-

Posts

991 -

Joined

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Justin P.

-

-

4 hours ago, glbarlow said:

He hasn’t faired the hull yet, I imagine most of it will disappear then.

Yes, I actually meant at the joints.

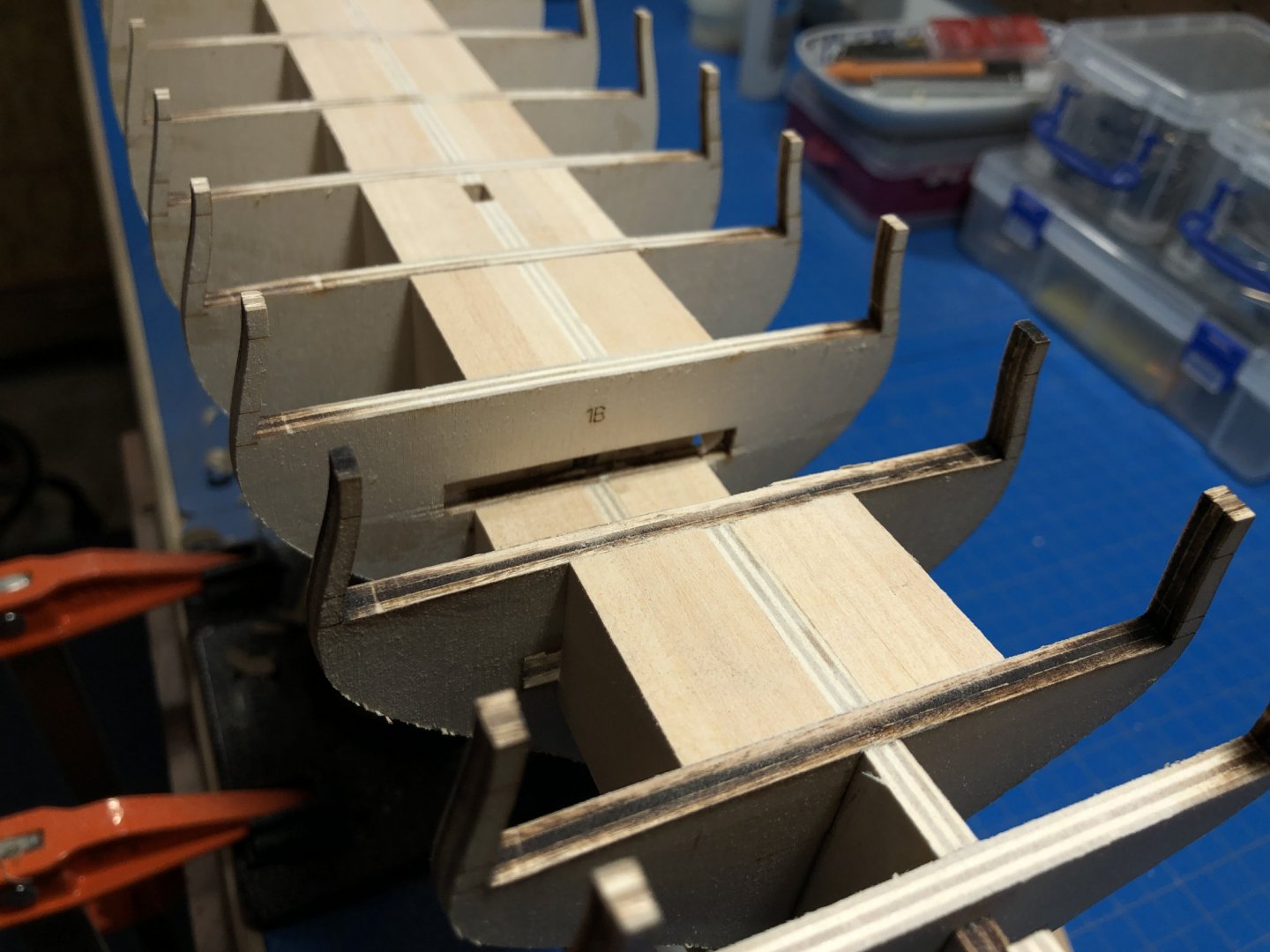

3 hours ago, ouizel said:What about at the false keel / bulkhead junctions? I've read arguments both for and against cleaning the char but it all seems down to individual preference. I wonder if the material makes a difference (wood v. MDF)?

This is what I meant, and should have been more specific. I, too, have read the arguments and ultimately decided it comes down to the precision of the laser cutting and the fit.

