-

Posts

1,477 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by vossiewulf

-

scissors, shears, cutters for rigging

vossiewulf replied to palmerit's topic in Modeling tools and Workshop Equipment

I am mostly ambidextrous with tools and I too get annoyed that my nice scissors won't cut right in my left hand -

I recommend Iwata airbrushes. They're not cheap but my consistent experience with tools of all kinds is you get what you pay for. If you want a permanent solution to airbrushing issues, get an Iwata.

- 50 replies

-

- academy

- Admiral Graf Spee

-

(and 5 more)

Tagged with:

-

Good luck, that's an ambitious project And....

-

I would use a spray finish, not a brushed finish, the brushed finish is going to smear the graphite. I would suggest a nice satin lacquer. That will prevent the deck from being stained, but I don't think it needs to be.

- 12 replies

-

Bit of a problem! HMS Speedy, Vanguard Models

vossiewulf replied to JohnEvans's topic in Masting, rigging and sails

Um I understand closing it out here, but I'll echo others who requested you do a build log of sorts for the repair, I would be very interested in following how you handle that mess -

Linus Napoleonic shipyard

vossiewulf replied to Linus Spjutsberg's topic in New member Introductions

Very nice work Linus! I may want to take a turn at 1/700 too at some point, I know where I'll go to look on Youtube when I do. -

Thanks Chris, I appreciate the kind words Keep in mind with thing like serving the stropping, I have like 500 fewer blocks to do than you do! And yes I am definitely enjoying getting up every morning and going to my workshop instead of dealing with crisis number ten thousand for Visa. I wish I was as far along as you, I'm nowhere near taking on Victory yet. Anyway, you're doing a great job with your Victory, keep it up I will be watching to see how you do with the serving.

-

My understanding was that they primarily used red ochre, which was about the cheapest paint color you could get. That's why I chose more of a brick red than a crimson red that you see on some ships. I don't understand the crimson reds, that would have been a pretty expensive paint at the time (as far as I know, which is admittedly not very far).

-

Thanks Chris! I only have what's in my build log. I've just gotten started on the rigging so all I've done so far is experiment with the Syren machine in making two fully-served jibboom guys and some ancillary rigging like the guns and the anchors. I can report that it's possible to serve line with 14/0 fly tying thread and it looks good, but it's slow going considering how thin the thread is. I tried some 6/0 thread to see if it would go faster and it did, but I didn't like the final result as much. Your mileage may vary, buy several different brown and black threads in different sizes and experiment, see what you like best.

-

Raising the grain is a small price for a good bend and can be quickly corrected either before or after you get the plank on. But basically it's an issue of getting the lignin in the wood up to the temp at which it plasticizes, you can do it with hot water or a heat gun or even a hair dryer, see Chuck Passaro's planking tutorials, he just uses a hair dryer.

-

Good, sounds like Chuck helped you work out the kinks. As for the serving, I am using 14/0 fly-tying thread at 1:64 and it looks pretty good. I think you should be using something similar at 1:72. Take a look here for fly-tying thread. The specific one I am using is the Gordon Griffith's Sheer Ultrafine Thread. Below is a thimble with fully served line as it's coming off my Syren machine.

-

Congratulations, very nice job! The Bounty launch sounds like a good first step into planking.

- 26 replies

-

- Solid hull

- Bregante

-

(and 2 more)

Tagged with:

-

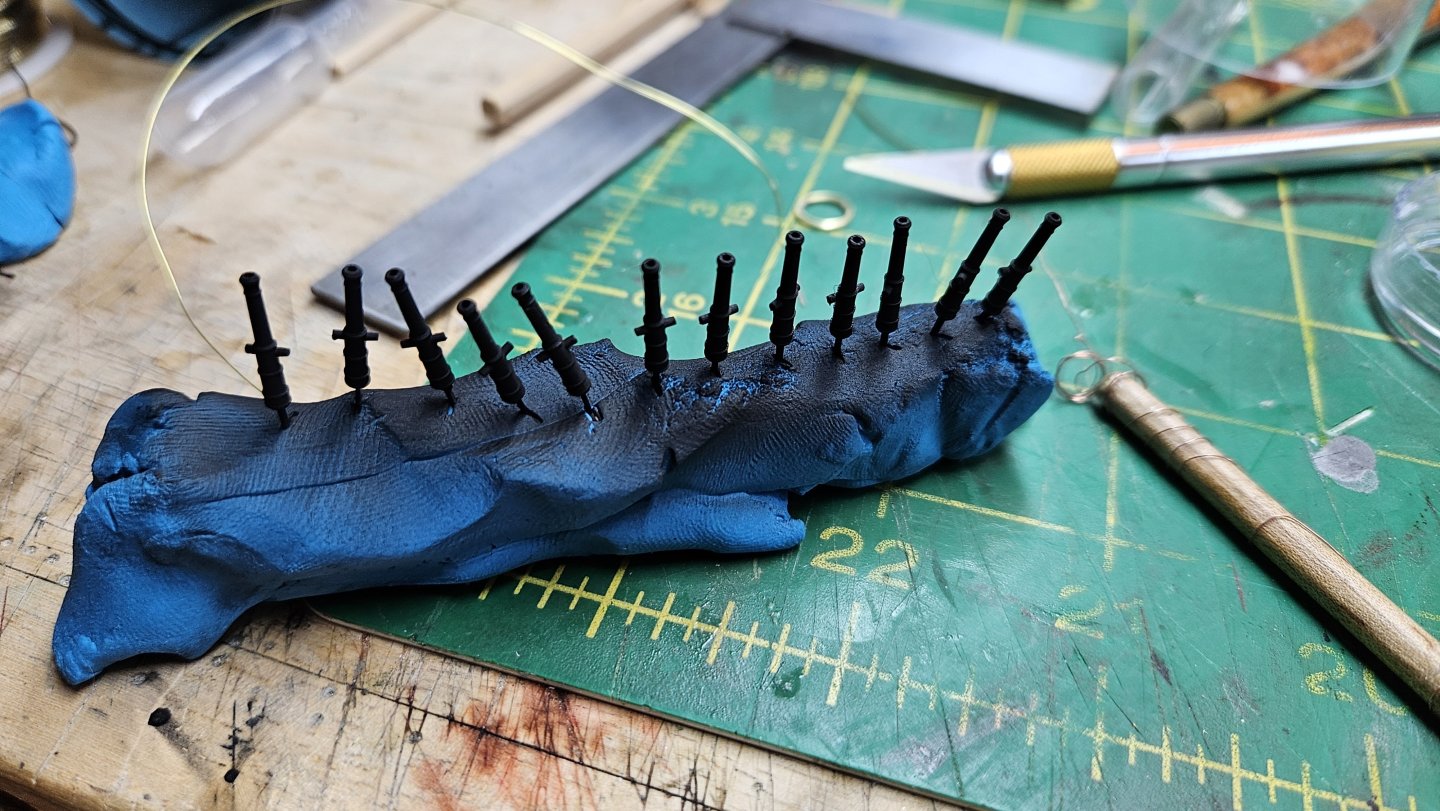

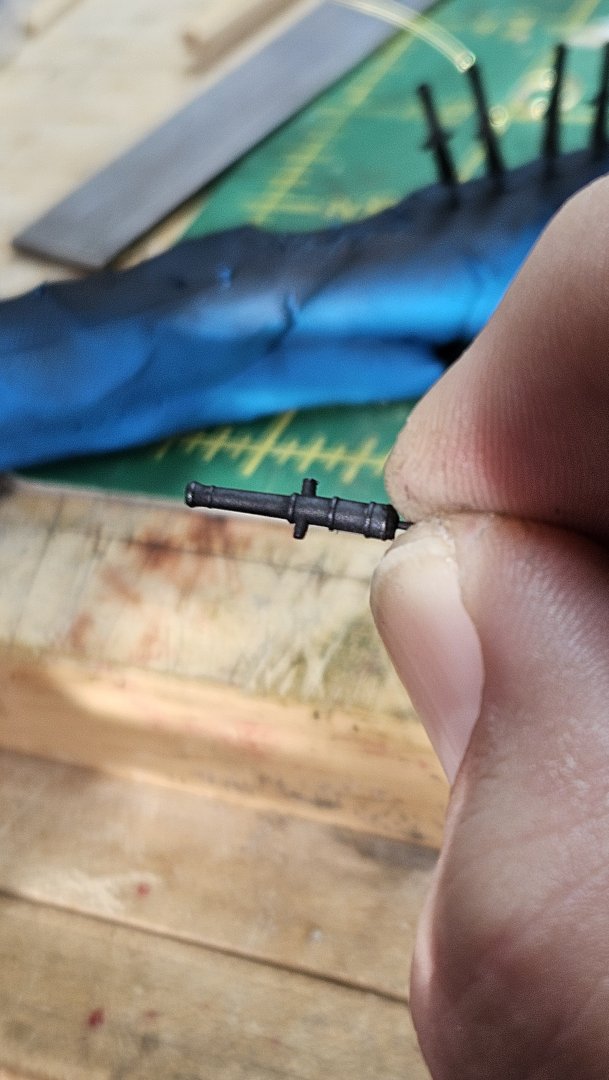

Thanks guys, I appreciate it Intead of more masting and rigging, I remembered I hadn't dealt with the swivel guns so I stopped to do that. First was mounting the pedestals (?) they mount on. This was somewhat fiddly work because of the changing sheer line curve and the tilt of the rails resulted in each one having to be fit individually to ensure they're perpendicular to the waterline. Which was a slight problem too, as the plans show the knightheads should also be perpendicular to the waterline whereas I unfortunately made them perpendicular to the rail. Now I have the pedestals and the knightheads pointing in two different directions which is annoying but nothing I can do about it now, getting the knightheads out at this point would be hard. The pedestals were reinforced with carbon fiber rod dowels. Here you can see the discrepancy between the knightheads and the pedestals. Also, I once again used the Faber Castell markers instead of black paint, which was very convenient. I also couldn't stand the swivel guns that came with the Lady Nelson kit, they're really not very good. I did a lot of searching for alternatives but eventually bit the bullet and just ordered a VM Sherbourne kit as that has accurate guns and PE gun mounts. So now I have a Sherbourne kit sans swivel guns for cheap if anyone wants it Oddly, the plasticine clay seems to have removed the blackening from the PE swivel gun handles that were attached to each gun. I'll have to touch them up once they're mounted. I painted the 3D printed guns themselves with Tamiya flat black. Tamiya flat paints have an interesting quality where if you rub them down post application, they get more satin and almost glossy. So if you take something like one of these guys and rub it down the high points of the reinforcing rings will become glossy while the paint in the recesses stays relatively flat. This accomplishes more accurately what folks are trying to do when they dry brush items to bring out details. And all done, now to store these for mounting after the rigging is done. And I'll turn back to masting and rigging now.

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

As a class of tools they're called ring clamps and they're indeed very useful for holding small objects that need to be filed/cut/manipulated. I have one with a wedge that you drive into the far end of the clamp and that can generate considerable clamping force. I also think a ring clamp would be worth trying for holding your scrollwork.

-

That's a good beginner choice. Lots of Aussies around here

-

Welcome to MSW! Excellent choice on a starting point.

-

Dye stains are mostly surface and will sand away very easily except on end grain, and they can be painted or sprayed on as they're just dye powder mixed with ethanol. Speaking of which, I recommend dye stains from luthier manufacturers, you want stains designed for thousand dollar instruments. They're not expensive, if you're really interested in options you should get some to add to your experimental program. I really like dye stains for their translucency, you still get the wood grain and figure even with the stain.

-

I'd suggest either a wash using oil paints and turpentine or using alcohol based dye stains. Neither will bother your white glue.

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

That appears to be a good beginner kit, the planking looks to be simple.

