-

Posts

7,989 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Louie da fly

-

Help! What is the Meaning of BIS

Louie da fly replied to robnbill's topic in Masting, rigging and sails

It happens in French as well. In fact French audiences don't yell "encore!", they yell "Bis!". And you occasionally get a couple of houses sharing the same street number (perhaps for historical reasons to do with subdividing the property, or a stuff-up when the street numbers were originally allocated) - where we might have No. 29 and No, 29A Veebelfetzer Street, they'd have 29 and 29 Bis Rue Veeblefetzer. -

Thanks, Druxey. To be honest, I'm pretty amazed myself that I was able to do that back then. I really don't remember how I did it, but it certainly seems to have worked. Here's a photo which gives some idea of the remnants of the railing before I pulled it all to bits for the rebuild:

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

Yes, it would probably have to be coated in something that looked like pitch. Most ships in contemporary illustrations seem to be black (= pitch). Then there's always the "wear and tear" to be expected on a working ship. I can't remember his name, but one of our members in Turkey has done a couple of Turkish working boats with all the mess and neglect you'd expect in such a vessel - and they looked fantastic. Still perhaps it's better to have it pristine. It's be a real shame to mess it up with a bad weathering job after doing such a wonderful job of building it.

-

No, but somehow they just seem to keep turning up . . .