3 hours ago, glbarlow said:I'm sure there are lots of opinions. Personally I've never cleaned the char from those. The glue will hold with the char there, it's somewhat a myth that it won't. I'd be more concerned about altering the fit if I sanded the bulkheads where they fit to the frame. You really want a tight fit. Sometimes you might have to sand a little to get that fit, but not to remove the char.

Ive never worried about the glue personally, more about that slight misalignment from recto/verso which might have an ill effect on squaring of the bulkheads. I certainly had builds where sanding was required otherwise the bulkhead absolutely would not square. Of course, Ive had some that were cut far wide and needed shimming to get a tight fit. So I guess you do what you need, when you need to...

Ultimately my question was more about James' approach (which he answered). I see some folks go through and sand every last bit of char before assembly and turn out wonderful models and I'm always hunting down those steps which separate their wonderful models and my middling attempts :). Was just curious how serious people are about that char, har har!

Thanks James, Ill stop hijacking your build log now!

- Ryland Craze, FrankWouts, Canute and 5 others

-

8

8

-

I noticed very little - if any- char removal. Are the bulkheads fitting well and square without intervention? I can never figure out if char removal is a rule-of-thumb or just a common, though perhaps unnecessary, step.

Thanks for sharing, as usual your photography is unmatched.

-

Im very interested, though I cant say Im particularly thrilled to see another Victory kit in the market - perhaps this one will become THE one. Looks like a lot of design work and prep went into it congrats to them, happy to follow along. Thanks for sharing with us all James.

- JpR62, chris watton, Ryland Craze and 6 others

-

9

9

-

I received an email about the new site, and went to comment that it looks great but it seems to have disappeared. Anyway, the site looks really great - a great big thank you to those who worked hard to make it a reality.

Huzzah!

-

-

It does become complicated, but I would caution against belaying as you go. Once everything is rigged, you'll need to tension everything up. I don't know what the appropriate sequence is for that, Ive just always gone bow to stern. BUT the important bit is that as you tension in one area you will need to re-tension in another and keeping things "un-belayed" helps tremendously with this. I usually coil the rope and attach an alligator clip to the length of line for some light tension (provided by the weight of the clip). Leave yourself lots of extra line and don't be tempted to clip the excess until well after you've completed the belaying of the entire model. Even then, wait like a day or so for things to "settle."

-

Those are a massive upgrade over the cast badges. Are you happy with them?

- WalrusGuy and Edwardkenway

-

2

2

-

-

-

If everything works out, it'll be my first.

- tlevine, mtaylor, Ryland Craze and 1 other

-

4

4

-

-

3 minutes ago, Overworked724 said:

Moving on...slowly slowly.

You are not the only one...

- WalrusGuy, Overworked724 and NovaStorm

-

3

3

-

29 minutes ago, Overworked724 said:

Hey...just thinking outside the box(wood)...the kit comes with some pieces laser cut in boxwood I believe. If you kept the fragments, I’m sure you could layer them to give you a good foundation for carving. Kind of like the ship’s boat. You could just layer the fragments and cut out the block size you need for carving.

Which parts are those? My list says basswood unless otherwise noted and the only thing "otherwise noted" is plywood. Maybe I have the amateur version, lol!

-

-

21 minutes ago, WalrusGuy said:

would love to hear some of your thoughts on this. And again I won't feel bad if you think I should just carry on with the castings, so please do let me know!

I think the time and effort in remaking these will be well worth it. As is obvious in Gahms build, the upgrade is truly remarkable when the time is put in to do it right. If done half as well, it’ll still be 10x better than the castings.

I would encourage you to keep working on it, or wait and get the material you need rather than settling. No reason you can’t make this the last step, if you need to move on out of sheer frustration. Make 20 of them if you have to! This detail I think is one of those critical ones. I intend to do the same on my own build... good luck!

- egkb, Ryland Craze and WalrusGuy

-

3

3

-

Looks great. Pulling up a chair! Jealous of you guys with active clubs in your area.

-

On 6/21/2020 at 7:44 AM, Brewerpaul said:

Are those basswood reinforcing blocks in the plan, or your own idea to make the whole thing more rigid?

They are, though intended to be solid blocks. I didn't have any, so I just built them up with sheets.

