-

Posts

947 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by cobra1951

-

I totally agree with every word Bill said. You have made great progress since my last visit :)

-

Thanks for the info Phillip

- 65 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

Hi Phil Extremely nice build How did you find the materials in your AL kit. i had to replace about 50% of the timber in mine and it's put me off another AL kit, Hoping it's just a one off in my case

- 65 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

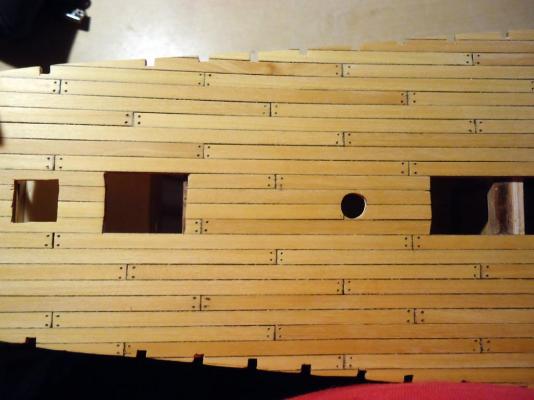

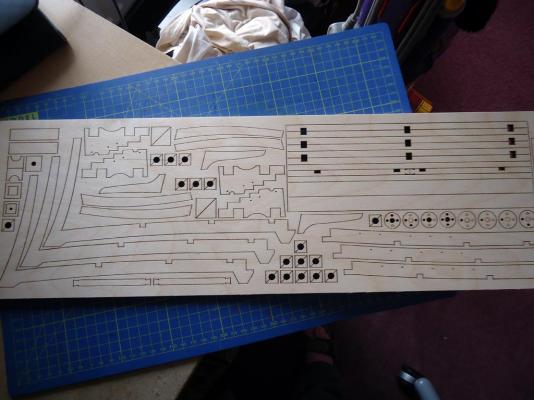

Quick update Finished simulating the treenails on the main deck Fitted stern plate Added the stern plate stanchions Ready to plank the stern plate. You may remember further back in the build i mentioned that besides the masts and decking i would probably have to replace a lot of the hull planking this is why. I may get enough pieces out of the warped ones to plank the stern plate or some of it at least.

-

Hi Nirvana, i will fax you a Danish and a coffee right over but don't make a mess on the couch

- 206 replies

-

- battle station

- panart

-

(and 1 more)

Tagged with:

-

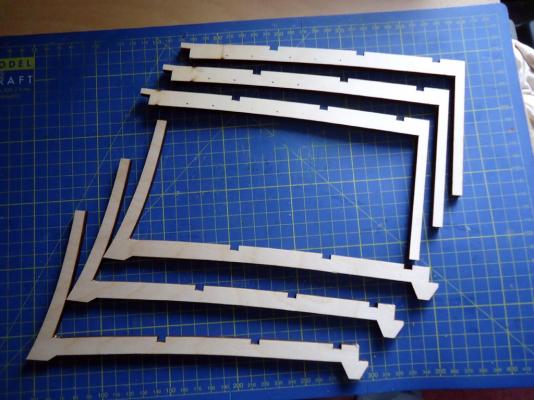

Finished the assembly of the main Frame, it went together very easily. Drilled and pinned all the joints with 2mm dowel and even though it has not dried and cured yet i am quite surprised how sturdy and rigid it is already Sitting patiently on my desk with all joints drying before i trim away the excess dowels

- 206 replies

-

- battle station

- panart

-

(and 1 more)

Tagged with:

-

Thanks EJ_L Paul i am going to sand the burn marks away and also paint the frames except for where planking will be laid.

- 206 replies

-

- battle station

- panart

-

(and 1 more)

Tagged with:

-

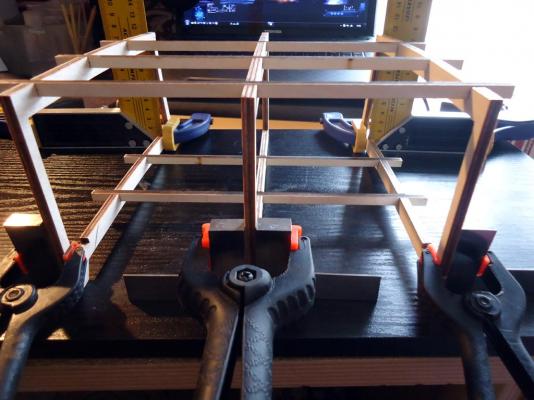

Assembled the main framework, to keep it square i clamped engineer squares to the upright parts. The bottom cross beams will be removed one at a time and glued into place. Once all three have been glued i will remove the top three beams to allow me access to drill and pin the bottom three where the beams and frames meet, while they dry the top cross beans will be replaced to help keep it all square. when the bottom beams are all dry i can then repeat the process on the top beams

