-

Posts

1,217 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gahm

-

Absolutely amazing, Chuck! Thomas

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

US Brig Syren by Gahm - Model Shipways

Gahm replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

Thank you, Johann! Your kind remark means a lot to me! Thomas -

US Brig Syren by Gahm - Model Shipways

Gahm replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

Oh Steve, I overlooked your question. The case design is not yet clear. Currently I am collecting images of all case ideas, which I like. I should have a pretty good collection once I will need to answer this question 😊 Thomas -

US Brig Syren by Gahm - Model Shipways

Gahm replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

Steve and Andrew, thank you for your kind remarks! And again, thanks for all the 'Likes'! Gulfmedic1, I apologize for the late reply. I did not have access to the internet for several days and therefore did not see your question. The rivets are imprinted the usual way, i.e. the result are really rivets which are not 'outward' rivets but 'inward' rivets. Amazingly due to their small size it is difficult to distinguish - like an optical illusion. To achieve this size - also to stay somewhat within the correct scale - I used diabetes needles for the inprint. Thomas -

You have created a wonderful model! Thomas

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

US Brig Syren by Gahm - Model Shipways

Gahm replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

Thank you, B.E. and Glenn! This kind of feedback is always highly motivational and appreciated! Thomas -

Fantastic work, Mike! What a beautiful model! Thomas

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

US Brig Syren by Gahm - Model Shipways

Gahm replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

Bob and Stuntflyer, thank you for your kind remarks! And thanks for all the likes! They are all highly appreciated. Thomas -

US Brig Syren by Gahm - Model Shipways

Gahm replied to Gahm's topic in - Kit build logs for subjects built from 1801 - 1850

