-

Posts

6,139 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by James H

-

I work as a Senior Tech in local government.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

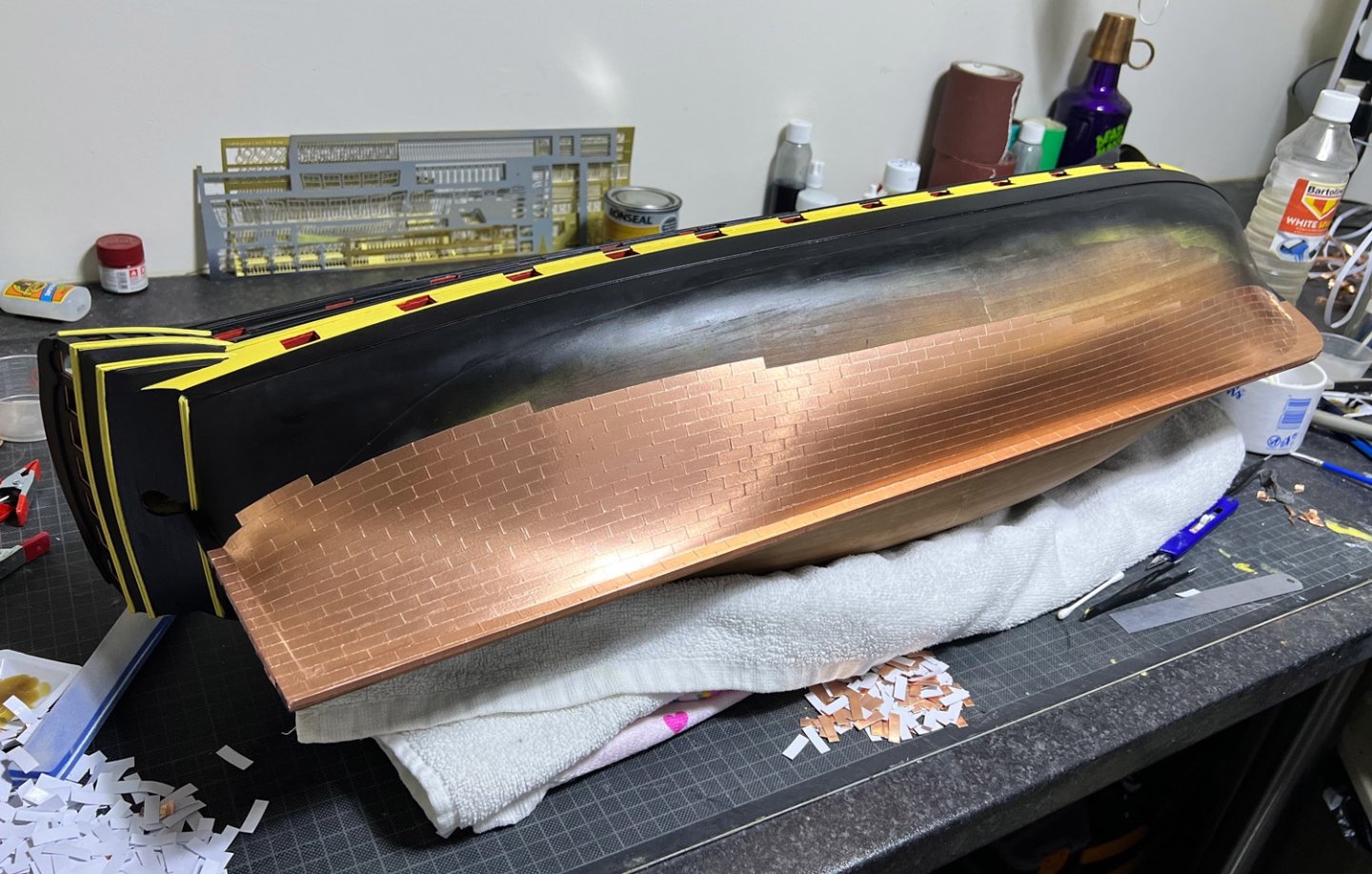

I'll do a proper update this weekend, but here's a quick phone photo of the coppered and trimmed hull. Other work I've been doing is finishing up the 24' cutter, painting the timberhead rails and building channels...as well as many other things. She will come together pretty quickly, but I do need to protect this copper from tarnishing.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

That is sort of ongoing as a possible plugin. Our forum uses proprietary software, and although we can make amendments etc. these things are best done by uploading as an app/module, and not by tinkering with pages of code that aren't ours.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

backing up a log

James H replied to Knocklouder's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

I think here is fine. Many people will have seen it here and can continue following. -

No, nothing has changed. It's as it's shown. I removed some char from top of parts, so things will look different.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

The New Up Arrow Button!

