-

Posts

991 -

Joined

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Justin P.

-

-

8 hours ago, BobG said:

That's great news, Chris! I've always had good online shopping experiences with Ages of Sail. I do think they could make a few minor improvements to their website which would improve the viewing experience for their customers though. I hope to visit their store soon too since they are only 1 1/2 hours from my home.

They have a store near Sac or is it in the Bay? Im flying into Sac in September to attend a professional conference up in Tahoe (along with some visits to old friends in the Nevada City area and might squeeze in a visit if I can!

Congrats to Chris and Wife for making a dream come true, Ill be doing my part to support the cause. Really want to do Speedy, Alert and now of course, Flirt.

-

26 minutes ago, Chuck said:

Justin.....I am actually cutting more Medway longboat kits this week. I am already about half way done with another six kits.

So sooner than later.....

Chuck

Thats great news Chuck! I was hoping to do that one before graduating up to a larger project. Cutting my teeth on the small boats has really helped with a lot skill progression. Perhaps better for me to hold off on SYREN. Ill watch the shop for them to go on sale. Thanks for the heads up.

-

2 hours ago, BobG said:

I need to experiment with various finishes and learn more about them.

I just use my iPhone and tweak them a little in the phone photo app. I'm too lazy to get out my DSLR and take photos for my build log.

Yep, Ive only ever used wipe-on-poly. I know other folks use different things, but Poly seems to have that non-bulky character that I like.

I only use my DSLR for final shots, iPhone for everything else. Although they are getting so good, Im not sure I need to use the dslr anymore.

-

I bought inserts supplied by Jim and have cut each for use with specific blades. Well worth it, and according to Model Machines, no damage the blade during this process (to my surprise). After the initial cut I run some sandpaper through the slot as advised and it came out great, with no contact between the blade and the insert.

- Retired guy, Rustyj, Ryland Craze and 4 others

-

7

7

-

17 hours ago, mtaylor said:

Richard popped my memory on this also..... when you put the blade on spacer, make darn sure that it doesn't slide off the spacer while tightening the screw or nut (not sure what Byrnes uses). If that happens, the blade will probably wobble and also seem to go up and down when spinning along with lots of vibration. Been there, done that, and always double check that didn't do it again.

Yep. Me too.

- Retired guy and mtaylor

-

2

2

-

-

39 minutes ago, BobG said:

I like your idea of using the sinker to try and get the gaff to stay where you want it. Mine still floats around on my Medway Longboat.

What's up next, Justin? Are you going to add to your small boat collection?

Thanks! Yeah it went by fast. Trying to take advantage of all this COVID time before I have to return to work full-time. The sinker is gone now, my gaff still floats around, I was using the weight to take out the slackness of the line and straighten out. Having it on there for a little over a week did the job really well.

I am actually. Next build log will be SYREN, but as I work through preparations for that I have an ongoing Bounty Launch project that has been haunting me for awhile. Ill be returning to that in the interim. I have no plans for a build log on that one, as I tried before and I ended up shelving it. I wanted to do Medway next, but Chuck reports that the availability of those kits are a while off yet.

34 minutes ago, Bossman said:Justin, a truly awesome job Sir! Very, very well done.

I appreciate the comment, thank you.

-

So I ended up wrapping it up this weekend. I got the last few bits sorted out, including the brass ornamentation and the fix with the rudder gudgeons. I decided to omit the oar locks. It seems stupid to have model with oars but no oar locks but they are just so ugly (in my opinion) that I just couldn't bear putting them on. Ultimately, Ill accept it as is and explain to whomever asks that I just exercised some executive decision making - right or wrong. I managed to get some coils I was happy with combining the ccoyle method I mentioned earlier and my own adaptation using the parts holder.

Shown below wet with diluted white glue for setting the coil, and on the right rigging a gasket coil as I could think of no other way a seaman might have dealt with rope that was only meant for use while the gun is stored under heavy swell. I used the same for the anchor for similar reason. I suppose when the anchor is stored, they might have used a gasket coil for the line. I don't know.

