-

Posts

2,732 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Glenn-UK

-

-

7 minutes ago, Oboship said:

Great job on the hull and planking! I'm curious about your doing the gun ports. I've seen this part in the manual already and I'm not quite sure yet how to deal with it (will start with Alert in a month or two after Jalouse is completed).

Best regards

UweThanks Uwe for your kind comments. With regard to the gun ports I plan to use my razor saw to cut the depth. I will probably then use a craft knife to remove the material. With the exception of the first gun port which is 6mm deep all the others are 4mm deep which is same depth as the top plank so it should be an easy task.

-

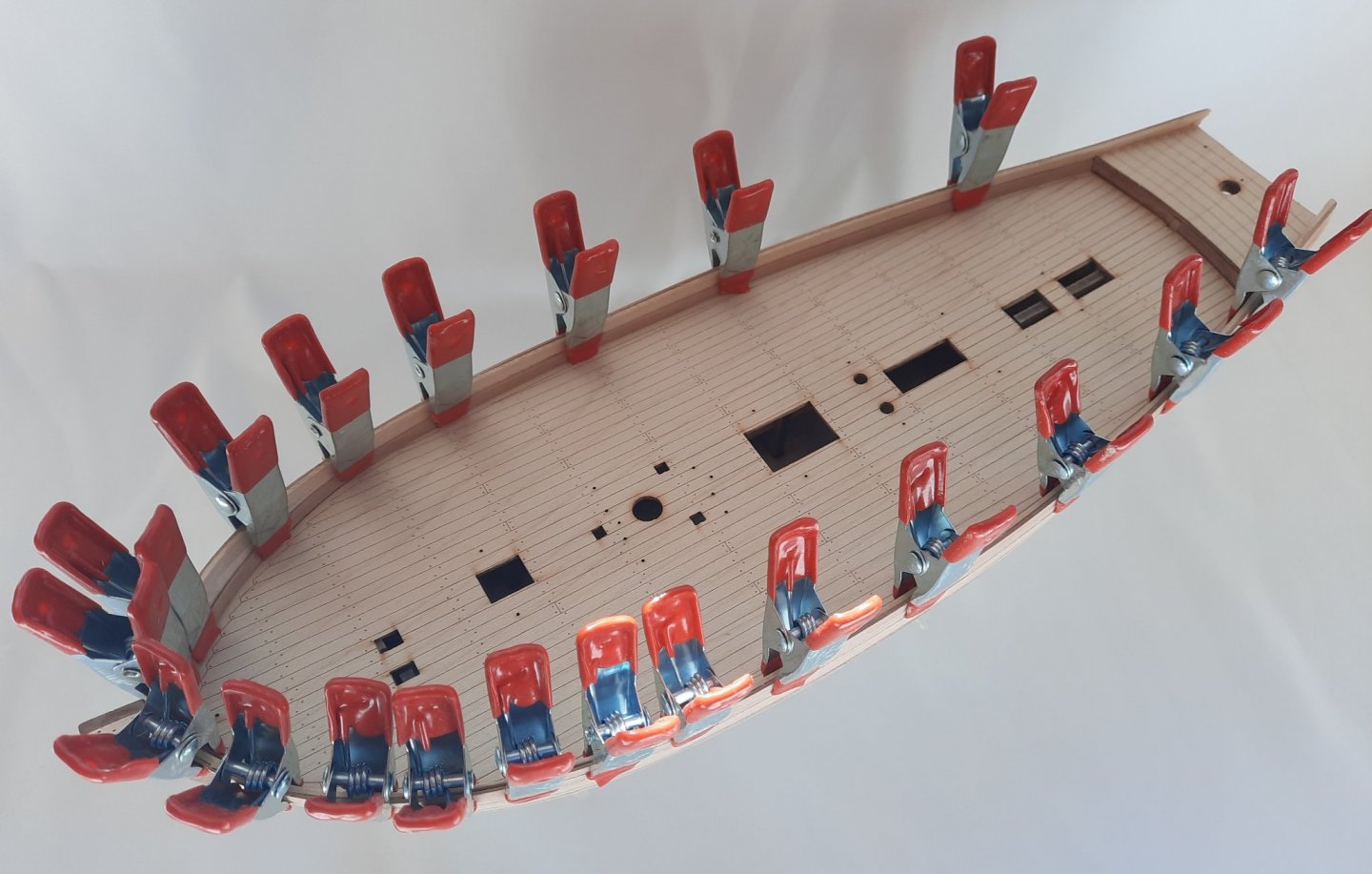

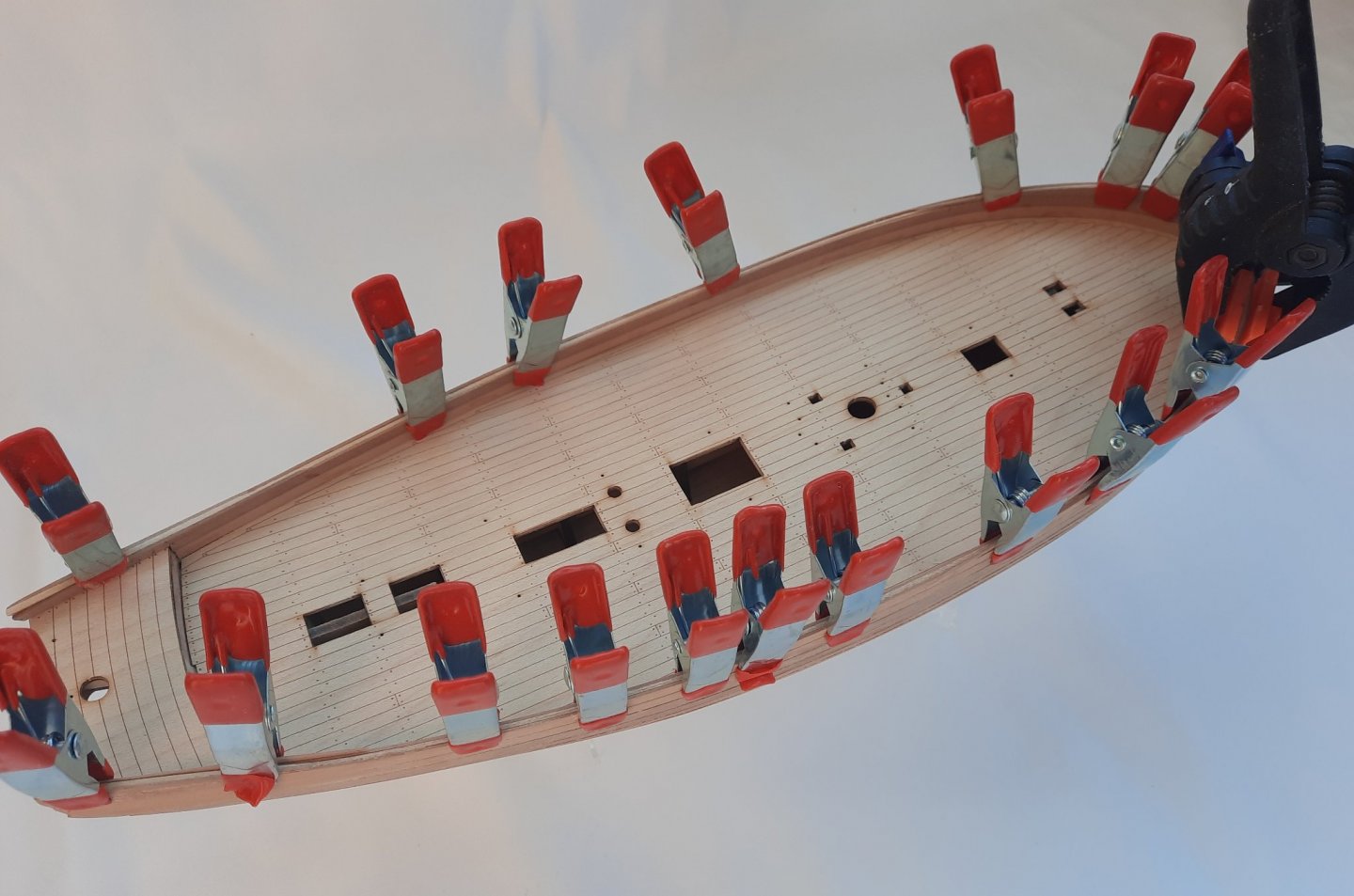

I have made more progress this afternoon and evening with adding the inner bulwark planking.

The left and right lower planks were dipped in water for a few seconds then they were clamped in position.

I then clamped the second upper dampened plank in position. Finally I added the tapered bow and stern third planks.

Once the planks had dried, retaining the curve, I applied a very thin coat of polyurethane varnish to each plank and then, once that coating had dried, I painted the planks with two coats of red ochre.

Once the paint had dried, using Titebond Original, the planks were glued in place. I now just need to trim away any excess plank material along the top edge and to plank the front face of the step between the lower and upper deck.

The next job will be to cut the gun port openings

-

1 minute ago, DelF said:

Wow. Just catching up - that paint line is really neat. Great job!

Thanks Derek, I took my time with plenty of sanding (and filling) between paint layers. I am really pleased with the end result.

-

It has been an interesting morning in the shipyard today.

I started by giving the unpainted part of the hull a very light sanding in a few areas to remove some unwanted pencil marks. I am really pleased with how the hull now looks, after adding the white paint below the waterline.

Forging ahead I then removed the bulkhead tabs and filed the stubs flush with the deck. I also sanded the inner bulwarks smooth removing any residual glue. In the photo below the 6 x stern tabs are still to be removed

With all the tabs removed I then proceeded to test fit the two laser cut deck parts. They were both almost a perfect fit. I just had to sand a couple of edges to ensure the decks would lay flat on their respective false decks.

The next task will be to fit and paint the inner bulwark planks, however before doing this I thought it would be fun to add the previously built deck items. The deck pumps are sitting very proud as I did wish to force them in position as the pump shafts will require a little bit of sanding. I will also paint the rear hatch red ochre to match the rest of the deck fittings.

I quite like the black and white version

-

9 minutes ago, James H said:

This one is moving along quickly. You're putting me to shame.

That is praise indeed😁. However I am still in awe of your skills and speed.

