mort stoll

NRG Member-

Posts

541 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mort stoll

-

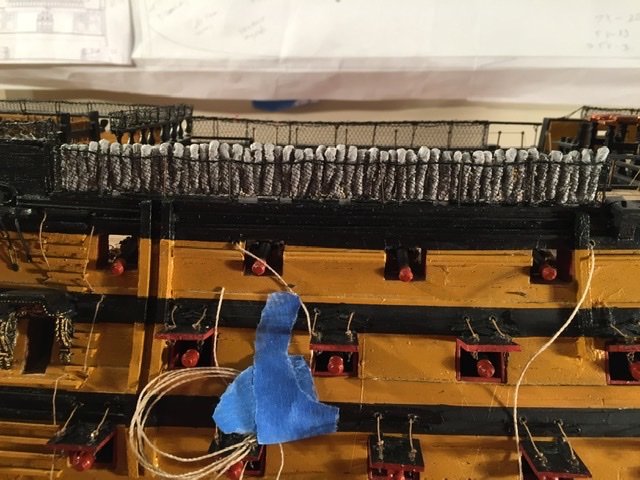

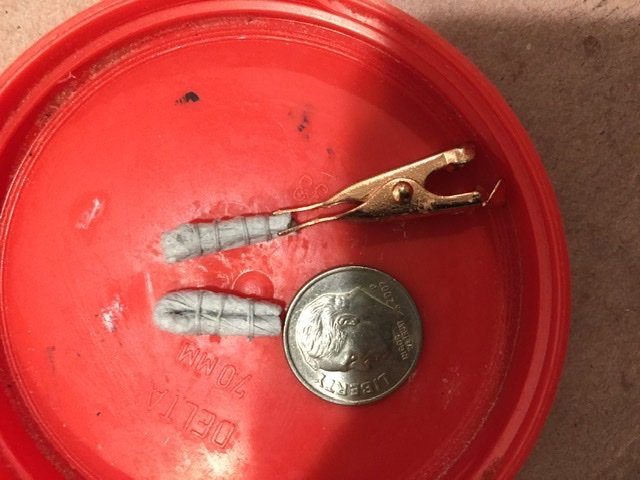

Have finished the hammocks as the above pictures show. The jig designed by a fellow club member saved me tons of time. It was a godsend. The height of the cranes varied depending on their location - quarterdeck, forecastle, break of the poop etc. Per Longridge in the “AOS” and Lavery in “The Arming And Fitting Of English Ships Of War.” It seemed more logical to have the hammocks in the cranes of lower height laid lengthwise, on their sides as opposed to being folded in half in a v-shape which was how I stowed the hammocks in the higher length cranes. In the shorter height cranes I’m sure the ships motion would have shaken them loose from the cranes. After researching the color - Lavery and Longridge - I made the hammocks from cocktail napkins purchased at Party City. Have a wonderful and safe 2022.

- 60 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

- 60 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

Am making the hammocks. Have a lot more to make, and have mounted the hammocks at the break of the poop and the ones on the starboard waste. Am still unsure how if I should mount the hammocks in the smaller cranes - on their side length wise as Lavery suggests in “The Arming and Fitting of English Ships of War - or in a ushape - as I’m sure the ships motion would shake them loose if they’re mounted in a ushape. I’d appreciate your thoughts. Hope you and your families are having a great holiday season, have a wonderful Christmas and an amazing 2022. Stay safe and well. Mort

- 60 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

- 60 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

The hammock cranes are different heights. The only pictures of hammocks in the cranes I’ve ever seen show them folded in half within the cranes. I would think that the hammocks in the shorter cranes would have been shaken loose by the motion of the ship if they were folded in half. Longridge, Goodwin in “The Construction and Fitting of English Man of War” and McKay in “The AOS Victory” make no mention of their proper stowage. Only of the cranes themselves. Mondfeld shows them folded in half. Lavery in “The Arming and Fitting of English Ships of War”says that within the lower rails “they must have been stowed - lengthwise - on their sides” - which to me makes perfect sense - but he’s specifically referring to the cranes at the break of the poop and quarterdeck. The cranes at the forecastle and quarterdeck are only slightly larger than those at the break of the poop. My question is how should I stow the hammocks in those cranes, folded in half or lengthwise on their sides?