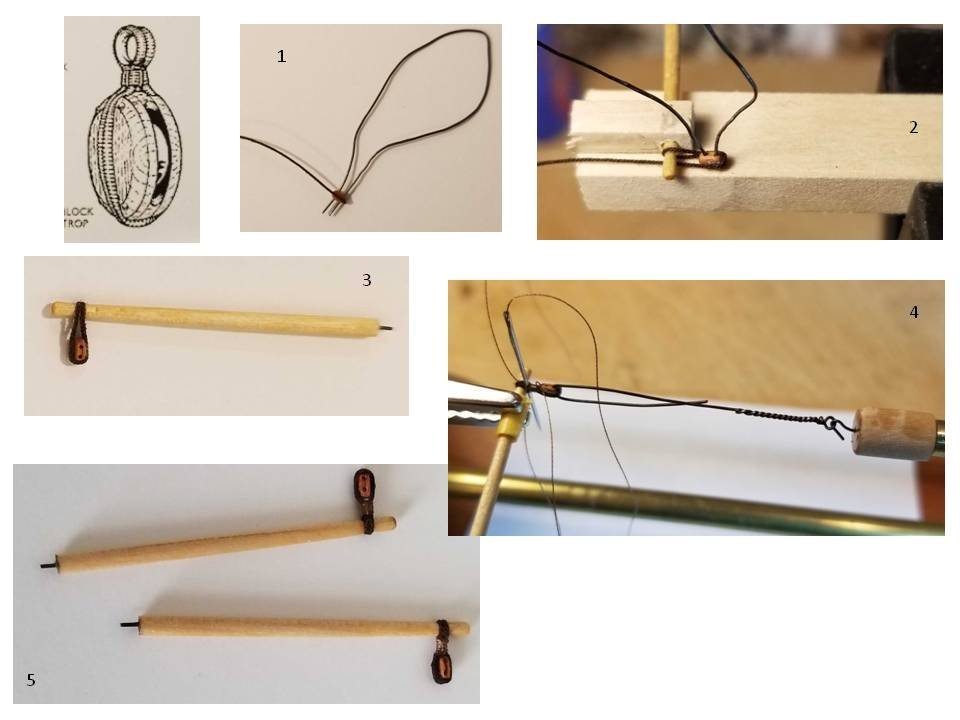

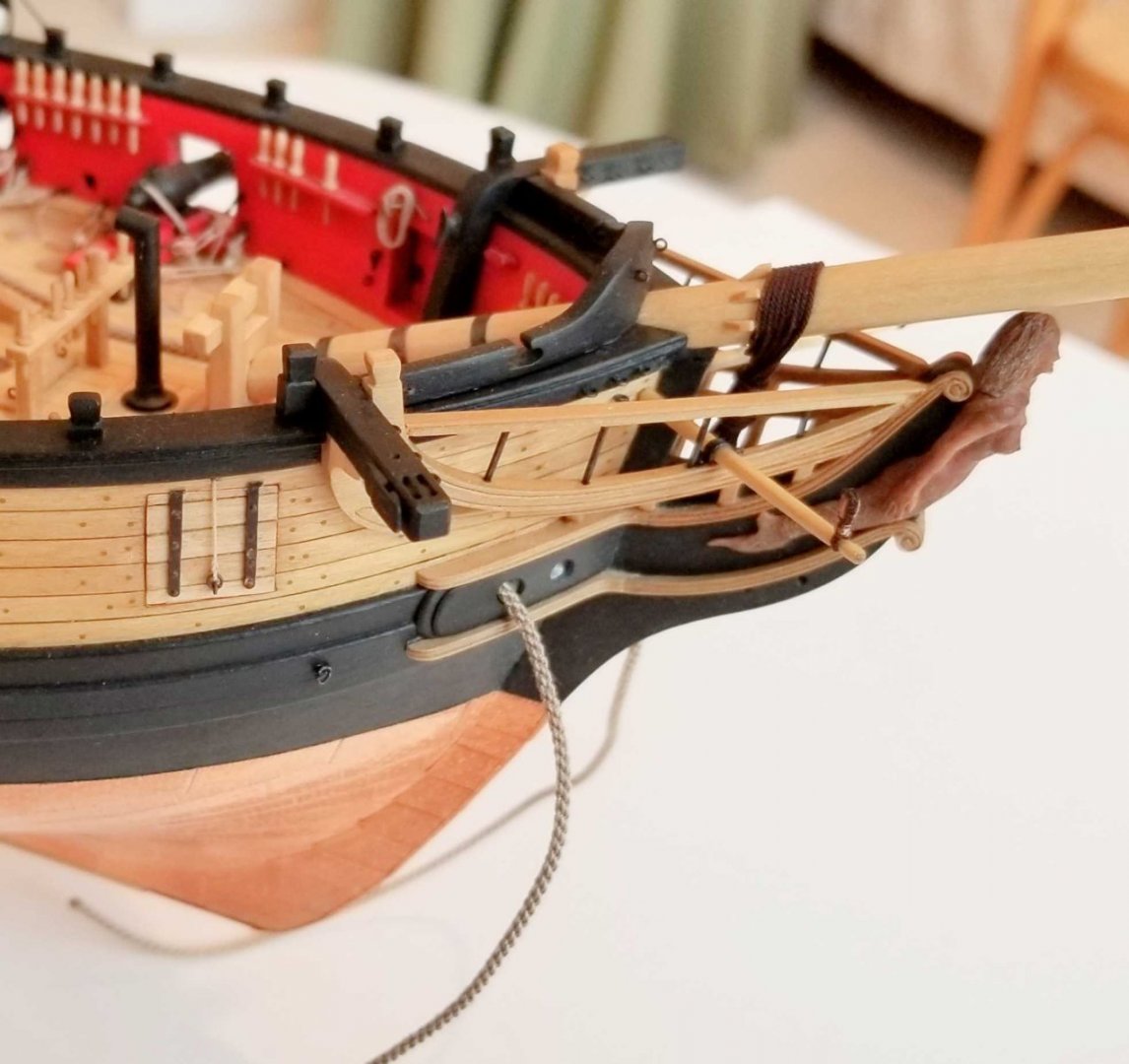

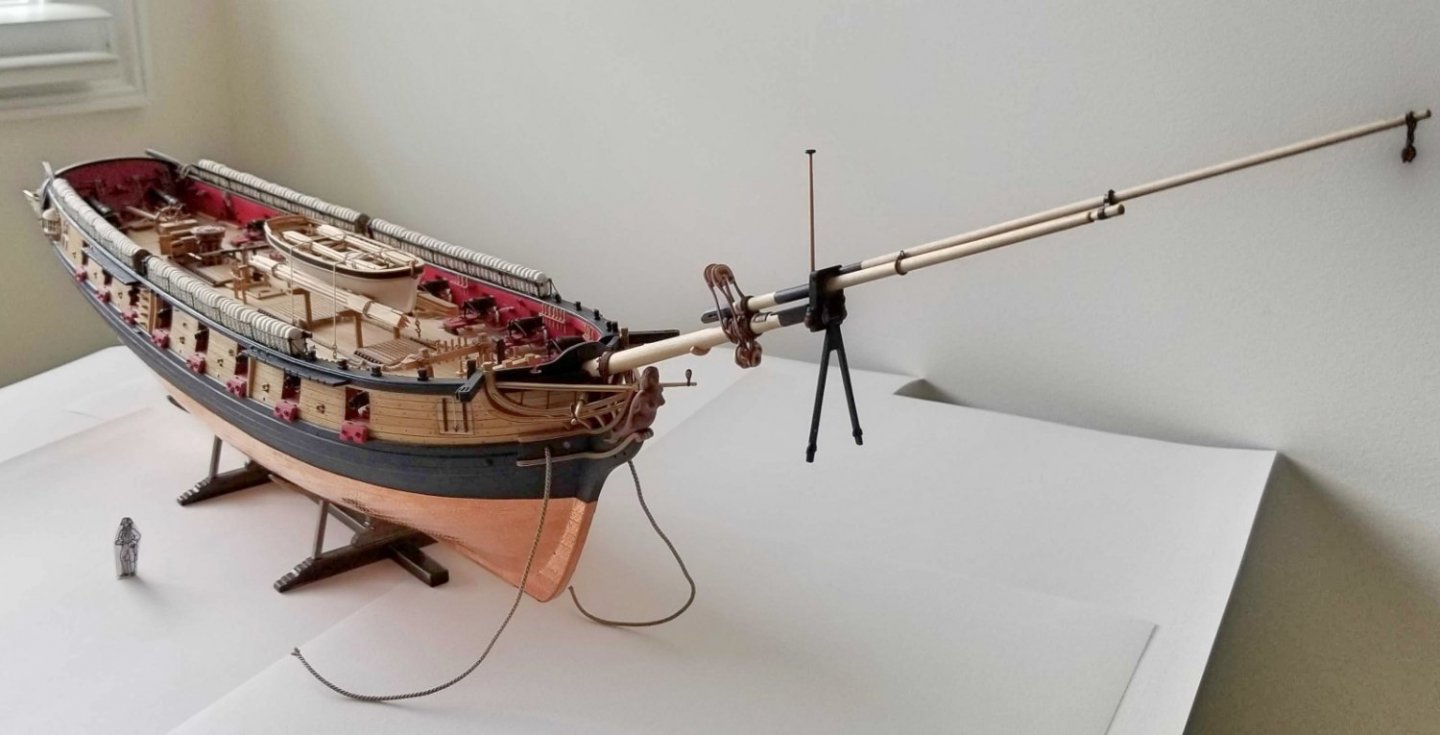

A little progress . . . the bowsprit is now permanently mounted. The splashguard was made out of three 1/32” layers of boxwood, sequentially wetted, the first layer bent around a jig, the following layers around the existing preceding one (or two), and glued together. This layer technique resulted in a very stable design, which held the shape and also presented no problems when cutting the fairleads (img. 1 – 3). The gammoning can be seen in img. 4 – 5. And finally I added the bumkins shown in img. 6 - 8 with double stropped blocks (img. 6). Double stropping nicely allows for the 90° between the block and the lashing to the bumkin. It also shows again how universally the Syren serving machine can be applied. Img. 9 and 10 give an impression of the current state of the model. Thomas Img_1 Img_2 Img_3 Img_4 Img_5 Img_6 Img_7 Img_8 Img_9 Img_10 -

Wonderful job, Mike! Your craftsmanship is outstanding! Thomas

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

What superb craftsmanship! Thomas

-

Your head rail construction is really impressive! Thomas

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You did it! Congratulations! She is a beautiful model! I am always amazed how complex the finished Syren is once the whole rigging is in place. Thomas

- 157 replies

-

- model shipways

- syren

-

(and 1 more)

Tagged with:

-

Gorgeous work, Mike! I love the fish ornaments on your binnacle! Thomas

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The lantern is a masterpiece of its own! You have a wonderful model there . . . ! Thomas

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Your focus on detail combined with your excellent craftsmanship really pays off! You have a wonderful model! Thomas

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.