-

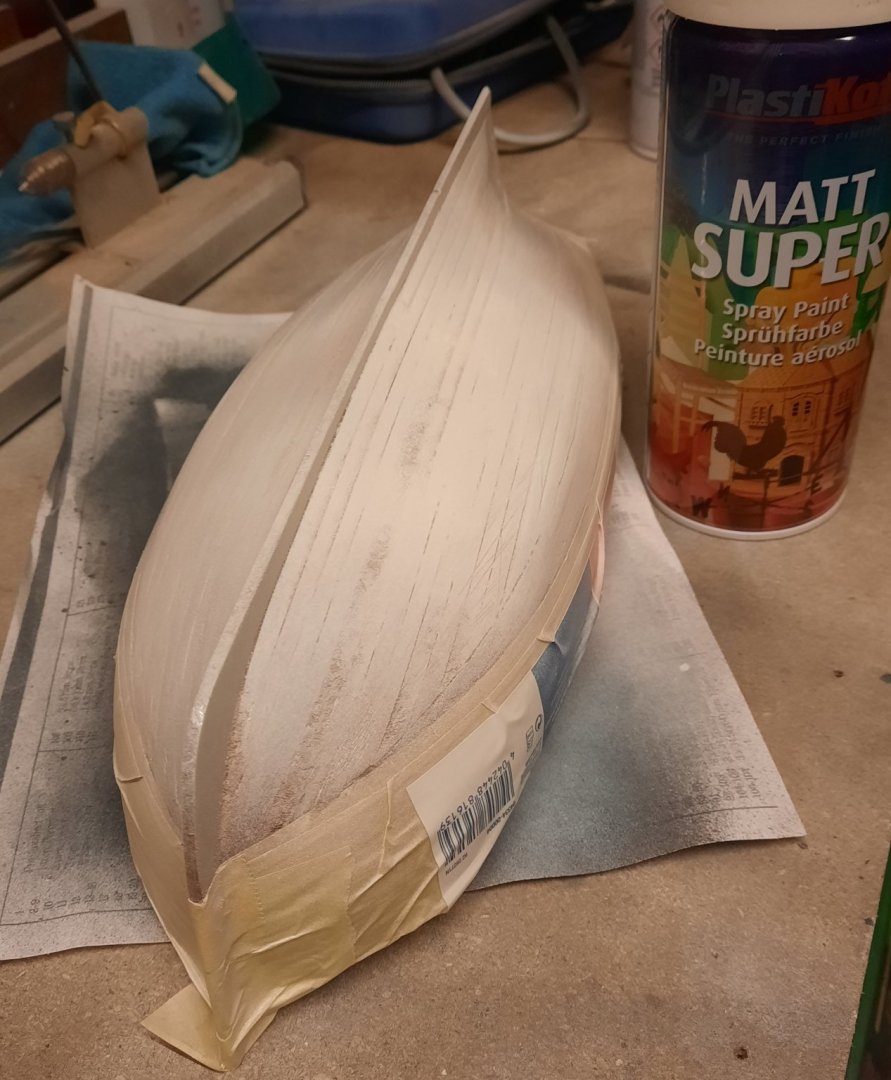

As I finally decided I was happy with how the white painted hull (below the waterline) looked I took the plunge this evening (while watching tv) to remove the masking tape.

As the upper tape layers were being removed I was a tad anxious to see if there would be any paint bled.😬

As the final waterline tape layer was removed I was very relieved to note there was no bled. I really like the sharp lines along the waterline and I am very pleased with the end result. 😁

I plan to give the hull a very light sanding above the waterline to remove some unwanted pencil marks as I did initially make a positional error with the initial waterline marking attempt.

A nice side picture of the painted hull

There is a little bit of work required on a plank half way up the stern counter pattern. I do have plenty of sawdust left over to fill the gap.

Bow area

-

3 minutes ago, Theodosius said:

And I'm a little bit jealous about your white. I mean, it was the the admiral who decided for Speedy and not for Flirt, because of the coppering. Bling bling, you know, lol :-). Hope it was not a mistake...

Thanks for you kind comments. I liked the coppering finish on my Speedy and Victory, the do look great when done. I liked the grey paint in my Yamato and white paint on my Duchess of Kingston.

-

I now believe I have completed the painting the hull white below the waterline. When I look closely at the hull there are still some very small "potholes" visible . I know I could continue to fill, sand and paint the hull to eliminate these few remaining "potholes" but I am not sure if it will be worth the time and effort required as I think these "potholes" actually add some character to the build therefore I am tempted to leave them.

I have attached a couple of pictures which shows how the hull now looks. Once I have finally decided to move on with the build with the hull as is I will remove the tape. Hopefully there will not have been too much paint bled.

Starboard Side

Port Side

Arial view

Arial View

- Theodosius, James H, DelF and 1 other

-

4

4

-

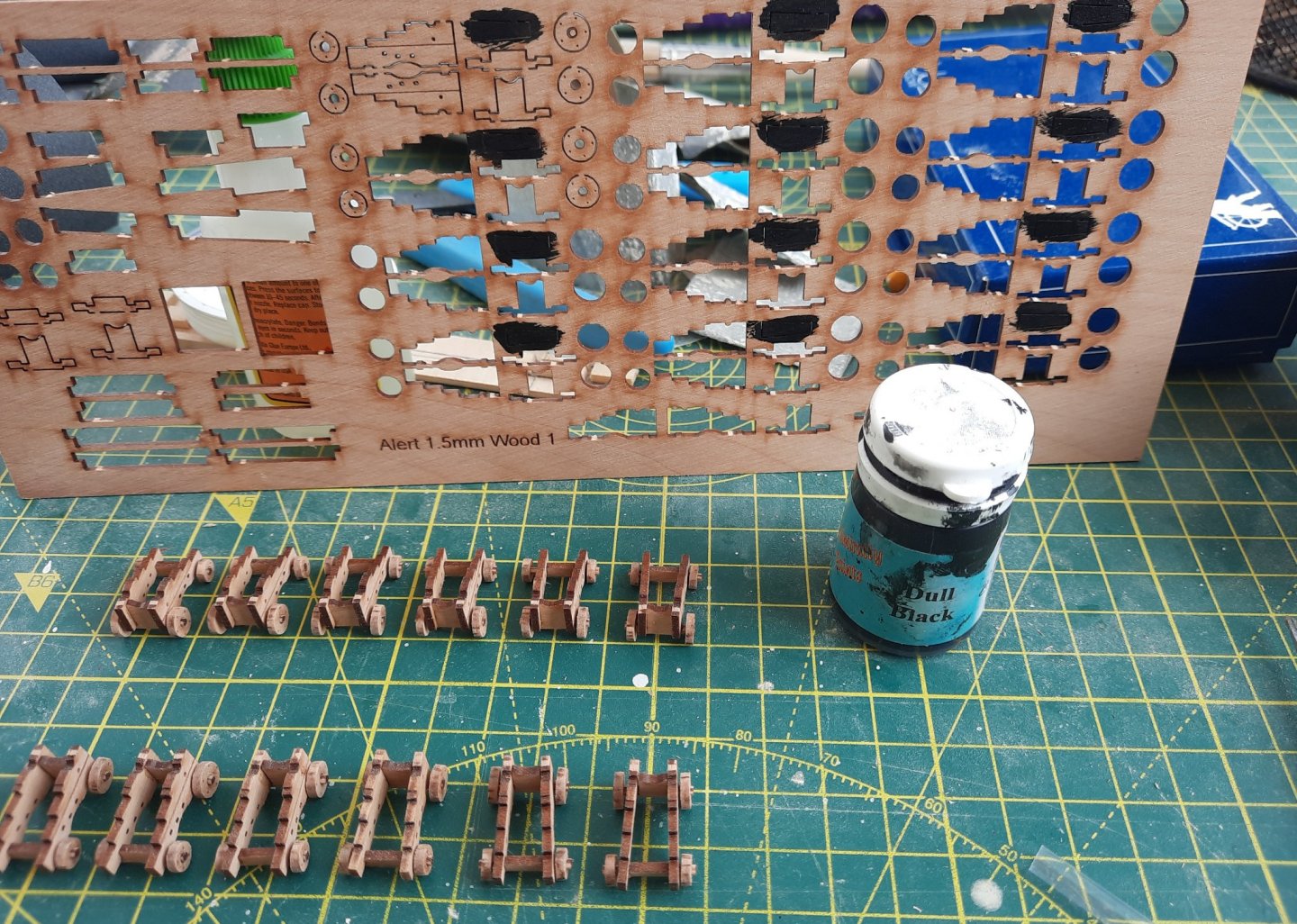

I am currently painting the hull white (below the waterline). After each paint coat the hull is sanded and filled as necessary. Hopefully the painting of the hull phase is now nearly complete. As there is quite of bit of dead time as each paint coat dries I thought I would use the time to build the 12 x 6 pounder cannons.

