-

Posts

4,564 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Blue Ensign

-

Thank you Glenn, I understand why Chuck included Cedar for the Windlass, a 10mm square section of Boxwood would be far more expensive. It is a preferable wood tho' if you can get it, and I quite like the colour shade difference for this fitting. @ Cisco - I use stuff called Carr's Metal Black for Brass, diluted with distilled water 50%. The brass is cleaned using fine steel wool, and a mild acid solution, before immersion for a minute or so. I then buff it using a cotton bud. It took well the first time, but I gave it a second immersion to deepen the tone. I think the main thing is making sure the brass is perfectly clean before starting the process. Regards, B.E.

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

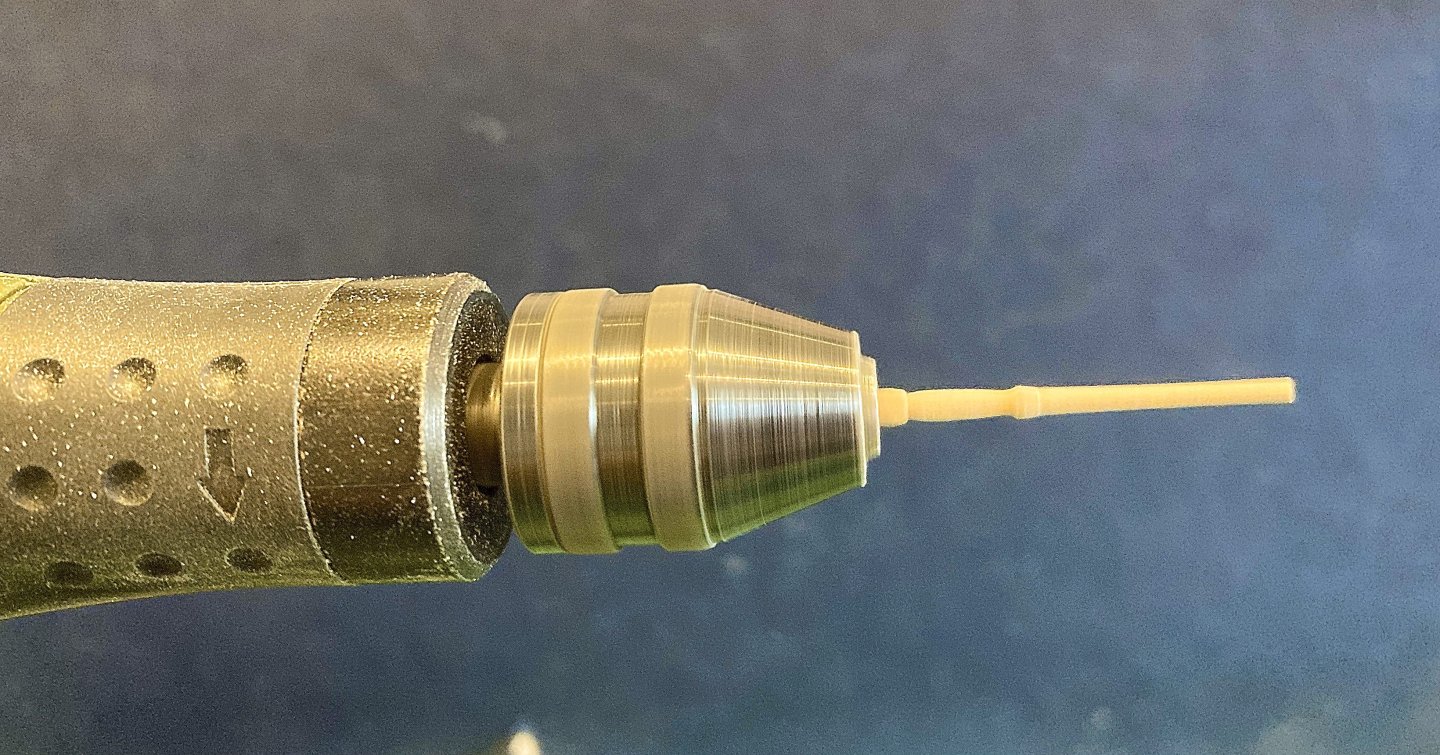

Post 33 Finishing the mast thwart This particular thwart has supporting braces for the Mainmast. The kit supplies brass strip, to be drilled, shaped, blackened, and glued and pinned into place. 0169 0181 0174 I use a mast jig to form the clamp shape which is held in position by the thwart straps. 0183 0193 Once satisfied the parts are chemically blackened. The straps are not glued into place, held simply by cut off brass pins smeared with ca. There are also four belay pins made from some Boxwood strip. 02625a These are chucked in the Proxxon mini drill for shaping. 02607a 02616a 0216 Delicate hands required for this task, seven started, five completed, but a morning’s work and it’s done. 0220 0219 0218 0223 0226 The thwarts will not be glued into place until I have finished with the construction work, and completed the w-o-p finish. B.E. 13/08/2024

