-

Posts

784 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ChrisLBren

-

Proxxon Planer DH40 Issue

ChrisLBren replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

I think the blades aren’t high enough on the drum - the unit grabs the wood with the auto feed but doesn’t cut. So obviously the screws that set the blade shouldn’t be flush with the drum slot. I love this tool and am hoping to get it working again with the new blades -

Proxxon Planer DH40 Issue

ChrisLBren replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

Any tips changing out the blades ? I got a new set and for some reason I’m having a difficult time getting them to the right height -

Wow Im impressed - I didnt know how you would be able to pull off the friezes and you've done it ! Kudos !!!!!

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Proxxon Planer DH40 Issue

ChrisLBren replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

Thanks for the feedback ! I read in the manual that the blades can be reversed if they are dull or simply replaced for 10 dollars. I agree Greg - I love this machine it works really well in conjunction with the Byrnes Thickness Sander but much more efficient to dimension wood. -

Hey Group, Am very curious if anyone else who owns this machine has had issues with it leaving bite marks on wood. I am thinking I need new blades - when first purchased worked like a dream. Any feedback is appreciated, Chris

-

Beautiful job on the planking ! I agree with you - the less is more approach works very well - heck I almost decided not to simulate caulking but have changed my mind there. No treenails for sure. Hopefully Ill be back in the shop this weekend after many honey dos to get the house ready for winter - which is coming early here in the Midwest. Kudos to a brilliantly executed model so far !!!

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Try FED EX - Ive had this issue before - they seem to have the only machines to handle this without "fit to size"

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hey Group, About to hit a milestone next month and the wife is asking what I want. I really would love more time in the workshop - LOL. However probably another tool is probably an easier ask. Here's what Ive collected over the past few years (I use all of them). The major three Byrnes tools (saw, sander and thickness sander), Proxxon thickness planer, Dewalt Scroll Saw on Stand, Spindle Sander, Proxxon MF 70 Mill and a really nice set of Lie Neilsen chisels. Only thing i may be missing is a lathe ? Any suggestions are appreciated - Im a scratch builder with the occasion cheat from Syren Ship Models.

-

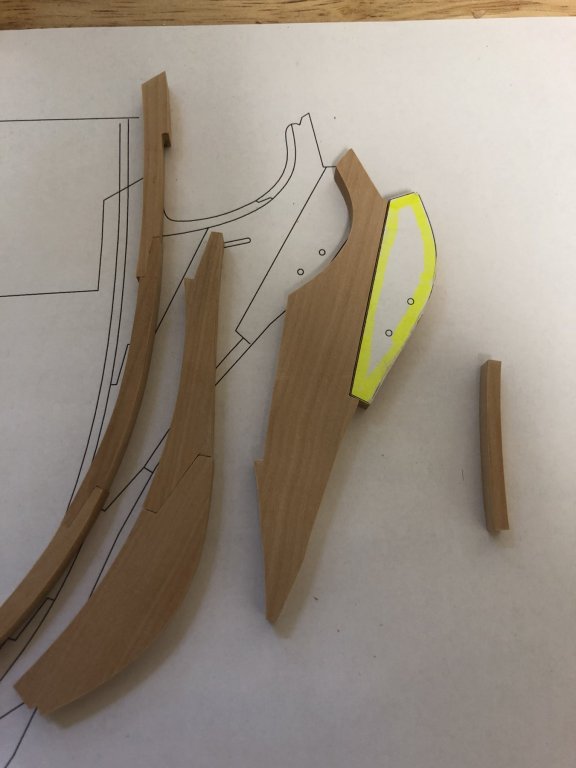

Nice work Rusty ? Are you building in all pear as well ? I had to swap out a few parts on my stem - hoping to get it together this weekend finally !

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

We’re our own worst critics !!! Nice fix

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Lou its trial and error - this is my third attempt on the stem to get the fit as close to where Im satisfied with the assembly. The flitch of French Pear I bought a couple of years ago is really nice. I had a local facility mill it to my specs for billets @ 3/8, 1/4 and 3/16 for 100 dollars - way cheaper than buying milled sheets. And you get consistency of color.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Who needs a laser cutter ? Keel cut out in three parts with my Dewalt Scroll saw - dead flat and true.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Congrats Kortes - beautiful job on one of my favorite subjects !!!!

- 306 replies

-

- schooner

- la jacinthe

-

(and 1 more)

Tagged with:

-

Looks terrific ! I notice a lot of Russian Modelers use Black Hornbeam instead of Ebony. Is it easier to work with - it certainly looks great. Thanks, Chris

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

Hey Chuck, Youre doing a beautiful job here - as Greg suggested - maybe try another finish. I do like the idea of either a shellac finish which the masters used - wouldnt be tough to learn that technique or sanding sealer for an unfinished look.... Regardless - nice work !!!

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looks terrific Marsalv I am also thinking of not adding the additional ports and build her as launched. I still need to finish my keel assembly ! Chris

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

Nice work - thanks for these close up shots of your keel - these are really helpful ! Have you decided whether your adding the extra gun ports or modeling her as launched ? Chris

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

ancre Le Gros Ventre by ChrisLBren - 1/36

ChrisLBren replied to ChrisLBren's topic in - Build logs for subjects built 1751 - 1800

Thanks John and Mark - you were with me every step of the way for Confederacy ! Don't worry Mark - Im keeping all of my "precious" French Pear scraps- since the ship will almost entirely be constructed out of it - Im sure I will find a use for most of it at some point or another.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.