-

Posts

13,377 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

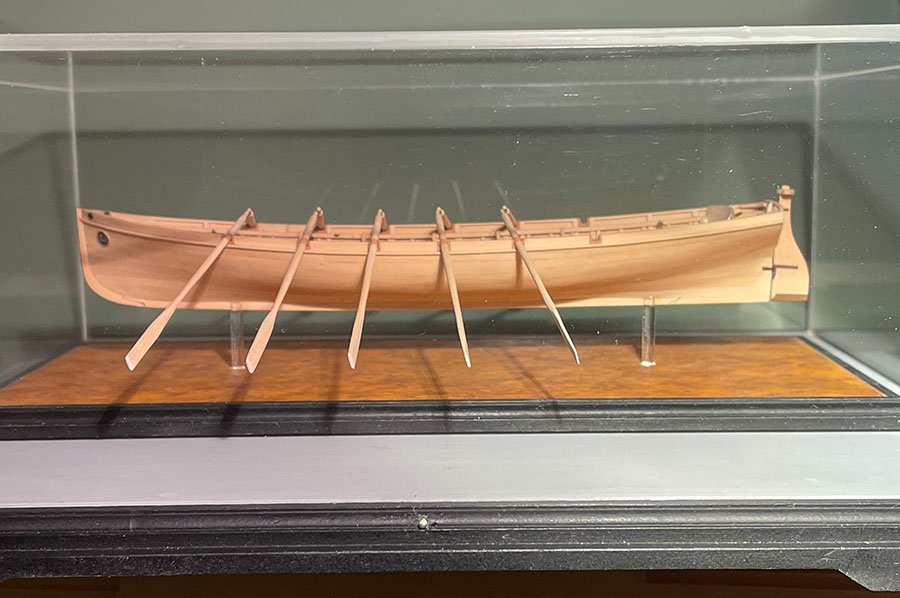

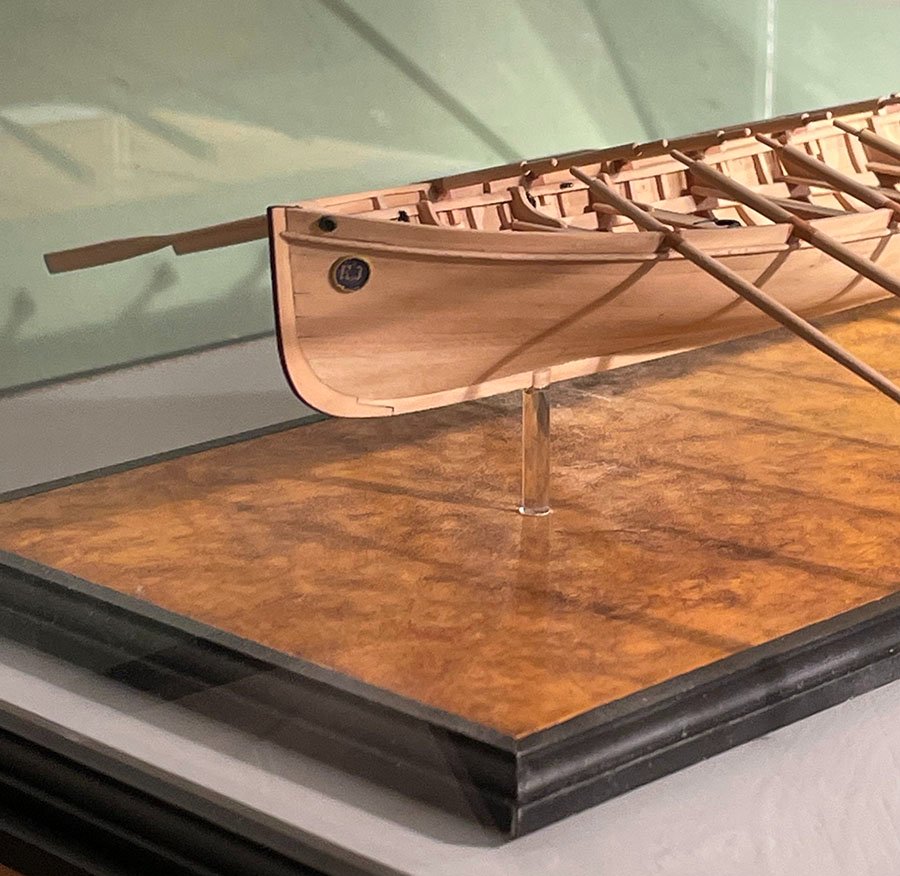

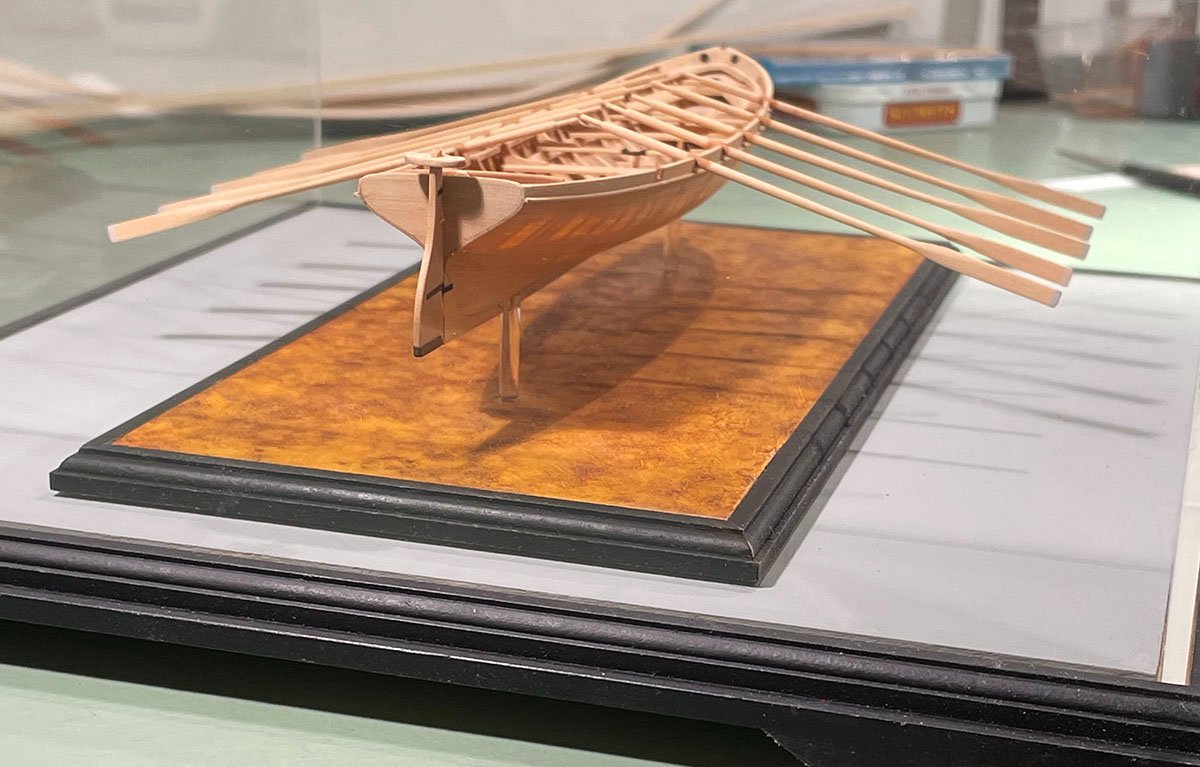

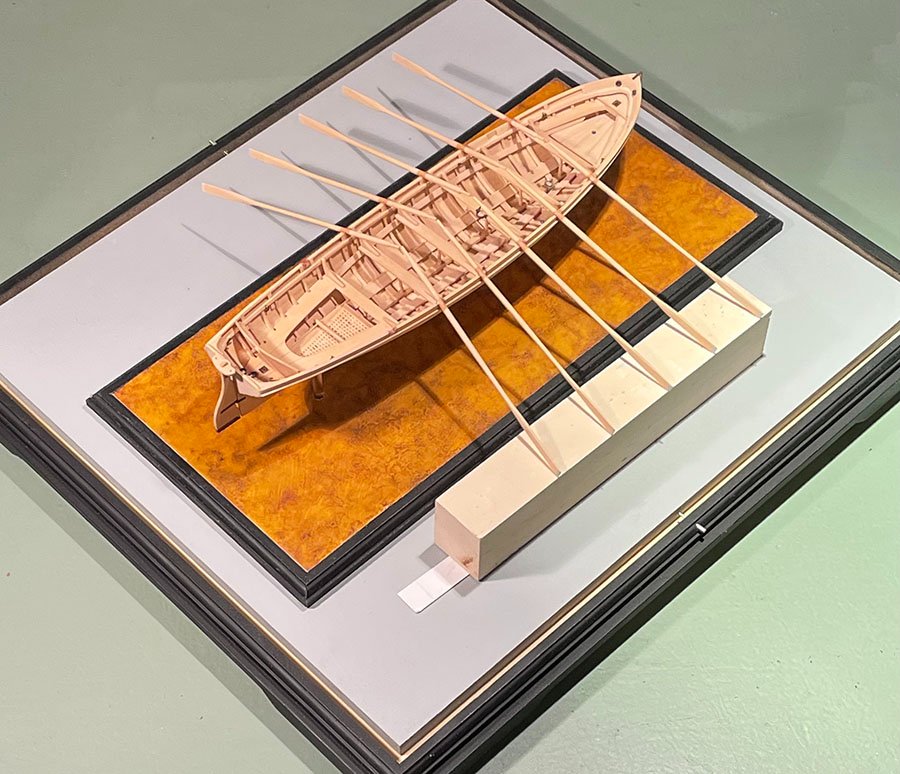

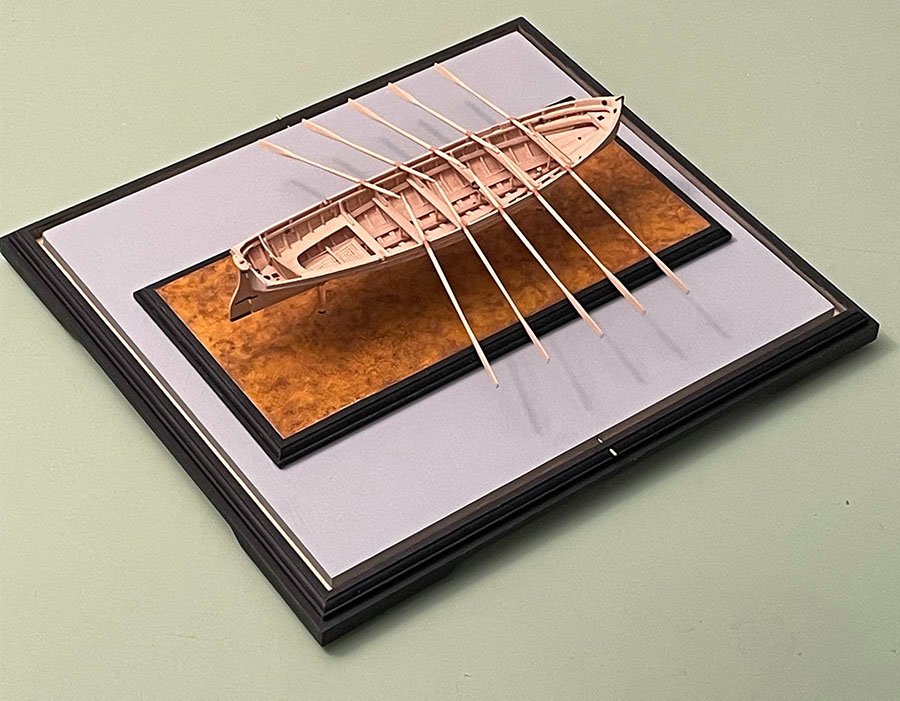

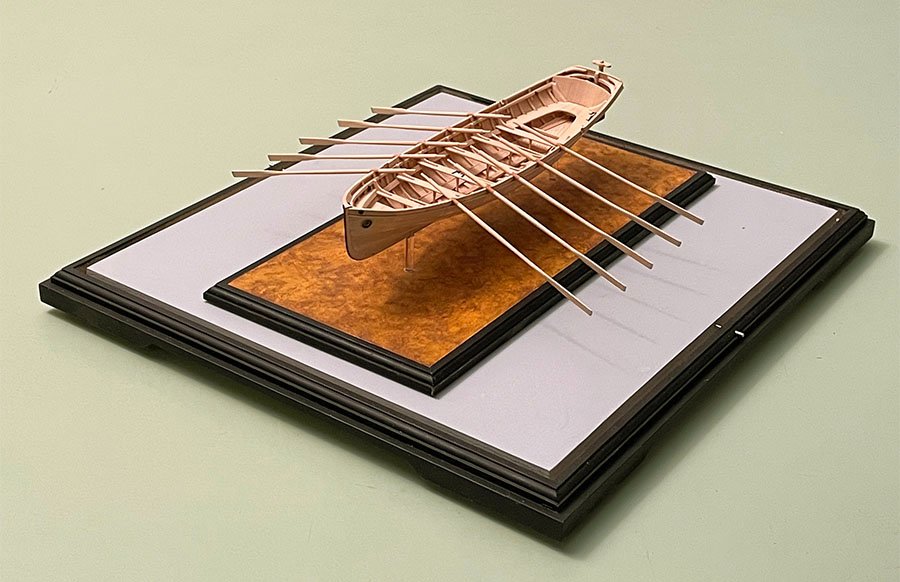

Shipman: Gosh, some folk are never satisfied! Here are some lower viewpoint pics. Hard to do through the acrylic. Thanks again everyone, for your interest and kind comments.