-

Posts

389 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Tigerdvr

-

Mike, you can drive yourself nuts trying to get the right colors. The colors on the full scale ship, plane, tank, etc. are always changing in real life anyway. Sun, dirt, age, time of the day can change how everything looks. Even how far away the subject is from the viewer. I just finished the USS Alaska which when done in Measure 22 has about 3 colors. Drove me crazy trying to get ones I felt were correct. Do some research, find what looks good to you and ENJOY. Cheers, Harley

-

Focke-Wulf Fw 190D-9 by Jörgen - Eduard - 1:48 - PLASTIC

Tigerdvr replied to Jörgen's topic in Non-ship/categorised builds

Thanks for sharing your experiences and techniques. I'm probably old enough to be your dad but have been learning something each time you post. We don't have time to experiment with all the options so sharing is a great help. Is your work station always that neat & clean, come on, fess up. That's a great setup. Looking forward to your next post(s) Cheers, Harley -

Airplanes and Tanks in plastic by Jörgen

Tigerdvr replied to Jörgen's topic in Non-ship/categorised builds

Really great work. May I ask what camera you used for the photos? Thanks for sharing, Harley -

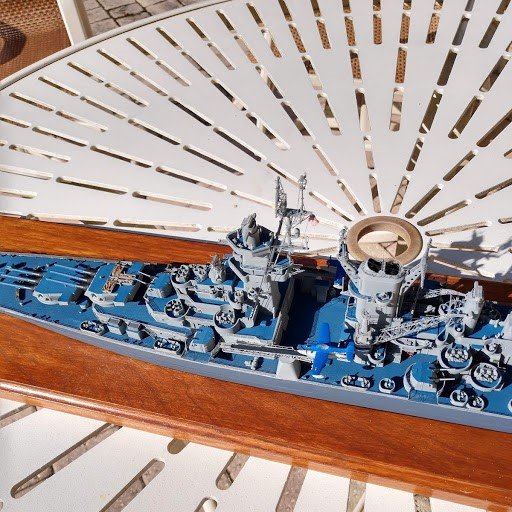

Case has arrived, been assembled and will provide a home FINISHED U.S.S. Alaska CB-1The case is by Acrylicjob. Well packaged, easy assembly, reasonable price, looks good. The finished Alaska Sunlight causes color change- Cased in the living room, will find some LEDs to get more light on her. U.S.S. Alaska start date: 10/20/18, completed 6/15/19 A great kit by Hobby Boss

-

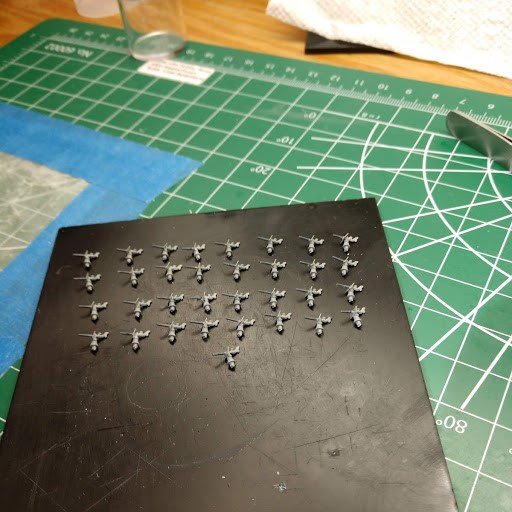

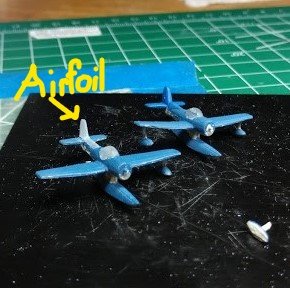

This is synopsis of steps bringing the Alaska project to a finish. Small parts, both plastic and PE abound Black fine E Z Line was attached to a small plastic rod and inserted into the flag bags then run to the yardarms to simulate the halyards PE work from the kit, Infini, & White Ensign was time consuming but worth the effort. Storage rack for the cranes Alaska was heavily armed with a main battery of nine 12" guns, secondary battery of 12 5" DP guns and an extensive array of 20mm Orlikon single mounts and 40mm Bofors quads. Her main mission was AA cover for the carrier groups. The main and secondary batteries have brass barrels by B&D. The blast bags were formed with Tamiya putty. The 5" mounts did not have blast shields as shown in the instructions. The sliding hatches on the main battery turrets were relieved as shown closed. My aviation background wouldn't let me finish the Curtiss Seahawks with such gross shaped wings & tail surfaces so they were reshaped and various colors tried to get an acceptable shade of blue. Radio masts are tiny More test fitting, priming, and painting to get ready for final assembly Assembly, main deck rails, and touch up for the completion of USS Alaska CB-1 Next time, Harley

