mort stoll

NRG Member-

Posts

543 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mort stoll

-

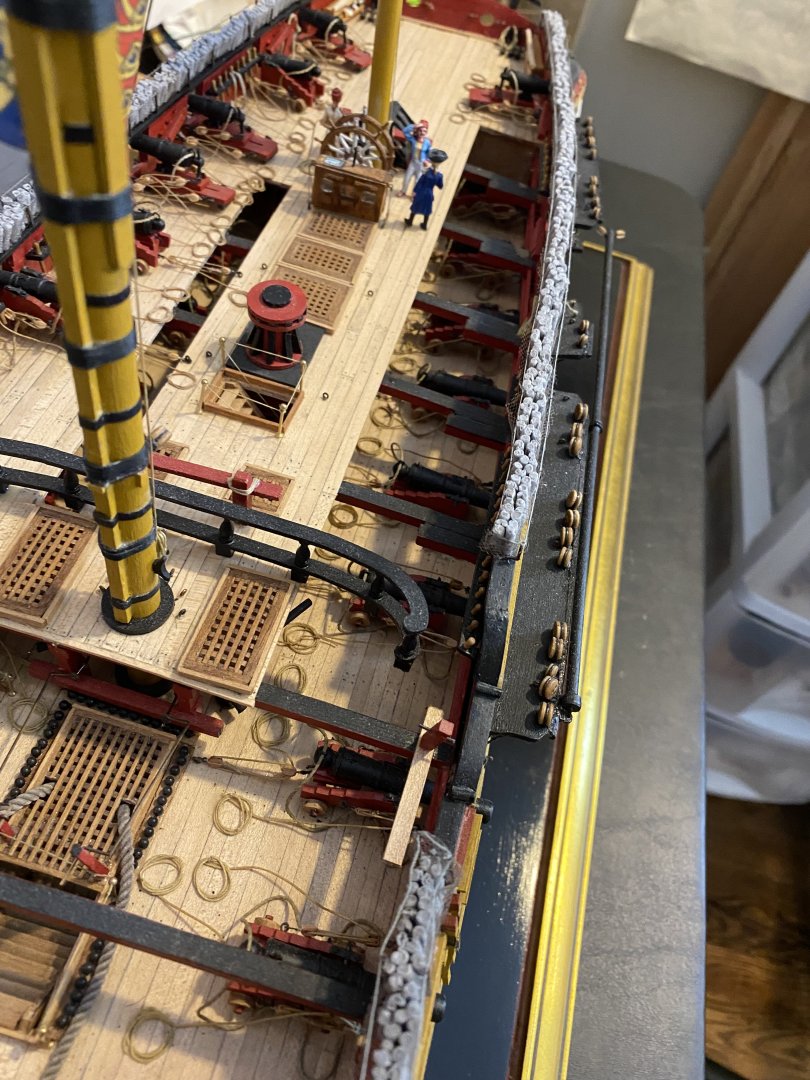

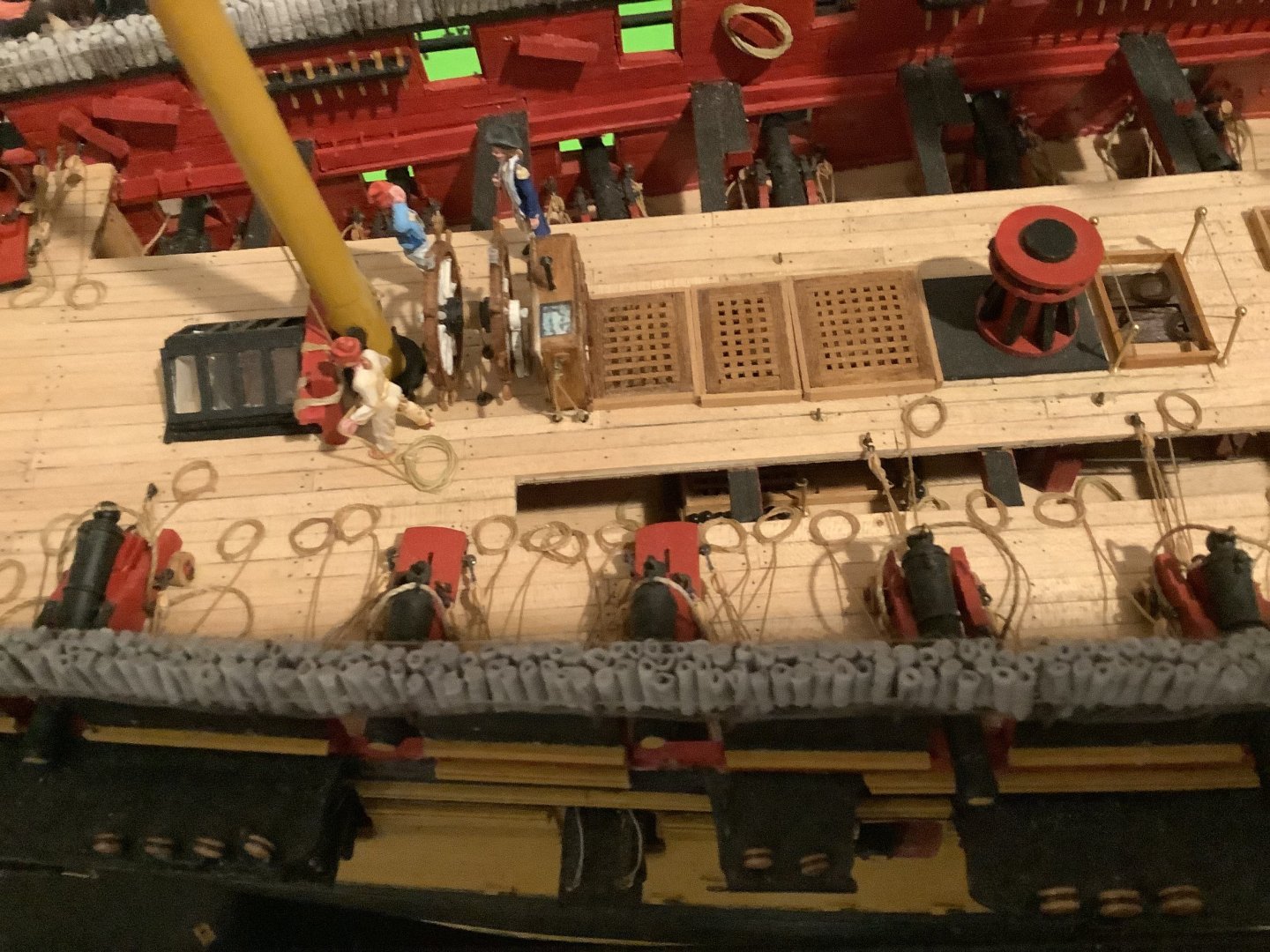

Interestingly the completed grating next to the Captain’s quarters are not included in the kit. It’s just an open space on the deck. Caldercraft includes the other four gratings. In the kit, there’s just an open space. According to the.AOS Diana there is a grating and a ladder way there which I added. All the best, Mort