I neglected to take a lot of photos during the last stages as is was just a lot of fiddling with details but much can be seen in the gallery I created using more formal photographs.

- Cathead, Ryland Craze, ccoyle and 4 others

-

7

7

-

-

Not much more to update, just some more shots of the rigging as Ive been cleaning things up and finalizing tension.

You'll likely note the funky sinker I added to the end of the gaff. The gaff has no opposing attachment so floats, and the line has some memory Id like to remove so this is my solution. This is temporary and meant to take some of the loose character out of the line. I hit the line with hot steam using a tube and fine tip nozzle and let it dry under weight and it will straighten out nicely.

Some oar work is coming along thanks to my Ibex planes, which are just a pleasure to use. I played around with sanding sticks, and lathes and ultimately found a plane and sandpaper did the job the best, the most consistent and the fastest.

Getting the anchor tied up properly thanks to some reference material and away I go.

Ive spent the end of yesterday and some today working on coils. Ive made many, and have been satisfied with none of them. Unfortunately this photo is dark, but pictured on the forward-port belay pin is the best one Ive come up with following a process ccoyle outlines here.

- Ryland Craze, Cathead, BobG and 2 others

-

5

5

-

-

-

29 minutes ago, BobG said:

it seems to get a bad rap from a lot of our forum members

It does seem like the black sheep! Frankly I think it comes down to what you are trying to do, and how confident you are in your final decisions. There have been plenty of instances where I regretted its use as I moved to undo something. However keeping some debonder around has helped a lot in this regard.

I tend to agree that CA needs to be used minimally if at all with rigging, but for everything else I think its mostly fine.

-

7 hours ago, BobG said:

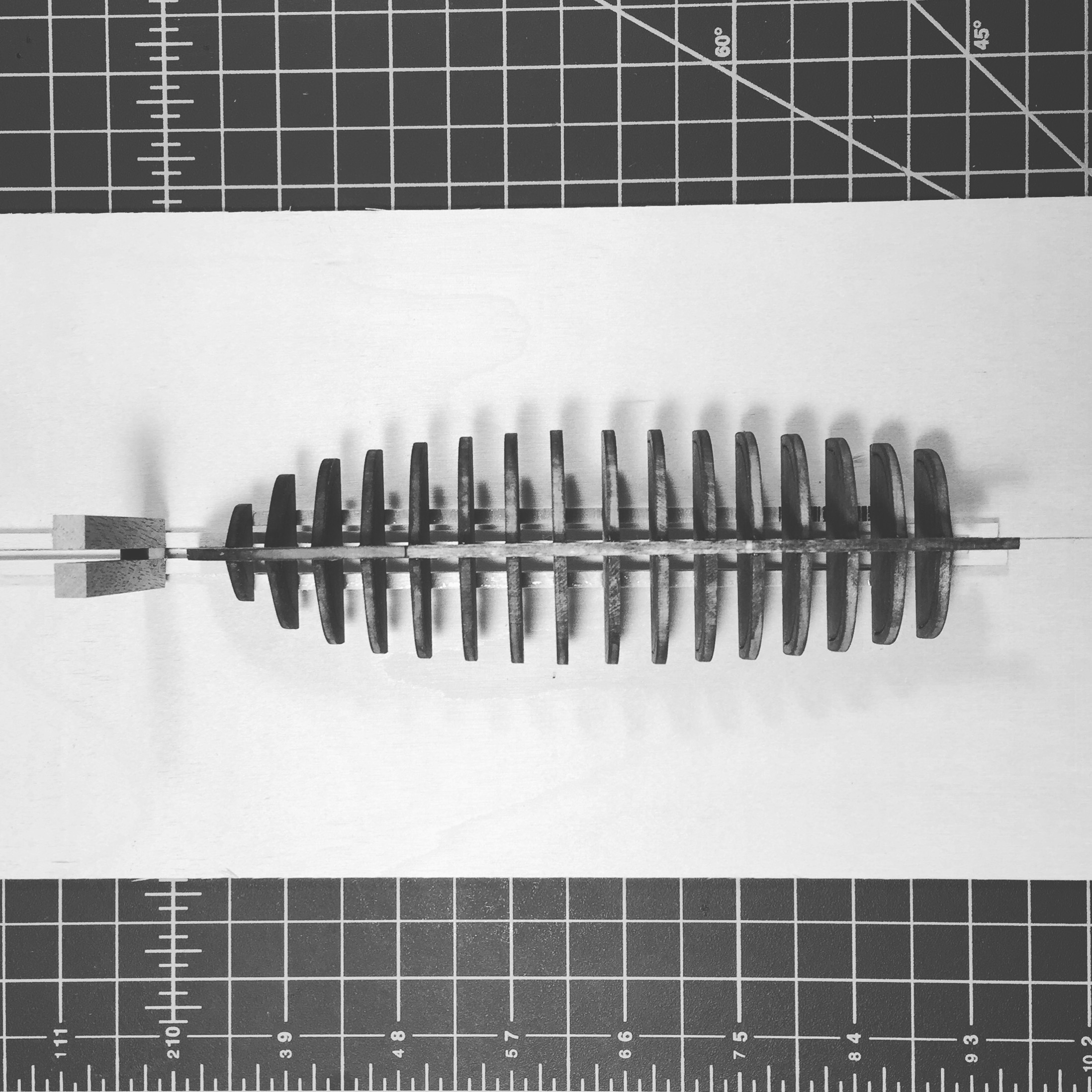

What is the clamping device you have that has all the pegs in it?

Thanks Bob, again I think undeserved but Ill take it

The clamping device is a "work holder" I picked up from Ages of Sail some time ago. Ive been using it more and more for the small stuff as it has some heft to it and thus give the work a bit more presence. Its also really great for painting small bits.

7 hours ago, BobG said:

The clamping device is a "work holder" I picked up from Ages of Sail some time ago. Ive been using it more and more for the small stuff as it has some heft to it and thus give the work a bit more presence. Its also really great for painting small bits.

7 hours ago, BobG said:Also, what is the foredom that you refer to for making the belaying pins. I used my Dremel for making them on my Medway Longboat and it wasn't easy.

Foredom is what I would call a more serious rotary tool than the Dremel. All the Dremel bits work with it, but as a tool the Foredom is much more purpose built. My own Foredom is over 25 years old. They are foot controlled so more speed precision and are much better designed and thus less hard on the hands. Well worth the upgrade if you are using your rotary a lot. I keep both a Dremel around and the Foredom. 99% of the time I use the Foredom. Its easier and faster to switch out bits and more flexible. I also think the Dremel is too fast for most things. https://www.foredom.net

7 hours ago, BobG said:What glue or glues have you been using?

Mostly CA to be honest, but when necessary Ill use a PVA.

-

Work continues as those of us who choose, hunker down, and wish the world the best. Ive been steadily marching towards the finish line checking off small tasks as I go and lengthening my "don't do that again" notes. So much learning goes into these small boats that Ive grown really fond of them. I look forward to Medway when it becomes available again. As my skills have improved Ive been contemplating some redo projects to complete a nice collection of small boats. We'll see...

In the last few days since my last post I was able to get the rub rails bent to shape and dry fit. The instructions have you bend them and then paint before installing but something about that sequence didn't sit right with me so I decided to install before painting. This allowed for more precise fitment and very minor gap filling where my miters weren't quite perfect.

After drying, I began painting the rub rails as specified in the plans. It turned out ok-ish. I guess the benefit of painting prior to install is the very clean line, however I felt it was a balance between my skills at getting the perfect fit versus painting the best line. Using a combination of masking tape and a careful, non-caffeinated hand I was able to get a passable result. Ive had to go back and forth through some areas, as one one would do when painting in a line along the ceiling in a house.

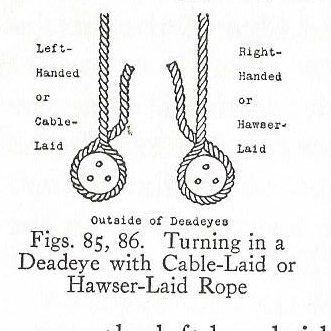

Ive also installed the bowsprit, deadeye chainplates and backstay anchors. The instructions here get a little imprecise, but with some careful study of other build logs, and a bit of common sense I was able to piece it together. Some details are depicted in the manual photography, but not mentioned at all in the narrative which I found frustrating.

