-

Posts

5,441 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Nirvana

-

Very nice, and the background does it better thanks to the Ludwig set!

- 90 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Blown away! Wow!

-

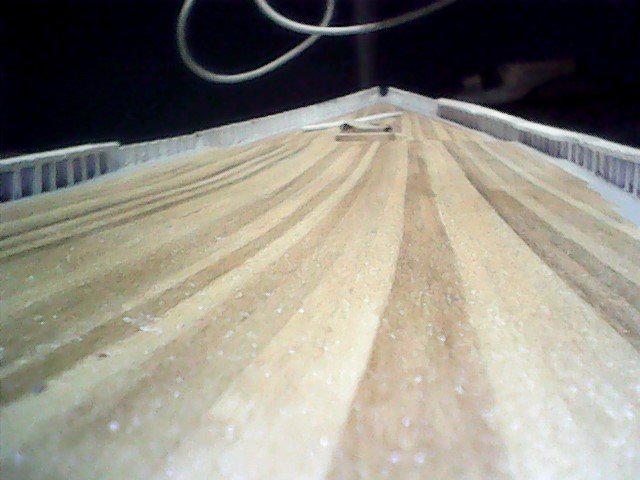

Waist inside has gotten the second coating of white. The waterways was painted with Valejo sky grey. It gave the deck and white a nice contrast. First part of the mainrail was glued into place. Here it's important to make a solid contact all the way. I don't want to see any light showing through with the waist.

-

Prudencio, Warm welcome to MSW. Please introduce yourself in English. It doesn't have to perfect english.

-

Long time ago my son was into Warhammer game, so we went to buy some characters for him. A little project we did together, mostly him. But in the box with brushes and dried paint I found this three piece set of files. The grit is good enough for wood as well, which was really helpful to finalize the opening. The files can be found in any hobby store selling Warhammer game characters. From top to bottom; coarse, medium and fine grit. A tool I like to recommend to all modelers.

-

It took some effort and meditation before I put the drill into waist for the hawse. Port side is being worked on, using my home made template (masking tape) I worked slowly. According to the plans the hole going through should have 2.5mm diameter. I may open it little more to insert a tube, which is not necessary. Doing so, I have been able to create an opening that I feel okay with. It will be interesting to see how bad it is after removing the tape.

-

Getting the hawse pipe opening is a tricky part. Here the two britttania pieces are mirrored and on top of that, several angles involved. Attaching blue masking tape to the waist, I measured 30mm on the plans and transferred the measurement to the tape. This would mark the aft part of the metal part. Next was to measure the top and bottom of the opening for the hawse pipe. Using the metal piece I traced inside of the part. I did the starboard which is on the plans. Doing the port side was a little trickier. But at the end I got the second opening right. Looking at the stem it looks like Bluenose has gotten eyes. Now I have the delicate job of drilling the hole for the "eyes".

-

Me and my pups feel your loss. The emptiness of a dear and loyal friend.

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.