-

Very well done, one of the best Syren builds that I can recall. Your rope work is exemplary and the photography and log are certainly top notch. Thanks for sharing with us mere mortals. Cheers, Harley

- 242 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Nice work on the boats, enjoying your log, thanks for sharing. Regarding your comment on lack of labeling on photo etch, I just received a photo etch fittings set for Fletcher class destroyers from Gold Medal Models. They label what each part is on the fret plus labeling for the round or square bridge Fletcher. Pretty handy. Their instructions are quite good also. Best, Harley

-

Fellow photo etch addicts, "There is a limit to (this) insanity", as Yves said, should be our official moto.😵

-

Please excuse this if it has been previously addressed, what adhesive and method of application are you using. Your work is truly outstanding and sets a high level for us mere mortals to strive to emulate. Thanks, Harley

-

I'm going to bight on a stupid question, what type/kind of alcohol are you thinning with, thanks Harley

-

Salt, my friend, I think you just killed my hobby budget. My Commodore has been after me to do a "don't paint the PE" project for some time. She just saw your latest project which, if I may add, is outstanding. She really likes it and I'm getting that look. We all know what that look means🙄 Thanks for sharing your log Harley

-

Greetings, Is that beautiful hull going to get the grungy weathering job? Following with great interest. Thanks for sharing Harley