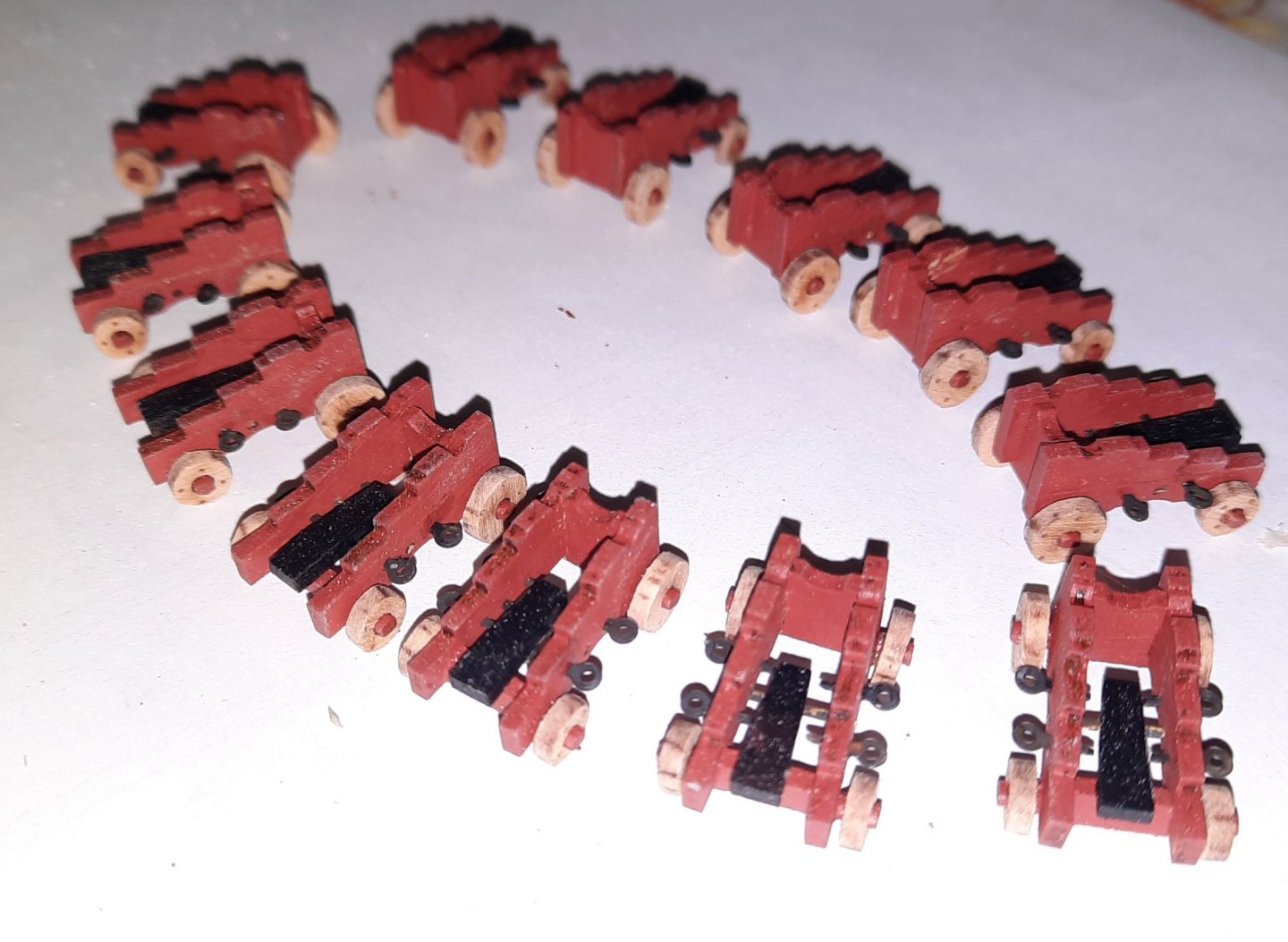

Stage 1 - Preparing the Axles

The first task was to file the edges of the front and rear axles so that the wheels would fit. As each axle was sanded I did test fit the wheels, as shown in the photo below. I also removed the laser char from the 24 front and 24 rear wheel rims.

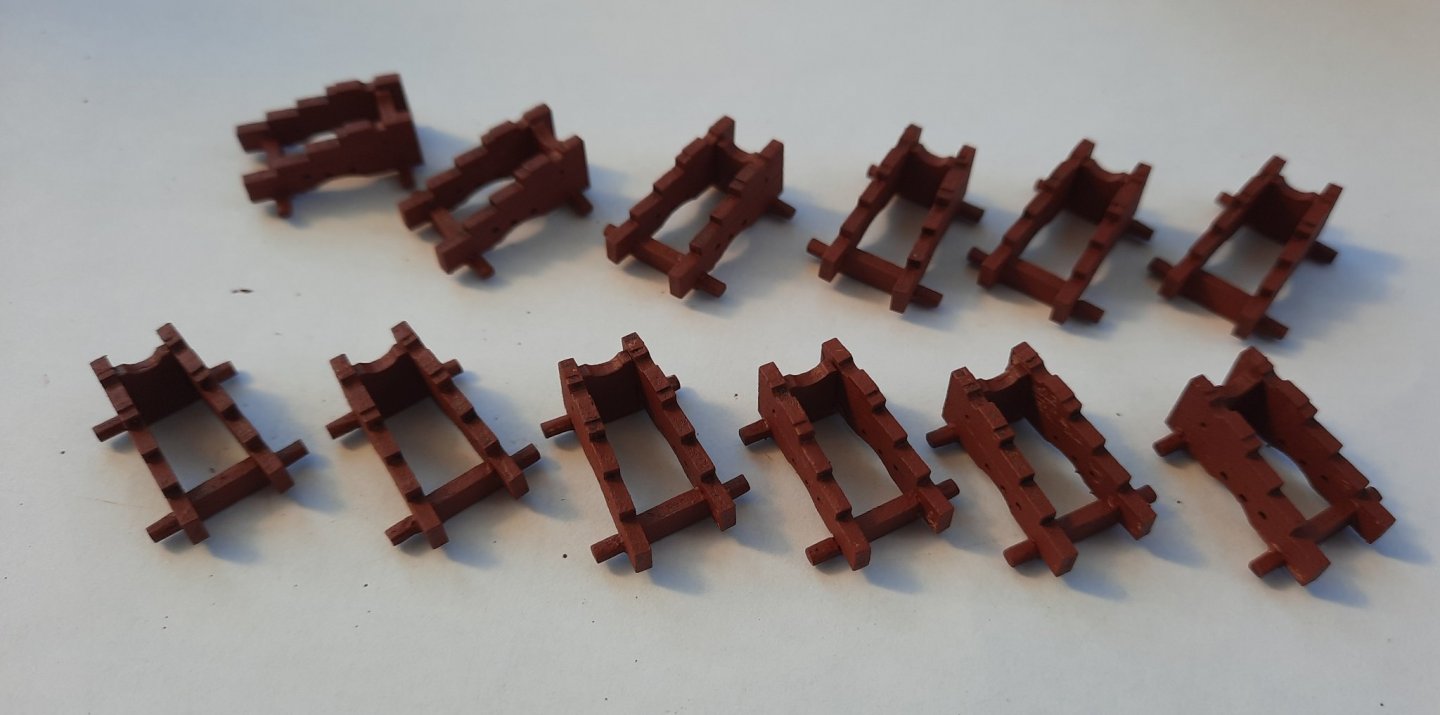

Stage 2 - Building the basic cannon frames

This was a simple task of gluing the left and right gun carriage cheeks to the front and rear axles. I applied a drop of Titebond original to the slots in the axles. I fixed both gun carriage cheeks to the front axle and I then added the rear axle.

Once the assembly was completed the frames were painted red ochre. I also painted the gun carriage beds black.