- 206 replies

-

- battle station

- panart

-

(and 1 more)

Tagged with:

-

Cut my masts to the sizes given in the instructions (hope that part of the instructions are correct) Squared of the ends so they fit into the mast steps All 3 masts fitted and are looking ok to my eye with a backward rake on the mizzen mast. Can't use a square to check because of the curvature of the deck, both sideways and lengthways All even and at the same angle

-

@ Antony Hi Antony, i agree the only way to make sure you get quality wood is to source your own as you do for your scratch building. Especially if you live near a supplier then you can go and look at what you are buying first. Most kit manufacturers will replace any faulty materials but AL wanted me to do this then when you have done it do that and so on. Easier to buy more even if it does double the price of the kit in the end at least you'll be happy with the finished model. I told AL that they should not put wood that is so obviously flawed in the kit in the first place, as usual they just stopped answering @ Chidokan Hi, If you contact your kit supplier they will usually get the ply replaced for you, if not contact the kit manufacturer. Sergal are part of Mantua so probably them. Take photo's of the parts and of your receipt for the kit and e-mail the photo's to them with your request. If you are worried about twisting the frame check the first few posts in this log and make yourself a slipway to hold it straight while you build and also when you start planking the hull and only remove it to do the last few lower planks by that time everything will be held square by the planking Someone else reading this may have a better way and may help

-

Main Deck is now planked and ready for varnishing, but before i go any further i want to make sure that the masts fit nicely through all 3 decks First job was to put the kit supplied masts in the scrap wood stash as they came out the box looking like my dog had used them as bones They are also curved so much they would make good Bows for archery. Some kit manufacturers seem to think supplying this rubbish is ok, but once the word goes around they will lose sales in the long run IMHO. Then i cut some new lower masts from the new material i had purchased Big difference

-

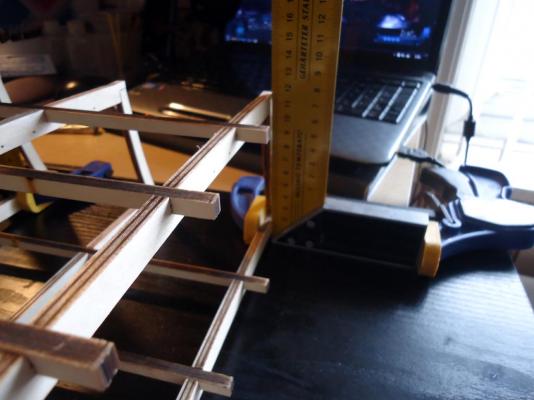

Assembled the 3 main frames Drilled 2mm holes in the 2 joints on each of the 3 frames Glued in 2mm dowel to strengthen the joints, and cut off, these will be sanded flat once the glue has dried

- 206 replies

-

- battle station

- panart

-

(and 1 more)

Tagged with:

-

Well you certainly made it look easy, excellent result, you have a great base for the second planking now

- 527 replies

-

- caldercraft

- victory

-

(and 1 more)

Tagged with:

-

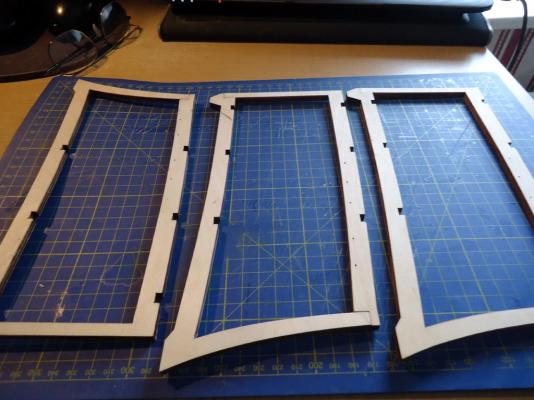

Compared to my Bounty the ply on this kit is luxury First pieces to make the main 3 frames cut out I like the fact that the top beams have had the holes for the eye pins already cut out, although they will still need a drill running through to clean them up. Also there are a few burn marks from the laser cutting to clean up as well

- 206 replies

-

- battle station

- panart

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.