-

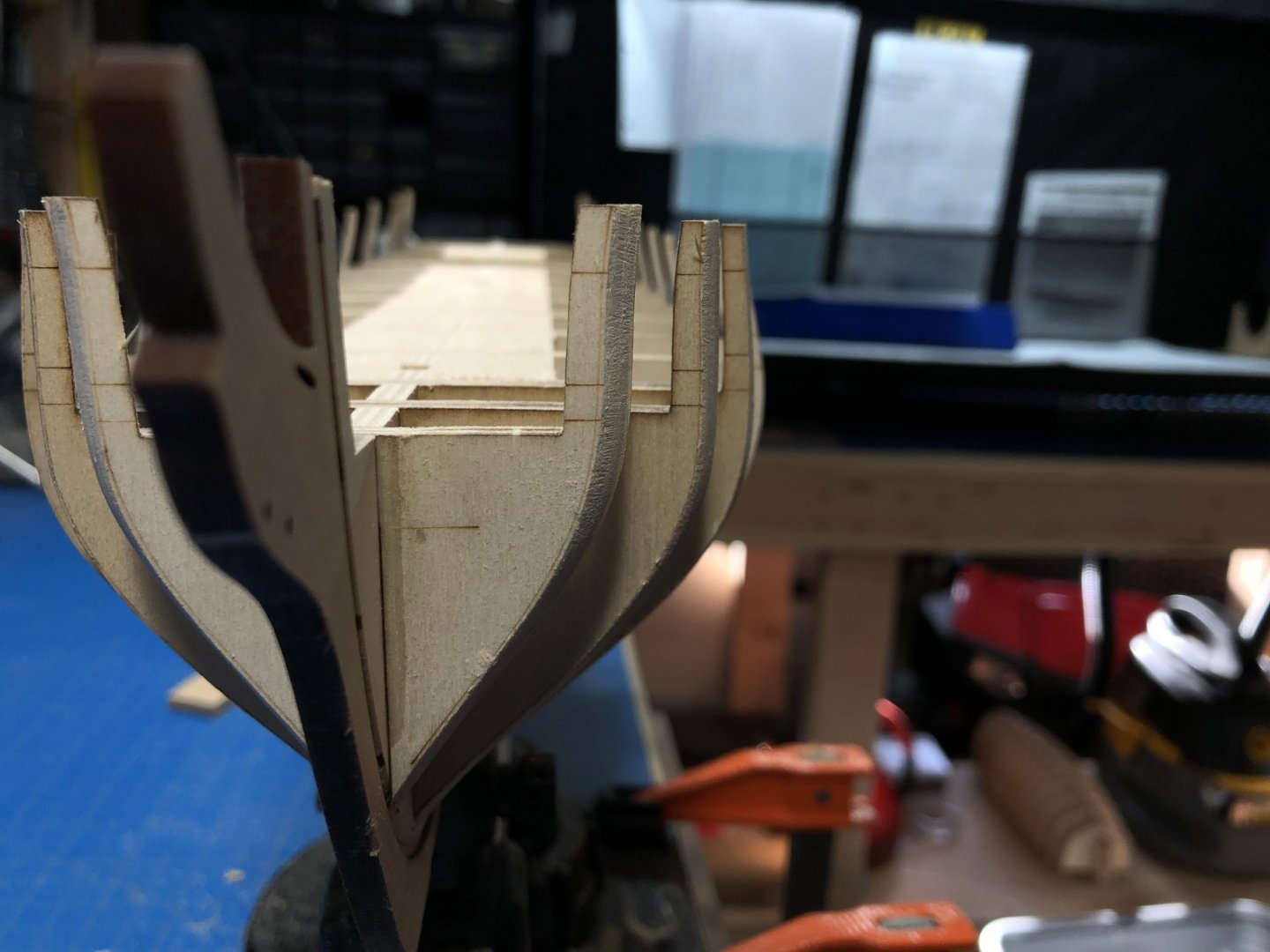

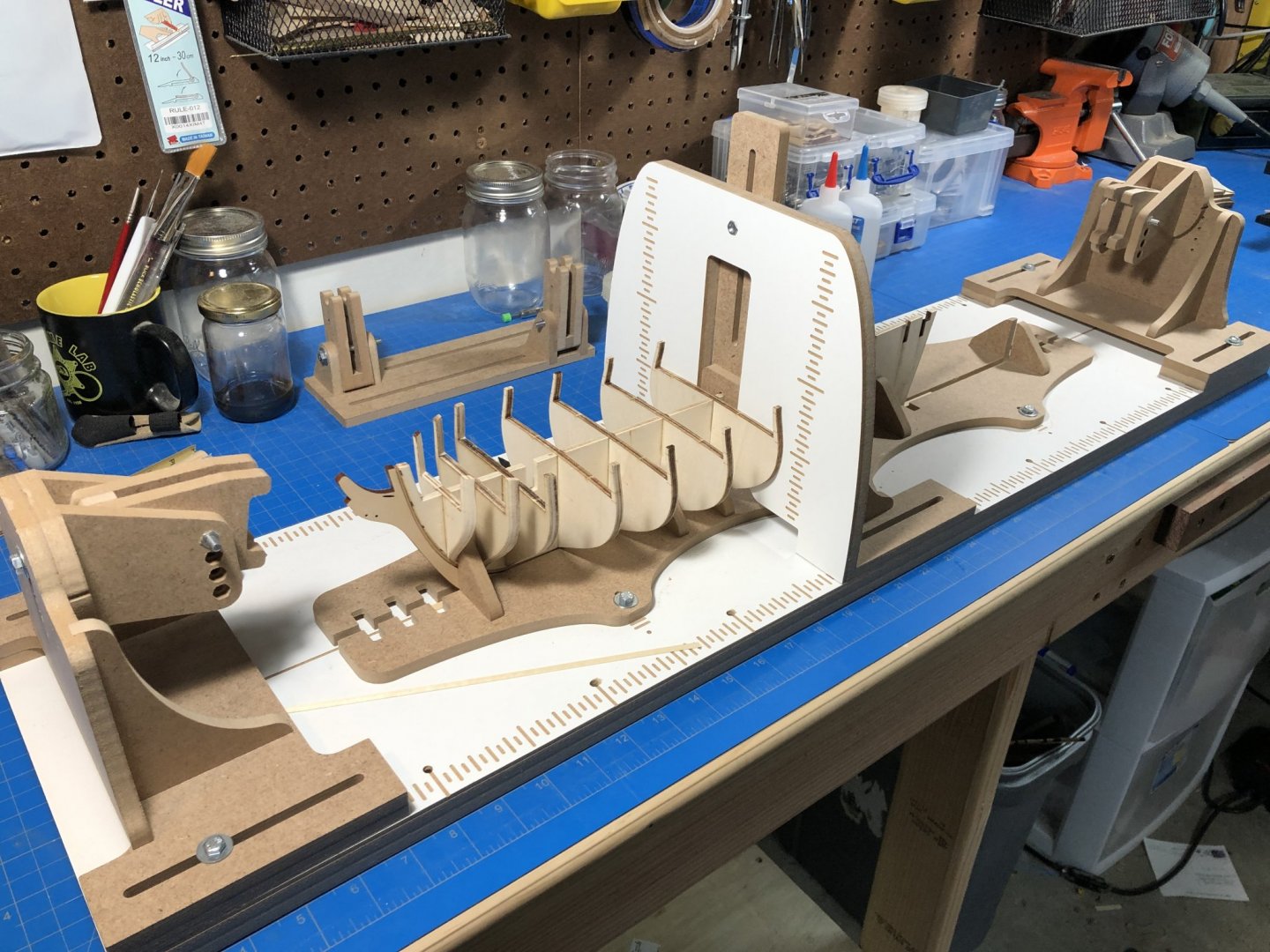

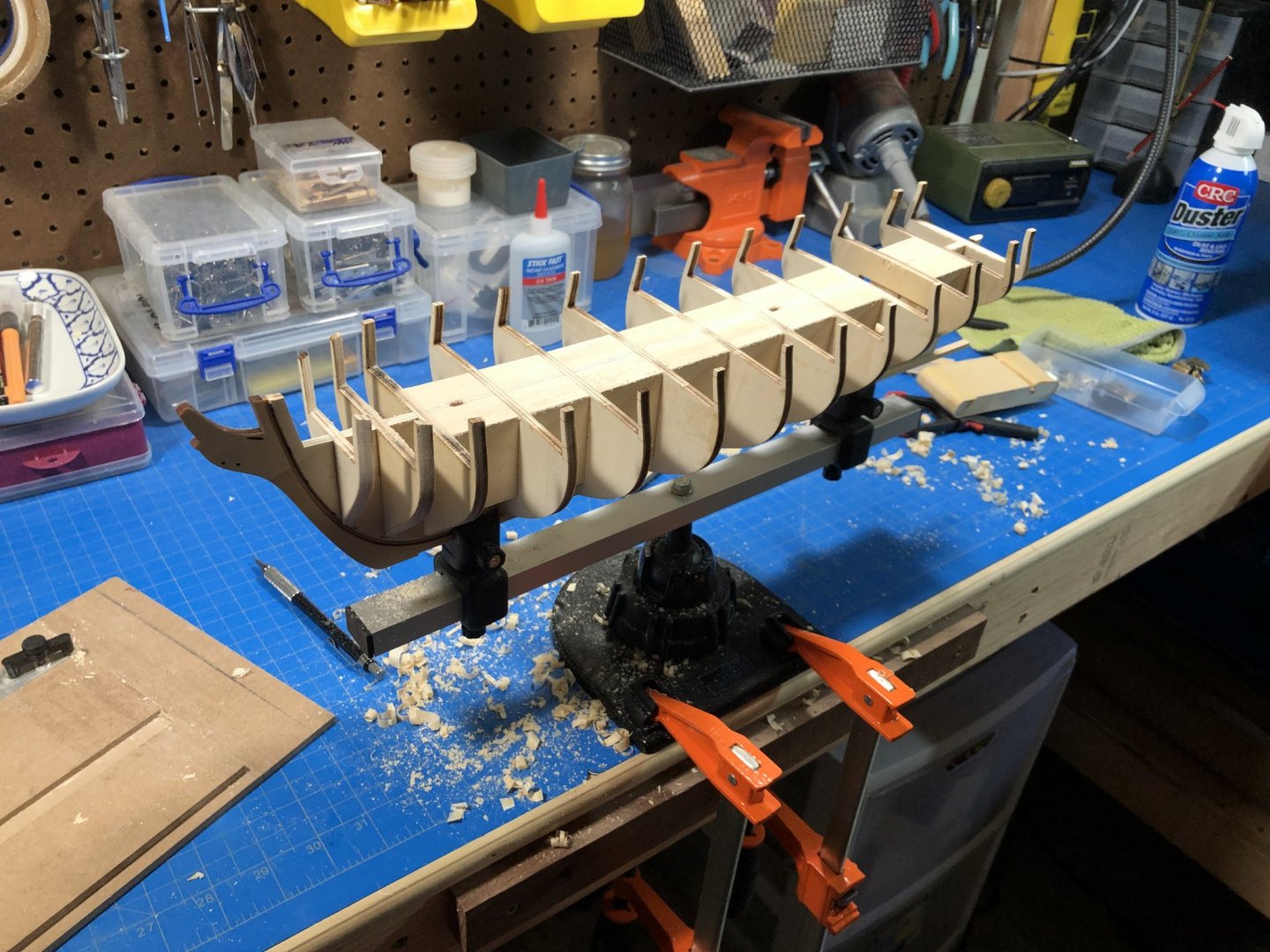

Not a lot to report thus far. Taking my sweet time on this one as I'd really like apply the "each step is a mini-model" concept. HOWEVER, right away I had to adjust the sequence a bit. Not a criticism of the instructions at all, I just couldn't seem my way to success as written. Particularly the step early in Ch.2 where one is meant to fair the hull prior to gluing or securing the frames to the bulkhead former (BF).

I wound up shaping them individually down to the guidelines as suggested and then test fitting them to the BF several times, before pulling out the model-building slip for gluing. I did try to fair without securing them and whole thing just felt to flimsy and some breakage in my future.

My local shop was plum out of basswood blocks of any significant size so I opted to go with 1/4" sheets cut down and laminated together. My new sliding table on the Byrnes made quick and very precise work of this process. Great addition to an already great tool.