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you Daniel, Brian Lavery, Arming and fitting of English Ships of War writes that Longboats were equipped with a windlass, as did the Launch that largely superseded it. Whatever size of the ship the Longboat was the heavy work horse required to carry the kedge and stream anchors, and lift the cables of the main anchors. It is difficult to say whether the smallest Longboats (19' - 21' ) were fitted with a windlass, but the Medway Longboat according to W.E. May, scaled to a 28' boat and clearly had a windlass. Vanguard don't have a Longboat in their ships boats line- up, but in terms of modelling I would always include one, if for no other reason that they are an interesting fitting. Always more questions than answers, Daniel. Regards, B.E.

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you Ross, others have managed very well with the cedar, but Boxwood worked for me. Cheers, B.E.

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Post 32 Windlass One of the most striking features of a Longboat is the Windlass, used for anchor handling. 0121 These can be tricky to make from scratch but Chuck has thoughtfully provided templates to set out the octagonal barrel of the piece. 0125 Cedar wood is provided for the makings, and early stages went well. 0132 I found it difficult to get clean square holes for the windlass bars. Repeated fiddling made the situation worse, and it all ended up like a dogs breakfast. As a significant feature I had no option but to reject it. Version two This time I went for Boxwood, being a harder wood I was content that it would hold a sharper edge and cleaner cuts. 0133 I was fortunate to have some very old English Boxwood of 10mm square section. 0135 Planed up, this wood is a joy to work with. 0136 0138 I used a No11 scalpel blade to cut the octagons, and a 3mm micro chisel to form the windlass bar mortises. 0145 To finish the windlass small spindles are created at the ends which are rounded. 0140 The windlass brackets are pre- formed and only require the addition of ‘nails’. They sit level with the underside of the adjacent thwarts and are fixed directly to the risers. 0141 I use a section of dowel to check the alignment before the glue set. 0149 Not given the w-o-p treatment at this point. 0150 0153 Satisfied I can now move on. B.E. 11/08/2024

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Headworks are such an important part on a model, and she looks just great. Well done Glenn.👏🏻 B.E.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Main and Fore Preventor Stay

Blue Ensign replied to Admiral Beez's topic in Masting, rigging and sails

They had fallen out of use towards the end of the the 18th c. Victory may well have had them in her earlier years, but perhaps not after her great re-fit of 1800. I note that the Vanguard kit of Indefatigable (1794) has them as part of the rigging. B.E. -

Main and Fore Preventor Stay

Blue Ensign replied to Admiral Beez's topic in Masting, rigging and sails

They are called Crows feet and were common on British ships also thro’ the 18th c. The purpose was to stop the foot of the topsail getting fouled with the mast top. -