6 down and 6 to go

All 12 completed

The gun carriage beds have been painted black

Gun Carriages painted red ochre

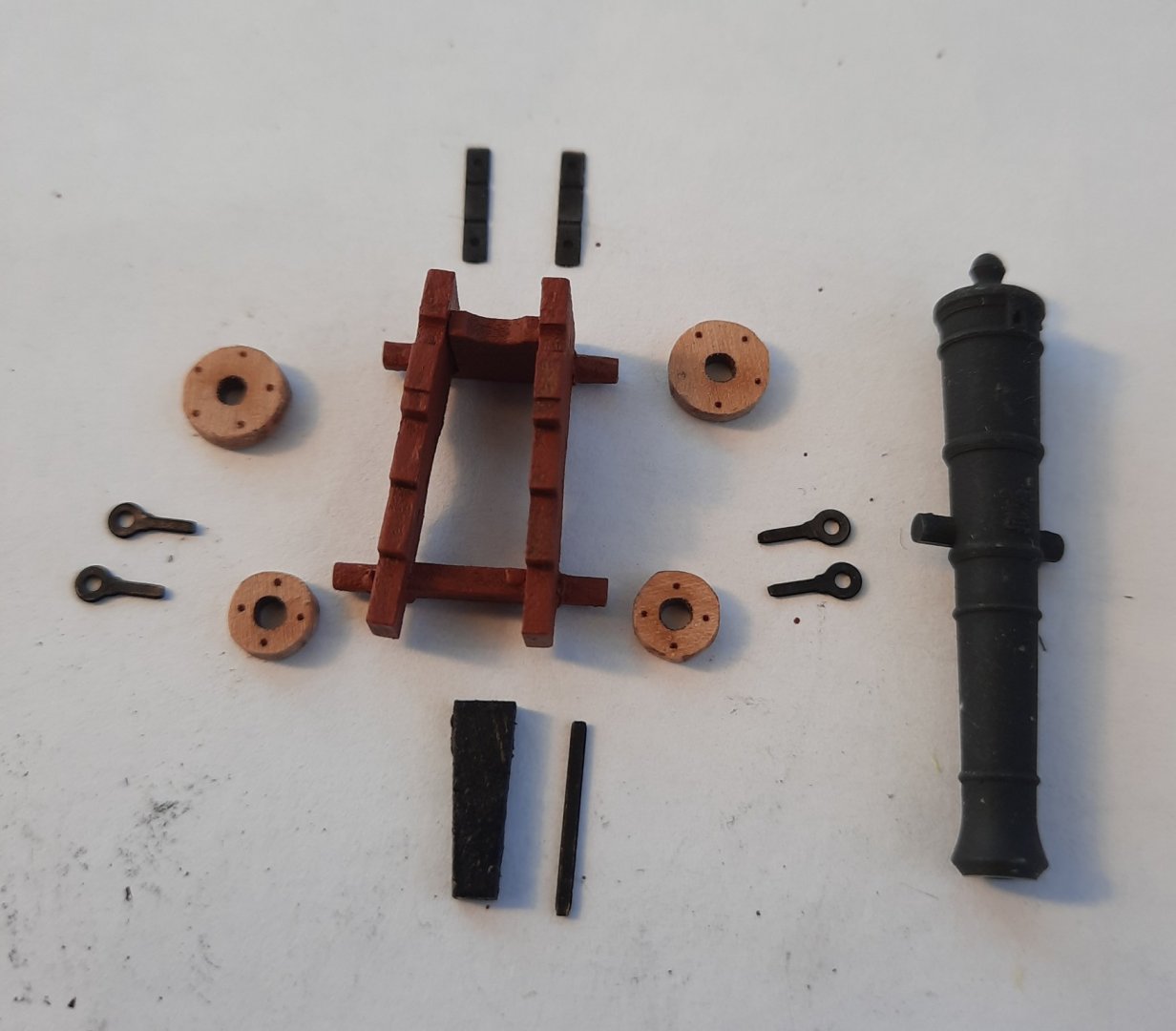

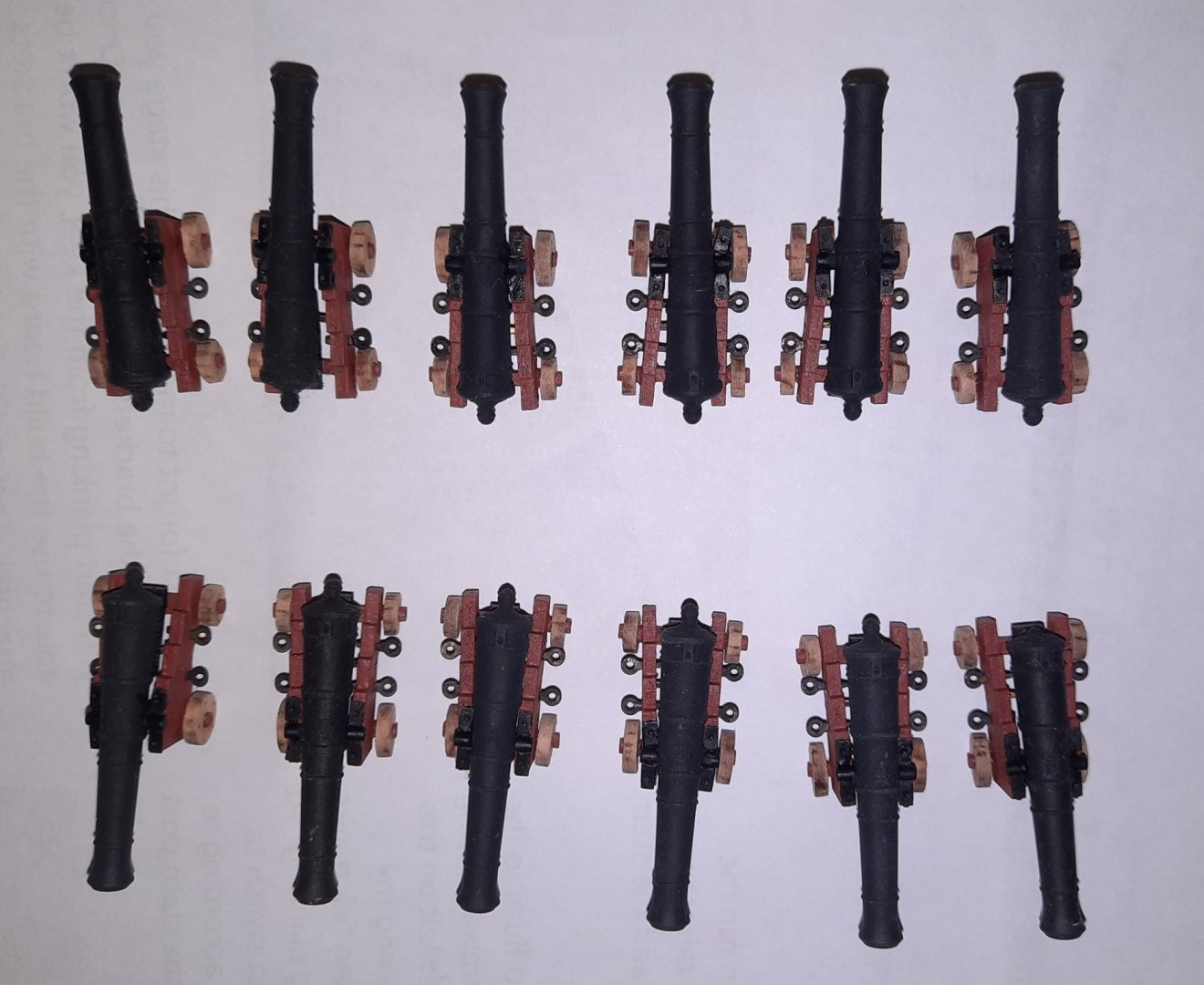

Stage 3 - Adding the PE parts

Each 6 pound cannon requires 1 x carriage transverse bolt, 2 x cap square and 4 x eyebolts. These are PE parts and need to be blackened. These parts were cleaned in acetone and then warm soapy water. Once they were cleaned and dried they were blackened using a burnishing solution.

Parts ready to be fitted

I started with fitting the carriage transverse bolt. Once these were in place I was able secure the carriage bed's. Next the four wheels were added to each gun carriage.

Picture with the cannon dry fitted

All 12 cannon frame assemblies completed

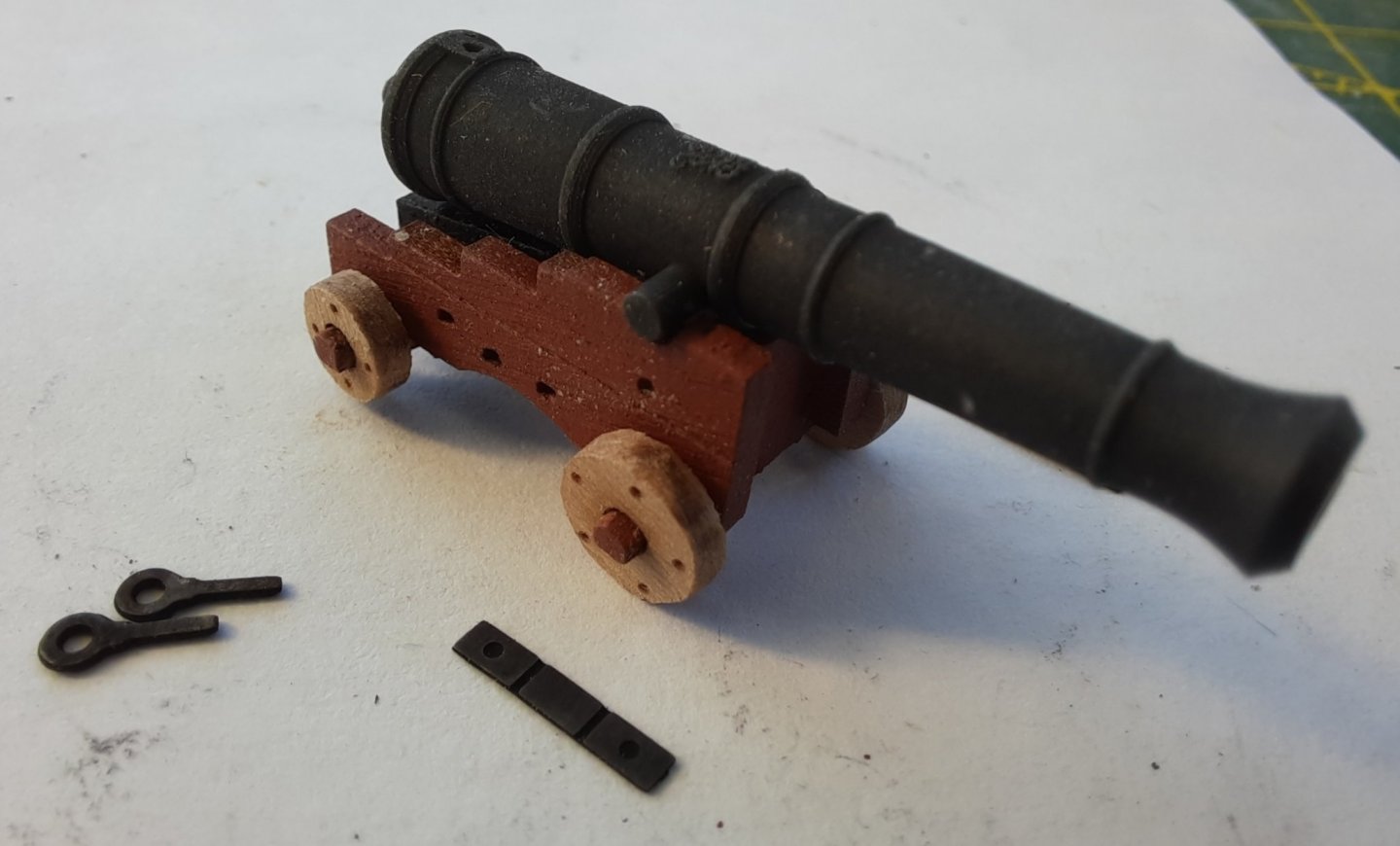

Stage 5 - Adding the cannons and cap squares

I used a touch of Titebond to secure the each cannon to the gun carriage. I ensured each cannon was correctly positioned with the crest and firing hole upmost. Once all the cannons were glued in place I added the cap squares.

Picture of 1 completed cannon, the crest and firing hole can be seen on the cannon

Completed cannon from a different angle

All 12 completed cannons

- James H, DelF, Theodosius and 2 others

-

5

5

-

-

25 minutes ago, ccoyle said:

Chris is leading the way in making complex subjects more accessible to modelers of average ability.

This is so true, I am somewhere between a beginner and average ability modeller and I have found a range of accessible and outstanding looking models to build.

- Keith Black, mtaylor and Rik Thistle

-

3

3

-

24 minutes ago, James H said:

Are you trying an acrylic filler with a little wood glue in, diluted of course? I apply this before any paint, and rub back and fill again. There's always more filler needed when the paint goes on though....never any luck with me in avoiding that 😆

I did start by filling and sanding back the obvious dips in the hull using a sawdust and diluted titebond paste mix. I then like to add a thin coat of paint as I find this highlights the less obvious areas that requires a bit of additional filler. For this I will use a diluted 50 / 50 titebond and Ronseal wood filler mix.

I did cut the waterline parts from both sides when removing them. Part 5 started to delaminate as it was being cut and was due to a fault in the material sheet.

