-

Posts

421 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Katsumoto

-

-

8 minutes ago, yvesvidal said:

That is fantastic work and this carving is gorgeous. You are a true artist.

The adjustable model bench/vise that you are using seems great. Where did you procure that tool?

Yves

Hi Yves.

It's the Professional building slip of Hobbyzone. I believe there is a review of this one somewhere on this forum. It's a great tool, but also has it's limitations like any other tool out there. Professional Building Slip (hobbyzone.pl)Thanks for stopping by and the kind words! 👍

-

Chapter 12 - Woodcarving and stern remodeling

In this chapter I'll focus on the stern. I had to remodel this part to my liking and I happily could buy some real boxwood.

Then I realized I made an error and the frame is to high. So, I took it apart again, adjusted the height, made a new frame and assembled it again.

Let's say I wasn't too happy in the beginning... 🙄

Time to find a use for the boxwood.....

I made a drawing of a Baroque theme of Acanthus leaves.

That's it so far, this topic is back on track with the current status of the build.

regards,

Peter -

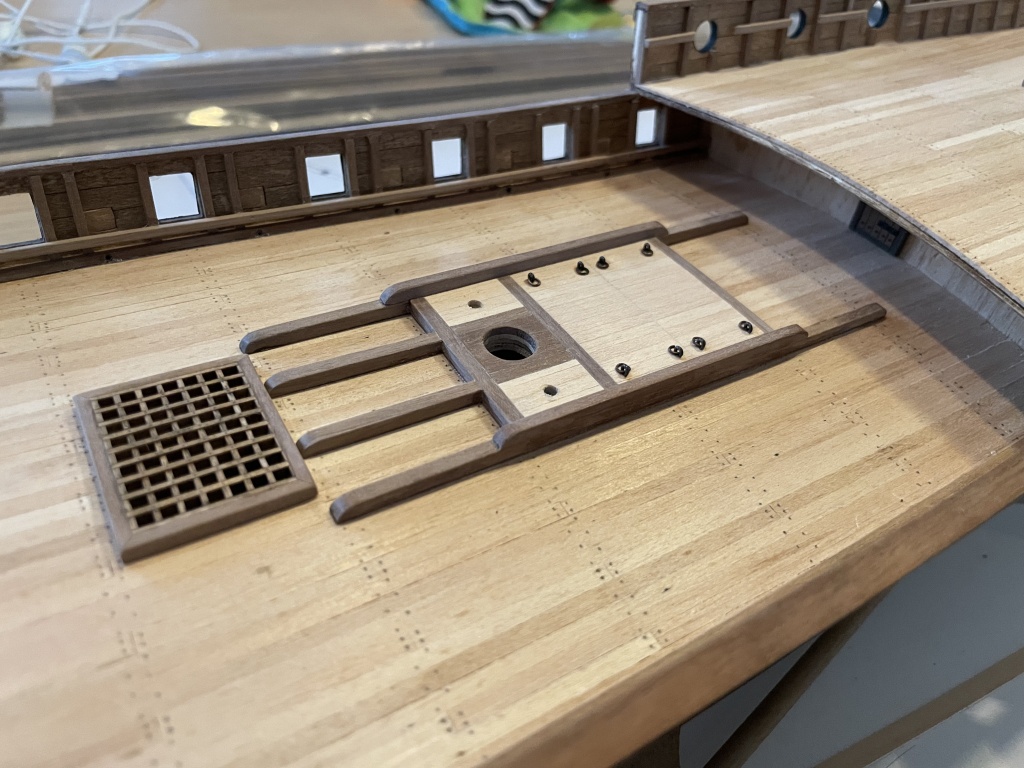

Chapter 11 - Main hatch, pumps and bell tower

In this chapter the hatches at the main mast are being constructed and placed on the main deck. I did not used the metal parts of the pumps and bell tower, made my own out of walnut.

Besides the main mast opening, there is a hole for the pumps installation.

Next chapter will be the stern remodeling...