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

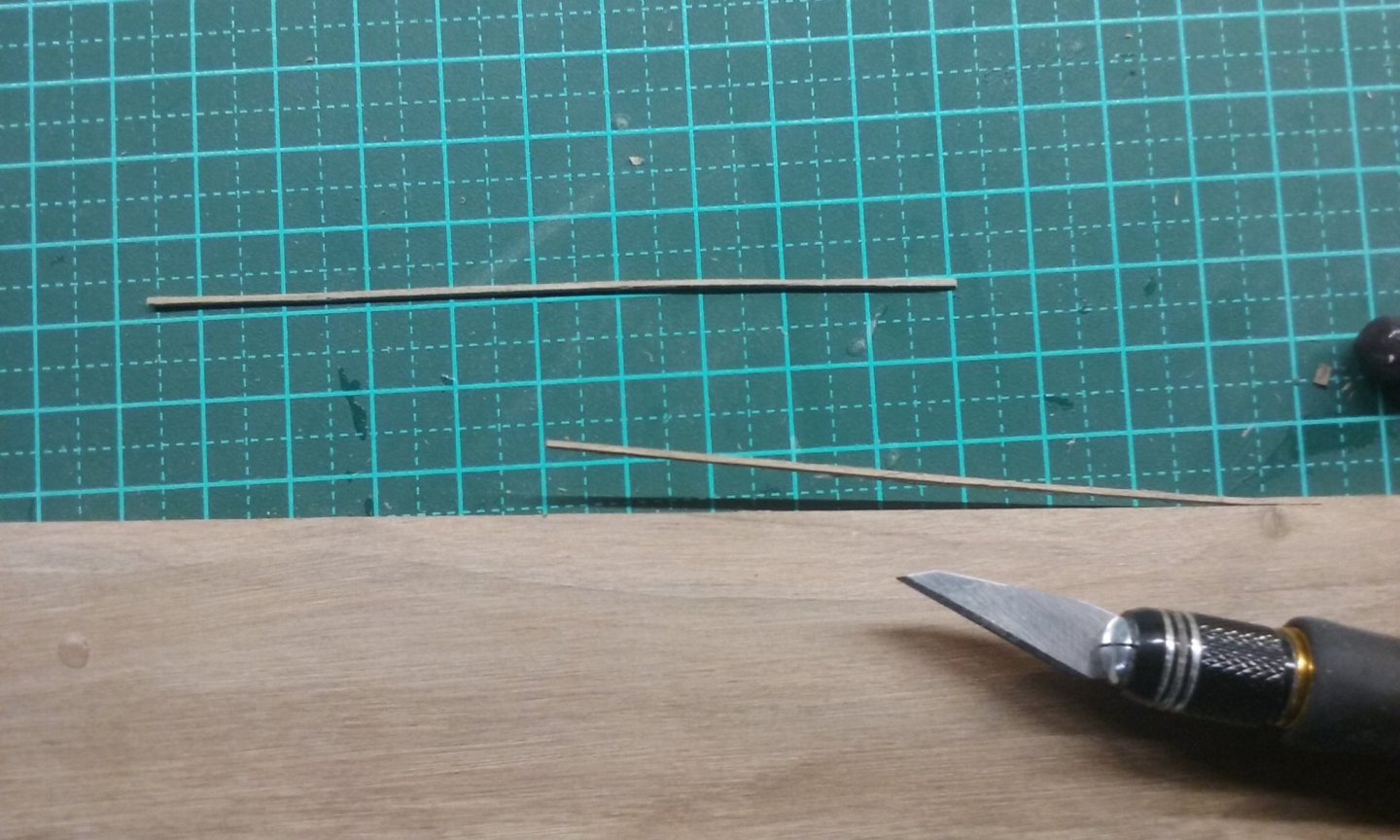

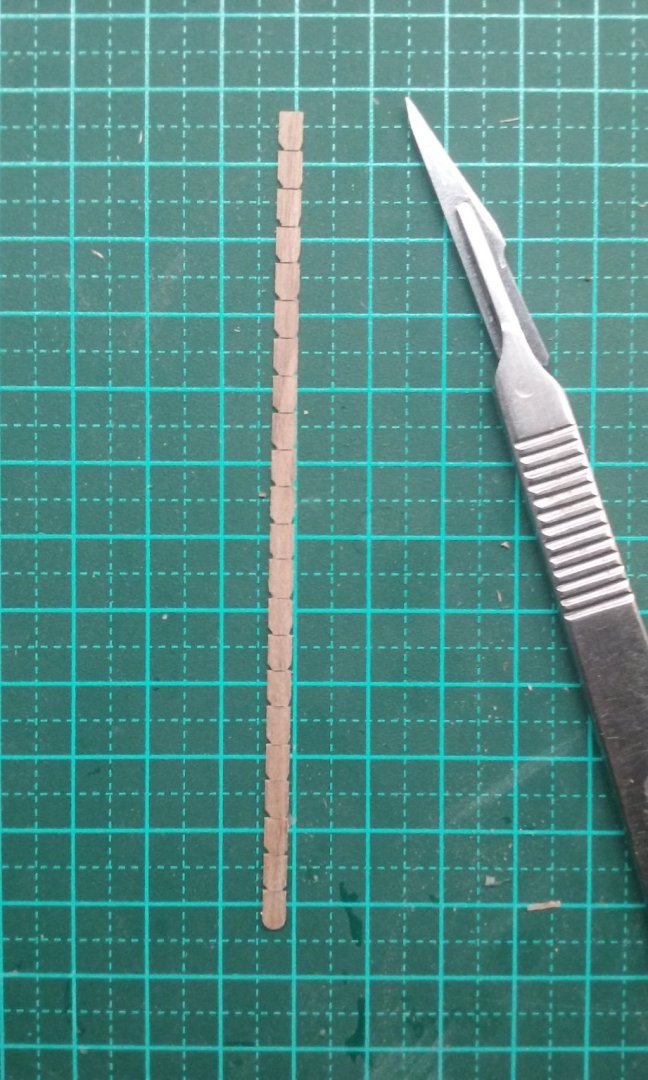

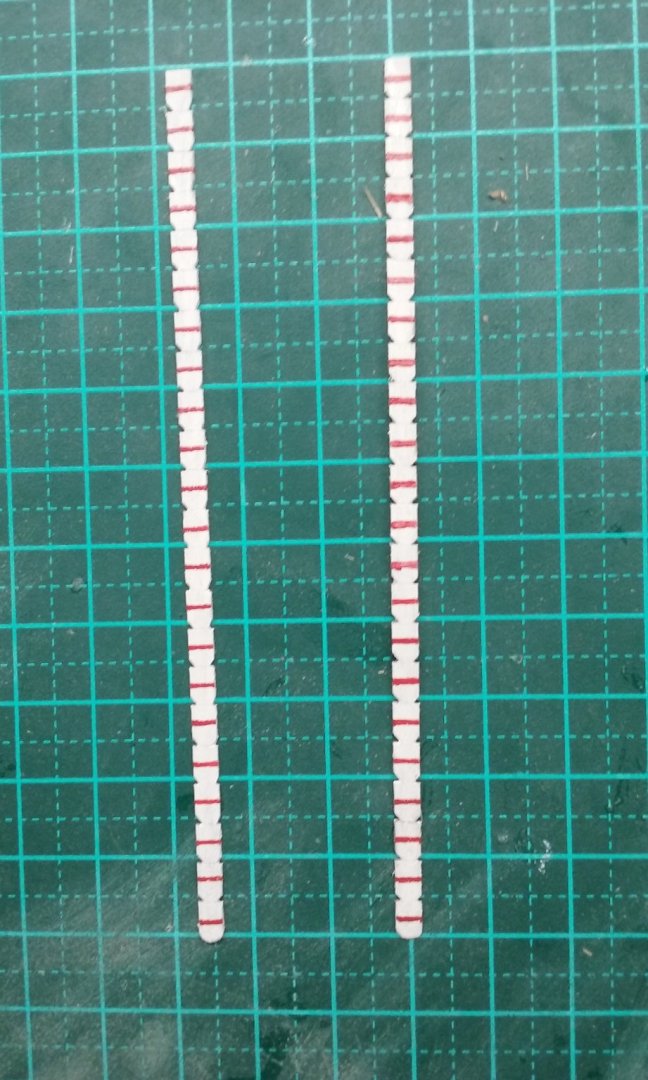

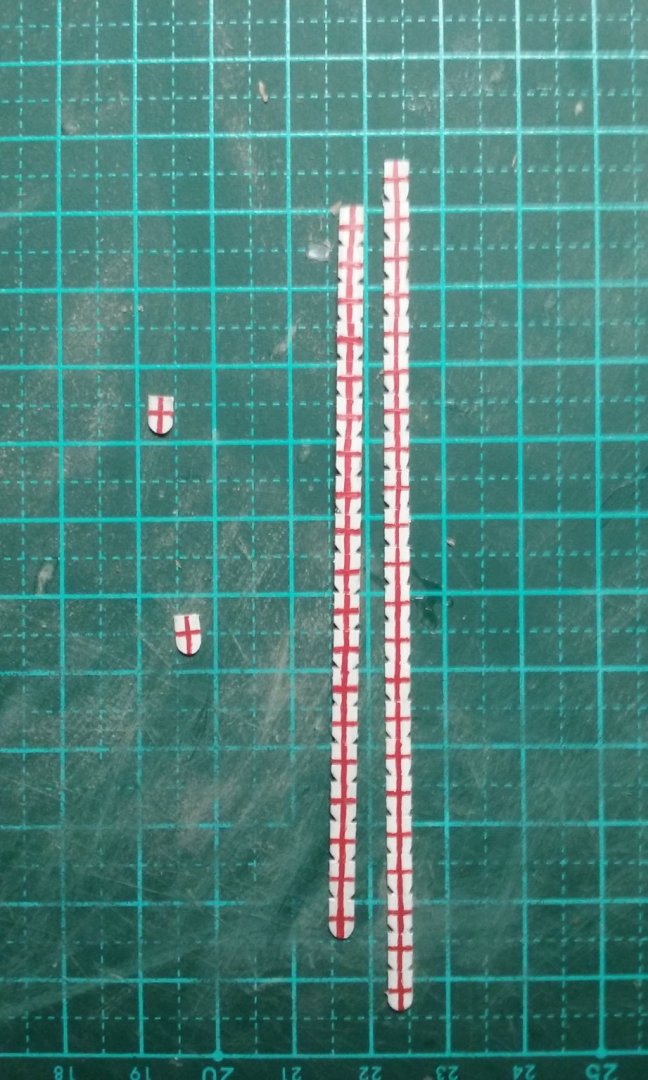

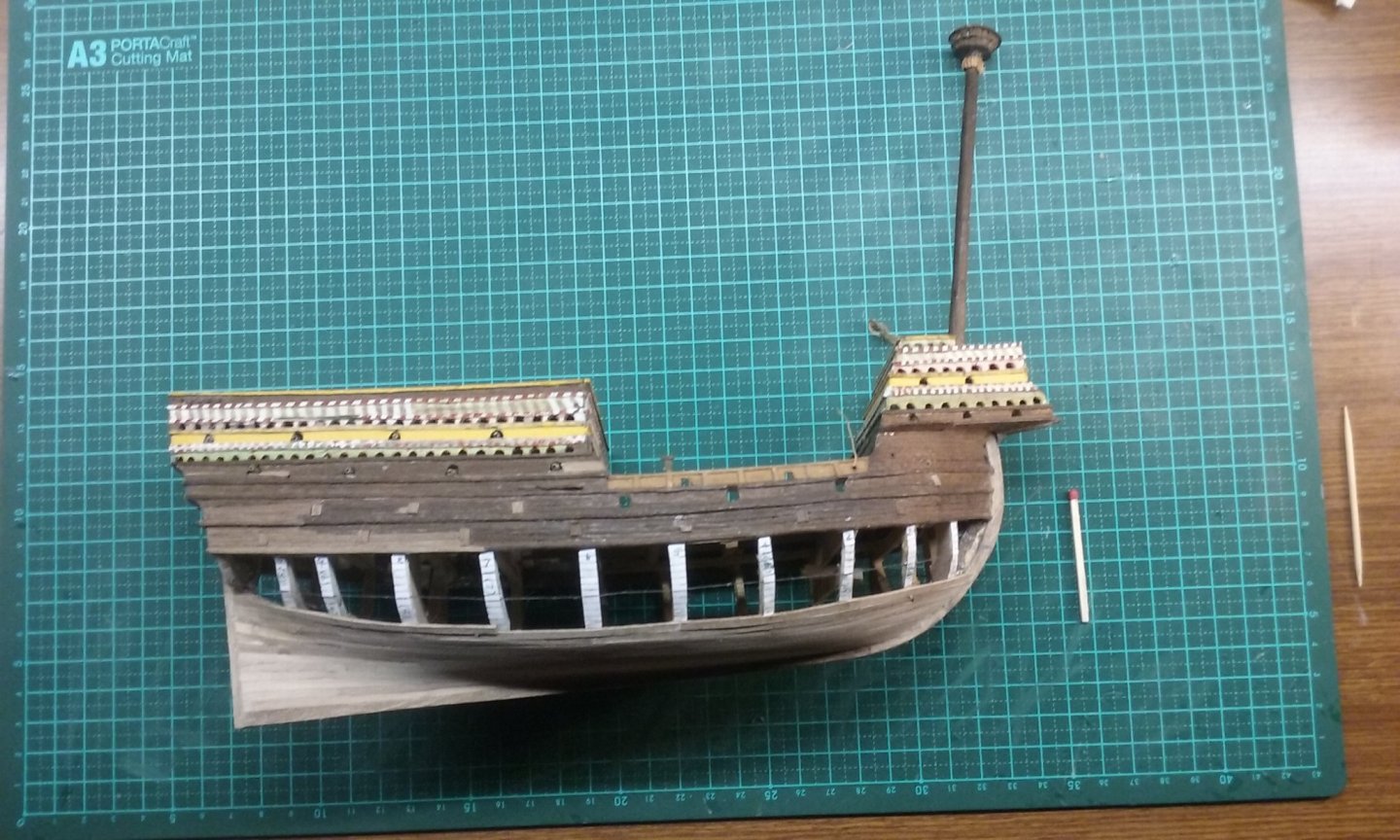

Well, I've done some more planking. It's a long process, and I sorry to say I find it rather tedious. Slowly getting there . . . I've done a few dropped planks here and there to follow the shape of the hull (e.g. there's one from frame 6 aft in the second row down.) I was getting more and more disillusioned with the look of the planking, and worrying that it wouldn't look any good when it was all finished. So I sanded the planks on the starboard side (except for the top two or three runs) to see how it would look. Turned out much better than I'd expected. So my confidence is restored. When I get bored with planking I've started making things that will come into use later. At various places the ship is to have shields with the cross of St George (England's patron Saint) lining the sides - the waist and the fighting tops. It