I also began shaping the mast and fitting it in the usual way. I found I had none of the problems observed by other builders with fitting the hardware to the mast so long as I was willing to make minor modifications to the cast metal parts. I feel perhaps this was always intended, with other builders expecting a bit more precision in the provided cast metal parts. I think they actually are made larger to provide more room for error - but that is just my opinion.

I also began setting up shrouds. Ive made the highly recommended decision to replace all the tackle and rope with Syren products, which is simply much more satisfying to work with, and the result much more in-line with the time and effort invested in such endeavors. I served my shrouds in the usual way using a Syren serving machine and used a jig to get the deadeye distances correct. The pictured jigs are NOT what worked by the way, I ended up using a scrap bit of wood with nails as is documented in many logs across MSW.

I then began work with the Gaff and Boom, back and forestays and the bowsprit rigging, all of which were not particularly well outlined in the instructions. Here Wolfram Zu Mondfeld's Historic Ship Models was an invaluable resource. In fact much of my rigging questions were answered through 80% that book and 20% perusing MSW logs of similar builds. Everything from block stropping, deadeye rigging, knots, and other peripheral rigging minutia is well covered.

I also decided to scratch build new belaying pins. The provided pins were absurdly small brass things that really did not look or function correctly, nor did the reference materials bear out the use of metal for a belaying pin. I knocked a few out pretty easily with some dowel stock and my foredom. I made a bunch until I got it right and could consistently make the same size and shape. Time well spent.

Currently working on the other bits as most of the rigging is done. I need to go through and shoot photos of all the cleaned up rigging and so forth which Ill include in the next post. I did get the deadeyes rigged and lines belayed. All that's left is coils and touch-up paint where my blackened metal components left some black scuffs on the paintwork. I also have a flag halyard to rig now that a glaring omission in the instructions has been cleared up for me thanks to BobG.

Ive also got to convince myself to add the oarlocks - which I think are just hideous as designed for this kit. The rudder and tiller gudgeons were not well executed on my part, so I need to return to that mini-model and see if I can recover it. Getting there.

- Cathead, GrandpaPhil, Ryland Craze and 4 others

-

7

7

-

16 minutes ago, Maury S said:

Thanks, all. Easy to see if the rope is not served.... and is the shroud always crossed before seizing? Makes it kind of bulky.

Maury

I’ve found bulkiness can come from disproportion in the chosen scale ropes and dead eyes. When things are correct (or close to correct) then everything looks “right.” But to answer your question, yes they should cross and be seized vertically at the throat. There are probably many ways to accomplish the right look without actually seizing, but figuring a way to do it is more rewarding even if frustrating and fiddly.

-

-

4 hours ago, BobG said:

I would assume that this model uses this method the same as on the Medway Longboat.

Thanks Bob,

I wouldn't assume much from this model. The instructions are good, but sequencing is confusing and some elements are half completed or ignored completely so there has been some guess work. Thankfully a essential third-party resources (of which of course is MSW) have gotten me through the vast majority of it. Thanks for the reply.

-

Arthur,

Can you help me understand where the Flag Halyard is meant to be rigged? Or point me to a reference? The instructions mention the Ball truck but then never return to it. Ive scoured pictures but can't figure out exactly where this line is being attached down at the hull.

Thanks.

-

-

What is the clearance on those clamps.... looks like about 3"?

- Canute, thibaultron and mtaylor

-

3

3

-

-

I hope everyone had a nice Memorial Day weekend. An especially solemn occasion for anyone who has known or lost friends or loved ones in war. I spent this morning watching the 21 Gun solute via virtual program at the USS Constitution. I thought the Sailors there did an excellent job with the reading of names and the salute. I thought they brought home the reality that those ships really were battlefields and not just vessels.