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Thanks again, all. Mark: I wish I had more insight as to the rudder and yoke arrangement, but unfortunately I don't. If anyone out there can shed further light on the mystery, I'd be grateful.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Thank you, everyone. So, we come to the end of this particular journey. I appreciate all who have followed along. Happy model-making to you all. BTW, I've no idea what might be next - yet.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

First, no book is entirely error free! It's not, alas, an ideal world we live in. The further we get historically from what we are trying to study, the harder it becomes. There is also a great difference between primary and secondary sources. Primary evidence comes from the time and place of the subject we are studying. Whoever wrote, produced an artifact or model is likely more reliable a witness to how things actually were. In the case of a model, things might be stylized or simplified, so one needs to be careful. Secondary evidence is from a later time and place. The creator may draw lightly or heavily on primary sources, but transcription and interpretational errors can creep in. As a history research professional friend observed; "Read elsewhere and read critically, always." He is so right!

-

Good progress there, Toni. It's difficult not to knock a chip or two of paint off during construction, but I'm sure it will clean up nicely in the end!

-

Yes, Eberhard, there are 'tin' bands on the oar blades, but it's hard to see them in the photos. Alan: There is no tiller, just a yoke with two lines attached. As I don't know the run of those lines, I'm omitting them. Steve: The oars are attached using both a dab of epoxy backed up with PVA. Belt and braces!