Spent some time cleaning up the deck to make sure things are nice and flush and Ill move onto final fairing. The hull is, of course, much more sturdy now so as long as don't really make any huge mistakes it should fair up nicely. Realized pretty quick some sandpapers are just crap when it comes to sanding ply (a process that I hate), but have good luck with a new type (Gator Zip) I haven't tried. Something about the grit type or something seems to work a lot better.

Next are the bow filler pieces and battens... updates to come on that.

Happy Fathers Day to all the dads out there.

- JpR62, Retired guy, WalrusGuy and 4 others

-

7

7

-

4 minutes ago, BobG said:

I'm onboard for the voyage as well, Justin. This should be a good one!

😲 5 hours of commuting a day!! How do you ever manage to find time to build your models with when you are not working from home?

Thanks Bob, good to have a familiar face :). Yeah, the commute is no joke. You get used to it, and if you use your time well it can have some good side effects. Luckily I don’t drive more than 1 mile of it, otherwise I might lose it. Ship modeling for me happens very slowly, Friday evenings and weekends when my duties are not otherwise assigned by Household Admin.

-

Looks great. What is the ship in the background?

-

1 hour ago, glbarlow said:

It’s a nice looking kit, I’ll enjoy watching another of Chuck’s designs come together.

where did you get those long brass clamps?

They sell them at Micromark, but you can also find them at Rocklers or even Amazon. Not cheap, but really nice for what they do.

-

-

-

US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

in - Kit build logs for subjects built from 1801 - 1850

Posted

Its looking wonderful. I hope to make some progress myself soon... thankful you are leaving me with some great leads to follow.