-

Posts

13,290 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

The joints will show more through paint over time, Maurys. If they show too much when first painted, that's not a good sign!

- 525 replies

-

- anchor hoy

- hoy

-

(and 1 more)

Tagged with:

-

Mike: frequent hand-washing and cleanliness in the shop are the keys to avoiding fingerprints.

- 889 replies

-

Thank you Michael and Wefalck, for the comprehensive and logical responses to my question. I assumed that there was good reason for using round rather than square stock, but now you've convinced me! I also hadn't thought through the fact that square collets are not available at those sizes.

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

Stanchions look great, Michael, even at large magnification. Would it have been a possibility to start with square section stock, drill the holes and then turn, or would cutting forces have snapped the work at the holes?

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

It's annoying that the draughtsman didn't draw the carved works! One would be fairly safe with either a standard lion or, perhaps, a classical soldier holding a pointy sword.

- 1,124 replies

-

Wood will tone down in time, Ben. She is coming back nicely now!

- 889 replies

-

Nice progress. How difficult is it to draw nickel silver?

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

After cutting a few of these joints, they should be easy! That last one looks very good, Maury.

- 525 replies

-

- anchor hoy

- hoy

-

(and 1 more)

Tagged with:

-

An excellent video of advice for folks contemplating a fully framed model. You are a very honest model-maker, Kevin! I appreciate you sharing your experience with everyone.

- 1,124 replies

-

Red Paint or Red Ochre

druxey replied to davyboy's topic in Painting, finishing and weathering products and techniques

To reduce chroma (color brightness) often a small amount of the complimentary color is added. A complimentary color is one found on the opposite side of the color wheel. For instance, to reduce an orange-red a greenish blue is used. It sounds counter-intuitive, but it works! -

Swan-Class Sloop by garyb - 1:48

druxey replied to garyb's topic in - Build logs for subjects built 1751 - 1800

At least you realized this early in the game and no wood was harmed! -

Well done, Michael. I assume the meltdowns referred to the stanchions and not yourself!

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

Michael Mott Designed Third Hand

druxey replied to BANYAN's topic in Modeling tools and Workshop Equipment

I too was a lucky recipient of one of Michael's third hands. It's a beautiful piece of small engineering. -

Red Paint or Red Ochre

druxey replied to davyboy's topic in Painting, finishing and weathering products and techniques

There is 'red' and there is 'red'. Both Orange-red and crimson red are 'red', but mixed with white or other colors will yield very different results. -

Pleased to oblige, Wefalck. Pictures as requested. They certainly are attractive instruments. There is a table of figures for setting every conceivable proportion one might want. I use similar strategies to yourself when subdividing distances, especially on curved surfaces such as hulls.

-

I'm afraid I have to agree with Wefalck. I actually have a beautiful pair of 10" dividers - rack and pinion, 110 division scale, with right-angled tips so that you can use the instrument parallel to your work rather than held vertically - and very seldom use them.

-

Rob: Gerald makes all his own tooling and jigs - superbly.

- 281 replies

-

- falls of clyde

- tanker

-

(and 2 more)

Tagged with:

-

I love the attention to detail such as the upper ends of the support pillars, Gerald. It must be nice to have the prototype still available for study! On a slightly different -but related - note; in another thread Cutty Sark is under discussion. I've been wicked enough to suggest that a model of her in frame would be a terrific subject for you. I'll shut up now.

- 281 replies

-

- falls of clyde

- tanker

-

(and 2 more)

Tagged with:

-

This is a service knock-about vessel, not a ship with a proud captain willing to spend a bit on his command. She would be, in short, a very Plain Jane. Decorate accordingly!

- 525 replies

-

- anchor hoy

- hoy

-

(and 1 more)

Tagged with:

-

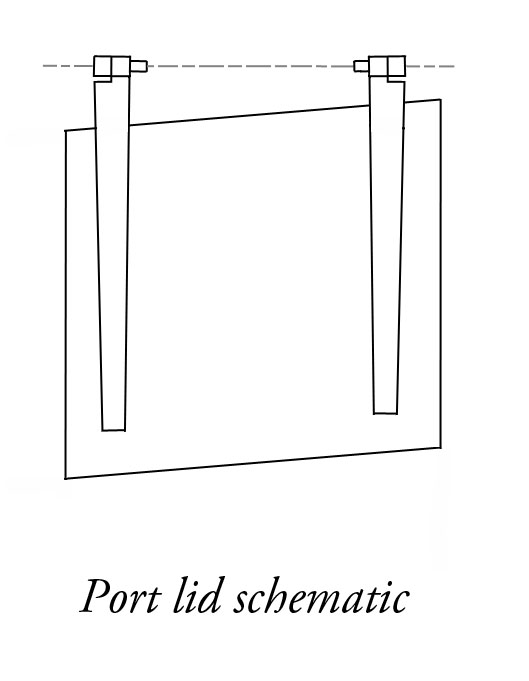

For an example of hatches, see the RMG 'Collections' site and search 'hoy model 1750'.

- 525 replies

-

- anchor hoy

- hoy

-

(and 1 more)

Tagged with:

-

Only most of the kinks, Mike!

- 452 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I suspect that there were no ledges: there are no guns or heavy on-deck items to be supported. It would be unlikely that the hatch covers had hinges: just square lift-off covers with ringbolts in opposite diagonal corners. Rectangular covers had ringbolts for lifting near their short sides.

- 525 replies

-

- anchor hoy

- hoy

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.