- 60 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

- 60 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

Hammock cranes mounted and nettings sewn onto .25 black line. It was very tedious and precise work. Seemed to take forever. I used black tule for the netting. Am now making the hammocks.

- 60 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

I assume you made all of the furniture in the Captain's cabin yourself. It looks great as does the rest of the model.

- 112 replies

-

- Bluejacket Shipcrafters

- Constitution

-

(and 2 more)

Tagged with:

-

Very sorry to hear that. I look forward to your new log. Main thing is that the model is still an undamaged work of art.

- 112 replies

-

- Bluejacket Shipcrafters

- Constitution

-

(and 2 more)

Tagged with:

-

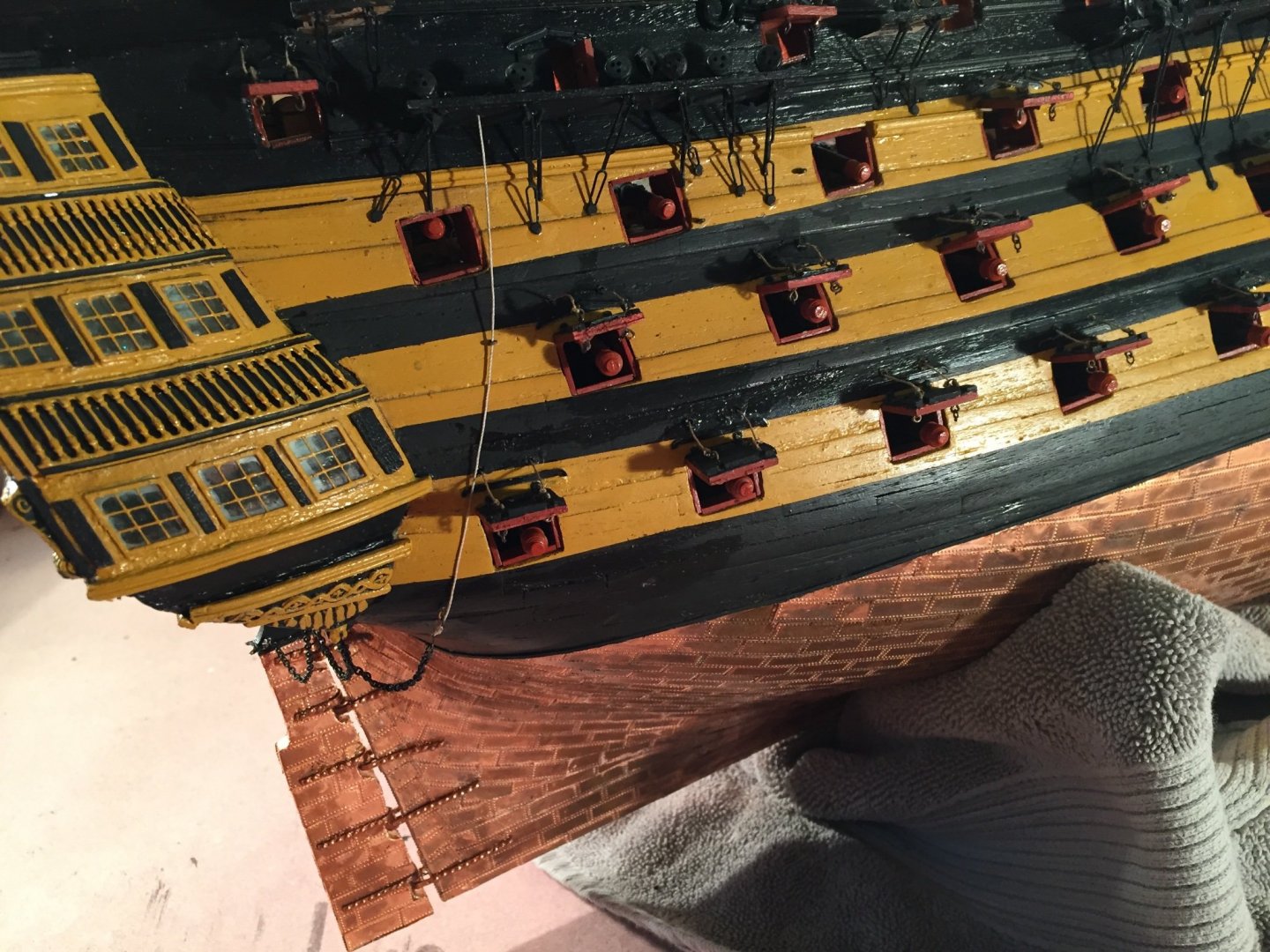