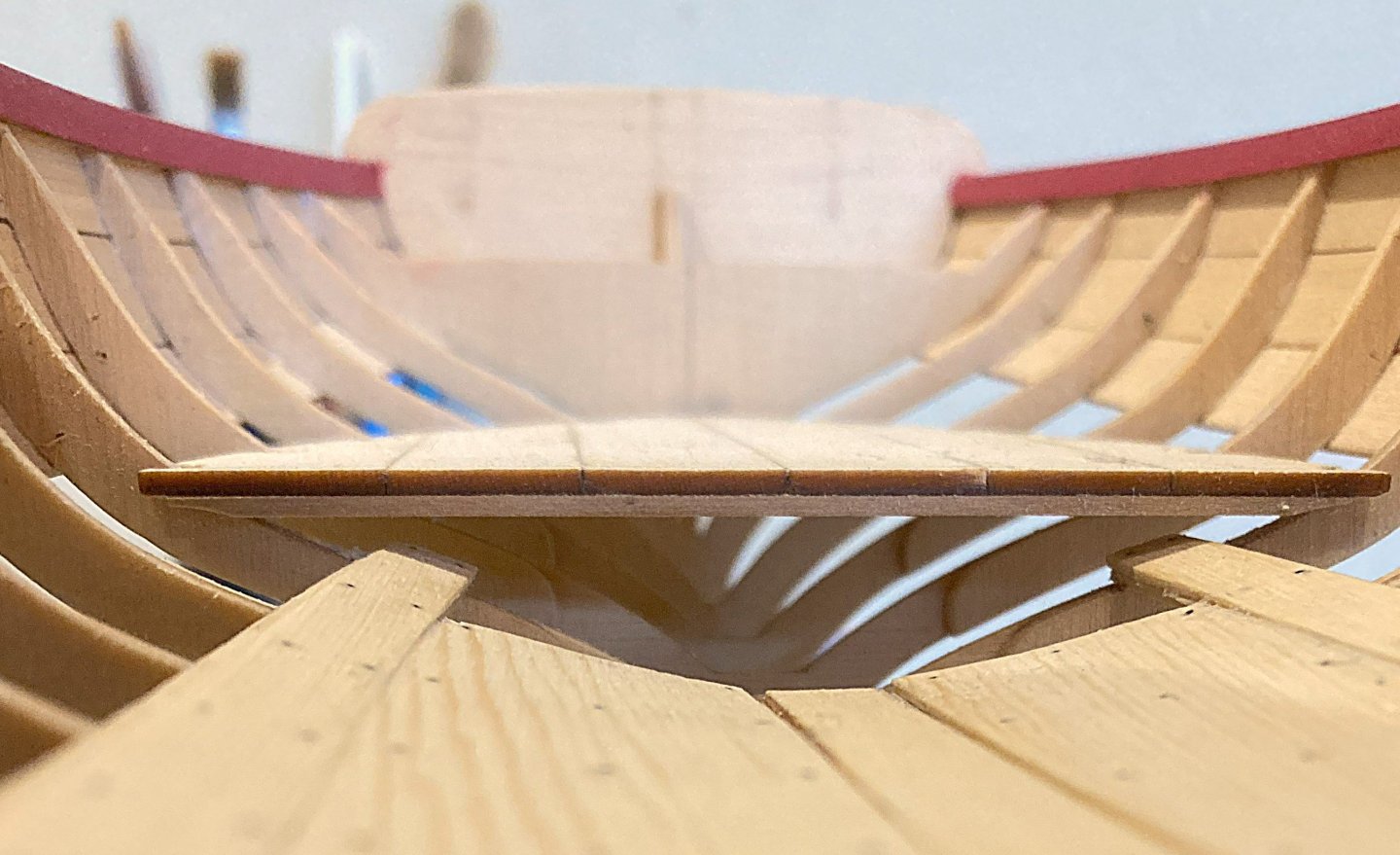

Post 31 Cockpit benches I found fitting the side benches of the cockpit somewhat tricky, and they took quite a bit of fettling. 0257 There is a lot of tweaking to get an acceptable fit. 0265 Several coats of paint were applied to the benches prior to fitting, but final coats will be applied once fitted. I couldn’t quite manage to get the aft end as close to the hull planking as I would have liked, but you reach the point of how much is too much, with the risk of taking it that one step too far and scrapping the whole piece. It is perhaps fortunate that this area is painted, as it allowed me to take a few liberties that otherwise wouldn’t have been an option. 0282 Side benches fitted and further coats of paint applied. The added support tabs for the central seat can be seen at the aft ends. 0285 The central panel has been fitted atop the stern post, and here the transom knees are tested for fit. I found it necessary to add small sections of wood to the knee ends to give a tight fit against the central panel. 0287 The final piece is the centre seat, this required a little tweaking to get a nice tight fit between the side benches. 0289 Additional coats of paint added, rubbed down with 1000 grit paper. The final coat will be applied once the whole area is complete. 0292 0293 0297 0298 0299 Starting to look like a Longboat now I think, the thwarts will be removed for the next interesting little construction. B.E. 01/08/2024

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Post 30 Thwarts ‘n all. The next stage is fitting the thwarts, pre-cut in cedar and formed of two layers to create a reveal on the thwart edges. 0266 Five of the thwarts require notching to fit over the frames and sit cleanly close to the run of the hull planking. 0267 At this point I have also started to add paint to the cockpit area. 0268 0270 0271 Fairly straightforward with careful measuring, but I did use ‘false’ thwarts as templates. I am satisfied that nothing untoward catches my eye in either level or squareness. 0269 Nothing is fixed at this point and the thwarts have yet to be given the w-o-p treatment. B.E. 29/07/2024