-

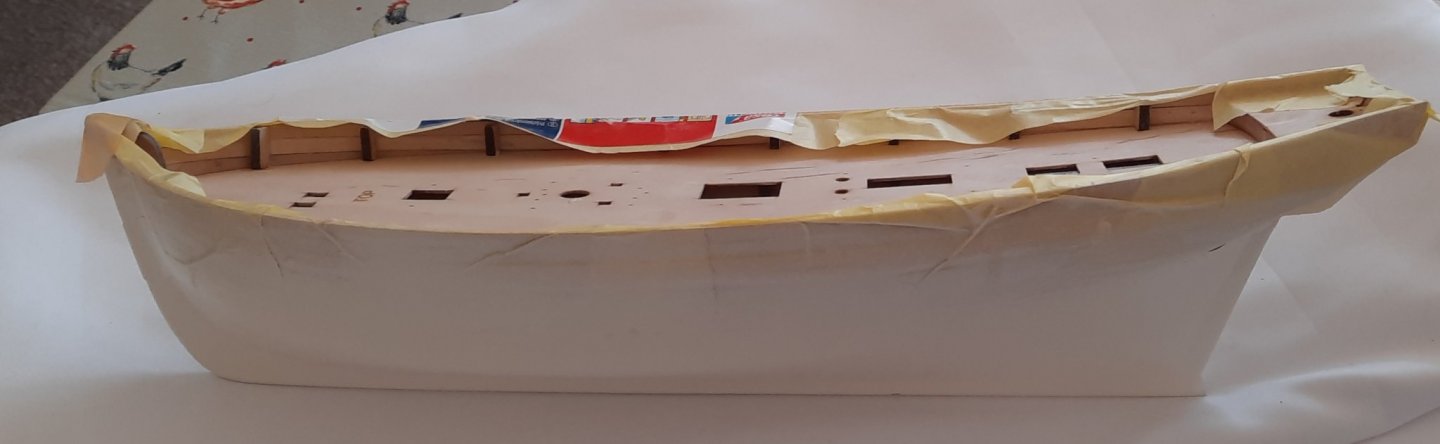

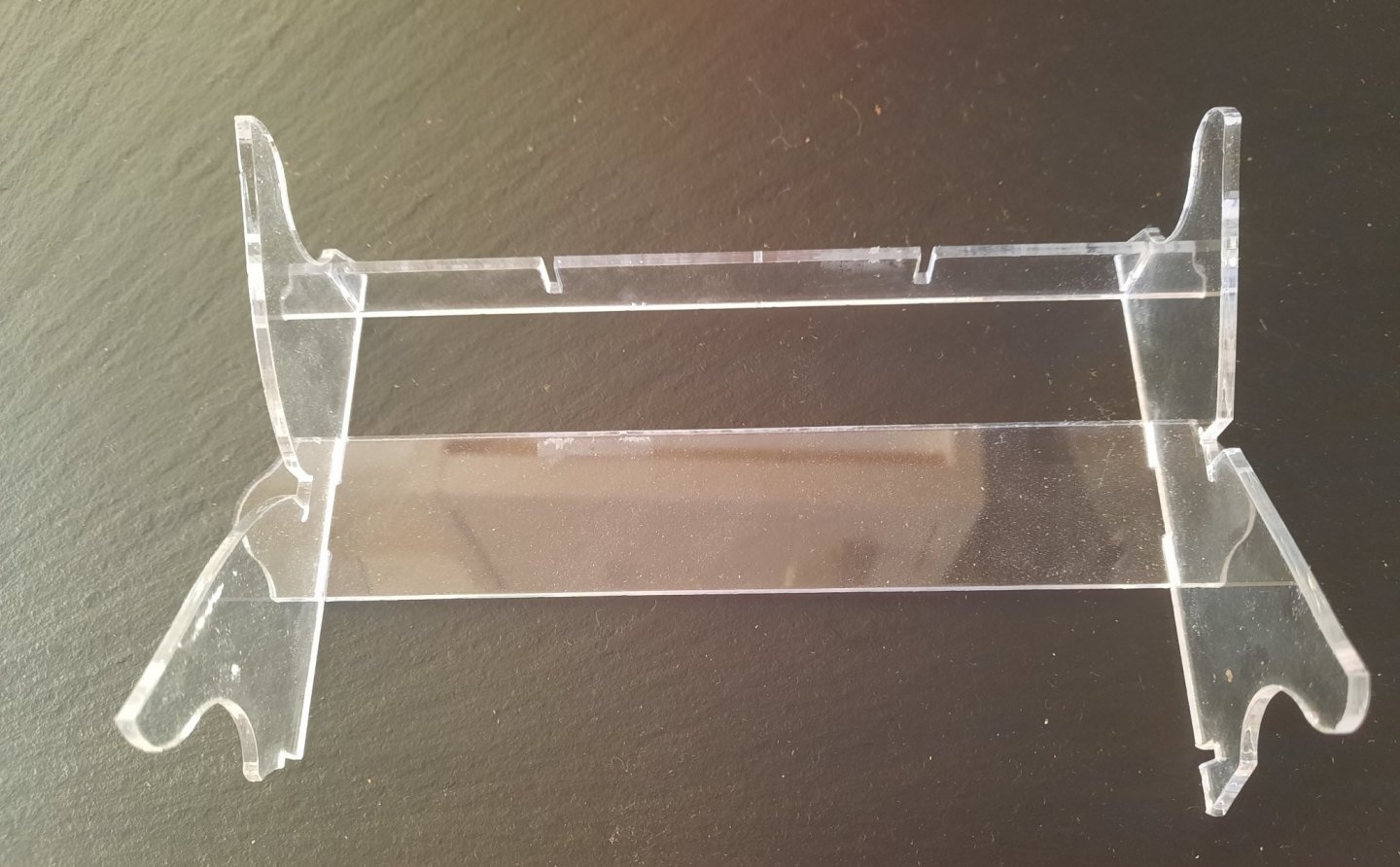

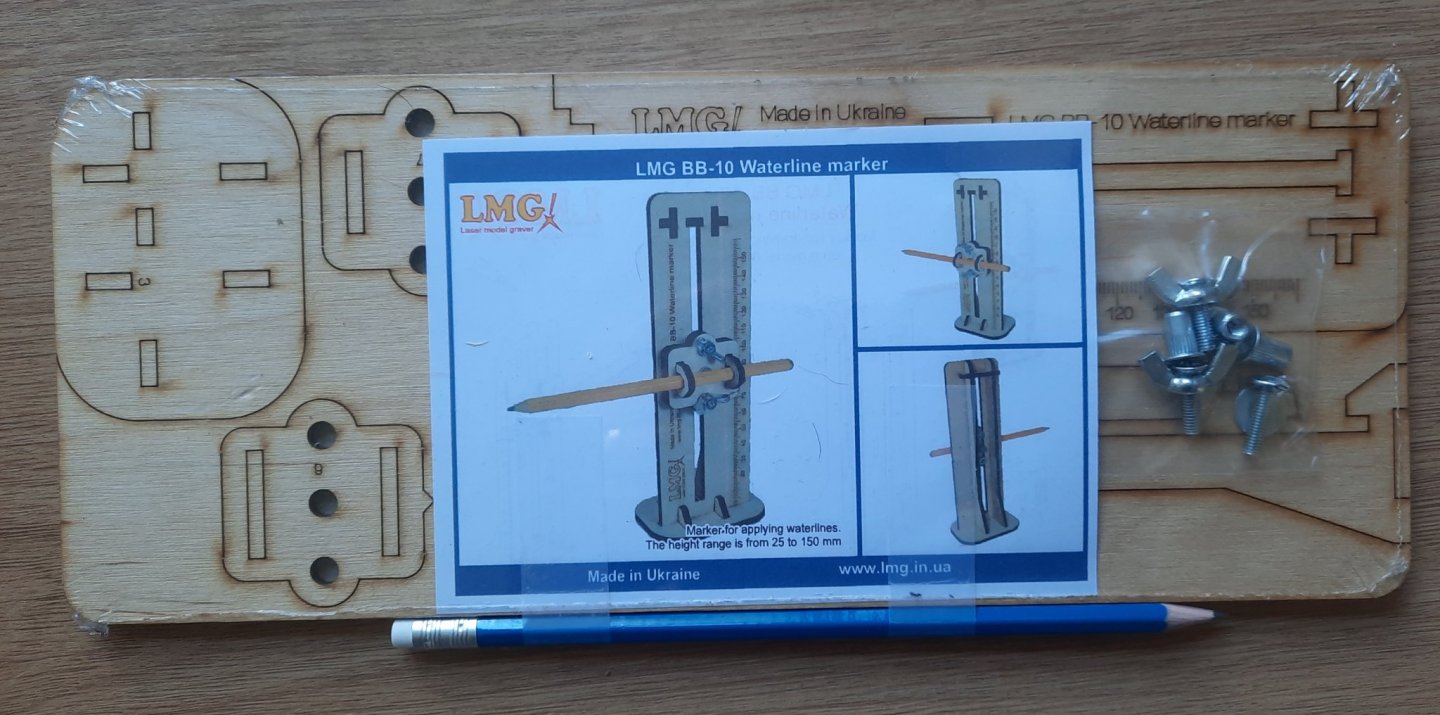

When assembling the stand for the Cutter Alert I managed snap some of the support brackets 😪 as I was trying to slot the parts together. I was gutted but thankfully I had enough unbroken bits to make a usable stand. As can be seen in the following photo both name plate brackets are beyond repair as it one of the long support strips and are therefore deemed to be missing in action.