used to have the full set, but many have got lost over the years. So I've had to make replacements. I rounded the edges of these lengths of wood a little, to suggest the curve in the shape of the shields. After the dromon, you'd think I wouldn't get involved in making shields ever again - must be a glutton for punishment. Also, the maintop and foretop are to have railings around them. Again, the ship used to have them but they've been broken over the years. So I've been making a replacement railing for the maintop (I won't do the foretop till later - as I can't remove it from the ship, adding a fragile railing would be a bad idea at this stage). I'm amazed that I was able to make something that fine and fiddly when I was 17 - a case of beginner's luck, I think - or perhaps ignorance is bliss; I didn't realise it was supposed to be difficult so I just barged ahead and did it. But how I got all those uprights to sit vertically when they were just butt-jointed to the edge of the top I really don't know. Perhaps the fact that they were sitting in a thick bath of PVC glue had something to do with it - I had to lift off all this thick layer of glue before I put in the new ones. Still butt-jointed, and getting them all to sit vertical and then attach the circular top rail to them and have it sit properly was a bit of a trial and error job. Here's the railing before bending, plus another piece to be cut into lengths for the balusters And the maintop with the balusters (roughly) in place. You can see that when I first built the model I got up to the point of adding the ratlines to one set of main shrouds but not the other. Same with the foremast. I even made a couple of deadeyes and fixed them to the shrouds - not the correct way at all, but I intend to do it the same way now as I did then. And the railing. It needed a fair bit of tweaking to get it to sit correctly, and there's still a bit of room for improvement, but I'm confident that in the end it will look ok. And here it is with the shields in place. So, more to come in due course. It would be nice to think I'd have all the planking finished by the time I'm ready to post again, but we'll see how that goes. Steven