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

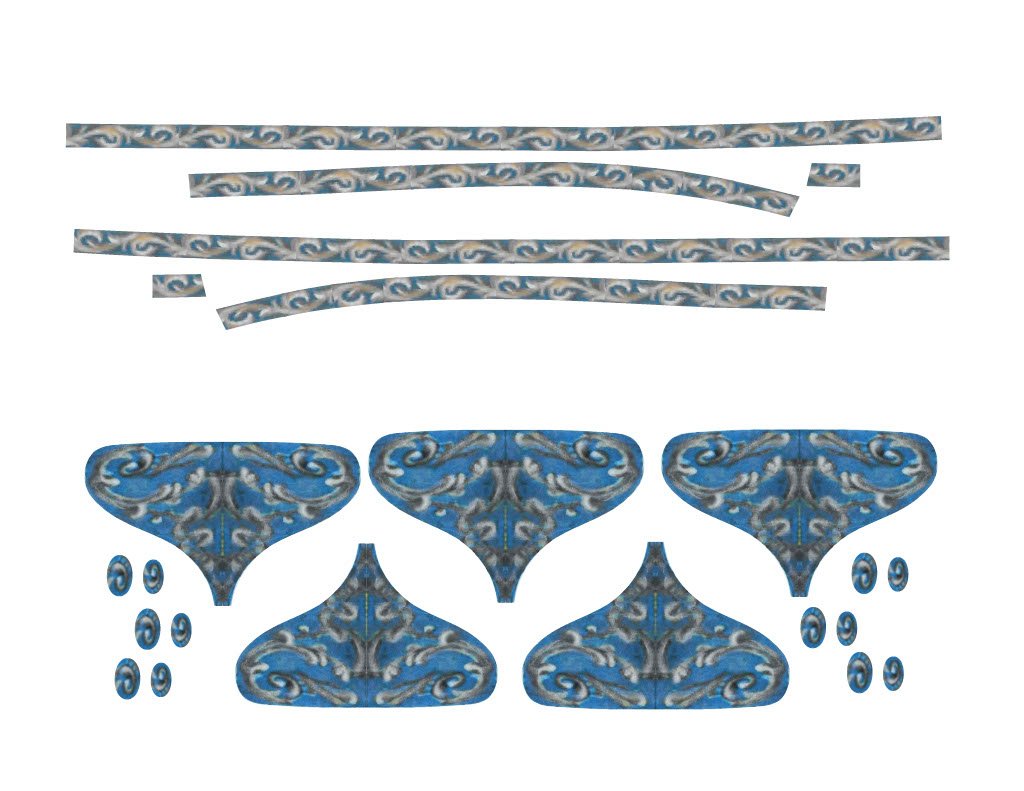

Post 29 Mouldings and friezes I was going to move onto fitting the thwarts but decided this was a better stage to fit the friezes and fancy moulding. 0220 The paintwork of the cap rails was firstly re-done and the outer edges cleaned up. The decoration which follows the contemporary model of the Medway Longboat 1742, is probably an artistic embellishment. It is unlikely that a heavy workhorse boat would in reality have such fancy work, although she may well have had a plain painted topside and stern panel. Still, it makes for a nice enhancement on the model. 0217 Before cutting out the frieze patterns, they were sprayed with Artist’s fixative. This also brings out the colour a little. 0219 0221 The friezes were applied using slightly diluted pva. No issues in fitting, if only I could say the same for the Transom. Chuck has provided several slightly differing transom patterns to hopefully give a little leeway to compensate for slightly differing stern shapes. NMM Fully planked Medway Longboat The idea is that an evenly sized border is created around the pattern, formed by the hull planking at the lower end. NMM in frame Medway Longboat On this contemporary model the margin is apparent at the lower end of the transom where one otherwise might expect the planking alone to form that border. None of the provided kit patterns were a good fit for my stern so I converted the pdf to jpg and tweaked it by degrees on a word doc to create an acceptable fit. 0248 I followed the contemporary model by trimming the lower part to show a margin on the lower transom. I thought this was aesthetically more appealing. Decorative strip. The makings are provided in the form of Boxwood strip. I scribed a simple moulding using the Artesania Latina micro shaper set. 0211 One of the profiles is similar to the style used by Chuck; a 3mm x 1mm profile which fitted the strip. It requires 4 strips to complete the moulding run. I made the joins around 2/3rd along the hull from the bow. The forward section required edge bending to facilitate the round of the bow and a touch of lateral bending to take the spring out of the strip. 0230 The moulding is clamped to the hull and given the heat treatment to further assist the fit. 0238 I used spots of ca to attach the moulding to the hull. Care must be taken to avoid any spread particularly onto the frieze work. 0252 0251 0249 I can now clean up the outer planking and apply w-o-p. I think w-o-p can also be applied over both the friezes and stern panel to further protect them. B.E. 25/07/2024

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Great work Daniel, a beautifully executed model, and excellent photo's. You should be very pleased with your work. B.E.