Hi everyone, Have just mounted the rudder. I used dome headed pins to simulate the rivets and added a rudder coat as per Longridge. I used .50 tan thread for the rope line to the mizzenmast channel. I couldn’t organize the stopper knot properly so I fastened the rope to a medium cleat. Happy Thanksgiving to all. Stay safe and well, Mort

- 60 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

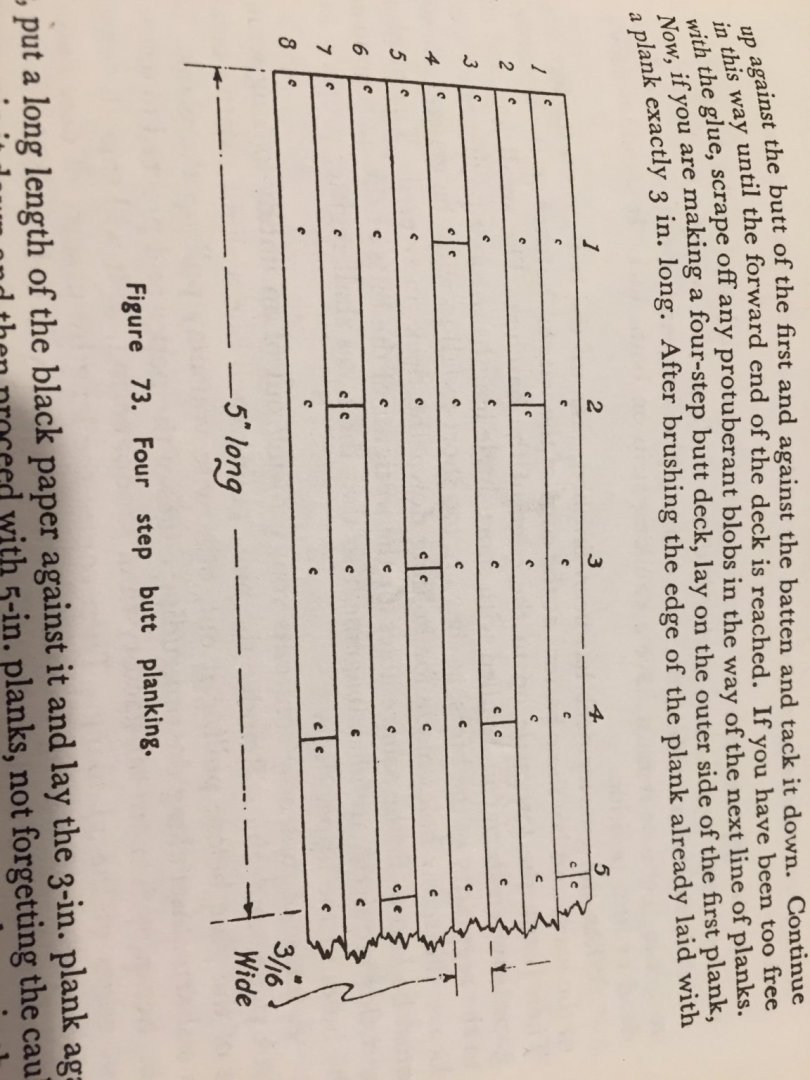

Quick update. I’ve completed and mounted the channels, their dead eyes, gunport lids and just finished installing the cannons with tampons. I made my own lids as I wanted the hull planking to be visible along with the lids interior planking. I used #28 wire for the second ring on the lids and as PaulB did I used 2 eye bolts and a piece of wire to mimic the latch on the lids inner side. Stay safe and well, Mort

- 60 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.