-

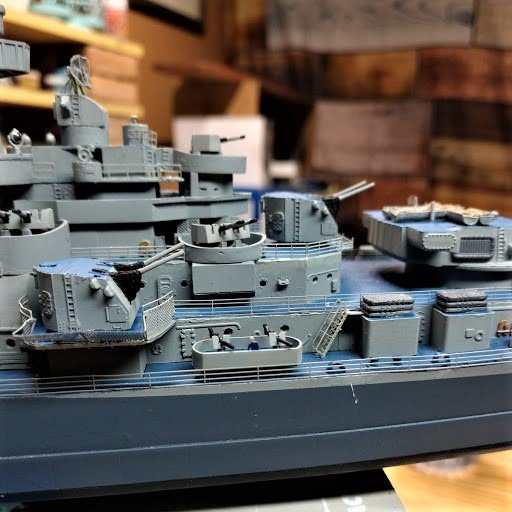

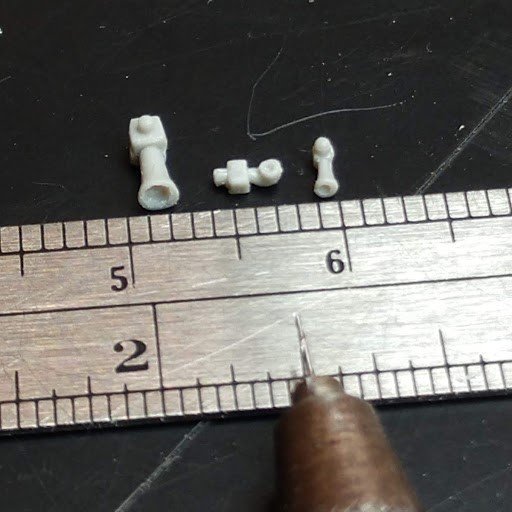

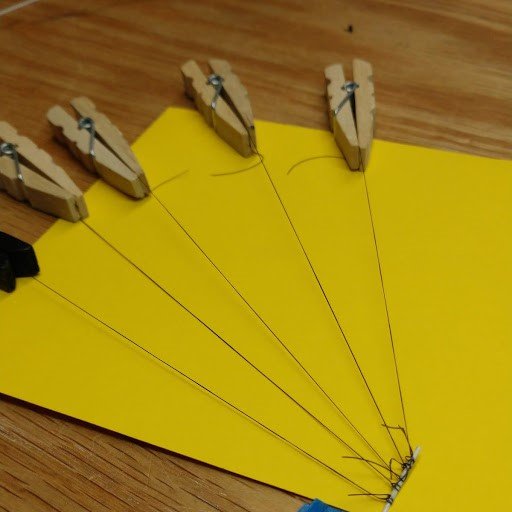

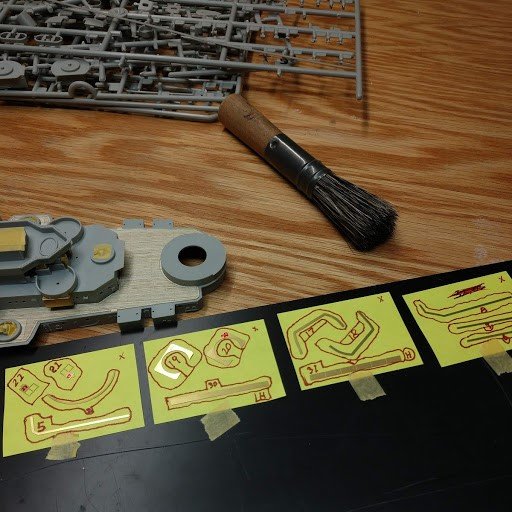

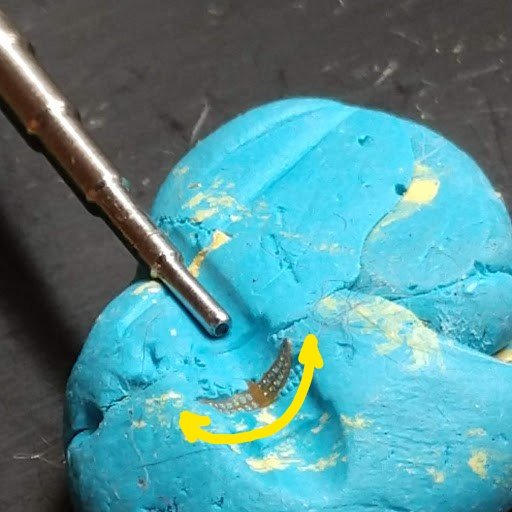

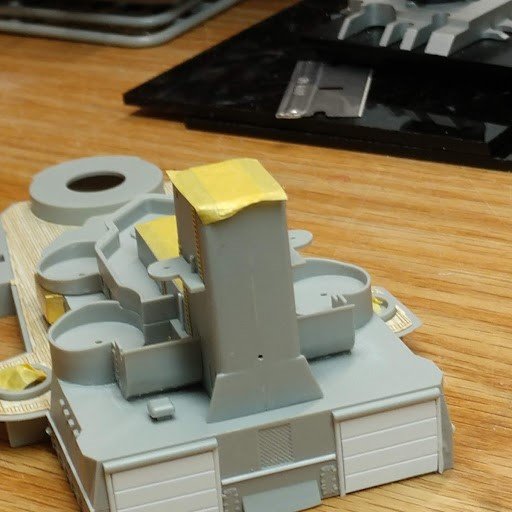

Multiple sub-structures being built: I have found myself working on a multitude of different structures simultaneously. All this was leading up to a point where I could prime as many sub-assemblies as possible at one time. A word about PE. I used the Small Shop bending tool for most PE applications. Small strips of plastic were inserted to strengthen some of the joints like the catapults and the cranes. Gator Grip Thin is used for initial PE bonding followed by some spot welding with CA for strength. As the various structures were assembled, all were checked carefully for fit, seams, and any surfaces in need of attention. Tamiya Putty and Mercury Adhesives Thick were used where patching was called for. I used Mercury Adhesives CA in various strengths throughout this project. The Tamiya Putty is pretty foul smelling to me but works well. Folks, I apologize for this hodge podge of pictures, the preview showed all ok. Alaska will be better than the log. I think I will just finish the model without having log headaches and, hopefully, be able to display a creditable model. Funnel interior PE More PE There about 70 pieces to the completed funnel Mandrel and soft clay to curve SG & Mk22 radar screens Early paint stage More Later- - -

-

Great weathering job. Was she really that beat up? The B-24s must have gone after the paint factories while hitting the oil refineries. Thanks for sharing your methods and techniques. Harley

- 345 replies

-

- graf zeppelin

- trumpeter

-

(and 2 more)

Tagged with:

-

That has to be one of the best Syren builds I've ever seen including my own🤔. Your log is very well done too. Thanks for sharing Cheers, Harley

- 242 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Glad your son is better, best wishes that he continues to improve. Regards, Harley

-

The Plan— It’s important to plan ahead to avoid conflicts and problems as construction progresses. Questions to be resolved: Degree of attainable accuracy, I consulted the kit instructions, Ashey’s book, and the Warship Pictorial #43. A lot of computer research time is being logged. Materials available, this dealt mostly with a choice of kit vs aftermarket/PE such as main battery barrels, plastic or brass. My current skill level, I have practiced PE on some 1/200 40mm Bofors quads by Veterans. I also did a practice build on a 1/700 Iowa to get up to speed on plastic adhesives, procedures, etc. The airbrush got some work. The paint job will be pretty clean. Oil canning and weathering hopefully on the next build. The kit supplied 40mm quads (14) and 20mm Orlikons (34) are reasonable so will be used. PE Orlikons are a real challenge to fold. The superstructure will be constructed as separate mini projects. The plan calls for working from the centerline out. Two major considerations for that are the paint scheme and fragile PE pieces and railings. Because most of the horizontal surfaces are blue and the vertical surfaces are gray, I feel it would be easier to paint most of the horizontal surfaces first and mask those surfaces when the gray is sprayed. I will prime all with Vallejo white surface primer. Both Vallejo and Model Masters acrylics are in the paint locker. Thanks to CapnMac82 for his paint color comments on RGL’s Fletcher DD. That will help on Alaska’s paint scheme. Painted deck glued to hull, brass capstans are wrong, the bigger ones should be inboard, fixed. Deck masked for first gray paint on gun tubs etc. Forward superstructure building up. Hanger doors are PE vents, ladders, etc. being added Evergreen .5mm V-Groove & .3mm half round Clay used to brace PE support while glue dries Forward mast (Infini) building up More next time, edit because the post fell apart!!