-

Chapter 11 - Davits

So the davits needs to be fabricated and some other parts at the Fore. I fabricated everything out of American Walnut and throw away the pre-cut plywood parts. They are horrible to place on the ship....

I was a bit anxious because I needed to cut out parts of the upper railing....there is no way back when you put your blade into it....

Next chapter will be the hatches at the main mast...

-

Chapter 10 - making gunportlids

In my previous post I made a single lid for one of the gunports. Time to fabricate a lot more. This is the process of making these lids.

The hinges are done, need to blue these with Birchwood Caseys Brass black.

On to the lids itself. The same process as for the oarlids. Cover every part with veneer...

I'll place these lids in a later stadium on the ship.

-

11 hours ago, yvesvidal said:

Thank you for building one of my favorite vessels: Le Chebec. I will follow your log with a lot of interest.

Yves

Thanks Yves, it's one of my favorite ships as well. We share the passion my friend!

4 hours ago, BobG said:

4 hours ago, BobG said:Beautiful work, Katsumoto!

Thank you Bob, for leaving a comment and following along! 🙂

-

Chapter 9 - Guncarriages

Pffff....I really did not update my log for some time......🤪

During last Christmas, the warf was closed, but I did some designwork on a guncarriage. The metal ones provided with the kit aren't too bad, but I decided to make a testcarriage out of wood.

Left the one provided with the kit. Right the one I made

Okay, these will do....now I have to duplicate 19 more

-

Chapter 8 - Profile strips and first steps into carving

I've made some walnut strips and cut out a profile into a dull blade. Time to scrape the profile into the wood.

This dresses up the sides of the hull a bit. Next step is to make a test carving out of Castello Boxwood. I prefer the real boxwood, but it wasn't available in my area.

I'm not convinced about the endresult tho. The castello boxwood is a bit softer than the real thing. I'll have to think this one over and I let is rest for now.

Time to experiment with the gunport lids. I made one as an example for the rest.

so, one down, many to go....

-

-

Chapter 6 - Bulwark reenforcement.

I've used some walnut to dress up the inside of the bulwarks.

The railings also placed on top of the bullwarks.

Time to place the two gratings. I've let them curve a little bit just in sync with the top of the deck.

regards,

Peter- GrandpaPhil, catopower, BobG and 4 others

-

7

7

-

-

Chapter 4 - Stern, gratings and prow

I've replaced the plywood stern and made a new one out of limewood strips.

All other plywood parts I've replaced with solid walnut.

At the prow of the ship, some gratings has to be made. I use a cardboard template to cut out the gratings.