-

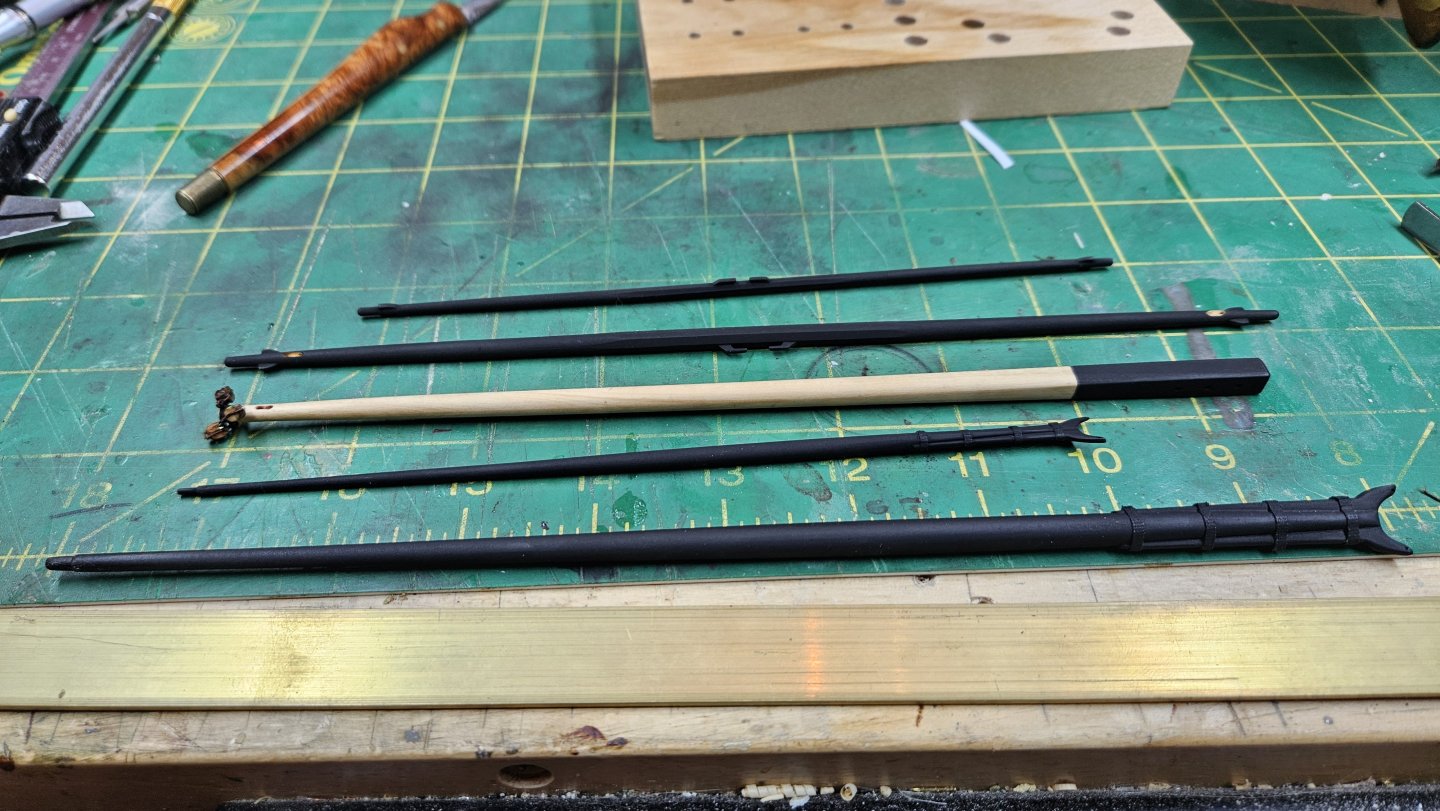

Yards and booms all done ready for rigging. And the topmast done except for paint. The little knob thing on top of the mast was made separately and attached to the mast via a reinforcing carbon fiber rod. Just need to make the main mast and we're fully go on rigging Lady Nelson. Actually I will probably follow Chuck's instructions and rig the bowsprit before making the main mast.

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

Advice on French 2nd or 3rd rate ship of the line

vossiewulf replied to James Flynn's topic in Wood ship model kits

Ancre Monographs, they have several books on ships of the line, I saw at least one Napoleonic three decker in there.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.