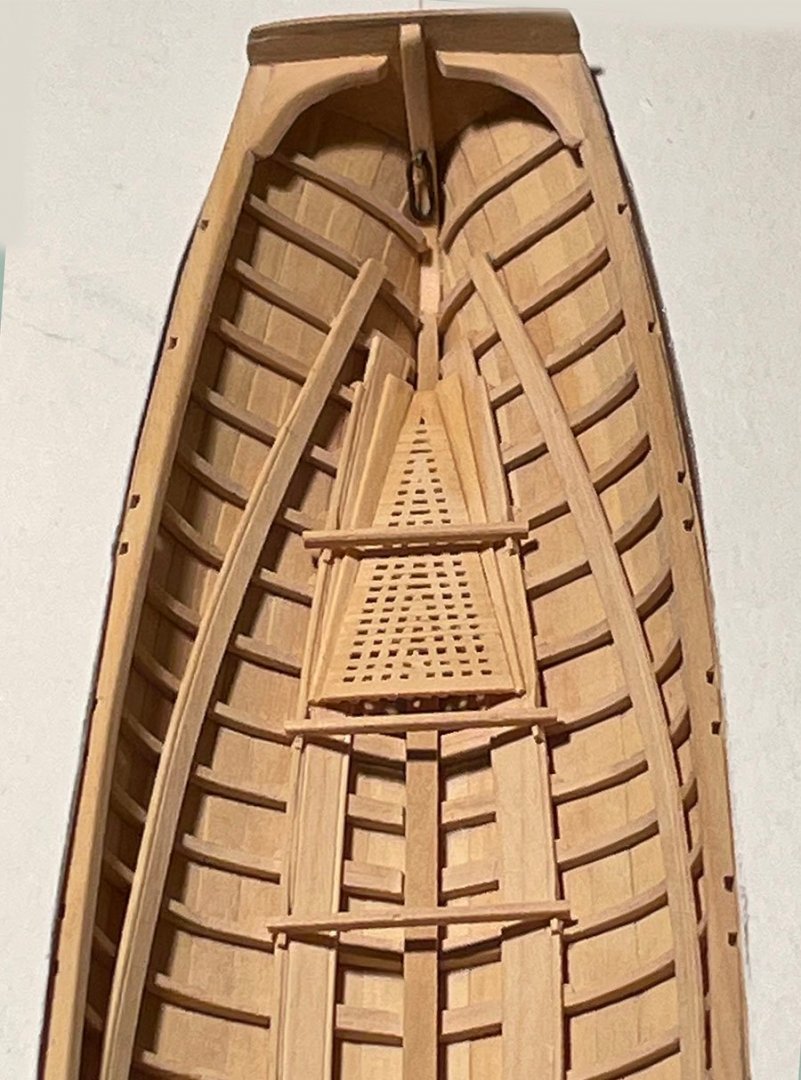

The stern sheets have been made and installed. These were made in two halves to make fitting them easier. The scores for the frames were under-beveled considerably to fit. There will be small turned pillars under the thwarts. Six will need to be made.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Perhaps part of the problem is conflating excellent draftsmanship with researched historical accuracy. The two are not always mutually inclusive. I would tend to accept both Frank Fox and Richard Ensor's work with less question than John McKay's. For instance, there are questionable items in the AOTS book by McKay and Coleman. Although beautifully delineated, for one instance, joggled deck planking was of later origin than 1779. A good friend of mine, the historian Karl Kessler, declared: "This is a very small book. Read elsewhere and read critically, always."

-

Practicing a new skill on scrap is a good strategy!