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

Post 28 Risers fitted Before gluing the risers I followed Chuck’s lead by applying the ‘nail’ heads using 10lb fishing line. 0179 I double checked the fixing marks before committing to glue and completed the Starboard side first. 0177 The port side rear riser was then clamped into place and the temporary thwarts used to confirm level and squareness. 0181 Moving onto the forward section riser on the port side. 0182 Multiple checks and re-checks are made to ensure that the thwarts are level. 0185 The temporary thwarts are used to confirm the levels at each point. I use the Proxxon vice to support hull and get a true level, and tweak as necessary. 0205 Forward portside risers glued into place, always relieved when this part is over. 0196 0207 Moving onto the thwarts proper. B.E. 19/07/2024

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Post 27 Installing the Risers. This is always a tricky area; getting the risers at the correct height and ensuring that the thwarts sit level and square across the boat. 0173 Careful measuring is required and as with my Queen Anne Barge build I used a simple depth gauge to mark the positions at each frame along the hull. There is a degree of sheer to the risers and the position does vary slightly along the hull. Before I commit to glue I do a lot of dry fitting. 0177 0171 0169 This extends to making up dummy thwarts to check the alignment. At near midships the thwart sits 32mm above the footwaling. This equates to 30” at full scale. The thwart above the aft platform is 20mm equating to 19” In modern parlance this is about the difference between a desktop and a chair. The dummy thwarts allow me to use my ½” scale rower to check relative heights. The 1:24 scale figure at 70mm represents a figure of 5’6” height. 0153 0158 Something looks a little awry here, there seems a very long drop to the footwaling. 0151 0165 Except that is for the stern sheet section, where the fit is spot on. The thwarts can’t be any lower because that would throw out the angle for the rowing action. The conundrum is that the same figure used on the 1/2” scale Royal barge model fits well for a realistic rowing position. 01712(2) 01713 Note the stretchers sitting above the bottom boards. 02526 Royal Barge seating. Unlike the Royal Barge, there are no stretchers fitted to brace the rower’s feet. I don’t recall seeing stretchers or cleats on the bottom boards of 18thc boats. 0163 Even so he does look somewhat incongruous sitting there. Fortunately, I’m not thinking of crewing this model so the disparity will not be apparent. On with the show. B.E. 16/07/2024

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you Diver, I had more than a couple of card template goes to get the pattern that fitted. You will see that I have deviated from the kit pattern for the bow platform by notching it into the bow stem, which was a good fit for my particular version. The contemporary model of the Longboat, seems to have a different set-up around the inner stem and framing, with two platform notches before the stem, but there is no really clear photo of this area. Cheers, B.E.

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Post 26 Bow Platform To make this platform, as suggested by Chuck you really need to start with a card template. The pattern of this platform is oversize so won’t conveniently fit between the forward frames to get a start with the notch for the bow stem. I found it necessary to indulge in a little origami to achieve the result. 0109 The pattern is folded in half and the notches marked and cut out on one side and when flattened out should fit across the board. The platform has to sit low down, a mere 16mm or so above the footwaling. 0098 I again used a height gauge to check the correct level of the platform. 0097 By these means I was able to get a reasonably close fit at the right level. Not out of the woods yet, with an open framed model there is no defining outer planking to guide the internal fitting. 0130 I used Tamiya tape to give a guide for the missing planking, to aid the platform final shaping. 0134 0136 0132 This shows the variation necessary to the basic wooden platform. (My build only, other builds may vary) 0137 0138 0148 Supporting beams were added as with the aft platform. 0143 I have not applied w-o-p at this point or fixed the platforms in place. I’m not even sure if I need to, the platforms are a nice snug fit. B.E. 13/07/2024

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you Ronald, at 390mm long by 132mm beam, she is quite a chunky model, and takes up a fair bit of room if masted and rigged. Just imagine how big the 1/2" scale model ship that carried her would be.😮 B.E.

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Post 25 Platforms continued Modification of the aft platform has been made. 0095 The forward end has been trimmed to create a half notch and support beams added to fit adjacent to the aft sides of the boat framing. 0096 For these I use 3.3 x1.3mm strip that I just happened to have in stock. Each beam was pva’d into place and the nail points marked. 0111 Using 10lb fishing line the ‘nails’ are inserted, secured with pva. 0125 0124 0113 0116 0118 Regardless of any authenticity aspects I think the underside now looks acceptable. Still some finishing off to do but I’ll complete the bow platform first. B.E. 12/07/2024

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Daniel, I obviously didn’t have my old brain in gear when I followed Chuck’s lead which is directed towards a fully planked hull, where such details don’t matter. What I don’t know is how permanent these platforms were. Could they be removeable for access to the space below, merely slotting into place between the frames, even fitted in two halves? Either way, I will replace the random supporting boards with specific support beams which match the nail runs and hopefully look aesthetically better from beneath. Regards, B.E.

