-

Posts

840 -

Joined

-

Last visited

About xken

- Birthday 02/09/1947

Profile Information

-

Gender

Male

-

Location

Morro Bay, CA

-

Interests

Scratch building of all venues and working with brass.

Recent Profile Visitors

-

abelson reacted to a post in a topic:

US Brig Niagara by xken - FINISHED - Model Shipways - Scale 1/64

abelson reacted to a post in a topic:

US Brig Niagara by xken - FINISHED - Model Shipways - Scale 1/64

-

abelson reacted to a post in a topic:

US Brig Niagara by xken - FINISHED - Model Shipways - Scale 1/64

abelson reacted to a post in a topic:

US Brig Niagara by xken - FINISHED - Model Shipways - Scale 1/64

-

abelson reacted to a post in a topic:

US Brig Niagara by xken - FINISHED - Model Shipways - Scale 1/64

abelson reacted to a post in a topic:

US Brig Niagara by xken - FINISHED - Model Shipways - Scale 1/64

-

abelson reacted to a post in a topic:

US Brig Niagara by xken - FINISHED - Model Shipways - Scale 1/64

abelson reacted to a post in a topic:

US Brig Niagara by xken - FINISHED - Model Shipways - Scale 1/64

-

abelson reacted to a post in a topic:

US Brig Niagara by xken - FINISHED - Model Shipways - Scale 1/64

abelson reacted to a post in a topic:

US Brig Niagara by xken - FINISHED - Model Shipways - Scale 1/64

-

abelson reacted to a post in a topic:

US Brig Niagara by xken - FINISHED - Model Shipways - Scale 1/64

abelson reacted to a post in a topic:

US Brig Niagara by xken - FINISHED - Model Shipways - Scale 1/64

-

archjofo reacted to a post in a topic:

USS Constitution by xken - Model Shipways - Scale 1:76.8

archjofo reacted to a post in a topic:

USS Constitution by xken - Model Shipways - Scale 1:76.8

-

archjofo reacted to a post in a topic:

USS Constitution by xken - Model Shipways - Scale 1:76.8

archjofo reacted to a post in a topic:

USS Constitution by xken - Model Shipways - Scale 1:76.8

-

archjofo reacted to a post in a topic:

USS Constitution by xken - Model Shipways - Scale 1:76.8

archjofo reacted to a post in a topic:

USS Constitution by xken - Model Shipways - Scale 1:76.8

-

archjofo reacted to a post in a topic:

USS Constitution by xken - Model Shipways - Scale 1:76.8

archjofo reacted to a post in a topic:

USS Constitution by xken - Model Shipways - Scale 1:76.8

-

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

-

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

-

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

-

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

-

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

-

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

-

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

-

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

-

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

-

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

xken reacted to a post in a topic:

1961 Showboat Dragster by xken - 1/8th scale - scratch built

-

helmarsowick started following xken

-

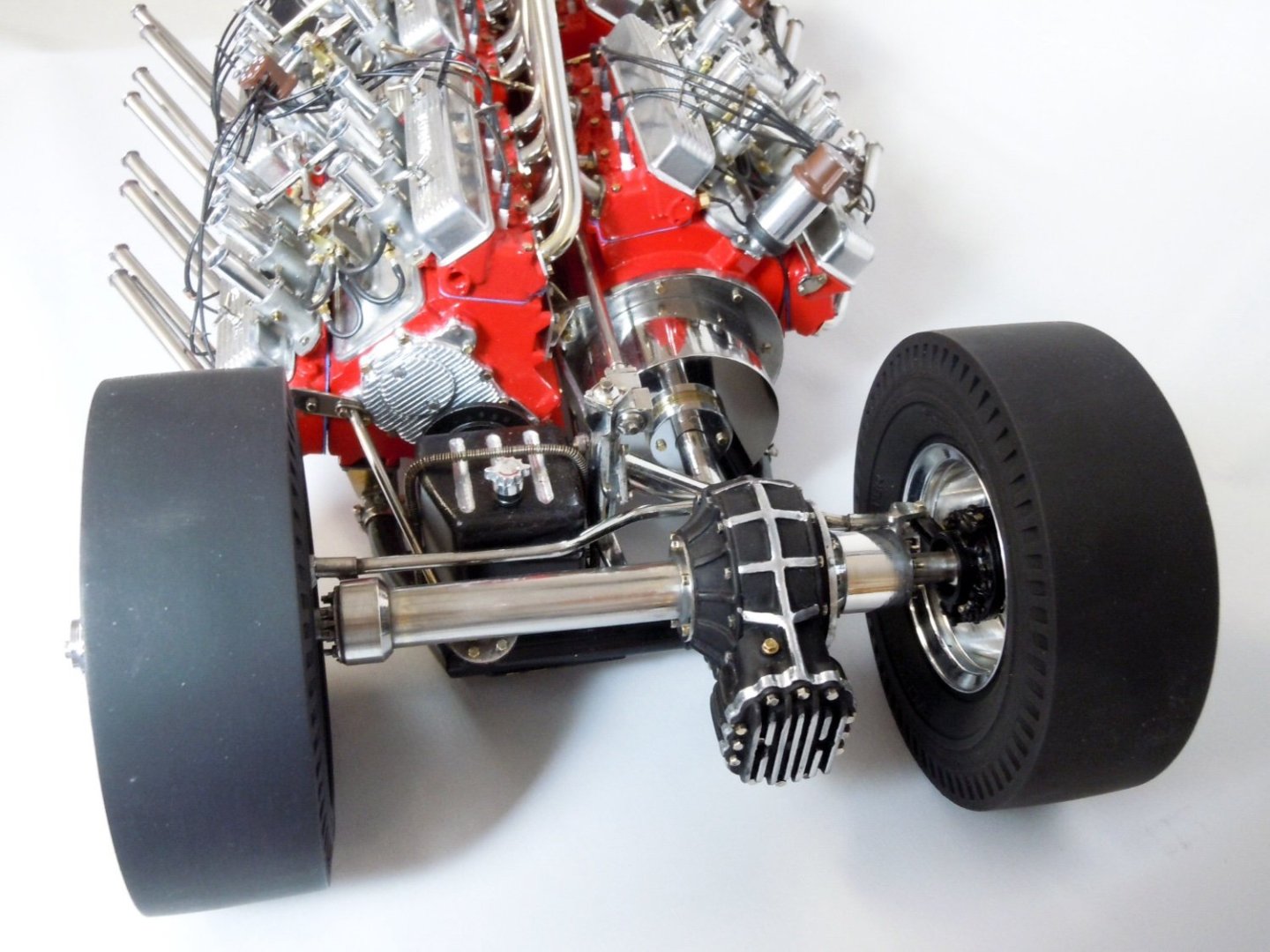

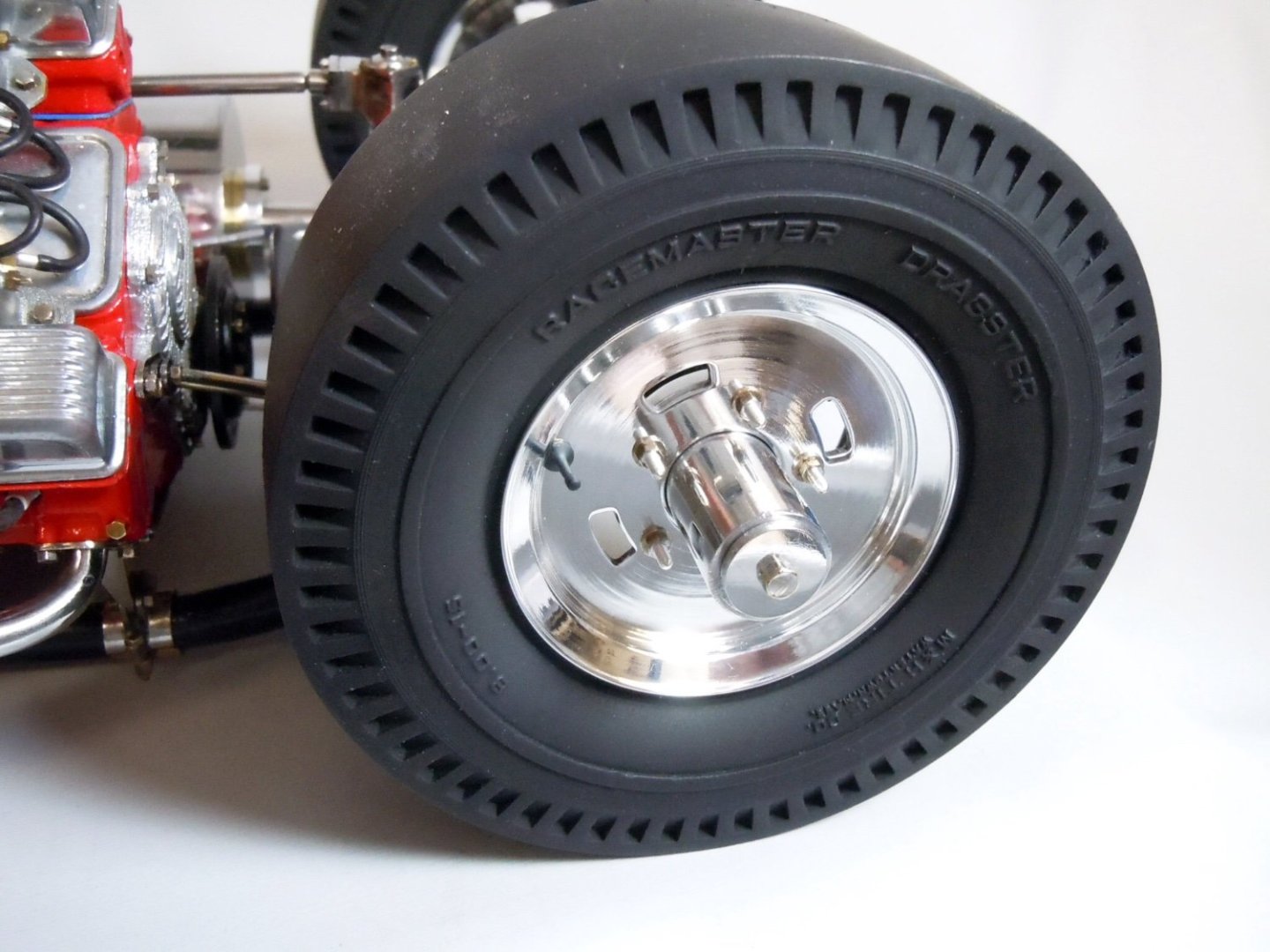

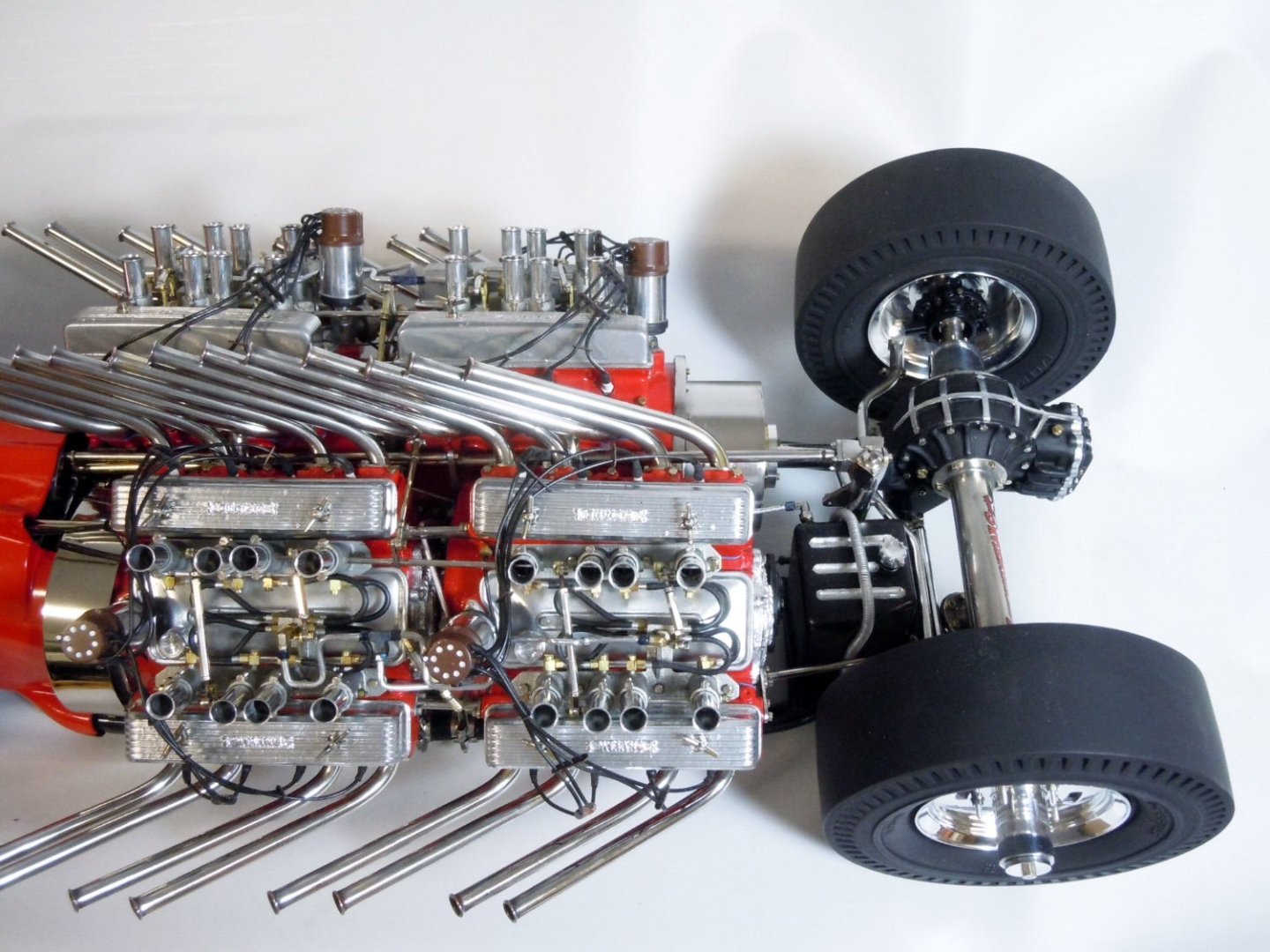

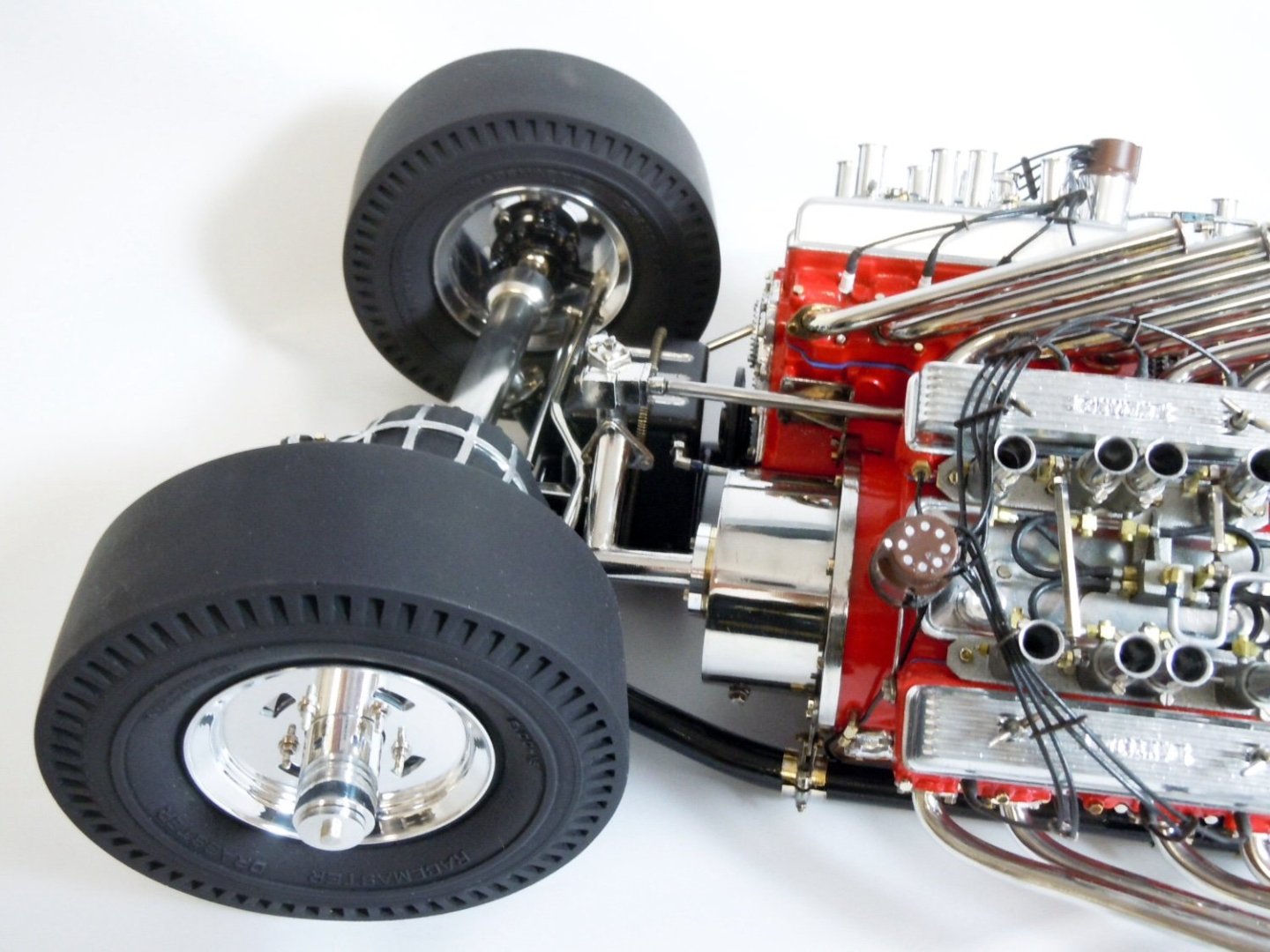

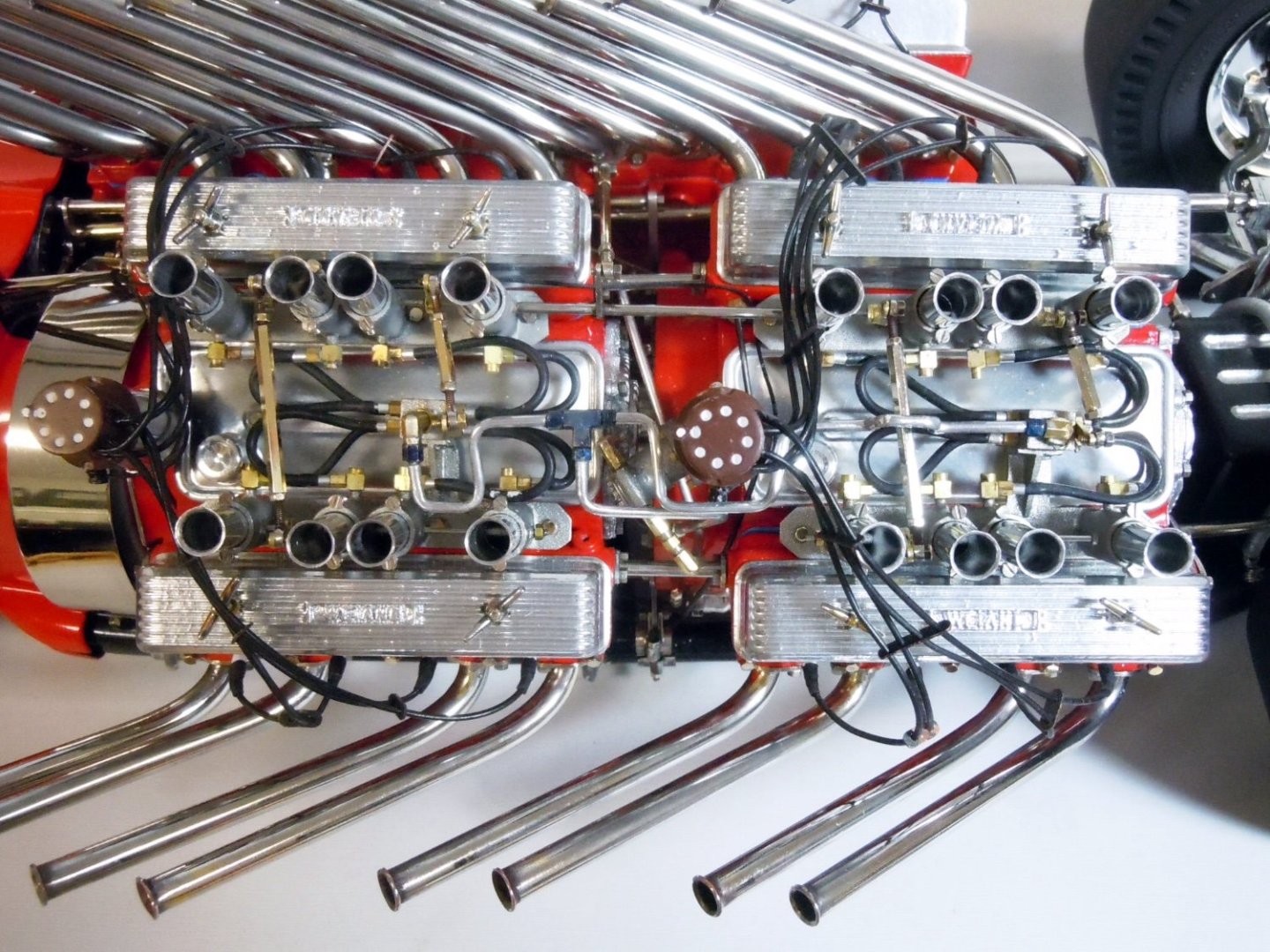

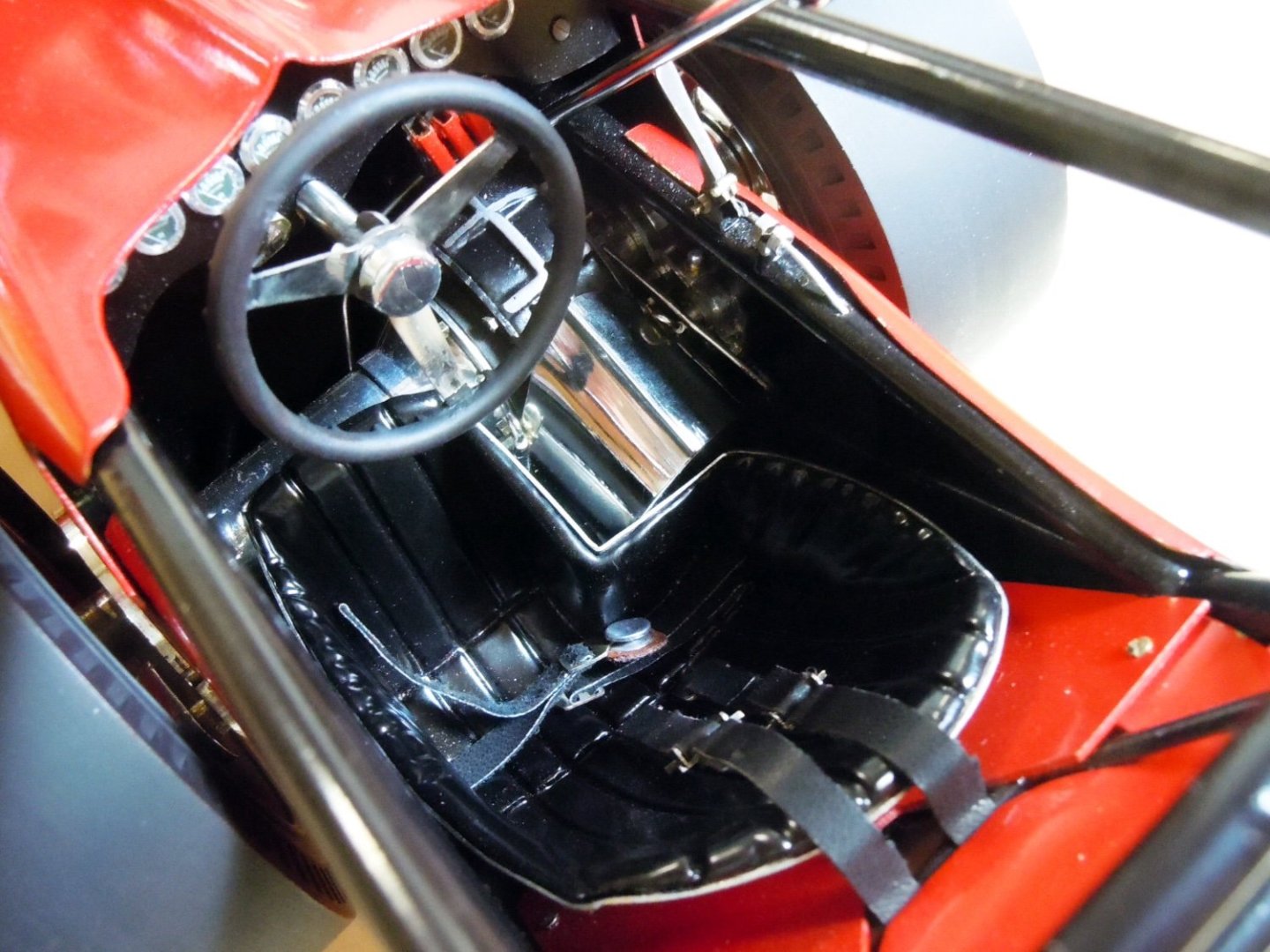

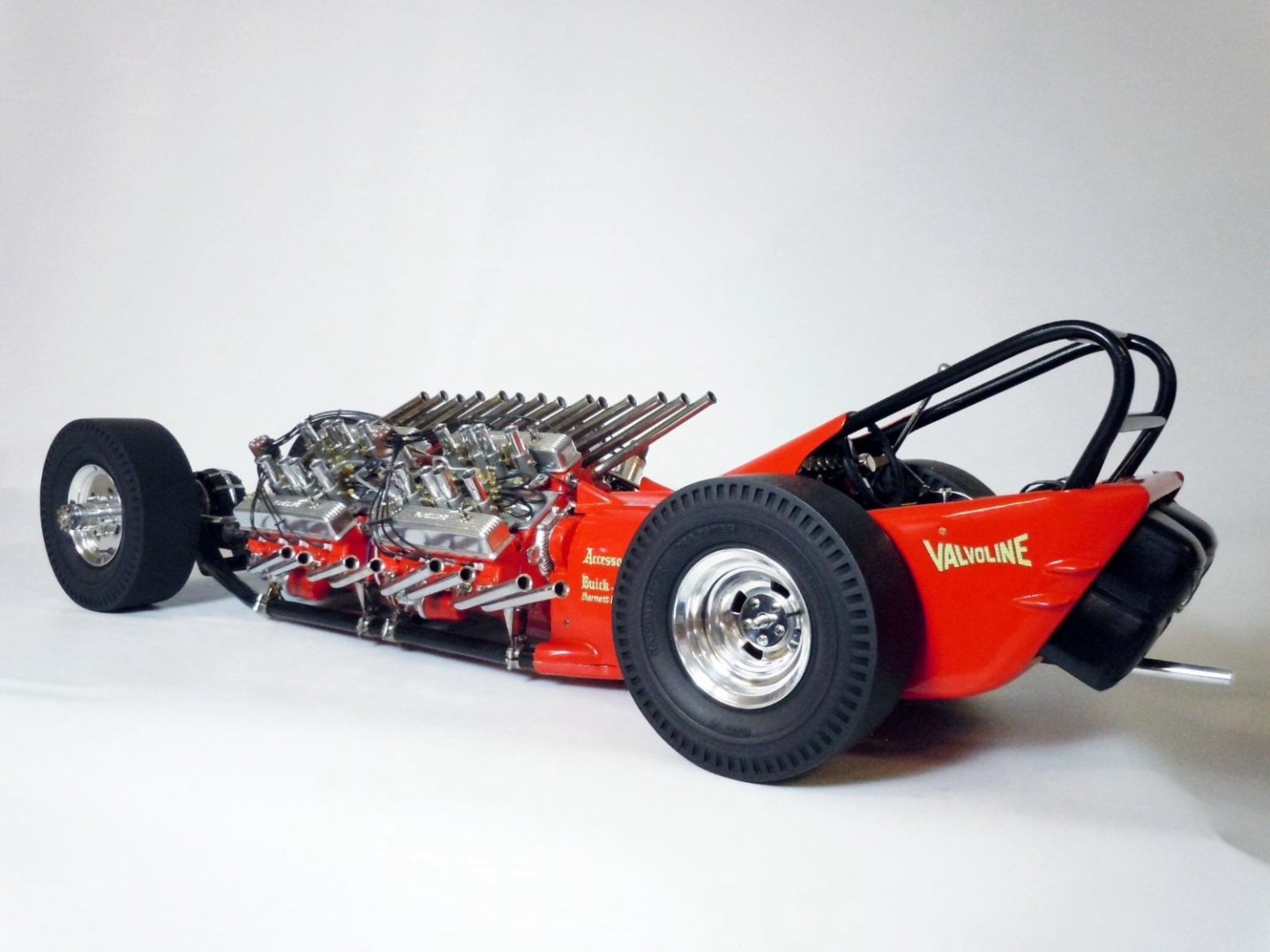

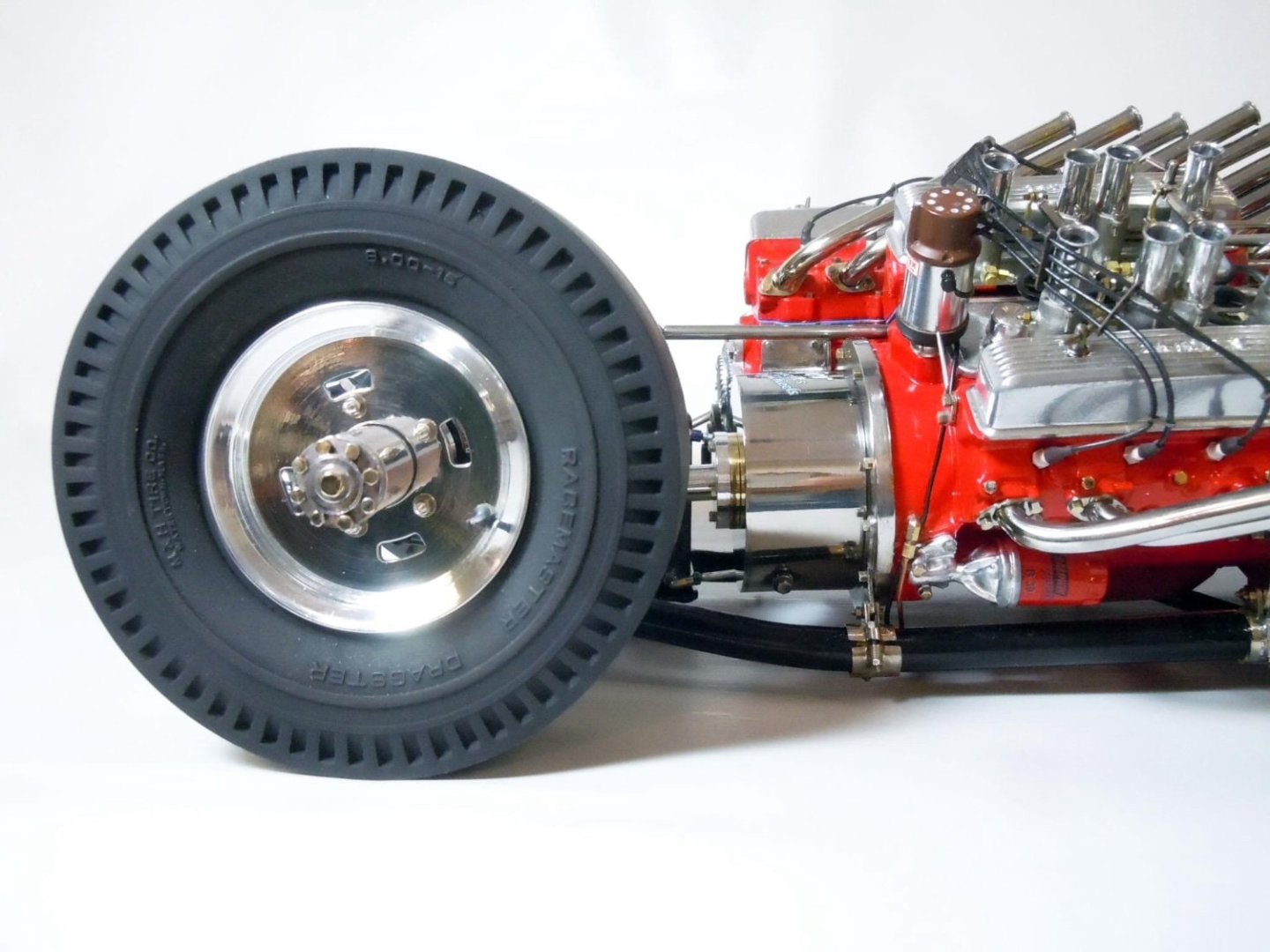

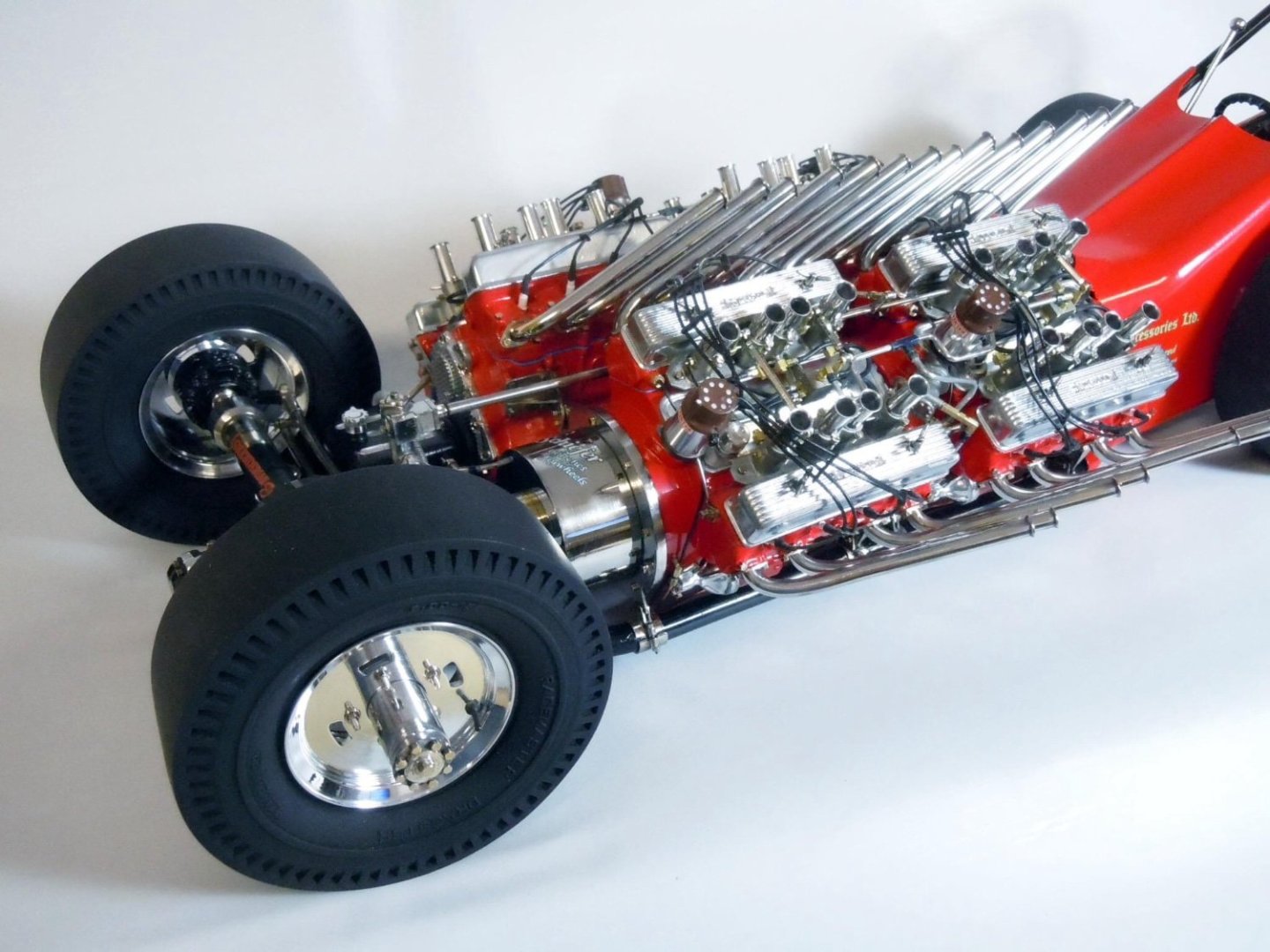

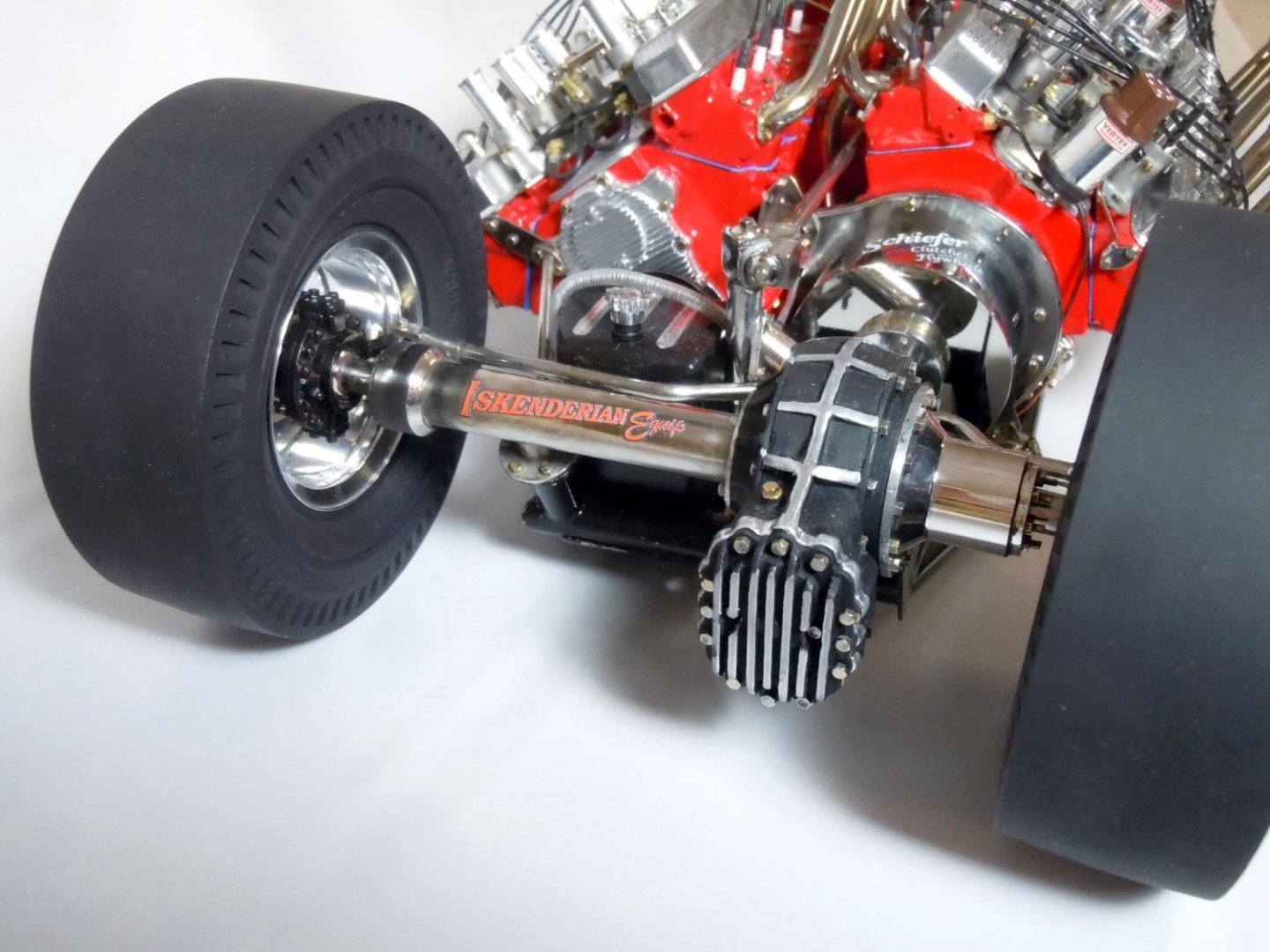

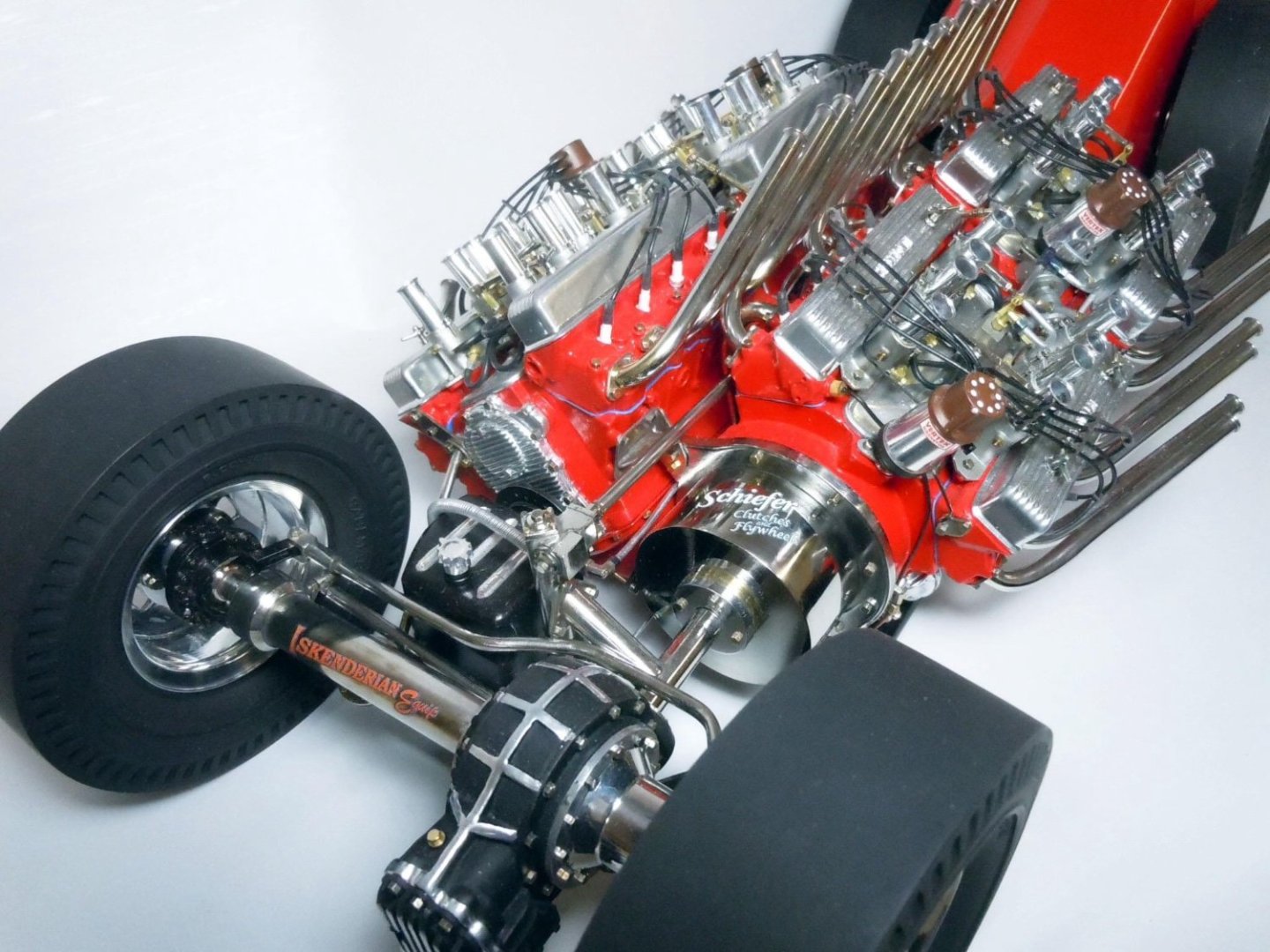

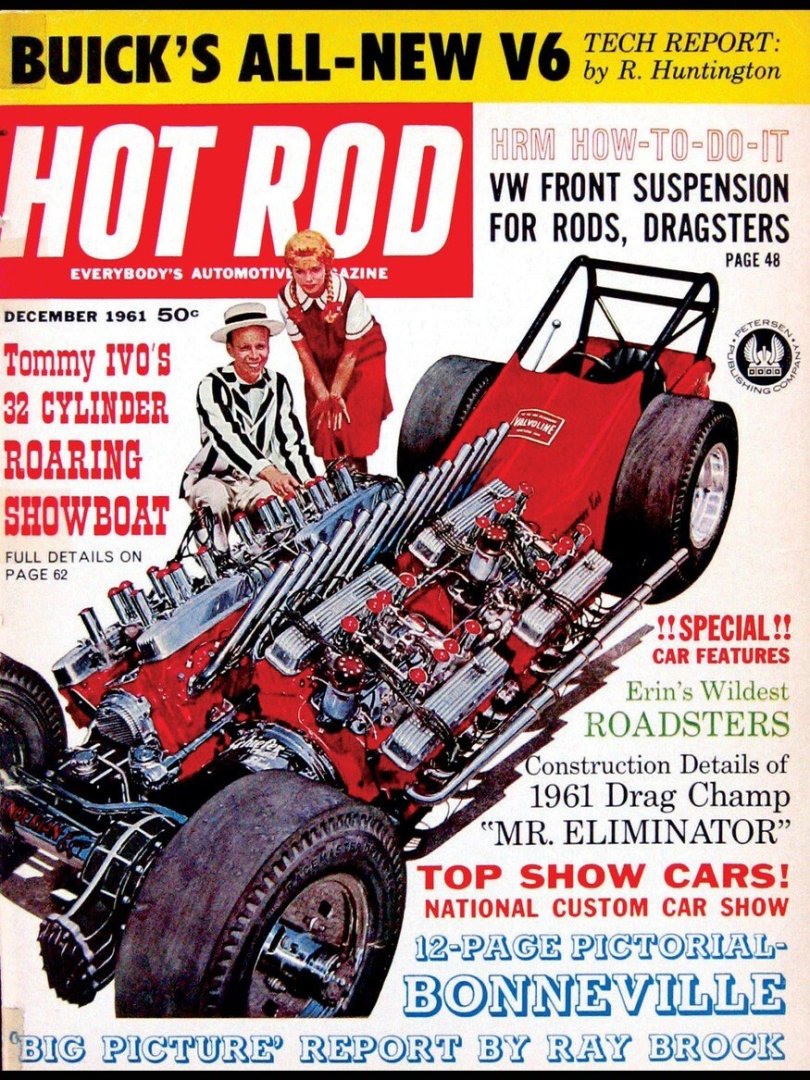

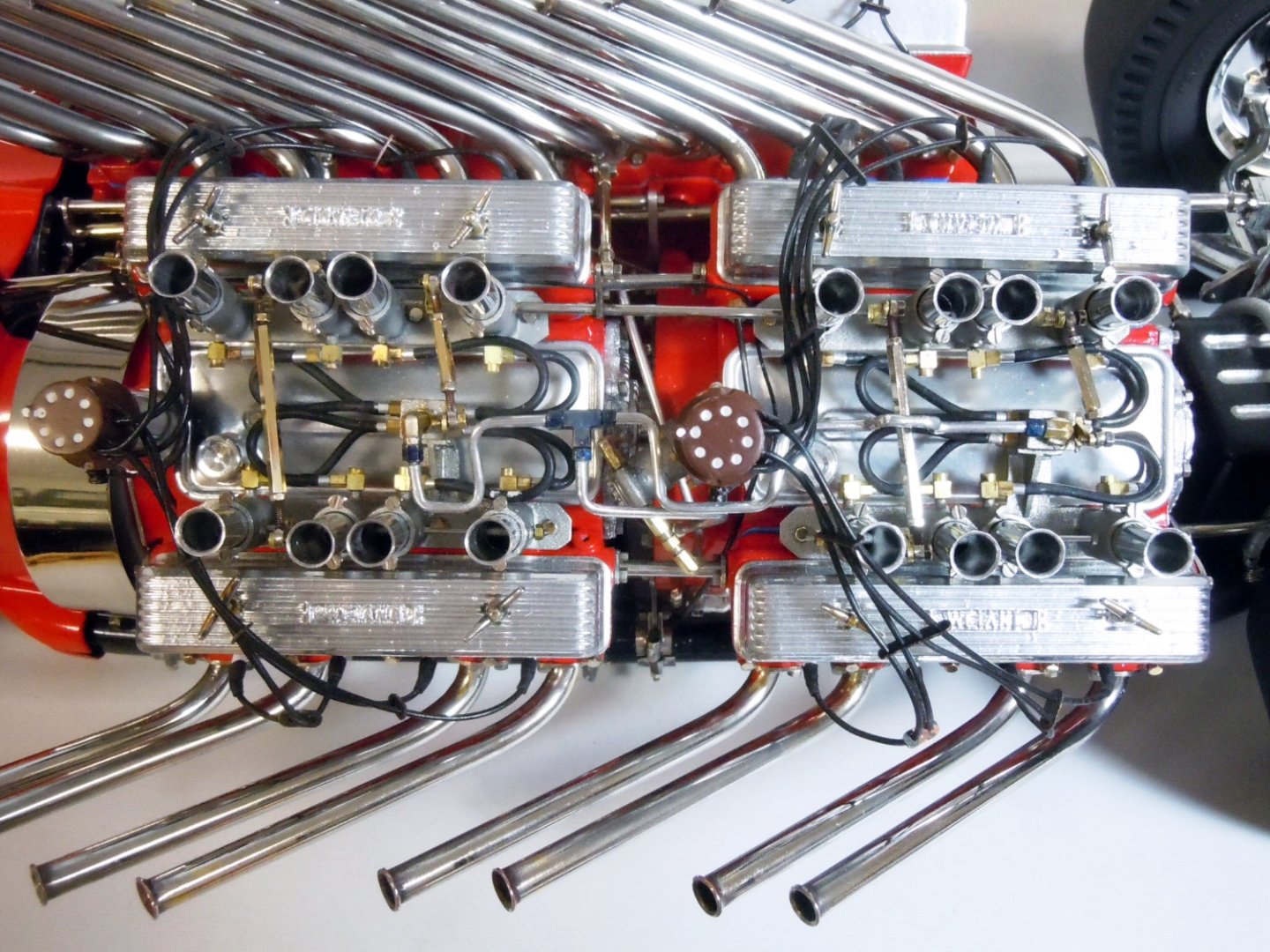

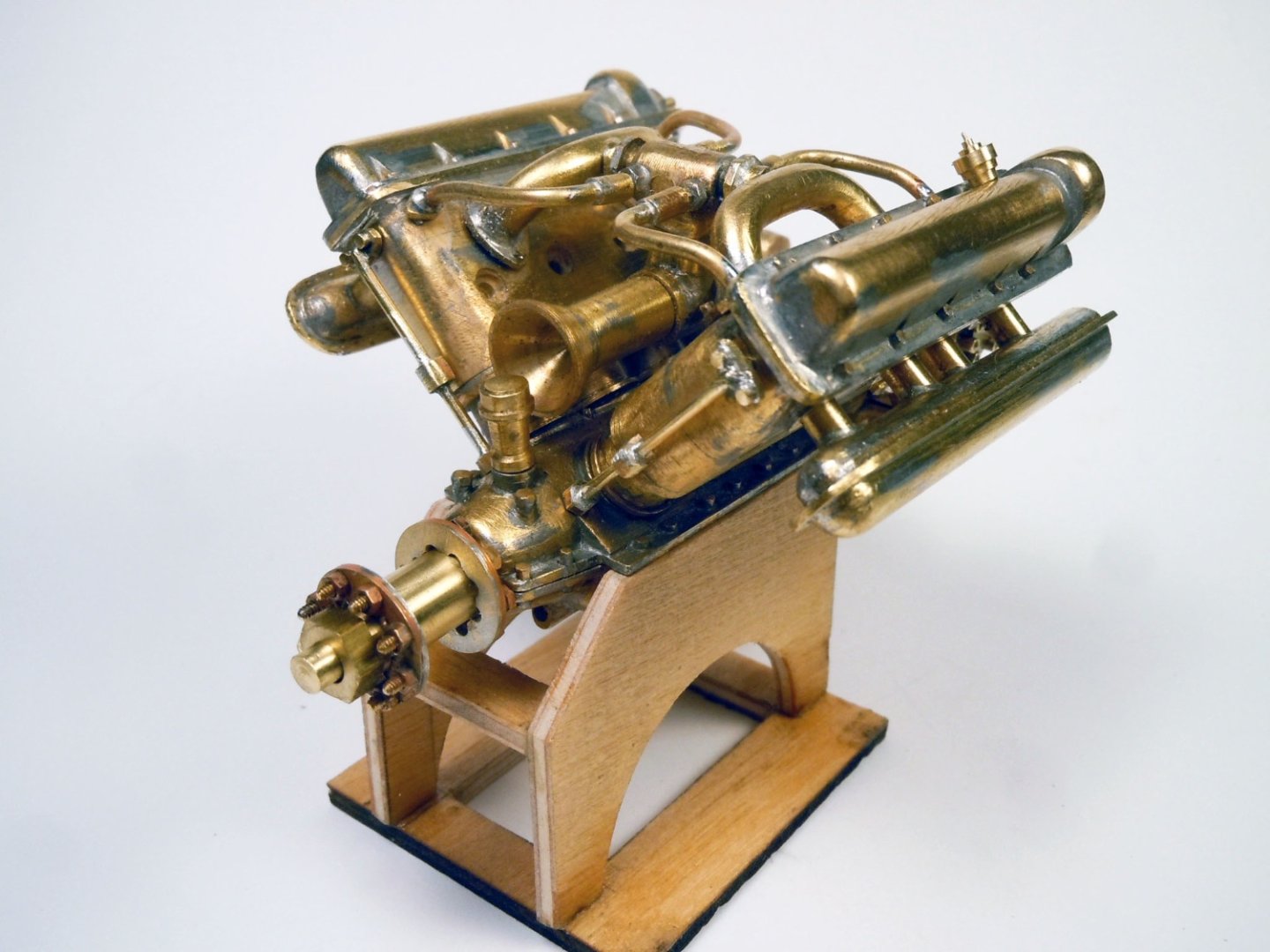

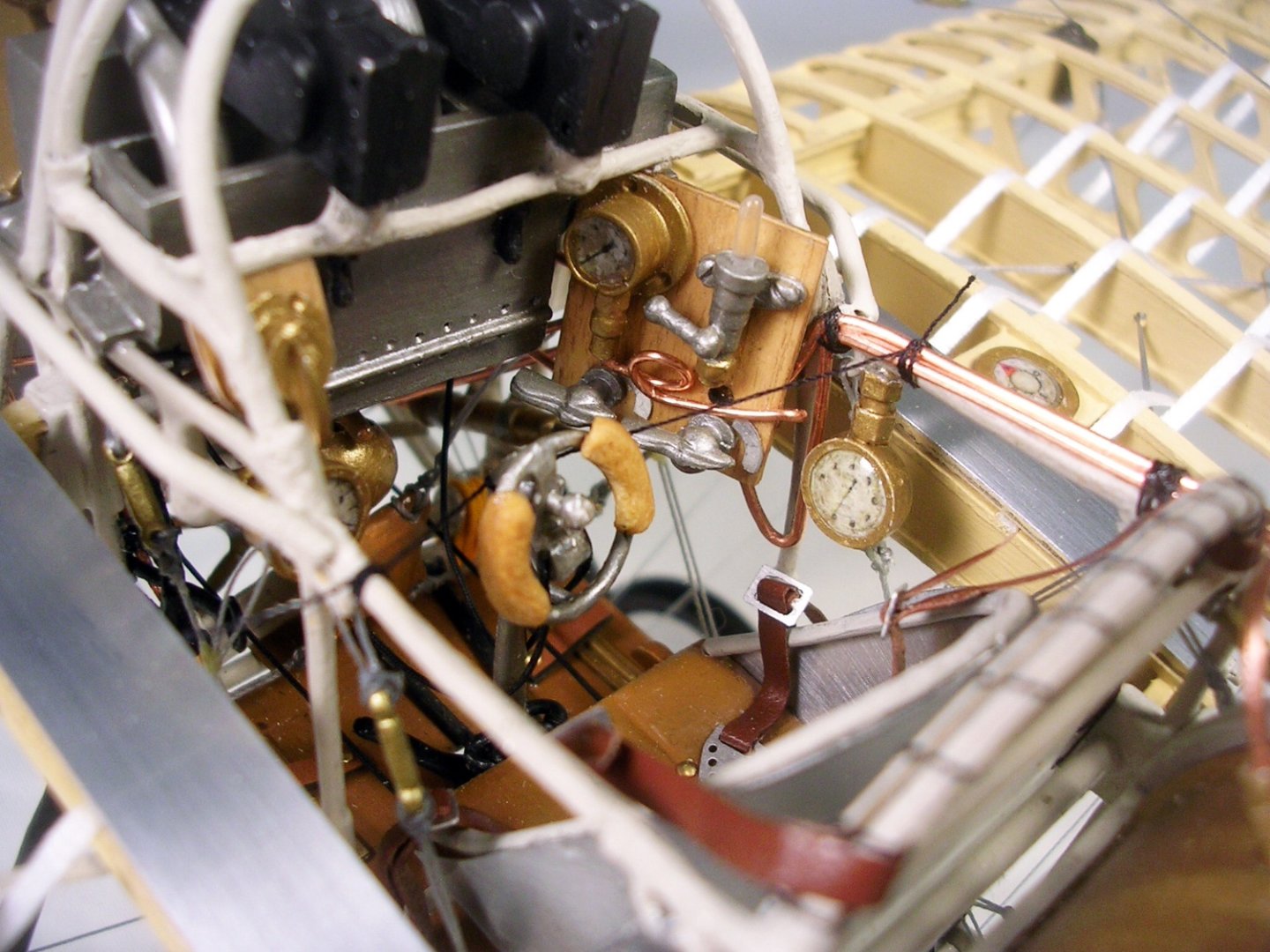

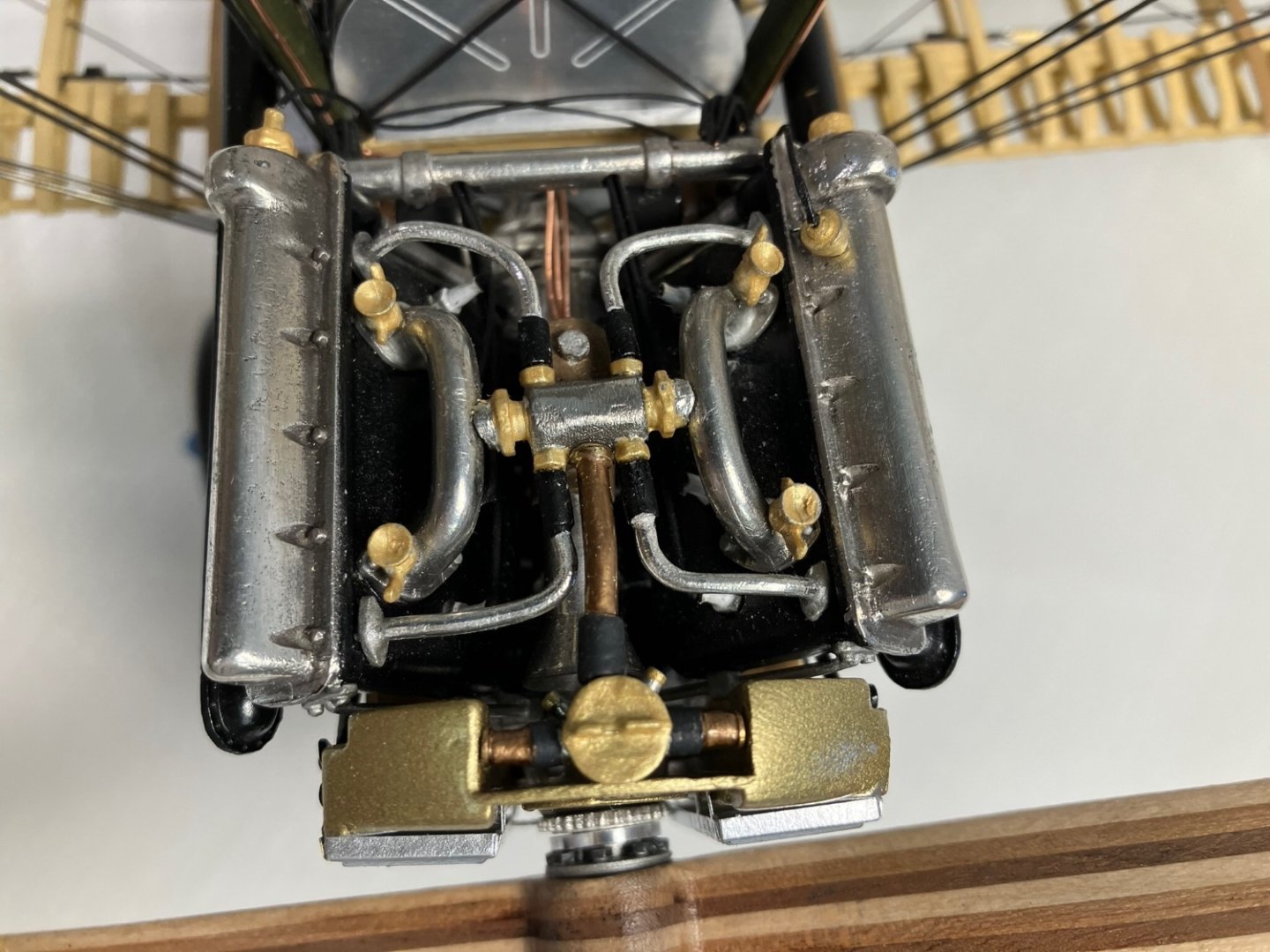

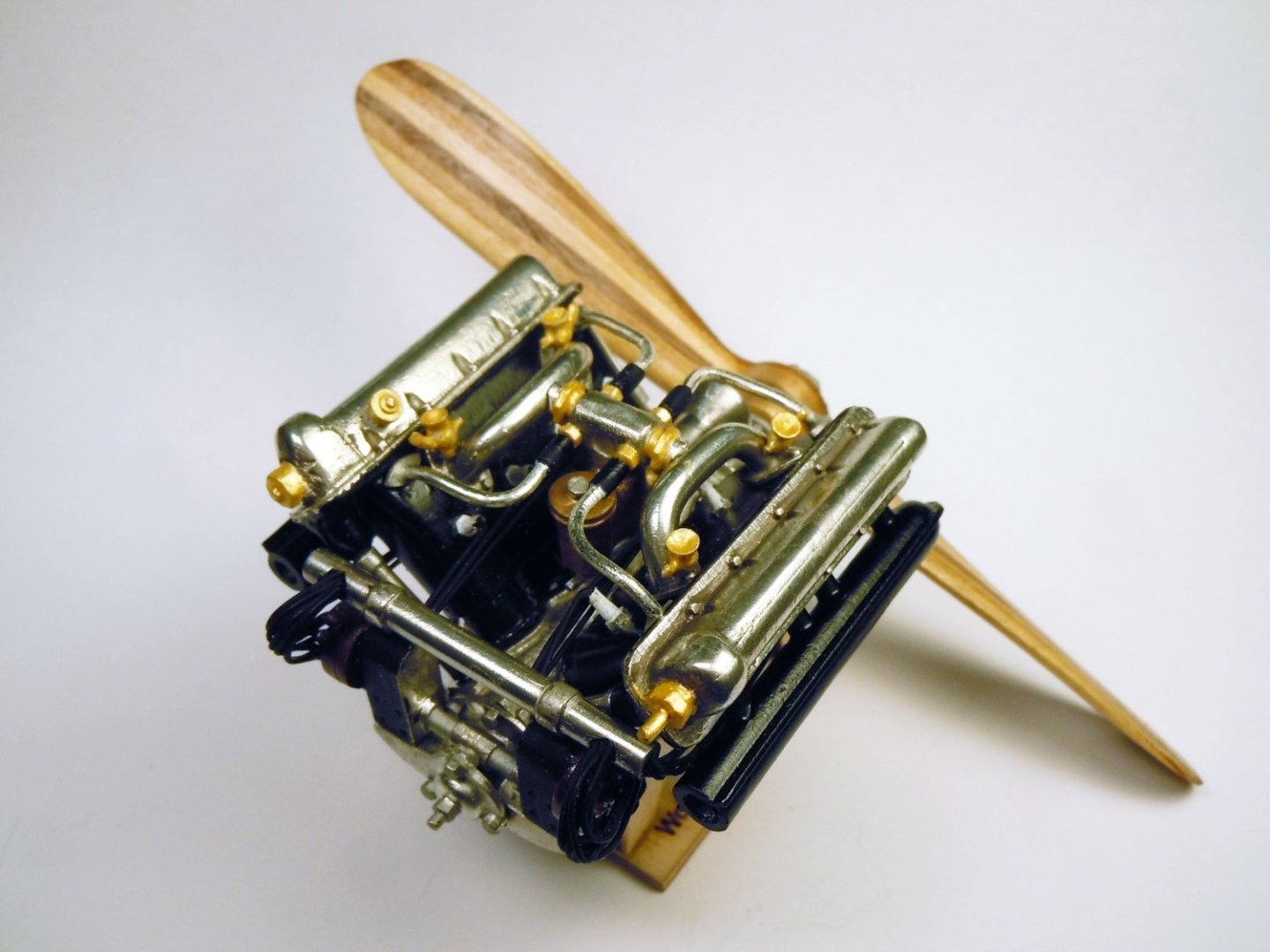

This was a tribute build of Tommy Ivo’s exhibition dragster powered by four Buick Nailhead engines. The left two engines drove the front wheels and the right side the rear wheels. They were geared so that only the front would smoke during the run. I was able to purchase four CD’s of pictures of the replica build from the original builder Bruce Dadra. The reference material was awesome in details. The engines were purchased cast resin and completely enhanced, exhaust pipes were bent brass. The body was .010” bass sheet formed and butt joints to