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

Beautifully worked out and convincing, Dick. A real working vessel. Are you going to weather it when it's complete?

-

Nice work. You're taking it slow and carefully, and it shows in the result.

- 179 replies

-

- longship

- Helga Holm

-

(and 1 more)

Tagged with:

-

Looking for plans or possible models of Magellan's ships.

Louie da fly replied to J11's topic in Nautical/Naval History

You and me both. Though I suppose the Great Harry is really one of those. But at 1:200 scale it's pretty small! -

Looking for plans or possible models of Magellan's ships.

Louie da fly replied to J11's topic in Nautical/Naval History

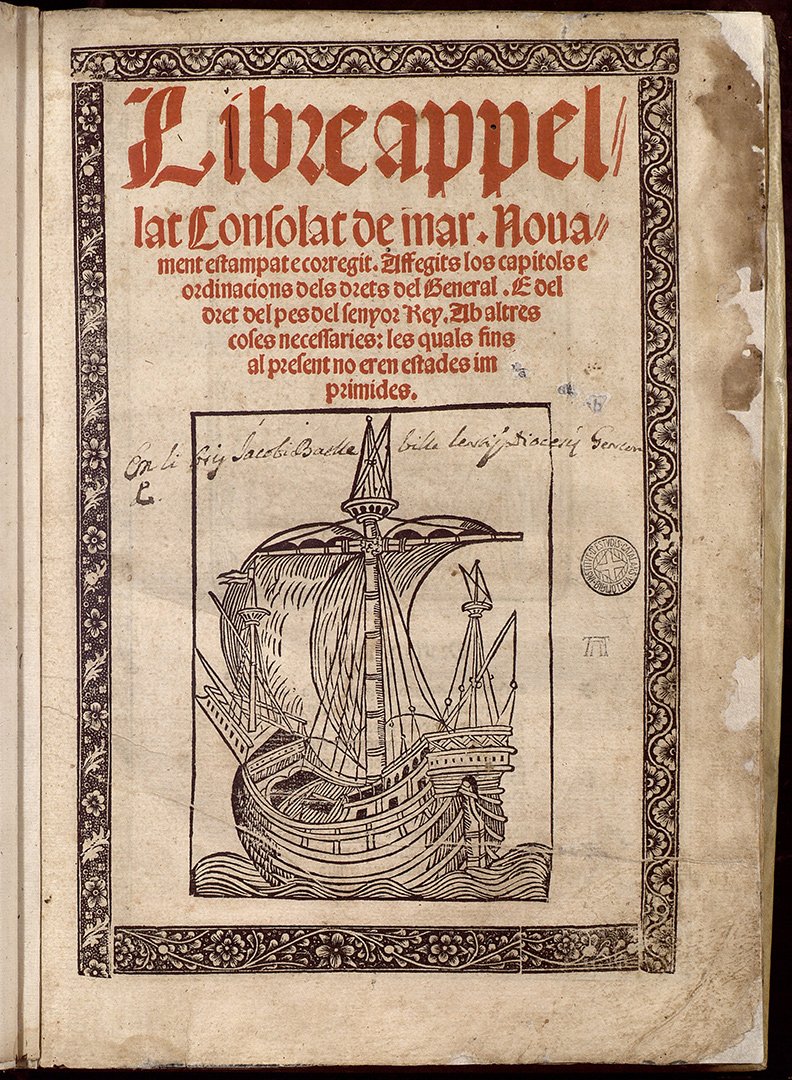

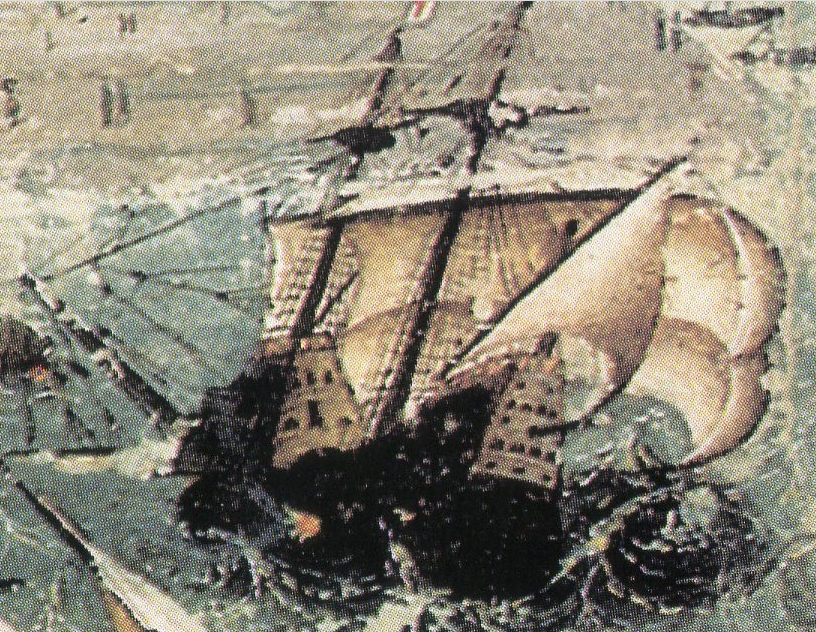

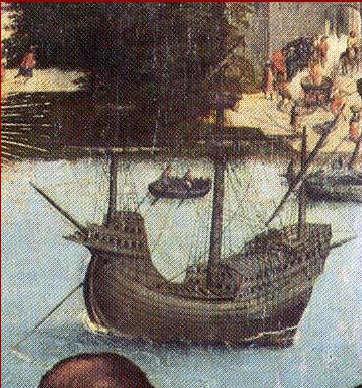

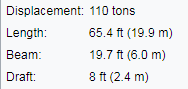

If you compare it with the illustrations, it seems to me the ships in the pictures were beamier than the model. Granted that the transom on the model is taller than on the Catalan line drawing above, the picture still seems to have a wider stern than both the museum model and that of the Santa Maria, and I think this would follow right through for the full length of the hull. Regarding the details, there are of course any number of individual variations between different carracks, and it's very much a judgment call as to which you follow. I'd be following Iberian ships as exemplars as much as possible. However, even Catalonia, despite now being part of Spain, was (a) a separate kingdom at the time and (b) is on the northern Mediterranean coast, not the southern and Atlantic coast. And the Zumaia pictures though from the Atlantic side, are from the very north of Spain, almost into France, whereas the fleet left from Seville, in the far south.. I've just been re-looking at the contemporary pictorial record and a few things have occurred to me. First, though the Zumaia pictures celebrate a victory of 1475, that is not necessarily the date the picture was done - it might have been quite a bit later. Second, there is evidence that bigger ships than I'd been thinking of