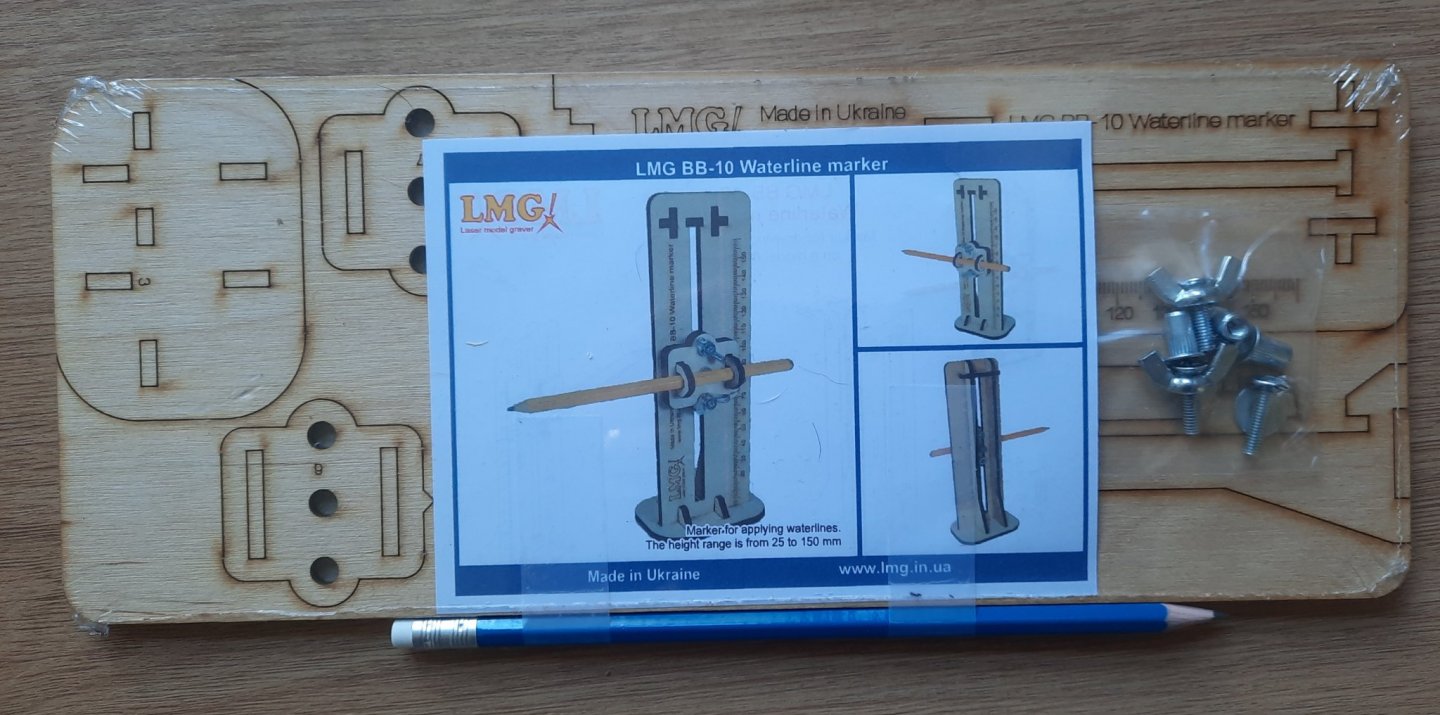

I also received the waterline marker I ordered from Vanguard Models at lunchtime today.😀

I will be honest I was not overly impressed with the quality of the materials of the waterline marker as a couple of parts suffered a bit of delamination which was an easy fix with some watered down pva. I also had to file some of the slots in order for the parts to fit together. I did change my mind on the tool however as I did find the tool easy to use when adding the waterline to the hull.

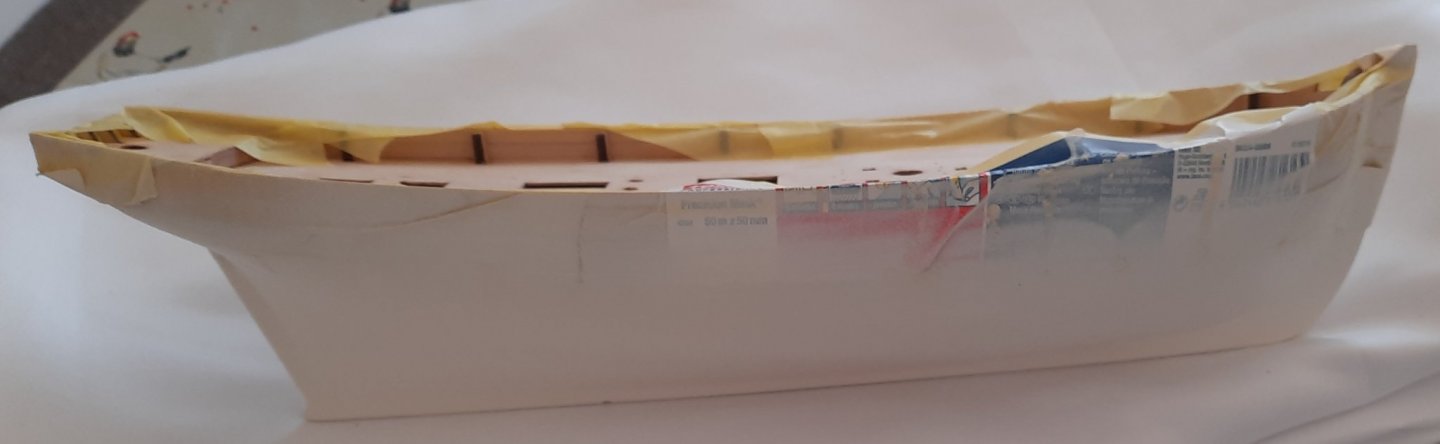

After I marked the waterline I applied tape to the hull in readiness for the painting.

I decided to use the Plasti-kote 3100SE Super Matt White Spray paint. I have now given the hull a light spray coat of white paint which is now drying. Once dry It will be a case of more sanding and filling (where necessary). I will then spray another light coat of white paint which will be followed with more sanding (600 to 800 grit) and light spray painting until I have an overall smooth white finish.

- chris watton and James H

-

2

2

-

- chris watton, egkb, Canute and 1 other

-

4

4

-

Today I have started the process of sanding the hull.

After the initial sanding all over (using 320 grit) I was pleased with how the hull looked. I will need to complete the hull sanding processes with a finer grit (600 or 800 grit) at a later stage. Before I do this as the hull is to be painted white (below the water line) it is very important to fill in any dips to get a nice smooth paint finish.

My first step in this regard is to fill any areas which are clearly visible to the naked eye. To do this I used my Gimour TPK-PT014 (a cheaper version of the standard Dremel) on some left over planks to collect some sawdust.

I then mixed some of the sawdust with a diluted pva solution in order to create a wood filler paste. The following photo shows the remnants of a paste mix and the brush used to apply the paste.

I apply plenty of the wood filler paste to the dips. It does not look to pretty (as can be seen in the photo below) but once the paste has dried it can be sanded smooth and any remaining dips can filled with more past.

The whole hull coated with areas coated with sawdust wood filler paste

I will post some more photos of the sanded hull to show the end result in the next day or two.

Once I happy with how the hull looks to the naked eye I will spray a thin coat of white primer paint (below the water line) which will highlight possible imperfections which are not visible to the naked eye. These imperfections will be sanded smooth or filled as necessary. I will probably use a diluted Ronseal wood filler /pva mix when I get to this stage to fill any remaining dips.

Hopefully the Vanguard Models waterline marker I have ordered will arrive in the next day or two 🤞😀 as I do not really like the Amati waterline I currently use.