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Post 24 Platforms. After a break in Devonshire and taking advantage of recent fine warm weather to work in the garden, I return to the Longboat build. Has it really been a month, better crack on. Fore and aft platforms are now to be fitted. Aft Platform Initial assembly is quite straightforward, it’s the notching to fit over the frames that is the tricky part. 0086 I followed the sensible approach of using card templates to mark the notches to fit over the frames before committing to the real thing. Even so, fine tuning the notching proved to be a frustrating business. Chuck indicates that the platform should be ‘pretty low’ on the model, but how low is low? 0083 I made a simple height jig from the plan to gauge where the forward edge of the platform sat above the floorboards, and notched away until I got close to the level. 0088 2479a 0093 For me this involved cutting notches somewhat deeper than the guide photos indicated. 0087 I hadn’t otherwise modified the boards at this point which seem to finish at the forward edge of frame seven from aft. Mine extended beyond frame 7 with a complete notch. One final puzzlement I had with the platform was the nailing pattern. There are five rows of nails running across the planks, but to secure to what? There are no corresponding supports below these points. Chuck has indicated the use of three random beams across the underside to secure the boards and provide lateral support but they bear no relation to the nail runs except perhaps for the fore-most one beneath the front edge. 0090 In terms of a fully planked version this has little relevance but for the open framed version what lies beneath is open to scrutiny, not a good look I think. As the frames drop away from the boards with their ‘V’ shape, a more logical approach would seems to be to have support beams holding the planks together either in line with the frames or between them. I think I need to change this. B.E. 10/07/2024

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Well done on completing this behemoth Glenn, she certainly has presence as a fully rigged model. 👍 B.E.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