maintain thickness. Tires we’re modified cast resin with aluminum wheels custom made by Dancing Bear Components. The decals I designed and we’re reproduced in Australia by a supplier that could do the gold leaf background. The parachute is carved wood with removable access panel to get at mounting screws. I did all my own chroming using Caswell’s products. The front wheels turn. The upholstered seat was done using Sculpty baked in oven. The seat belts are leather and work. I also added the Hot Rod magazine cover from 1961. Tommy did send me a wonderful email telling me how great the details were.

-

Kits that I have designed to date are: Mountain Buckboard; Allerton Steam Pumper; Ladder Wagon; Hearse; Armed Longboat; USS Constitution Cross Section; Jail Wagon; Fokker EIV; Oberusel 14 Cylinder Rotary Engine; Wolsey Eight Cylinder “Viper” Engine; SE5a British Fighter; Beer Wagon; Horse Harness (pulling); Horse Hitches for Wagons- 1 Horse; 2 Horse; 4 Horse. They said that they have plenty more in the lineup; I will be 76 next month so who knows how many more. The BeerWagon and some others are at the Nuremberg International Toy Fair, Germany. Life is good.....I get paid to do my hobby what more can one ask for. Amongst all of this I did these personal projects: the Niagara; USS Constitution; Maersk Detroit (WIP); Dirty Dozen; and 1961 Showboat a pet project. A couple of stained glass windows for local church. Here are just a sampling of them.