James H replied to Matt D's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

-

backing up a log

James H replied to Knocklouder's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

No, we have nothing that can do that, or access via third-party plugins. Browsers are generally equipped to export as either a web page or PDF, and also to print whole pages you are on. It make take time over a large build log, but there's nothing we can do about that. We keep several backups of MSW at all times, and backups are made 4 times per week, into several different locations. If you feel you need to back up your build log, for whatever reason, you'll have to do this manually. -

I think the point of this is that Chris has made it abundantly clear many times what his plans are with regard to his larger naval vessels (period etc), and that countless requests for ironclads and yachts, as well as the multitude of typically unknown vessels, simply won't fly. Discussion should revolve around announcements/releases etc. On this note, Chris has asked me to lock this topic so he can start a fresh one. This one is currently 78 pages!

-

backing up a log

James H replied to Knocklouder's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

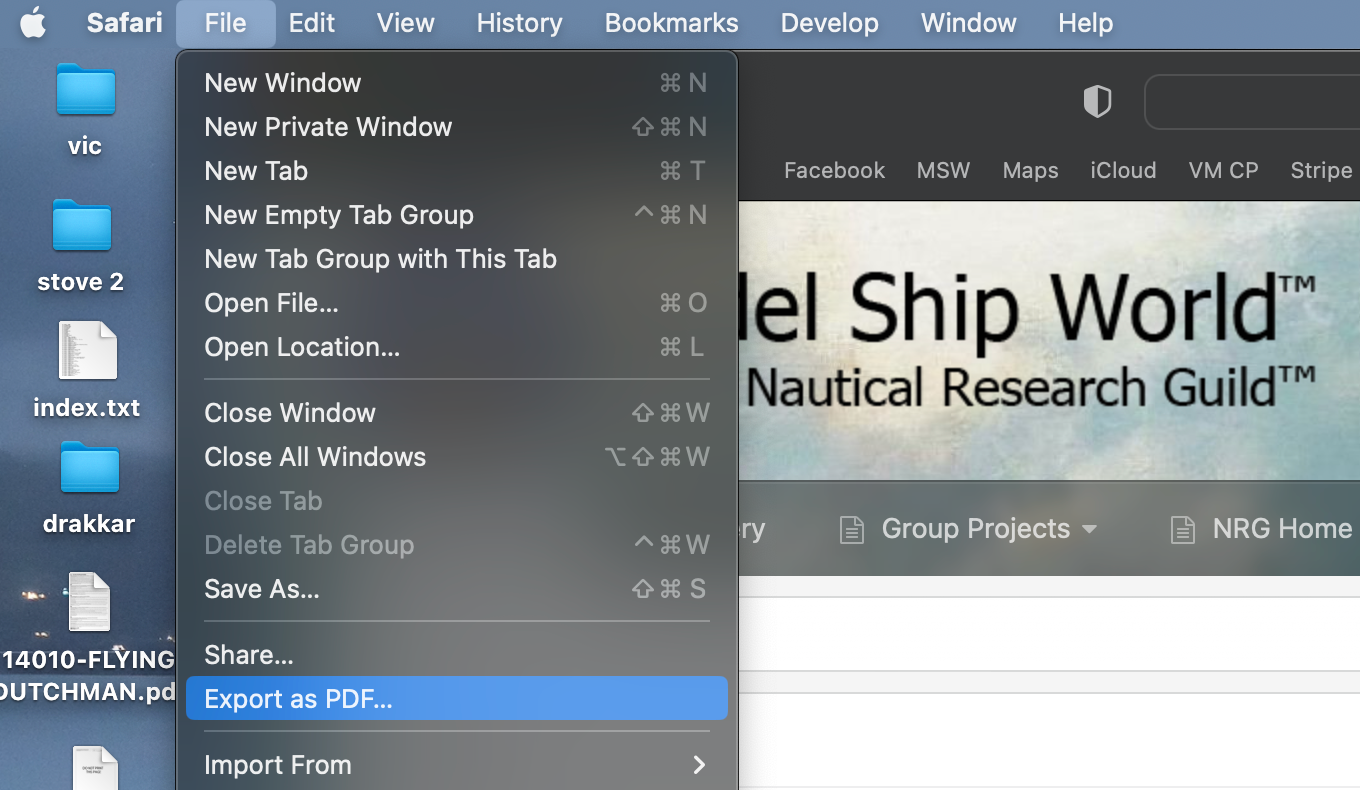

The forum software won't cater to that, but it's easy enough through your browser. Ok, I'm using Safari on Mac here, but this should be available on most, if not all browsers. Just export each page as a PDF and save to your computer. -

I would paint the swastika first, using masks, then add the hardware over it and paint. BUT, Amati have supplied the kit with the last known iteration before it was sunk. At that time it had no swastikas. They were painted over.

-

It's great to see you back! You were one of the very first members of MSW 1.0!!