regards,

Peter -

-

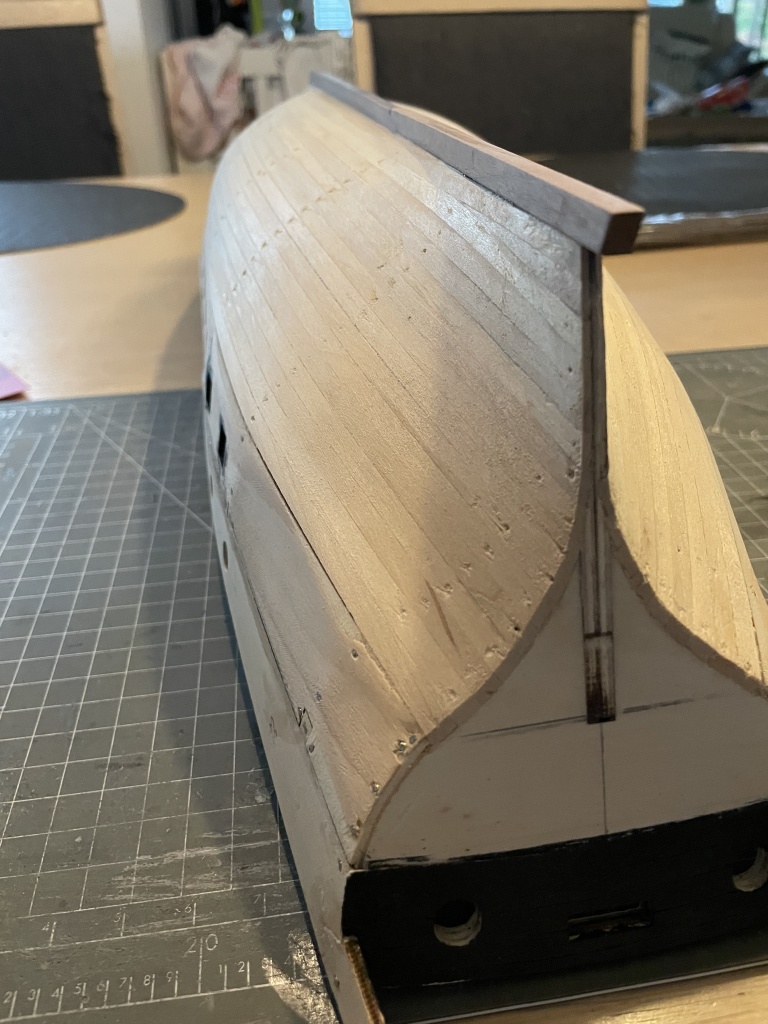

Chapter 3 - Second layer hullplanking

I've done my prepwork prior to planking. Did my calculations, battons placed (green lines) so time to put some planks on shall we?!

I work from the wales to the first green batton (line). Each section contains 5 strakes. On all bulkheads the width of my planks are even.

Now I fill in section by section until the last garboard strake will be placed. I can place the garboard as last strake, because there is no rabbit in my keel otherwise I suggest to place this one as the first strake on the hull.

One side done, other one to go!

-

Chapter 2 - preperation of the hull first layer planking

In this update I'll show you the first layer of hullplanking. Some photo's were lost during editing, but I can show the result.

I begin with the stern. Btw, this ship will be bashed beyond believable.....My mission is to let you forget this is a kit....

I used East Indian Ink to blacken the bulwarks.

The kit comes with Sapeli veneer strips. It's a sort of Mohagony color. I'll change this for American Walnut.

Placing the wales...

Preparing the hull for second layer of Walnut veneer. Put some lines on the hull for reference....See these as temporary battons which devides the hull into three parts excluding the garboard strake.

-

I have to blow off the dust of my buildlog. I'm sorry for that, just so bussy with work. I did continue a lot and I'll post my update more frequently from now on.

So, the kit comes with standard laser-cut parts out of plywood. It's been stained with a dark "walnut" stain. I do not like it so I discart these parts and make my own out of solid walnut.

More to come, have some catching up to do in my buildlog... 😅

Regards,

Peter -

Hello my friend. Your RC looks lovely! Great ship she will be when she's finished!

Keep following your build!

I'm back building my new project and started yesterday with my first post.

See yah later Messis and keep posting those lovely updates!Peter

-

***OcCre - Cazador Jabeque / Xebec 1750***

Hello my friends, it's been a while since my last buildlog of Santa Maria Buildlog.Today I would like to present my new log of the Xebec Cazador of OcCre.

As a child I was fan of the Redbeard comics, maybe known by some of you. Anyway, one of the titles was "Fight With The Moors" (1973) and describes a story of Moorish pirates who looted merchant ships in the Mediterranean sea. The ships they used were fast, agile and armed to the teeth Xebecs! In the story, ships were plundered, crew were killed, the ship burned to the ground and women were kidnapped and sold on the black market as slaves.

It intrigued me because regular ships, even well armed were not capable to cope with these dangerous circumstances and the Xebec's with their ruthless crew were winning most of the fights. Ofcourse this Redbeard story was fiction but based on true events in that timeperiod. A different and dark time compare with today so to say.