- 440 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

The Niagara now has a much steadier and lower base to rest upon. My daughter found this in her travels and immediately bought it. Now people can now look down at the deck details which was not possible before. Perhaps the Detroit will be displayed above it whenever I get back to it. ModelExpo has been keeping me designing various model kits for them.

- 440 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

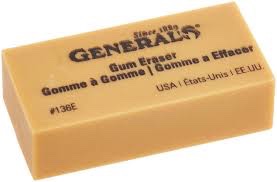

In the past I have had good cleaning results with the rubber like gum eraser used by artists. It really grabs stuff in the teeth be it wood; brass or resin. The coarser one at the bottom worked best, but that also depends on the size of the teeth. I”

-

After years of dust and battle damage she was put up in dry dock; cleaned layers of dust and battle damage repaired due to young growing girls. Then a brass plague added, new base to index a custom built glass case she now resides for years to come completely protected. The granddaughters now truly appreciate the work involved in building models having grown up watching me build various model subjects. In fact the younger one now builds Star Wars spaceships with LEGO blocks that are quite intricate. Fair winds and following seas in her new home!

- 440 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

Ben, I have made the propeller, but have really been buried non stop designing model kits for Model Expo and they have several more in the line up. They are various subjects and time consuming. I started this for my son in law as a spare time project and guess what no spare time yet. It is one of those good news, bad news situations. But it will get done some day. Thanks for checking in.

-

2020 NRG Conference

xken replied to kurtvd19's topic in NAUTICAL RESEARCH GUILD - News & Information

We have visited that museum twice, all are in for a really great experience and time. Just a fantastic place to see and explore. -

Is there a Beginner’s Guide to Metal Work?

xken replied to VTHokiEE's topic in Metal Work, Soldering and Metal Fittings

Kurt, I to use Staybrite almost exclusively and with a 120 or 45 watt soldering iron. If a brass part is really thick then I will use a propane torch bottle type from hardware store. Also what dvm27 said is true for best results in most soldering operations. -

I just finished reading your book! I just wanted to thank you for taking the near-infinite time and patience to create such a clear and delightful book. There is so much information packed in there! It changed my thinking about what can be accomplished at small scale as well!