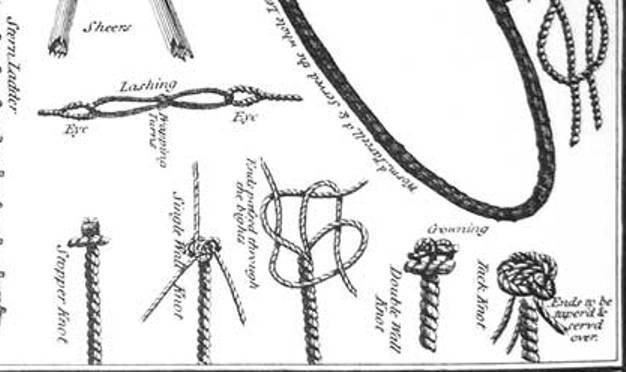

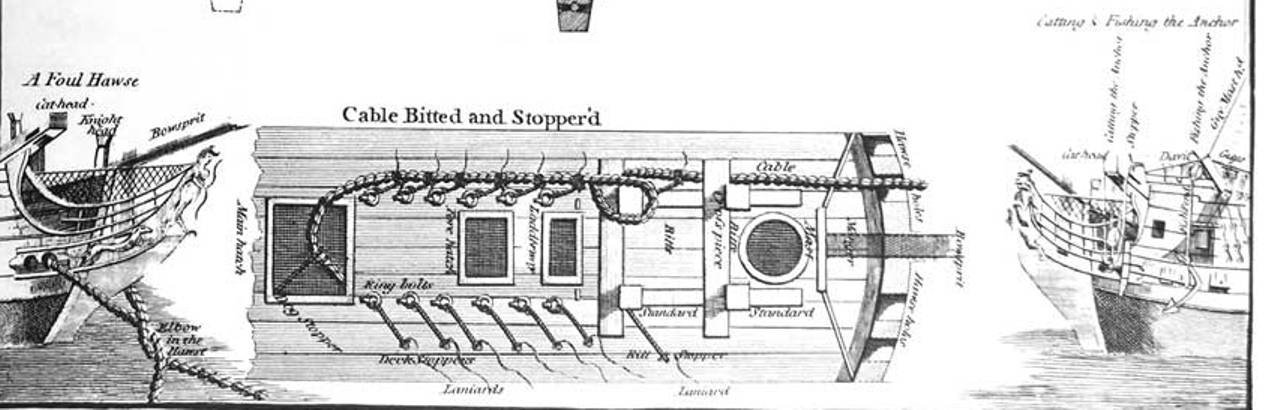

Anchor cable Rigging – Pegasus I have been contacted a couple of times recently about the rigging of the anchor cables along the deck of Pegasus. It seems I missed the inclusion of this element when I reconstituted my Pegasus log after the great crash. So, for the benefit of any who may be interested this is a summary of my approach. Anchor Cable. The given size is 13" circ which scales to 1.64mm dia. I have gone for a slightly larger dia. preferring the look of Moropes 1.75mm stuff. 1983 As a nod to authenticity this is left hand cable laid rope, as it should be. I considered how to pass entry down the Main Hatch; Was the grating removed during the cable stowage process, or were there cut outs in the hatch grating to take the cables? Something I missed from the early stages of construction tffm shows the Main hatch grating in three sections, so the forward one could be removed to allow passage of the hawser. 2010 The grating was modified to reflect this. 2091 One of the drawbacks of using non-natural Morope is the springiness of the line, which is a big disadvantage when it comes to things like anchor cables where an appearance of weightiness is desirable. To counter this I immersed the line in diluted pva, followed by stretching to take the spring out of the cable before fitting. 2019 In reality the cables would be stored in the hold but of course there is no hatch on the lower deck. When I fit the cables they will be weighted and coiled neatly out of sight on the Lower deck. If you are considering adding the anchor cables to the model, beyond simply stuffing the rope ends into the hawse holes, early consideration should be given to the Main hatch gratings. Stoppers While the Riding Bitts took the majority of the stresses on the cable of a ship at anchor, additional security was provided by use of stoppers attached to ring bolts in the deck and seized to the cable inboard of the Bitts. According to Steel these are the proportions of the stoppers. Cabled 7" ( 0.88mm ø ) Finished length of short stopper before fitting 8' 3" (39mm at scale);seizing with 1" (0.1mm ø) line. attached to cable with a 2" (0.25mm ø)lanyard There are six stopper ringbolts each side of the deck. These were made from brass rings and eye bolts clenched together and blackened. These ringbolts also doubled up for the relieving tackles of the Upper deck guns. This is what Steel has to say about stoppers.+ STOPPERS. Short ropes, used to check the cable, suspend weighty bodies, and retain the shrouds, &c. in a fixed position, after being damaged, or otherwise. ANCHOR-STOPPERS are used to suspend the anchor, when catted: BITT-STOPPERS are those stoppers used to check the cable: DECK-STOPPERS are used to retain the cable when the ship is riding at anchor: DOG-STOPPERS are used as additional securities when the ship is riding in heavy gales, or bringing up a ship with much sternway, to prevent the cable from snapping at the bitts, and to ease the deck-stoppers: WING-STOPPERS are used for the same purposes as dog-stoppers: SHROUD-STOPPERS are used to confine a shroud together, when damaged, or shot. FORE-TACK, and SHEET, STOPPERS, are for securing the tacks and sheets, till belayed. STOPPERS, DECK and BITT, are divided into ten short and two long stoppers. The two long stoppers, from a first rate ship to a sloop, are cut sixteen feet; and, when knotted, to be twelve feet six inches. The short stoppers are each cut twelve feet six inches; to be, when knotted, eight feet three inches long. One end of each stopper has a double wall-knot, and the ends led up through the middle, and whipt with spunyarn: the other end is only whipt with spunyarn. PREPARATIONS NECESSARY TO BE MADE FOR ANCHORING. On approaching an anchorage, the anchor and buoy are got clear, and a range of cable stretched along the deck suitable to the depth of water. Care should be taken, that nothing is in the way to check the cable, or stop its running out: then, at a proper distance, a turn is taken round the bits with the cable, thus: First pass the cable from the anchor underneath the cross-piece, then take up a bight of the cable abaft the bits, and throw it over the bit-head. The end of the cable is clinched round the orlop beams in the royal navy, and round the main-mast in the merchant service. It is necessary to have water near the bits to prevent its firing by the friction. Stoppers and ring ropes of all kinds should be ready for use. The stock lashing being cast off, and nothing but the anchor stopper and shank painter retaining the anchor, men are stationed to stand by them, and let go at the moment ordered. To secure the cable when out, DECK STOPPERS are thus previously prepared: they are turned into the ring bolts on the deck, round a large iron thimble, and fastened with a throat and end seizing. Each stopper has a laniard spliced round the head, under the knot, by which several turns are taken round the cable, and the end stopt. BESIDES the deck stoppers, others are used as an additional security to the cable; such are the BIT STOPPERS, &c. BIT STOPPERS. Each stopper is reeved through a hole in the standard knee, against the fore part of the riding-bits, and is turned in or spliced. It has a laniard spliced round the head, under the knot. When used, several turns are taken with the laniard round the cable, and the end stopt. It is to check the cable in bringing up