were in use earlier than I'd been aware of: This is from the view of Lisbon of 1500-1510 that @rybakov put up a link for on the previous page of this thread And this is variously dated 1475 (unlikely), or more probably between 1510 and 1514. It is from the Portuguese painting "S. Joao em Patmos" (St John in Patmos) by the master of Lourinha. If these dates are correct, then some of my statements about the Victoria may be wrong and she may have been bigger and more advanced than I'd thought. Which means the reconstructed ship in Patagonia could be very close to how she actually was (except for the flat stern). Unfortunately, these realisations are probably making your job more difficult rather than less (sorry!) The more I learn the more I realise I don't know . . . However, against this we need to set the fact that when they set out from Seville the Victoria's crew was numbered at 45 with a burthen of 85 tons and the flagship, the Trinidad, had a crew of 62 and a burthen of 110 tons (see https://en.wikipedia.org/wiki/Magellan's_circumnavigation ). This would give a fair idea of the size of the ship and indirectly of the complexity of its form. In comparison, the figures for the Duyfken (which is tiny! So tiny they launched her by hoisting her into the water in a yacht cradle - see https://www.youtube.com/watch?v=HIWE4ot672E - and check out the fishing boats nearby!) are: So Victoria was by no means a big ship. If my maths is correct, the comparative figures would be for a ship of 85 tons - Length: 62 feet, Beam: 18.66 feet Draft: 7.6 feet So probably not one of the "super-carracks" shown above. Back to the Catalan line drawing above after all, I think. -

That's fascinating stuff, Binho. One thing that the link makes clear is that many, if not most weathervanes originally had short metal "streamers" coming out from them - there are still holes showing where they used to be. The "miniatures" show them as they must have been - The other thing is that the ones that had their decoration just engraved rather than "pierced" through the metal plate probably had different decorative motifs on the different sides.