The Spanish Crown built Cazador mid 18th century to fight the Moors in the Mediteranean Sea. To me, this was the conclusion to take on this ship and build her myself. A beautifull representation of a Spanish Xebec in combat with the Moors is shown below. It's a picture of Ángel Cortellini Sánchez!OcCre - Ocio Creativo made a beautiful kitmodel but compare to reality it has some shortcomings. I'm not sure if I have the possibilities to change a couple of things, but we will see on the way. My workplace is the dining table in the dining room with only my handtools and hopefully a lot of creativity! ☺️

Some specifications of the kitmodel

Ref: 14002

Scale: 1:60

Length: 860mm / 33.9 inches

Height: 630mm / 24.8 inches

Width: 160mm / 6.3 inches

Chapter 1 - The Box and parts

The boxart is pretty basic but neat and tidy. It looks like OcCre use the box design for almost all their models kits. A picture of the ship makes the difference and is a piece of paper which sticks to the box. It's the contents of the box that has my interest.

Wel about the contents inside the box. All things are neatly packed and the milled wood looks all right. Not perfect or of the highest quality, but just fine.

What bothers me are the plywood parts. Even the keel, transom parts are made of plywood and stained into a walnut color. I prefer walnut parts instead of stained plywood.

Chapter 2 - A new beginning

To me the scale of the ship and the less complexity of the model is ideal for the dining table situation. After modeling I can easily clean up the table and put the box, tools and the ship away for the next moment.

After inspecting the parts, I start with numbering the plywood parts.

After numbering the parts, I'll cut the parts out of the frame and dryfit the bulkheads.

The plywood it very thin and brittle. The bulkhead fits nicely on the main plate of the ship. After putting some glue on the bulkheads, it's time to cut out the main deckplate. Hopefully this give the structure some rigidity and strength.

Time to plank the deck. I choose a pattern and start laying the strips. Unfortunately the strips a not consistent in thickness and varies widely between 1 - 1,3mm.

After a while...

Job's done. Time to scrape the deck flush.

Also the upper part of a bulkhead needs to be covered with the same strips but placed verticaly.

At the aft of the ship, strips of veneer are placed horizontally. I bend the veneer with an iron so it follows the curve of the bulkhead. It's hard to do, but to me it looks a bit nicer instead of straight strips.

Time to put another deck plate on the ship.

Also this needs to be covered with some strips of wood...it's the same process as on the main deck.

Well, it's a start so to say. I'll try to update once a week if possible. If you like to leave a comment, I'll appreciate it and please feel free to ask me any questions.See yah later!

Peter -

Hi Lapinas,

For a first ship, you are doing and have done a wonderful job. Very very good for a first model with an excellent planking job on your hull. Even for experienced modelers this is a difficult task for most!

I have build the SM also, but from another brand (Artesania Latina) both look similar but things are very different in both kits.

I wish you all the luck and fun of building your first modelship. Remember, a tip from one to another. Your first model is not about a perfect build, but to complete the model and use it as a study / learning proces for the next build.For finishes I'm font of "oils". So I use Danish Oil as a finish. It's easy to whipe on and after two or three thin layers a nice matt / semi gloss finish as a result. Remeber when using oil as a finish, only apply oil on the surface of the wood when nothing else has to glue onto it.

1: oil on rag / towel / cloth and whipe on,

2: after a few minutes, whipe off with clean rag / towel / cloth,

3: repeat step 1 and 2 of another 2 times, but use a couple of hours in between so the layers can sink into the wood, depending on the brand.

Have fun!

Peter- Louie da fly and Lapinas

-

2

2

-

Thank you PJTheJet for mentioning me, or better my buildlog in your topic. You have done some spectacular research which will come to good use during the build. I will follow with great interest.

The manual and the pictures provided by AL are rubbish for this particular kit. You will raise some questions for sure when you get to the rigging part.

Good luck on your build mon-amis! -

On 9/16/2019 at 3:13 PM, Sunsanvil said:

Meticulous work. Fine finish. A truly inspirational build.