-

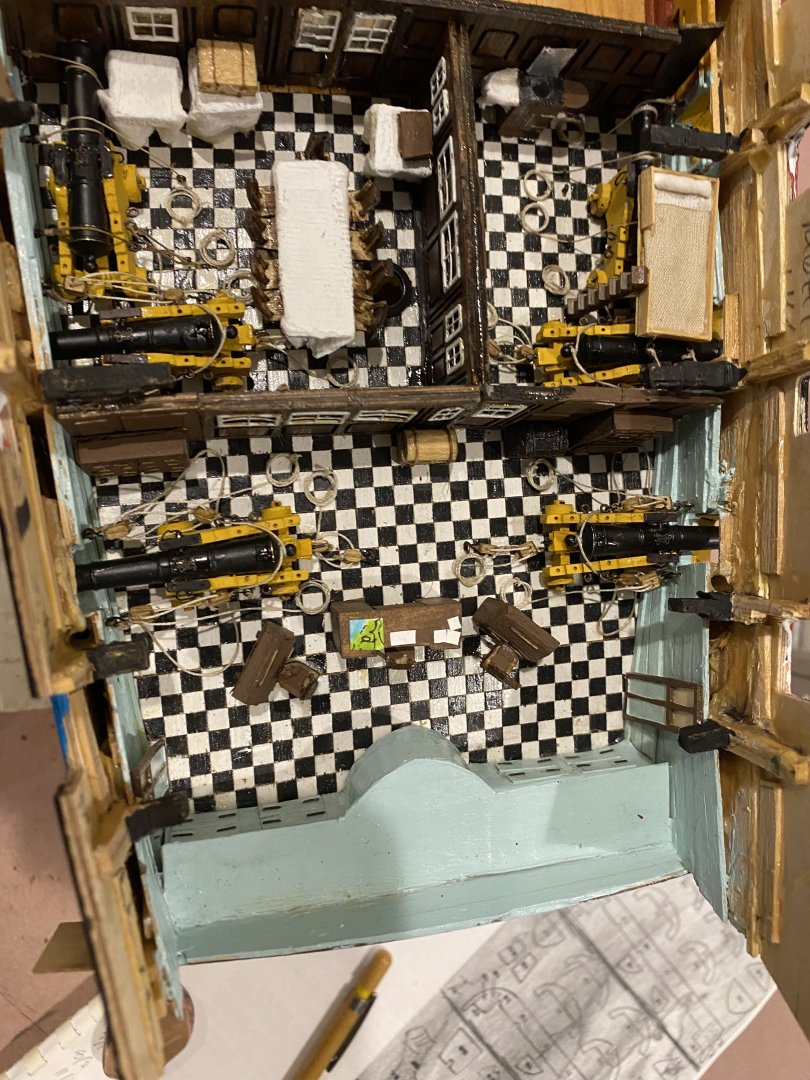

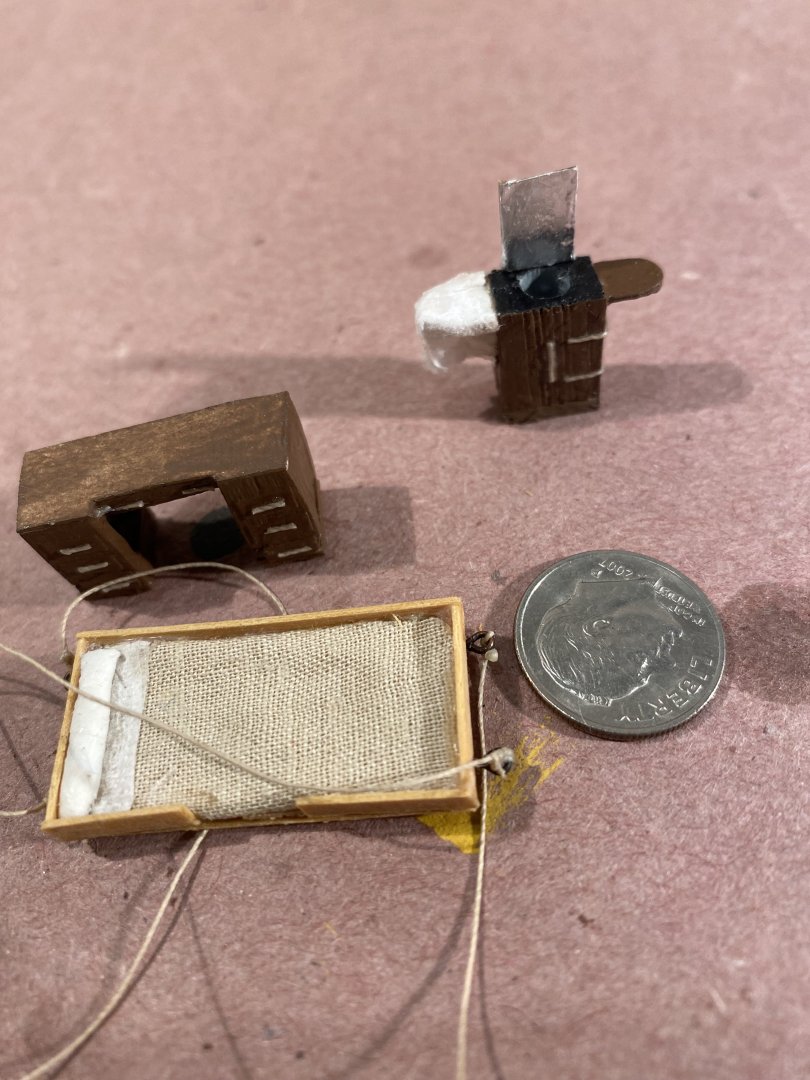

The modeler had also finished and painted both quarter galleries to which I added doors to the great cabin, a commode and hanging lanterns. For the great cabin I made doors to each quarter gallery, a desk for the Captain, 2 smaller ones for his clerk and secretary, 2 chests and trunks for his clothes and a large bench seat with storage drawers at the stern. For the sleeping cabin - which you can see dry fitted - ( please ignore the as yet to be painted guns - there’s a hanging bed, a washing/shaving table and 2 clothes trunks.

-

As such I removed the stern gallery taft rail and facia, the quarter deck beams the last 2 bulkheads #’s 16 and 17, the 2 gundeck extensions #24 and the 4 stern counter patterns #’s 26 and 27. With the help of the AOS Diana I was able to estimate the limits of the Captain’s area and removed any gun deck planks there in as I was going to substitute a parquet floor.

-

I December 2023 I bought a partially built model of the HMS Diana at an auction of the New Jersey Ship Model Society. As you can see the guy deck was planked, the hull double planked, the quarter deck beams, the stern gallery taffrail and facia were also in place. This is my second Caldercraft Diana build. My first was completed in 2017 before my Victory. While doing research for thet build I learned Diana had a sister named Jason. My younger son who I was building Diana for is named Jason so HMS Diana became HMS Jason.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.