-

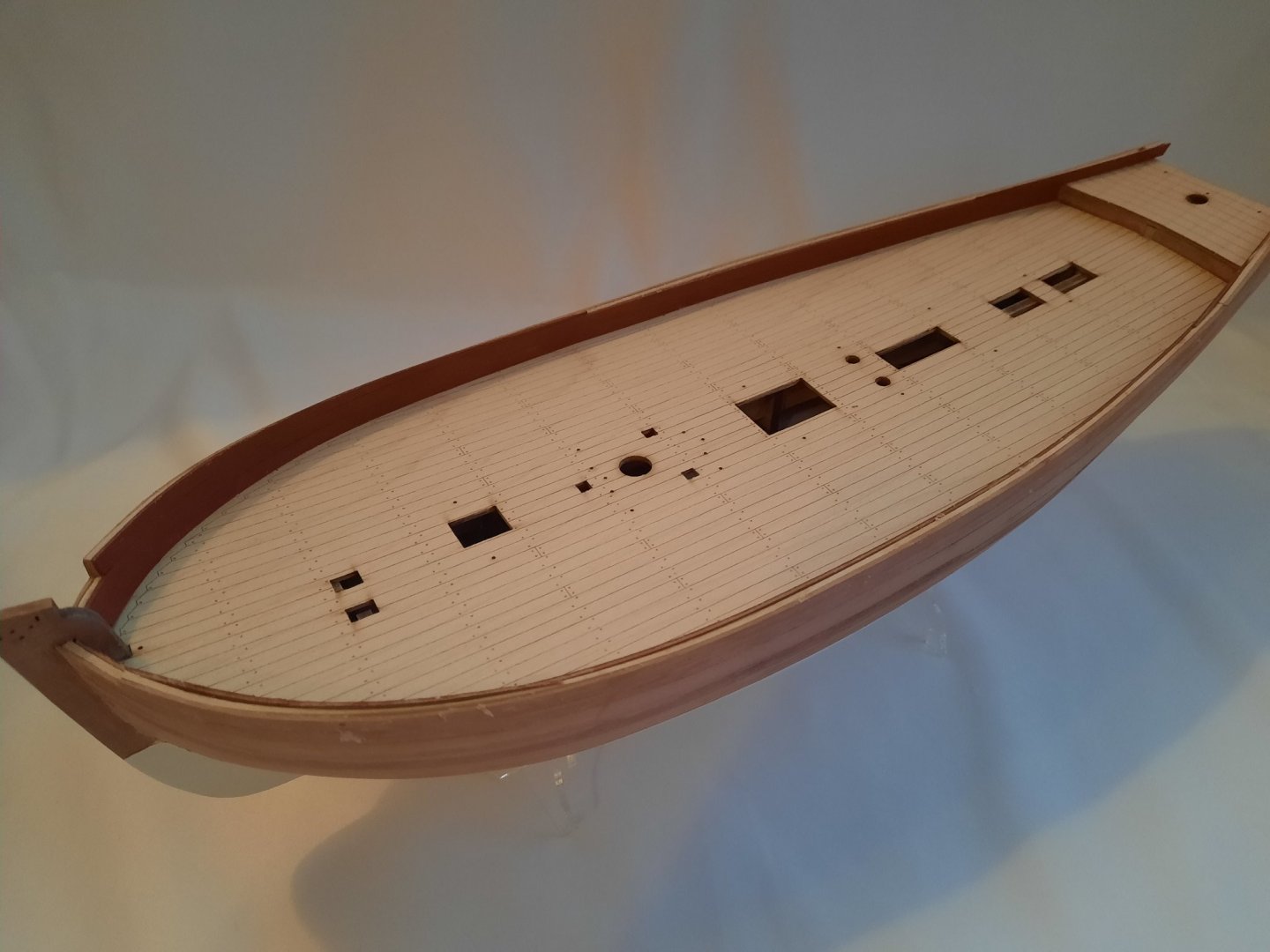

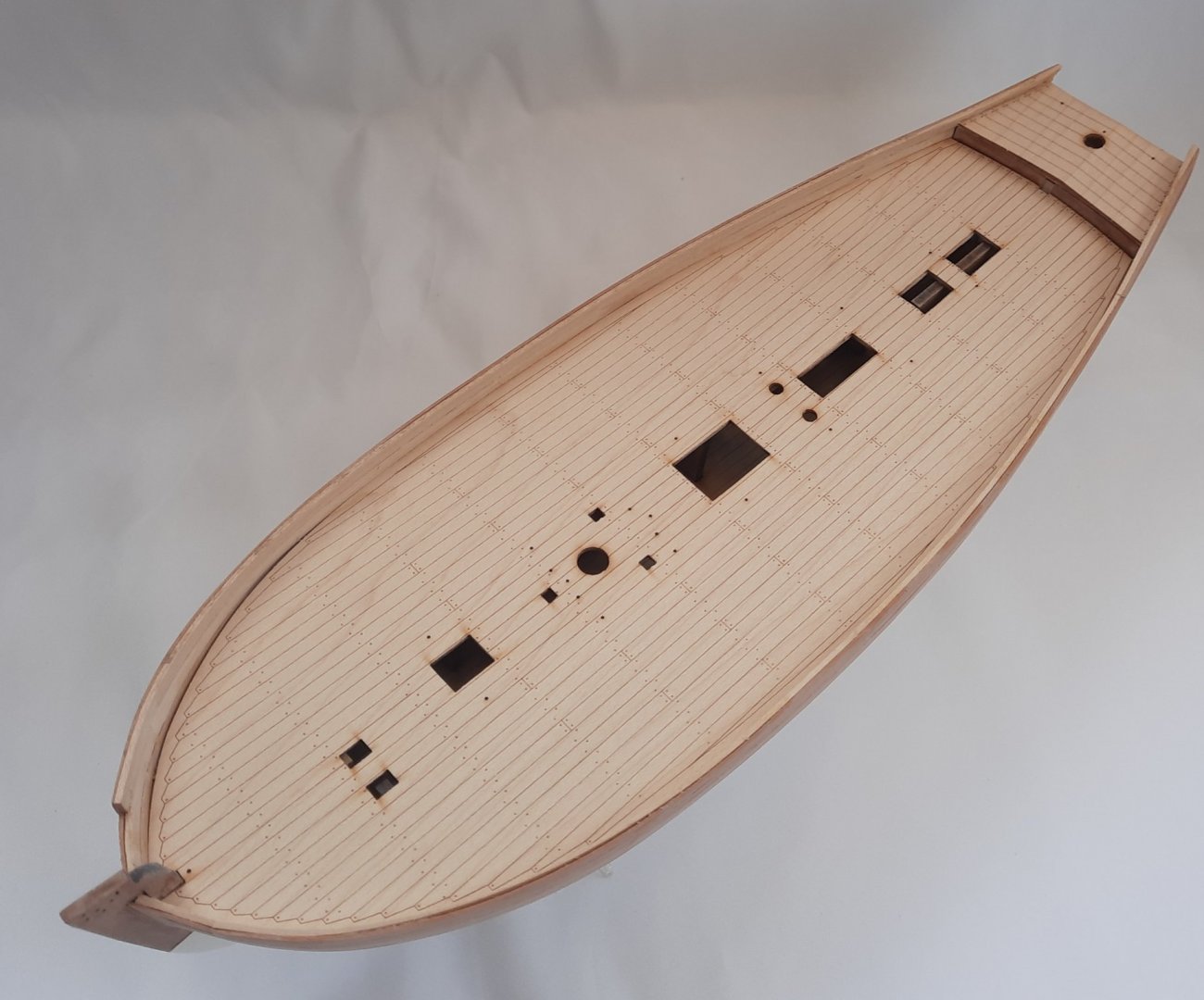

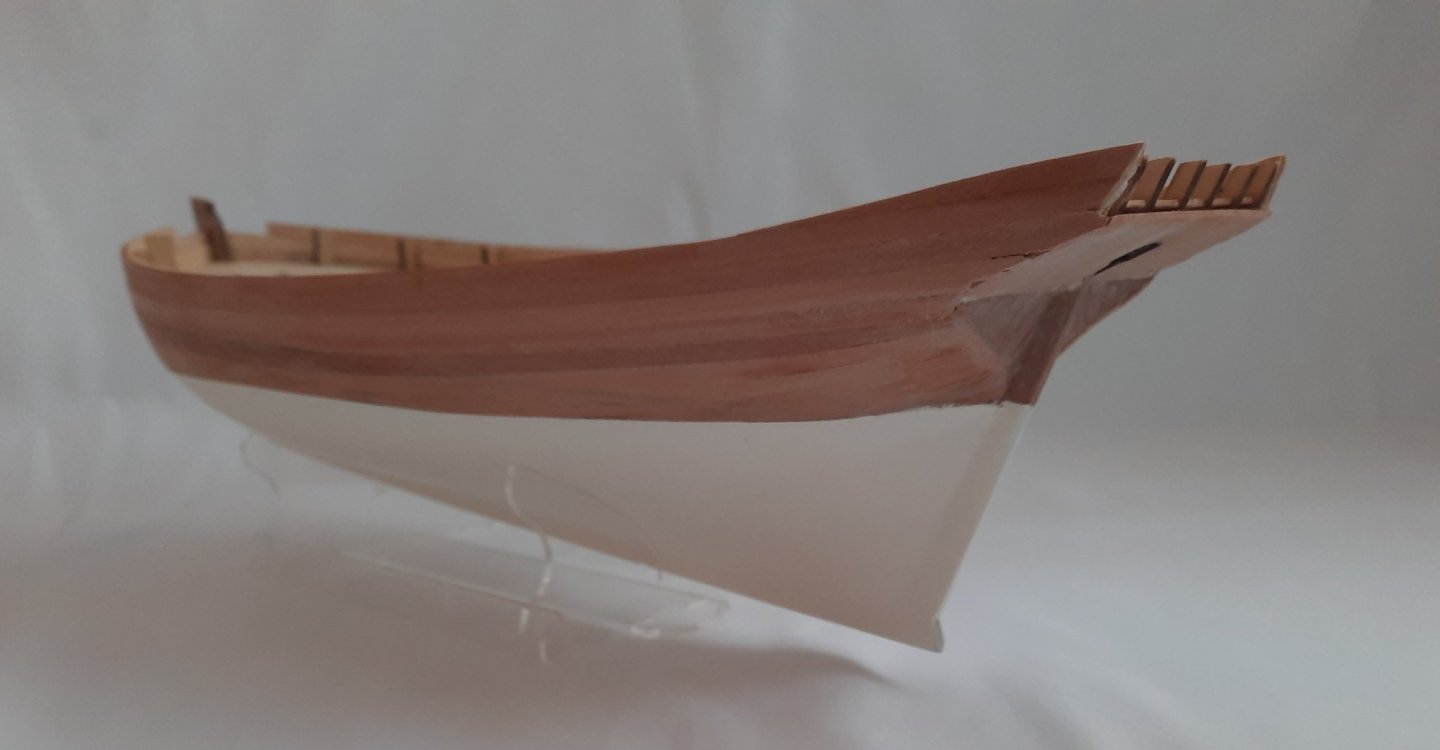

I have had a good day in the shipyard today and I finally completed the 2nd planking. The 2nd planking has been trimmed around the stern area.

I then applied a thin diluted coat of pva over the hull and gave it a light sanding in order for some of the sawdust to fill any gaps between the planks. The hull will require more a bit more sanding (and filling where necessary) before I can move on to the next phase of the build.

Here are some pictures.

- Ryland Craze, Theodosius, DelF and 1 other

-

4

4

-

Very excited about The Sphinx it looks amazing. Fingers crossed for a July release date.