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

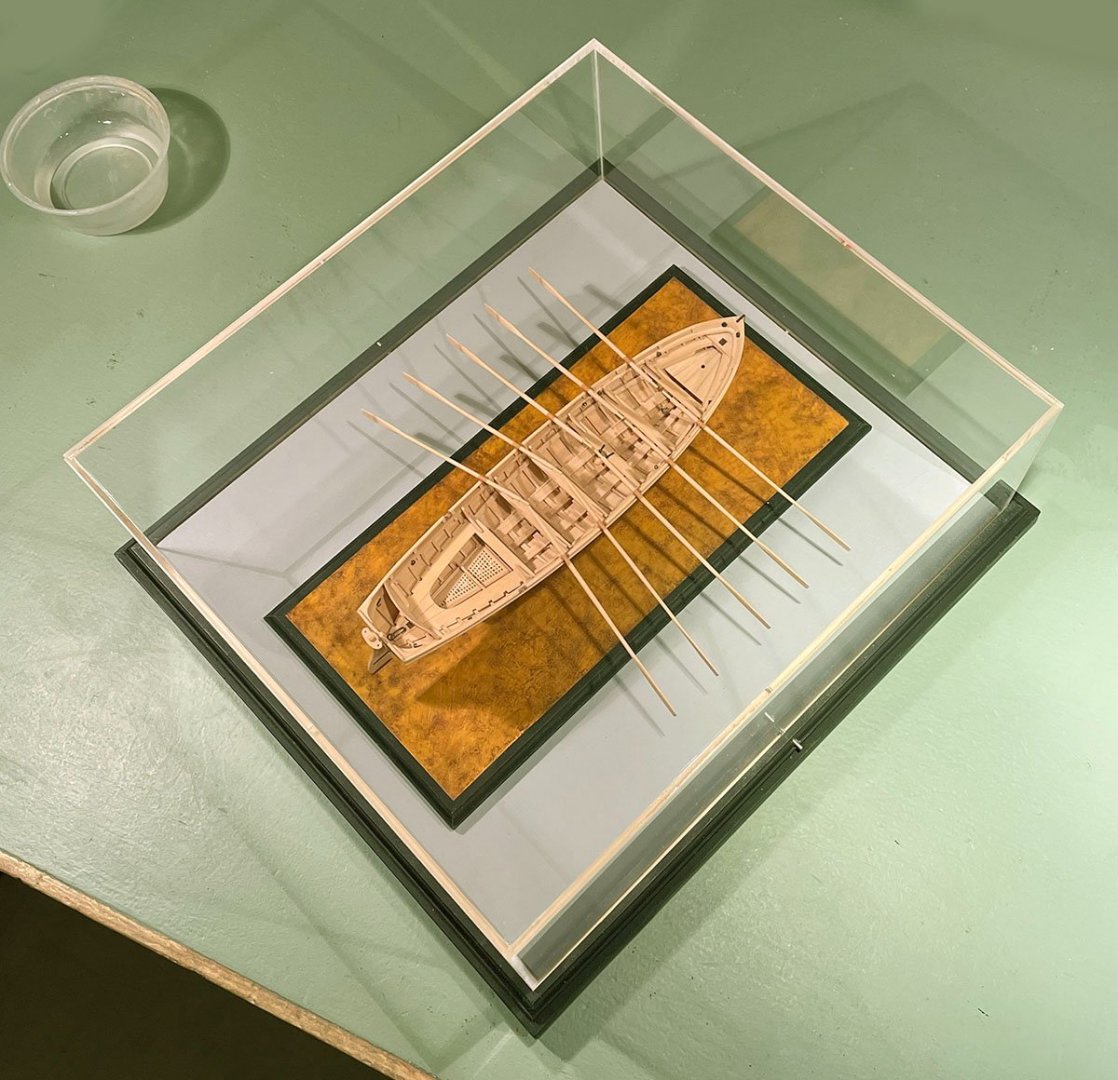

Thank you, one and all. Almost complete now! The oars have been installed and all that remains are final touch-ups, dusting and adding the case over the model. In the first photo you can see the second bank of oars going in, resting on a block of suitable height and shimmed with card. The retaining pins for the acrylic case are also done and temporarily inserted.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