the ship. Another bit stopper much approved of, is about four fathoms long, and tailed out like a nipper at one end, and knotted at the other. Let this stopper be rove through the hole in the standard knee. To pass it, let it be held aft, inside, over the cable, and under the bits, outside the cable; then worm it round the cable before the bits. Then, as the cable runs out and it is required to check the ship, haul tight the worming; and, by the cables drawing forward, it will tighten the stopper, and bend the cable so close to the bits as effectually to bring the ship up. This stopper is not likely to jamb, Therefore is extremely well calculated for bringing a ship up with ease; as, by slacking, and hauling tight the worming, the cable may be suffered to run out, or be checked at pleasure. In heaving up in a heavy sea, when, by a sudden pitch of the ship, the messenger or nippers give way, this kind of stopper will be found extremely serviceable; for, upon these occasions, this stopper may be always passed ready, and the bight triced up abaft the bits, with a rope-yarn clear of the cable. Another bit stopper, made with a large eye, that it may be thrown over the bit head, and shifted over from side to side, is also much approved of. DOG STOPPERS. One end is clenched round the main-mast, and the other end wormed in the cuntlines of the cable, and stopt in several places; then brought back with several turns over its own part, and the end stopt. It is of little service, unless it be long enough to clap on above the coamings. WING STOPPERS. One end is clenched round the orlop beams in the wings, and the other end is clapt on as the dog stopper. RING ROPES are occasionally made fast to the ring bolts in the deck and to the cable, by passing the ends through the ring of the bolt, and through the bight, then clapt on the cable with cross turns, and the ends stopt. Ring ropes may be better single than double; they are passed with less confusion of turns. To pass a single ring rope, and have it in readiness to check upon veering away the cable, take also three slack turns through the ring bolt and round the cable, one before the other, and hold up the parts fair; then take as many slack turns of worming round the cable, before the ring, and they held up fair, leaving sufficient room for the cable to pass through. When the cable is to be checked, haul tight the worming; and by the cables running out, it will readily draw the turns tight through the ring, and bind the cable so close to the ring, as to prove an excellent stopper. Ring ropes are similar to the laniards of stoppers, to check the cable when freshening the hawse, or to add security to the stoppers in a heavy sea. For the stoppers I am using Chuck's tan rigging line .035" which conveniently scales to 0.88mm ø spot on for 7" circ. cable. 2131 The first job is to attach the stopper to the deck bolt. It should be turned into the ring of the bolt using an iron thimble and finished with a throat and an end seizing. I use a needle to work the seizings of 0.1mm line. Good job I hadn't glued the ring bolts in place. At the scale involved for me at least, I don't think it viable to represent the thimble as it would be very small and thin inside the bight of the stopper line, the throat and end seizings present no difficulties. I decided to fit three stoppers each side, partly to demonstrate the purpose but mainly to secure the anchor cable and keep it taut from the Bitts to the hatch. To determine the length of the stopper I did a temporary fit against the anchor cable and marked off the length. The next real tricky problem is how to represent a Matthew Walker knot at the end of the stopper. Having looked at how you form one of these, I dismissed trying it in a nano second, there are far simpler ways of driving yourself mad. So, this is my approach: Take some of the stopper cable and soak it in diluted pva. Form a very tight ring and slice it where the two ends cross. Immediately seal the cut ends with ca. Using ca apply the ring to the stopper and use more ca to glue the two end of the knot together. This is the result. 2141 At scale I think the knot looks ok, the overall length of the stopper is only 15mm. 2140 The anchor cable is secured along the deck for fitting of the bitts. 8989 09000 Constant minor adjustment to the cable and the stopper is required as it is seized to the cable, to keep things looking reasonably taut. 8990 8992 8993 The anchor cables are coiled and secured between the frames below decks. Note they are crossed as they enter the hatch, this was an accepted practice to make handling easier, and in modelling terms it also allows a better lay of the cable. So, if you're thinking of attaching the cables to the anchor this job needs to be done at a no later stage than this to avoid access problems on the model. Note: This arrangement is stylised in the sense that the anchors are at the cathead but I'm showing the cables around the riding bitts and secured along the deck with stoppers. Securing the anchors like this would normally be when the ship is at anchor, and the stoppers are to relieve the strain on the bitts. My intention was simply to add interest to the deck details whilst showing how anchor cables were secured. B.E. 08/07/2024

- 366 replies

-

- pegasus

- victory models

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

crop.jpg.2ae83ef0e5bdfb951da9d131786d0e42.jpg)

a.jpg.2ce726513244230c5aafa17211db2871.jpg)