- chris watton, Nirvana, Canute and 1 other

-

4

4

-

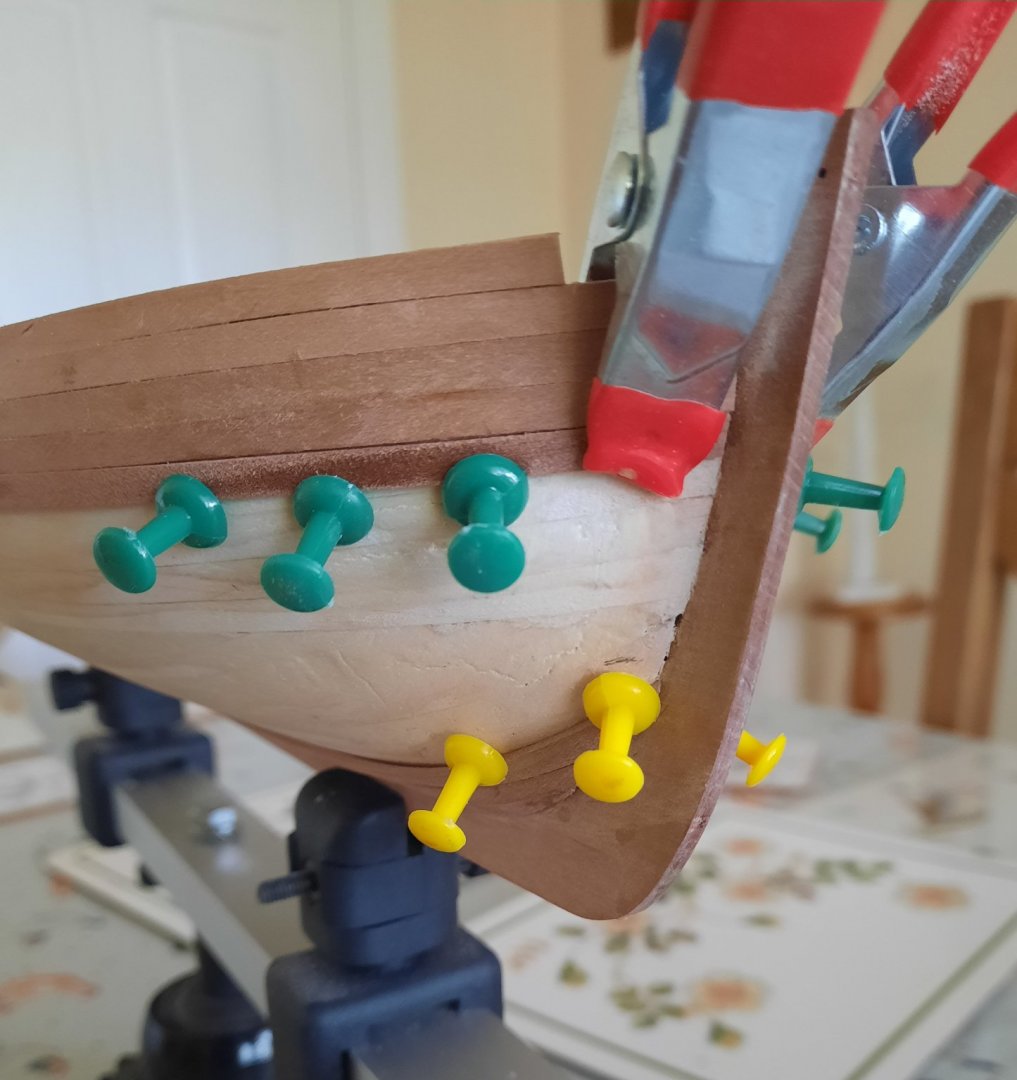

I have continued on with the 2nd planking and I expect to complete this task within the next 2 or 3 days time. I do have an Amati water line marker but I have never been happy with it as I have found that the pencil tends changes position when I attempt to add a waterline mark. I have therefore ordered the waterline marker from Vanguard Models (new tools section) which I hope will be better, fingers crossed it will arrive in time.

I have been using my quad hands to add the lateral (side) bend to the planks. One advantage of using the quad hands for side plank bending is they can be stacked up so multiple planks can be bent at the same time. In the picture below I have a left and right side plank being bent after a quick 5 second dip in water.

With regards to adding the second planks I have continued to use a combination of Titebond original and map pins. Initially, when working in both directions (up and down), I was adding 4 planks at a time (2 port and 2 starboard). However once I reached the waterline mark (at the bow), which is where the up and down planking met I moved on to just adding 2 planks at a time (one per side). It takes around 5 to 10 minutes to shape, bend and chamfer the planks. Once they are glued I normally leave them for around 30 mins before removing the map pins and moving on to adding the next plank pair.

The following set of pictures shows the current state of play. The holes left by the map pins can be seen, but will be covered up when the next layer of planking is added.

A small amount of filler is required below the water line where some planks meet the stem post.

Before I was adding the lower stern planks I sanded the depth of the plank to try to get a smooth line with the keel and stern post. It may not look like that in the picture, but is pretty much the case as it stands.

-

20 minutes ago, James H said:

I made up the test one tonight and I do like it. Nice and stable and easy to move around.

Ordering one first thing in morning and will hope for a Speedy delivery😀😀

- Canute, Ryland Craze, chris watton and 1 other

-

4

4

-

I'm not a big fan of my Amati waterline marker. I will need to add the water line to Cutter Alert in the next few days. I am very tempted to buy the one you have for sale.

- Ryland Craze, mtaylor, chris watton and 2 others

-

5

5

-

-

3 hours ago, drjeckl said:

Glenn - Glad I found this. Pulling up a chair to watch and read. Looks beautiful so far. And I love to read your great descriptions of how to each task. Keep it up....

John

Thanks John

It should be an interesting build, and once have completed the 2nd planking (which I am taking my time with) I should be able to crack on much quicker. I will keep up with a detailed build log of my methods.

You might also enjoy my build log for the Duchess of Kingston (Vanguard Models) which I completed earlier this month.

-

2 minutes ago, DelF said:

I'm watching your use of PVA with interest here Glenn. I seemed to develop an adverse reaction to CA gel when I used it a lot on Speedy's copper plating. Now I can only use the thin odourless version which I don't think would work with planking. You seem to be getting on well with Titebond - would you recommend it?

Hi Derek

Last time I used ca glue for planking I ended up sticking more planks to my fingers than the hull.🤣🤣

I really like the Titebond Original. I normally put a small amount in a dish, enough pva for one plank usually. I use an old paint brush to apply the glue. It grabs very quickly which I really like.

-

Work is still slow and steady with the 2nd planking. At the moment I am using Titebond original pva for the second planking which are held in place with map pins. The method I am using is much more time consuming than the more common method of using ca glue (or ca gel)

To start the process the planks are shaped as necessary. Next I chamfer the edge so it is a nice fit to the plank it adjoins.

Once I am happy with how the plank looks I mark (on the back) the area to be bent. The planks are then soaked in water for around 5 minutes and bent using a heated plank bending tool and then pinned in place. I usually leave the planks pinned for around 30 mins.

Each plank is then given a coat of Titebond original and pinned in place a various points along the length of the planks. The map pins are normally removed after about 30 mins.

4 wet planks pinned in position

Wet planks pinned in position

The end result

The next planking strip will cover up the map pin holes.

- Oboship, Edwardkenway and DelF

-

3

3

HM Cutter Alert by Glenn-UK - FINISHED - Vanguard Models - 1:64 scale - by Glenn Shelton

in - Kit build logs for subjects built from 1751 - 1800

Posted

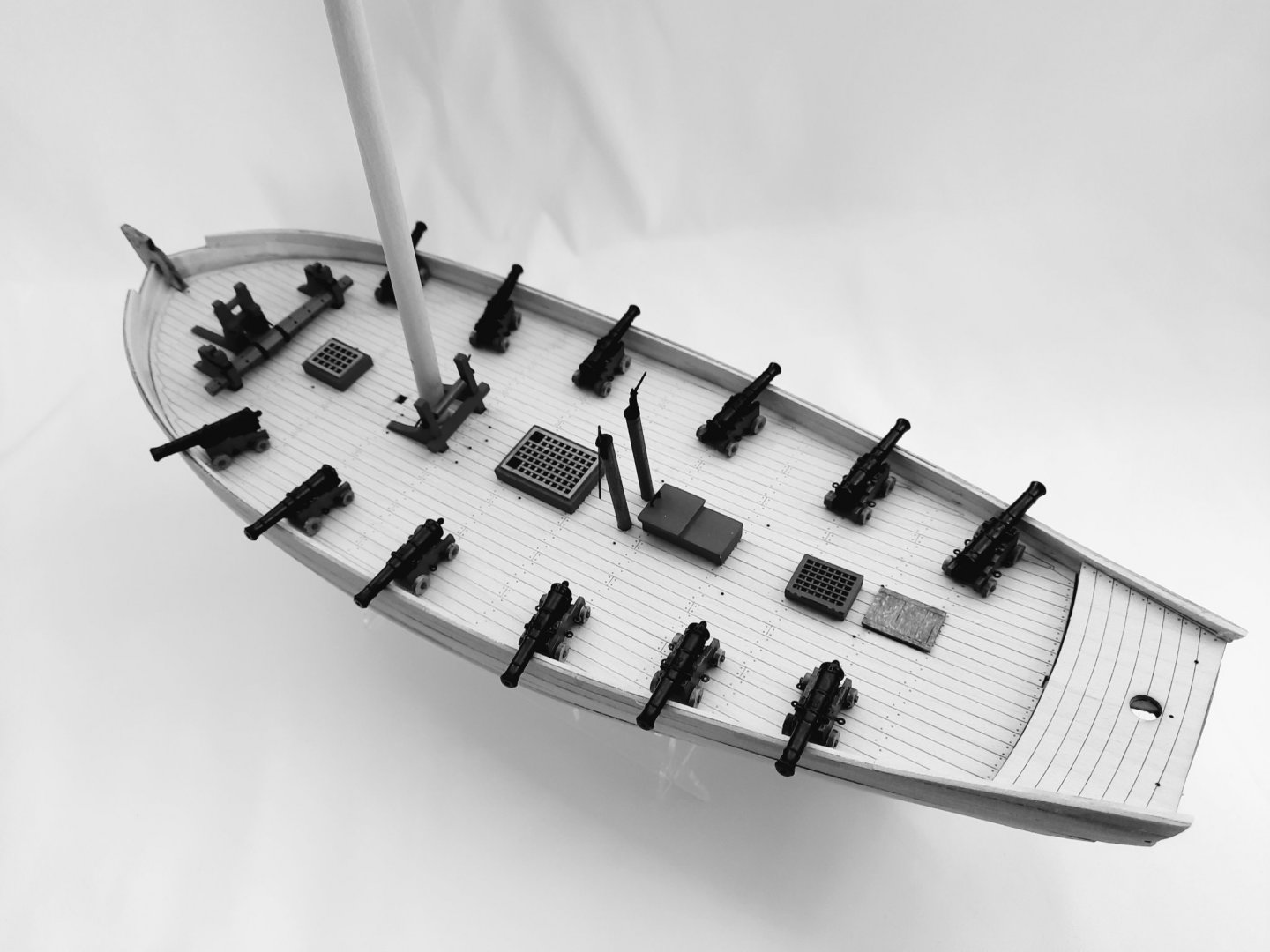

Sometimes when building these models you get a nice surprise. Today I added the gun port cut-outs. This was a task I was dreading for many reasons but it turned out to be a very simple and trouble free task.

The gunwales were marked with the position of the gun ports. It did not take me long to mark these positions on the hull. Next the gun wales were cut to size. I then marked out the position of the gun port using some tape. The gun wales were used to double check the position of the taped area. Once I was happy I used a razor saw to make both vertical cuts. With the exception of the bow cut-out, all gun ports were cut to a depth of 4mm, which matched the width of the top plank (both for inner and outer bulwarks). I used a craft knife to make the vertical cut along the joint line between the first two planks. Therefore it took very little effort to make a clean cut and the resultant gun port opening required very little sanding.

The picture below shows a taped gun port during the cutting process.

Once all the gun ports had been cut out I painted all the edges ochre red. I thought it would be good to dry fit all the deck items for the photoshoot.

This is a close up of a gun port

I like this picture of the deck items

A different view of the deck items

I have also painted the gunwales black so they are ready to be glued in position in the morning.