-

I think all the adjectives have been used up but an outstanding build and informative log. I may have missed it but what did you use for the rigging. I'm thinking of trying E_Z Line on my Alaska. Thanks, Harley

-

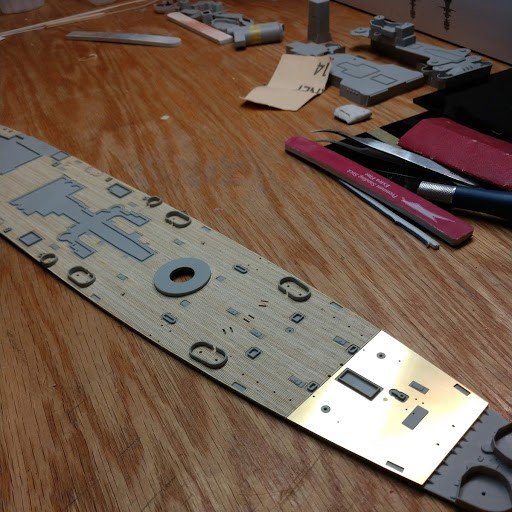

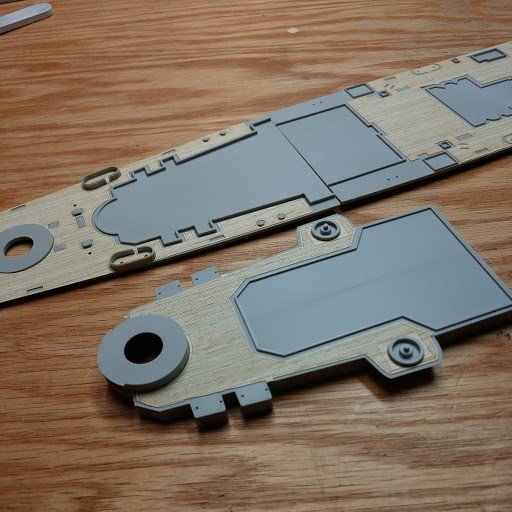

Wood deck: The wood deck went on with no problems. There are a few places where Gator Grip Thin Blend was used to assist the deck adhesive. The deck kit included the “steel” deck from the capstans forward and the area of the aft 40mm mounts. Brass capstans, hatch covers, and other PE deck fitting are included in the deck kit. In most cases the PE hatches fit over the hatches already on the deck so little sanding was necessary. The PE deck fittings were all easily assembled per normal PE procedures. The pictures of making the PE flotation net bins went to computer heaven unfortunately. I'm going to hate painting the deck blue.

-

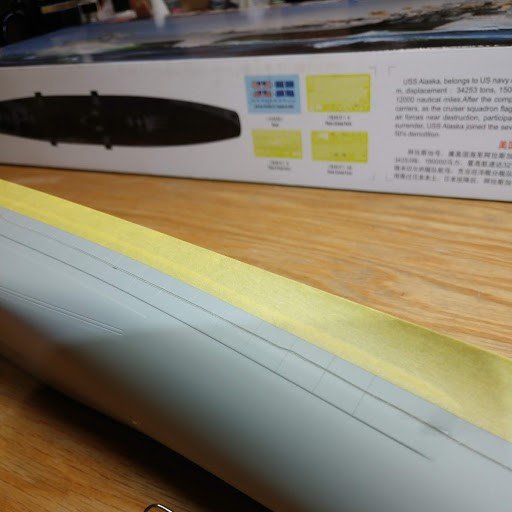

A Waterline Configuration-- I used my Dremel to cut away the bottom of the hull. Care had to be taken to minimize melting the plastic. The picture looks really gross but it looks worse than it was. A number of cross braces were installed to minimize the hull flexing while sanding it. The hull was dressed and leveled. The hull was used as a template for the making the boot line. A piece of 2mm black polystyrene by Evergreen, was rough cut using the template. This was glued to the bottom of the hull and shaped to provide permanent boot line. Cell phone pictures

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.