The rest of the day was spent wrapping up a weekends worth of work. I've made progress but its no longer linear in the way one might expect reading through the kit instructions. Because I was waiting on lumber to scratch build the cockpit seats, I had to spend time elsewhere so began work on the windlass, rudder and tiller, as well as the oars.

When the lumber finally arrived this weekend I also spent time fashioning up the cockpit seats. They will look odd to anyone familiar with this particular kit, as I chose to impart a bit more fluidity in their lines and made them a bit more narrow than was called out for in the kit. The issues of scale are becoming much more apparent with the more kits I build so recognize much that is starting to go awry. I was also able to get the cap rails installed, seems filled and the lot painted, as well as the transom knees and thwart knees shaped, painted and installed.

A sharp eye will note the backwards transom knees. This unfortunately is not the result of artistic license, but more the result of too late a night and acceptance. I spent so long shaping them to fit all the angles and fit was so good I just accepted they were backwards. I only realized it, of course, after they were well and glued in place... ho hum.

I finished up the day working on the rub rails, which required another scraper and some time sanding. They'll go in once I figure out how to make the process for fitting, bending, painting and so forth work for me.

- Ryland Craze, Nirvana, JpR62 and 7 others

-

10

10

-

US Brig SYREN 1803 by Justin P. - Model Shipways - Scale 1:64

in - Kit build logs for subjects built from 1801 - 1850

Posted

I decided to jump into the deep end. Wish me luck. Ive spent countless hours reading through logs of this build, staring at my own kit and going through bits and working out a plan and knowing that it would be a long, likely arduous project. I had intended on procrastinating further with other projects, but given the continued COVID related time at home I decided to go ahead. I had planned that Medway Longboat would be my next build log, and it may yet become one of two ongoing projects but until I can get my hands on one of those I really only have this sitting around and a long abandoned Bounty Launch build to focus on.

So, with being fully aware that I might come and go from this over time I decided I might as well get started.

My kit came like all the rest - in the ubiquitous blue box, filled with random bits and sticks. I was a little disappointed as others have been, that some of the castings and other parts are not nearly as nice as the design, planning and instructions that were created for it. I was pleasantly surprised to discover that I have none of the warping in the plywood parts that others have observed. Everything appears flat and ready to go. The manual is hearty, but not made from the best paper so I'll likely transition that to a three-ring binder as it will never survive intact in my workspace over the time it will take to finish this build. I do a lot of highlighting and marking up, which means it goes with me to work (2.5 hour commute by boat and train, each way) and will need something a little more conducive to travel. I don't know about you guys, but with these manuals, I don't really fully grasp what Im reading until the third time through - so to say it gets used would be an understatement.

Today I started in on Chapter 1. The only issues I noted were that none of the various keel and bulkhead former (BF) parts were the same dimensions, though they were definitely intended to be. Everything seemed off by a 1/64" between the BF, stem knee and keel. Finally, the timber provided for the false-keel is also off by 1/64". No big deal. In order for the stem knee to properly transition into the keel, I had to run the 3/16" x 3/16" timber through the thickness sander to take it down to match the thickness of the pairing end of the stem knee and provide a flush and completely flat surface with which to mate the false keel which also happens to be a hair shy. I tried all 10 provided sticks and found they were all shy. That is to say, the 3/16" was taken as a suggestion in the production of my kit and not a rule.

Forming, gluing and carving the rabbet.

I found the design and construction process of this rabbet far more pleasurable than past projects. The bearding line was a little confusing, but I think will work in the end. The laser bearding line cuts right through the center of the much heavier bearding guide holes so I followed as well as I could despite the fact that I wasn't sure If the guide holes should have been better accommodated in the carving.

Assembling the stem knee and keel went by easily enough. After determining where I needed to intervene to correct the dimensional issues everything came together very nicely.

Next Ill probably go ahead and notch out the BF for masts as was originally suggested by Novastorm here whose also got an ingenious sanding violin bow (post #3) thing I intend to experiment with, and whose mast alteration step was seconded by Walrusguy here. Both of whom Ive been following closely. Ive also been following Patricks build here, whose hand skills are evident in his careful and clean construction. I hope to learn much during this build from them, and the rest of various SYREN builds in the archives.