Working with metal is new to me (as is ship building; I'm new to MSW), but I will endeavor to work up to something approaching your style and point of view. (I believe it will take few years, at least!) Best wishes and thanks again!! -

EricWilliamMarshall started following xken

-

Fokker DR 1 by Torbogdan - FINISHED

xken replied to Torbogdan's topic in Non-ship/categorised builds

Nice build and great presentation the medal is a nice touch! What’s next?😎 -

Paul, your build came out great! I really enjoyed seeing the alterations and detailing you did. I have always considered kits to be jumping off points for extra detailing. Keep up the great work and the next thing you know you will be scratch building.

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

Paul, please keep in mind that the 5/16" dowel is a reference dimension for the dowels to be ordered by M.E. for kit production and given manufacturing variances dowels can be slightly larger or smaller. Please reread page 34 where is says use the boom ring as a gauge when tapering the mast. The cast parts are labelled correctly. As for the 3/8" that is tolerance to allow straightening the mast allowing for variances in the build by individual builders if the mast foot is slightly out. I personally do not like to see crooked ( out of perpendicular) masts. I hope this helps. Look at page 37 for the finished part. I learned very early on about plan reproduction which is why I include a 1 inch reference square on my plans. Plan reproduction variances can be large or small based upon the machine settings, quality of machine and quality of paper. Also file transfer can cause issues as well, to minimize this I and the M.E. folks both work with CorelCAD now. They were using CorelDraw to covert the CAD files for plans and laser cutting and when I would get laser cut parts they were usually 5% off in size due to the conversion from on program to another. This also happens with PDF files we discovered, hence they finally bought the CorelCAD so we all worked with the same program. None of these I can as a kit designer control. I have seen variance as much as 3/8" and if using plans as dimension guide could be disastrous. The greatest challenge I have with the kit designing process is writing the instructions which is a balance between enough information to too much information and I like to err on the too much side. Builders also have to use a degree of common sense and allow for variances in building. When working with laser cut parts the finished dimension is on the bottom of the part sheet not the top, and laser cutting based upon the thickness of wood will have a slight taper (draft) though the thickness of the wood. The hexagon versus octagon is my bad, I should have caught that, but neither did the three other Proof Readers.

- 168 replies

-

- 18th Century Armed Longboat

- Model Shipways

-

(and 1 more)

Tagged with:

-

Arthur, not sure why you are experiencing the problems you are having. The boat in the pictures in the instructions were built from the laser cut parts in the kit and before being released M.E. also had two independent builders assemble the kit as well as part of the proof of production and the only issues were tweaks to the instructions for better clarification of terms for new builders. This is a standard practice I have asked M.E. to do with all kits I have done for them. I also purchased 1/24 scale sailor figures for my build, not to be included with the kit just for my own display purposes. See attachments. Here is an image of the rear cockpit area using the laser cut parts from the kit. Here is just the hull completed with all the laser cut parts from the kit and all fitting well. As for the quality of the wood in the kit's Basswood that I have no control over; however, they do supply me all the materials used. Good luck with the rest of your build, should be smooth sailing here on out.

- 95 replies

-

- Model Shipways

- 18th Century Armed Longboat

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.fc5d633a7b34428fcf19419a73d56d55.jpeg)