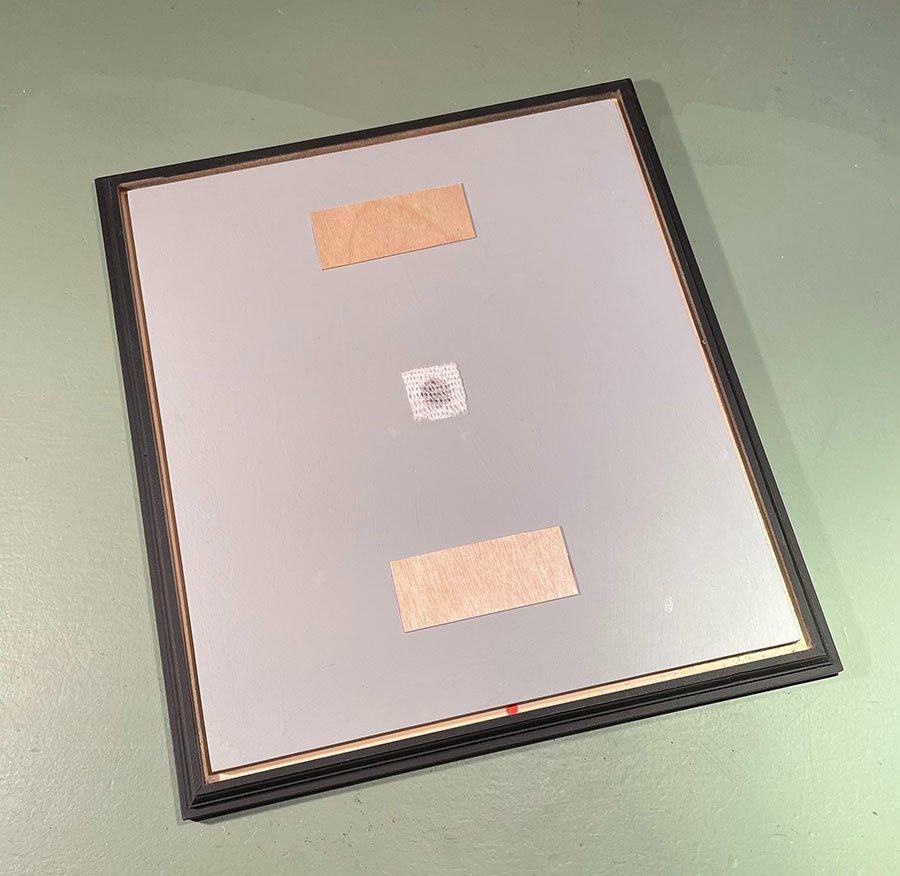

Thank to all for the discussion and comments. Finally some progress to report! The sub-base is complete to fit the acrylic case. For those curious, there is a central hole for air circulation with gauze meh to discourage insect infiltration. The two pieces of 1/64" ply act as an air gap between the sub-base and base of the model. Oars will be added tomorrow.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Ouch! See post #21. Next time, scrape the paint away where you will glue and that won't happen again. Good recovery, though.

- 70 replies

-

- Lowell Grand Banks Dory

- Finished

-

(and 1 more)

Tagged with:

-

Rigging taken a whole is very daunting. But, as you say, line by line it ins't so awful. looking good so far!