- 160 replies

-

- Model Shipways

- norwegian sailing pram

-

(and 1 more)

Tagged with:

-

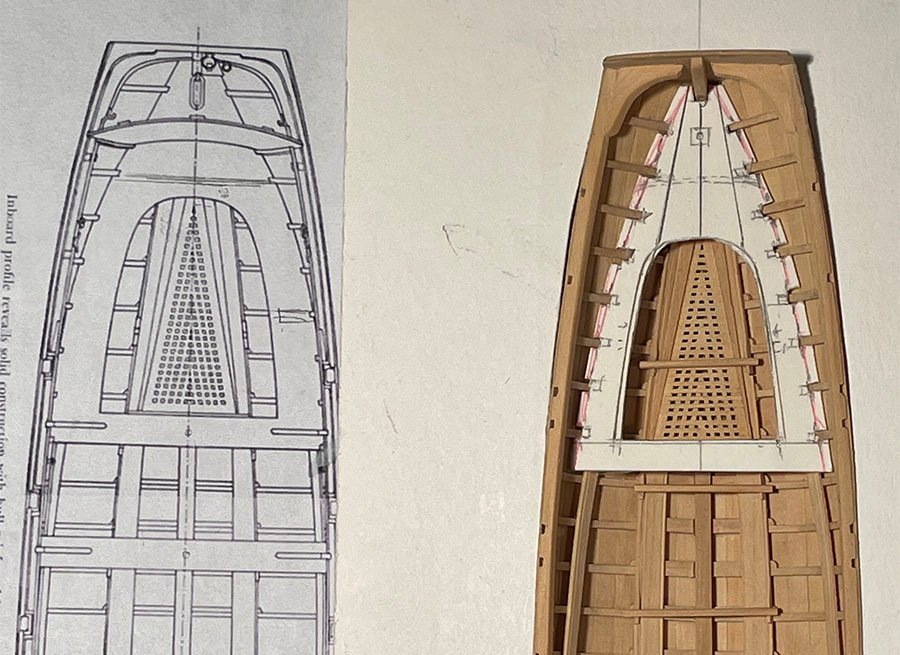

So, onward again. Next are the stern sheets (seats). Here is an interesting departure from the published plans. The card pattern has a distinctly different outline when fitted to the model. I checked immediately whether the riser height that supports the thwarts was too low. It it is on spec. If the lines plan is true (and it faired out perfectly) then the plan of the stern sheets must be wrong. This, I suspect has to be the case, so will continue using my pattern shape. Beneath the stern sheets is a low partial bulkhead and two supporting knees. These are not shown other than in section on the profile but are seen in the photograph, post #203. (The knee is only just visible to the right of the anti-hogging post added by the museum.) These photos are as good as a time machine! Thank you again, Eberhard. Thanks for dropping by, and remember to sign on for the Trafalgar project!

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

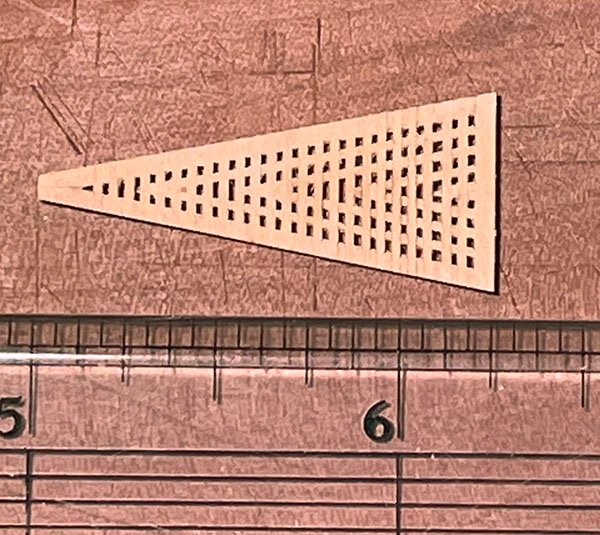

Rarely has such a small part taken so long to make. However, it was finally done (pic before cleaning it up), refined and then installed. The white 'background' is actually Foamcore board with a cut-out to act as a kind of girdle, cinching the hull in to the designed beam. I've found that carvel hull boats always tend to spread a bit, whereas clinker boats do not. In this instance, the spread was four scale inches. The hull will stay in this until the thwarts and their standards (inverted knees) are installed. This will stabilize the hull shape.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

YOUNG AMERICA 1853 by Bitao - FINISHED - 1:72

druxey replied to Bitao's topic in - Build logs for subjects built 1851 - 1900

Apart from the superb quality of our build, your rate of progress is remarkable!- 257 replies

-

- young america

- Finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.