I have what might be a silly question (please forgive if this was addressed somewhere in the middle and I missed it): Why no drain holes at the sides of the lower deck? (I think they are called scuppers).

B

Good question B, I did not make these holes due to the scale of the ship. They would be so tiny and also on the outside of the hull a real pain in the @$$ to make. So I choose to make the model without.

-

19 minutes ago, Ab Hoving said:

Well, I happened to be one of the three people (together with Herbert Tomesen and the late Cor Emke) who were responsible for the present design of the 7 Provincien, the ship on the stocks of the Batavia wharf. Regrettably the built was stopped a few years later as a result of a lack of funds. It was decided than and there not to apply the shell-first method, but to use a more modern way for safety. This was because the first effort to build the ship shell-first failed as a result of a lack of experience with the method. No criticism about the volunteers on the ship-yard, but they are not always as well informed as could be hoped for.

As a rule ships in the 17th century were built shell-first in Holland, although there are indications in literature of a different method of construction for the Rotterdam area. However no archaeological find has confirmed this so far, so about some aspects of this matter we are not quite certain. In the eighties, when I discovered the different methods described in contemporary literature, I tested both methods in model scale and both appeared to be successful. Maybe one day we are lucky enough to find indications of this deviating method somewhere on the sea bed.

Like you I am proud to see the beautiful ships that were made in Holland, in spite of the simple tools and the tough materials that were used. Modelbuilding is one way to spread the word...

Well spoken, thank you I can talk for hours on this subject! 🙂Time to get back to your model! 😉

Peter

- Piet, druxey, FriedClams and 1 other

-

4

4

-

10 hours ago, Ab Hoving said:

Hi Peter,

In my opinion the best way to understand the shape of Dutch ships and the way they are planked is to study the method of construction. In many southern countries, including England, people used a way of building with pre-defined frames. Use of the mezzaluna was custom. Shipbuilders applied moulds and other ways of deciding the shape of the frames before planking their ships. In Holland that method never landed. Up to the end of wooden shipbuilding we built ships shell-first, laying the planks of the hull first and filling in the frames later. That method reaches back to the Scandinavian method of how for instance drakars were built.

That and the obvious shallow waters in our region caused the flat-bottomed shape of our ships and I am always surprised to see how our shipbuilders succeeded in giving their vessels such a beautiful and flamboyant shape. That is something that will always intrigue me and my aim has always been to show that to other people, hoping they will see the same beauty.

Hope this explains a bit of your question.

Ab

Thank you for your answer Ab! The shell first method so...I mean at that timeperiod the biggest ships were build in Rotterdam and Amsterdam at the “admiraliteit”. Someone on the Bataviawerf told me that the shell first method was a common method used in Rotterdam but not always in Amsterdam. By that they followed the Amsterdam way by placing the frames first for the 7 provincien replica. Your answer tells me that this was probably not true at all and it was the custom to build shell first on all the “big” shipyards in the Netherlands, they just forgotten how to build it that way and tried and failed to use the frames first method.

I love the shape and ingenuity of the Dutch ships...makes me proud to be a Dutchman. 😉

thanks again,

Peter

-

Hi Ab,

Big fan of you and your work of historic Dutch shipbuilding.Planking method of a 17th century Dutch vessels hull differs a lot for instance with a English, French or Spanish vessel of that timeperiod. Do you know the reason why the Dutch choose a different way of planking? May also the "vlakbouw" method be of importance in this instance?

Also the hull shape is smaller / sleeker and at the bow much more flatter. This is also good to be seen at your yacht.

These differences has alway's intrigued me, but the answers are not clear to me.

Following your build with great interest!

regards,

Peter

Cazador Jabeque / Xebec by Katsumoto - FINISHED -OcCre - 1:60

in - Kit build logs for subjects built from 1501 - 1750

Posted

Chapter 12,99 - constructing the rudder and helm

I've done some work on the rudder. Made out of walnut of course...

Next update the rudder with helm will be placed on the ship.

see you next time and thanks for all the likes and comments!

Peter