-

***Please note*** Any further posts regarding chain pumps will be deleted from hereon in. It's superfluous to the discussion and serves only to derail what I'm trying to achieve here. I've even received PMs demanding to know why I removed member's posts after me needing to cull my topic (for the third time!). It must stop. Now.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I must admit that the thought of running a rivet tool, freehand over the hull, would fill me with dread. If I opt to rivet the hull, I think I'll do one plate at a time with a beading tool. I'm quite used to that method for adding rivet lines to large 1:32 airframes.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

It certainly works faster and is more forgiving. If I get a plate slightly wrong, I can just reposition it or throw it away and add a new one. No more CA gel, but you also don't get the nail marks (if you wanted them). These can be added with a rivet tool from VM or a beading tool.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

The original Indy clearly shows the chain pumps fitted, but the drawings made for the razed iteration shows that other changes were made too...one of them being the chain pump omission. The guys doing these plans surely knew what they were doing, and adding the smaller pumps would've been a very unusual move and not one that would've been done without them being specifically requested. That's what the drawings show, ergo, that's how the deck is fitted out.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

What a great start you made here on MSW. Off to BanLand you go.

-

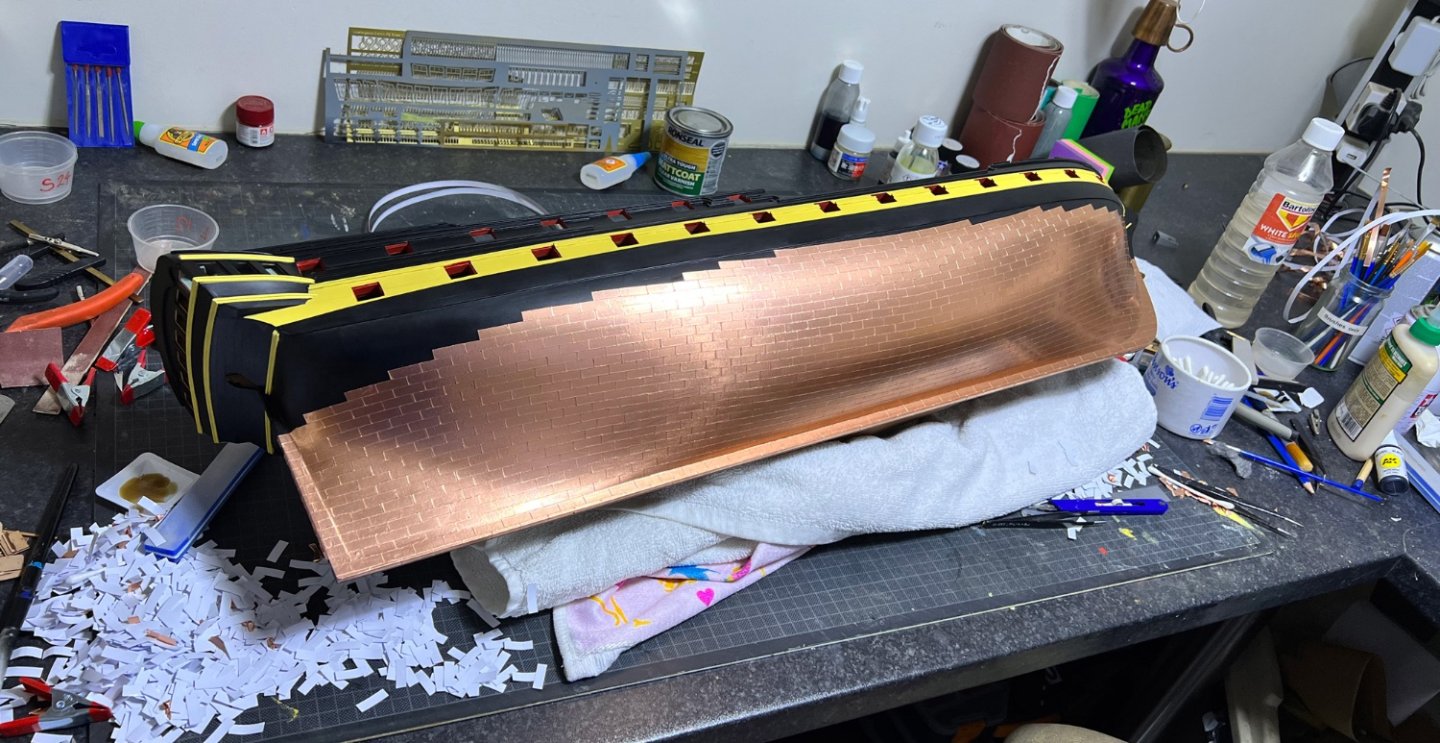

I've coppered the first side and will do an update once I've coppered the opposite side and trimmed it down to waterline level. Here she is so far.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I'll do a proper update in a few days, showing coppering, but until then, here's a photo showing the work so far. Coppering is a fairly quick process, thankfully, and fairly therapeutic.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.