-

Looking for plans or possible models of Magellan's ships.

Louie da fly replied to J11's topic in Nautical/Naval History

Jonathan, that Museo Naval model has a lot going for it, and a lot of things I like, such as the clinker planking at the sides of the aftercastle. However there are a few points I don't agree with - not major, but I think they ought to be noted. As in this Catalonian picture from 1468 the planking at the break of the forecastle should follow the curve of the forecastle rather than be a flat plane (No. 1) and the hull planking immediately below the forecastle should also be curved (No. 2). And it might just be me, but it seems to me that the model is rather too narrow. Also most of the contemporary illustrations (where you can see it) show the forecastle coming to a sharp point rather than cut off as in the model. And this is the case with the Mataro ship model above, as well. This is Catalan, from 1494. In my opinion this picture is probably about as close as you can get to what Victoria really looked like, As I understand it you want plans already drawn rather than having to draft them for yourself (which is totally understandable - a whole extra level of difficulty there!) and they just don't exist to the level of accuracy you need if you want to do a nao as close to the historical Victoria as humanly possible. You might still be best getting a round-sterned Santa Maria kit (the Dusek kit has a round stern but no forecastle, but the hull seems a little narrow) and bashing it to follow the pictorial evidence. I hope this helps. Steven -

Greetings from the Cumberland Mountains

Louie da fly replied to RandyR's topic in New member Introductions

Welcome to MSW, Randy! Having already done some ship modelling in the past you're starting from a better place than some new people. And it's like riding a bike - you never really forget how to do it; you just wobble a bit when you first get back into the saddle. Yes, certainly start a build log. There's a lot of experienced people in the group who you can turn to for advice and help as you embark on this journey. Don't be too concerned if you make mistakes - it's a learning process and your modelling improves every time you do another build. And have fun with it - that's why we do this stuff! -

Welcome to MSW, Mike. I remember when I was a kid learning that Grimsby was a fishing port. And learning later that its name was a Viking one - comes from "Grim" one of Odin's nicknames. I second Mark's advice to start a build log. It's a great way to get help and advice and encouragement. The instructions are here: And you can probably use the search bar at the top right of the page to see if anybody else has done a Caldercraft Bounty. (Actually, I just did, out of interest - there's quite a few of them, including at least two finished models. They should be helpful in doing your own build: https://modelshipworld.com/search/?q=Caldercraft Bounty&quick=1 Don't worry if you make mistakes - we all do that; the more experienced members just make more interesting ones . A lot of very friendly, helpful people here, so ask questions! LOTS of questions! That's what the forum's here for. And have fun.

-

Beautiful work, Clare. Just as well your tiller was such a snug fit! And it's a shame they don't warn you in advance - DO NOT INSTALL TILLER YET!!! - you might have had to unglue it with all the associated chances of breaking something.

- 175 replies

-

- hanse kogge

- shipyard

-

(and 1 more)

Tagged with:

-

Your approach, making two holes instead of a slot is better than the method they recommend in the instructions. Yours will look much more realistic.

-

Funny I never noticed that scene in the movie. I'll have to have another look at it.

- 175 replies

-

- hanse kogge

- shipyard

-

(and 1 more)

Tagged with:

-

Usually called rubbing strakes - or fenders. Very nice work. That's a good looking model, very crisply made.

- 93 replies

-

- santa maria

- amati

-

(and 1 more)

Tagged with:

-

Hmmm, 1190's? Seems a little early for a cog, but what the hey, one or two centuries in a historical movie's not too bad. The Vikings (set in the 860's AD) had quite a nice nef, more appropriate to around 1290, in one of the early scenes.

- 175 replies

-

- hanse kogge

- shipyard

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

annotated.jpg.f1705129c8d339413e82994959594da3.jpg)