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

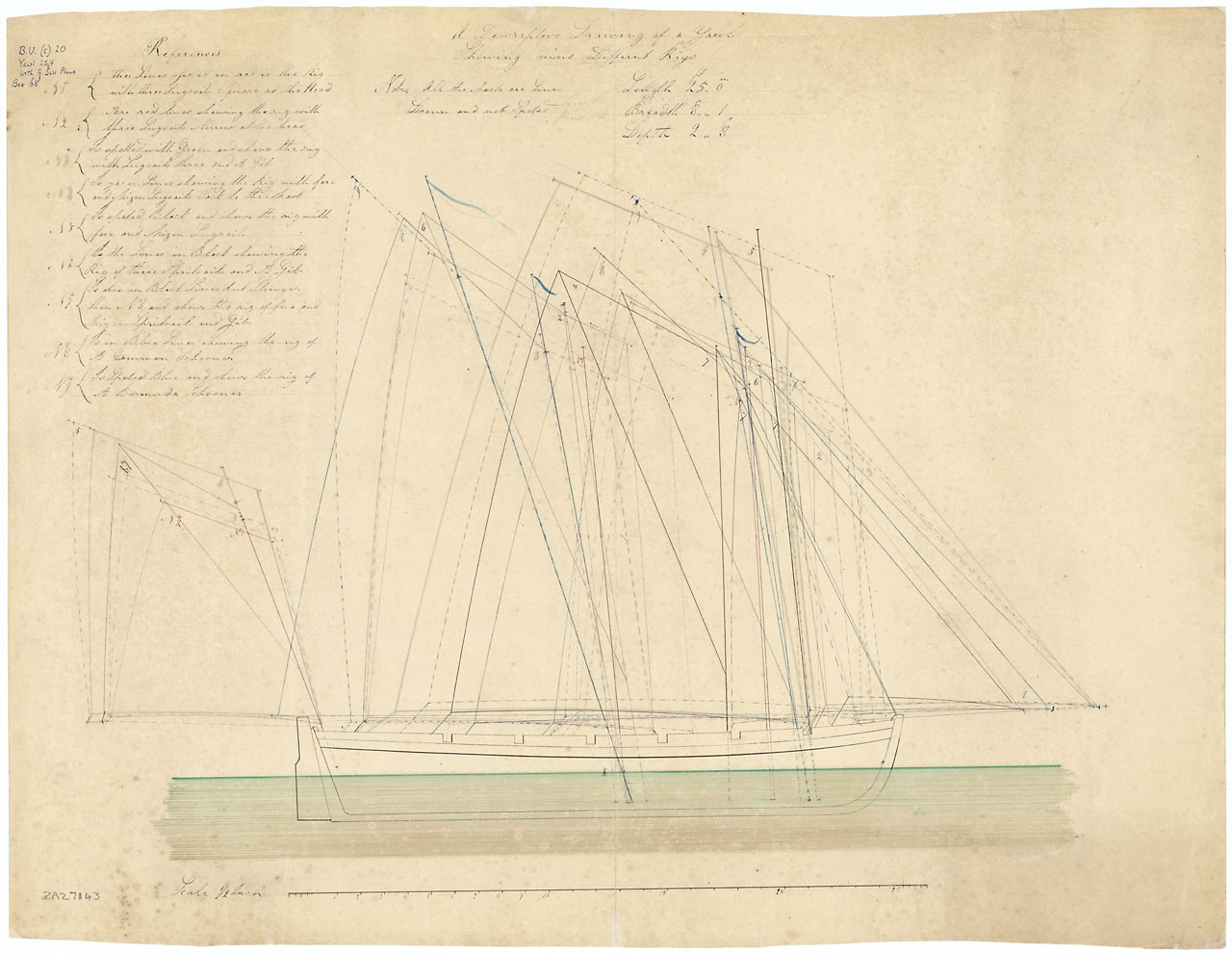

Well, Shipman, there are ringbolts attached to the inwales as well as hooked cleats near the stern. These all must be for attaching rigging. There are two ringbolts a side forward and one on each side aft. In addition, there is an eyebolt on each side just forward of the mast step. An example of cutter rig from the period is: This is ZAZ 7143, a 25 foot cutter in the RMG (NMM) collection. However, I'm unsure how a bowsprit (if present) was rigged on the 28 foot American cutter. This is one reason I'm not rigging the model.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

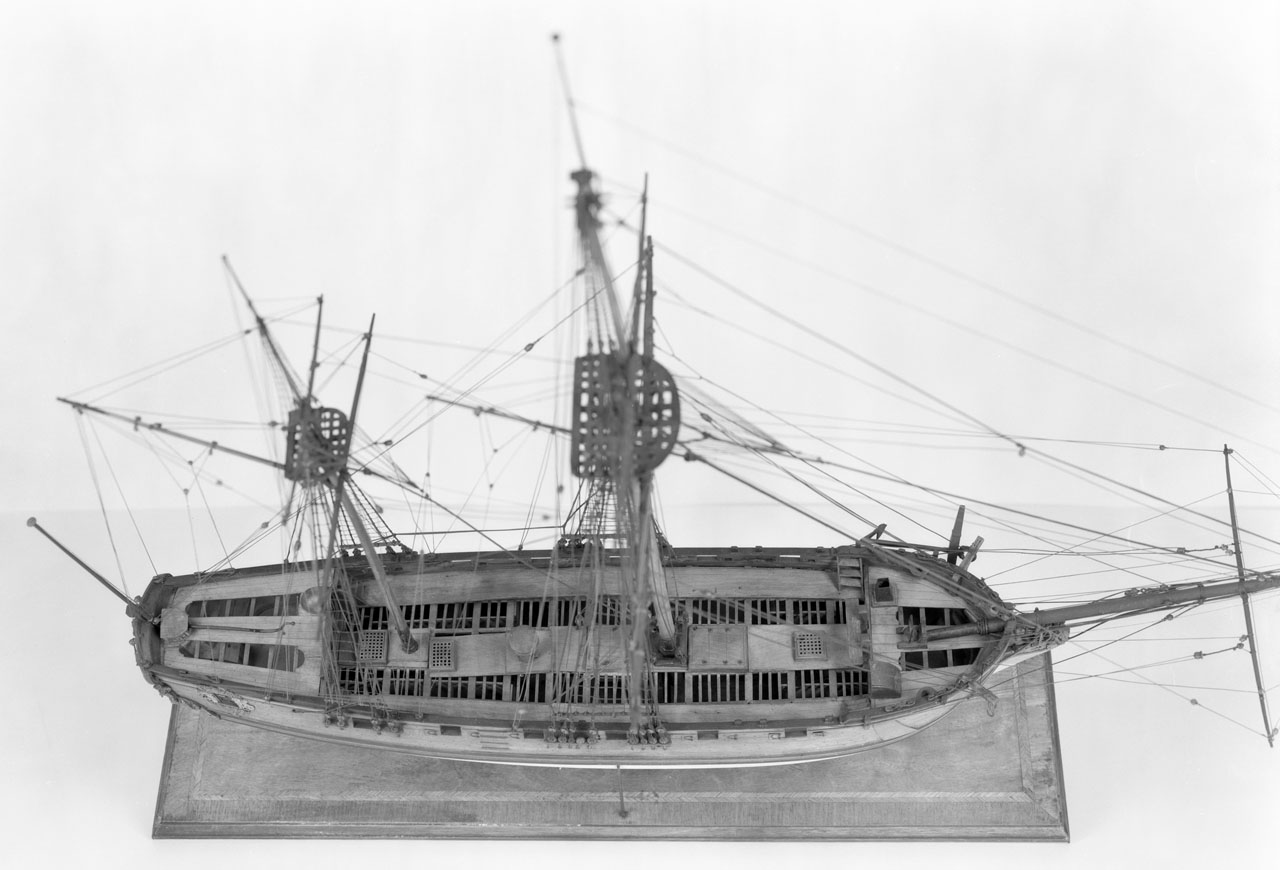

HMS Euryalus 1803 by rlb - 1:48 scale

druxey replied to rlb's topic in - Build logs for subjects built 1801 - 1850

- 122 replies

-

- Euryalus

- Plank-on-frame

-

(and 4 more)

Tagged with:

-

The acrylic case has arrived and the sub-base is boing constructed to fit. As soon as the casework is complete, I shall mount the base on the sub-base and set about deploying the oars. Stay tuned!

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Glad all is well! Nicely bevelled and fitted thwarts there.

- 70 replies

-

- Lowell Grand Banks Dory

- Finished

-

(and 1 more)

Tagged with:

-

Neatly done, although I might suggest that you scrape paint off where any glued joint is. Even if the glue holds, there is a possibility of the paint shearing if the riser were bumped.

- 70 replies

-

- Lowell Grand Banks Dory

- Finished

-

(and 1 more)

Tagged with:

-

YOUNG AMERICA 1853 by Bitao - FINISHED - 1:72

druxey replied to Bitao's topic in - Build logs for subjects built 1851 - 1900

Congratulations on completing a superb model, bitao! I hope she will be protected in a suitable case.- 257 replies

-

- young america

- Finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.