-

Posts

1,308 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Kevin Kenny

-

-

- GrandpaPhil, dvm27, tlevine and 5 others

-

8

8

-

I am doing all that Alan, its the scale that is giving me the challenge. Also on the Mill its difficult to see the depth of the cuts. Ive made some 10 scrapers so far but not happy with the results. Today i am going to see of i can hook up one of my cameras and blow it up on a monitor to get a better feel for the depth of cut. My Turbo carver is small enough to cut the curved surfaces on the hacksaw blades but my smallest files are useless.

- mtaylor and billocrates

-

2

2

-

-

-

-

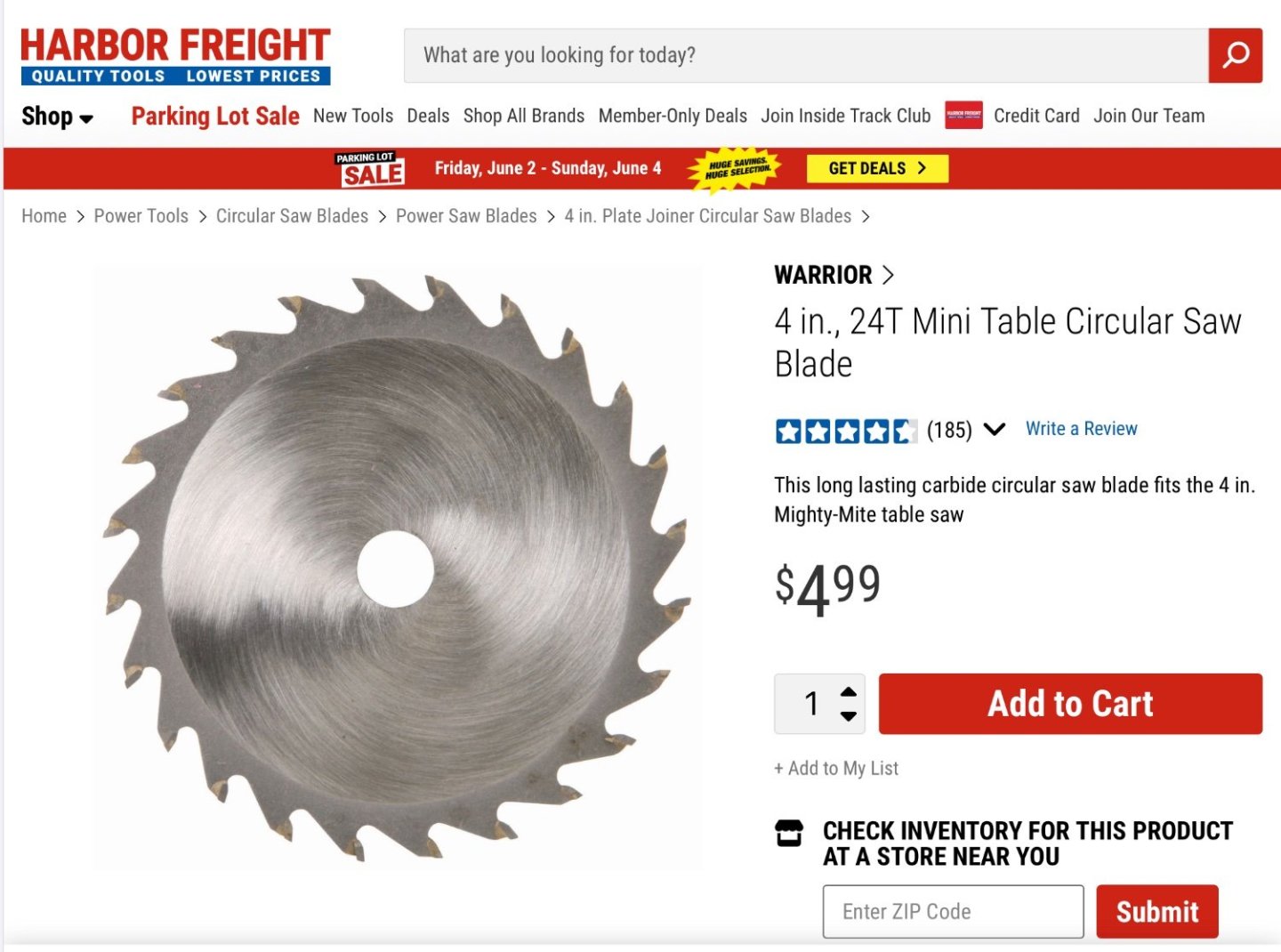

Harbor Freight 4” saw blade.

I forgot to say i purchased a 4” saw blade with a 1/2” arbor for the Jim Byrnes saw and it works great. Its a bit noisy but i can now make 7/8th cuts when making bulk stock. It is a bit noisy but works great. At $5.00 how can you go wrong. In the past i used my Proxxon to do this work but it would struggle when making large amounts of stock.

- mtaylor, GrandpaPhil, KentM and 1 other

-

4

4

-

-

Thats exactly how i made them Greg and it worked great. The only problem i had in the beginning is when shaping they got hot and the solder melted, so i used jewelry soft solder and that solved the melting issue.

- KentM, mtaylor, billocrates and 1 other

-

4

4

-

Your soldering work is epic.

kevin

- mtaylor, giampieroricci and usedtosail

-

2

2

-

1

1

-

You make it look so easy. Beautiful work as usual.

- mtaylor, dvm27 and giampieroricci

-

2

2

-

1

1

-

-

-

-

-

- James G, yvesvidal, chris watton and 6 others

-

9

9

-

-

-

-

-

-

-

- billocrates, albert, GrandpaPhil and 5 others

-

7

7

-

1

1

-

- AON, billocrates, druxey and 5 others

-

8

8

-

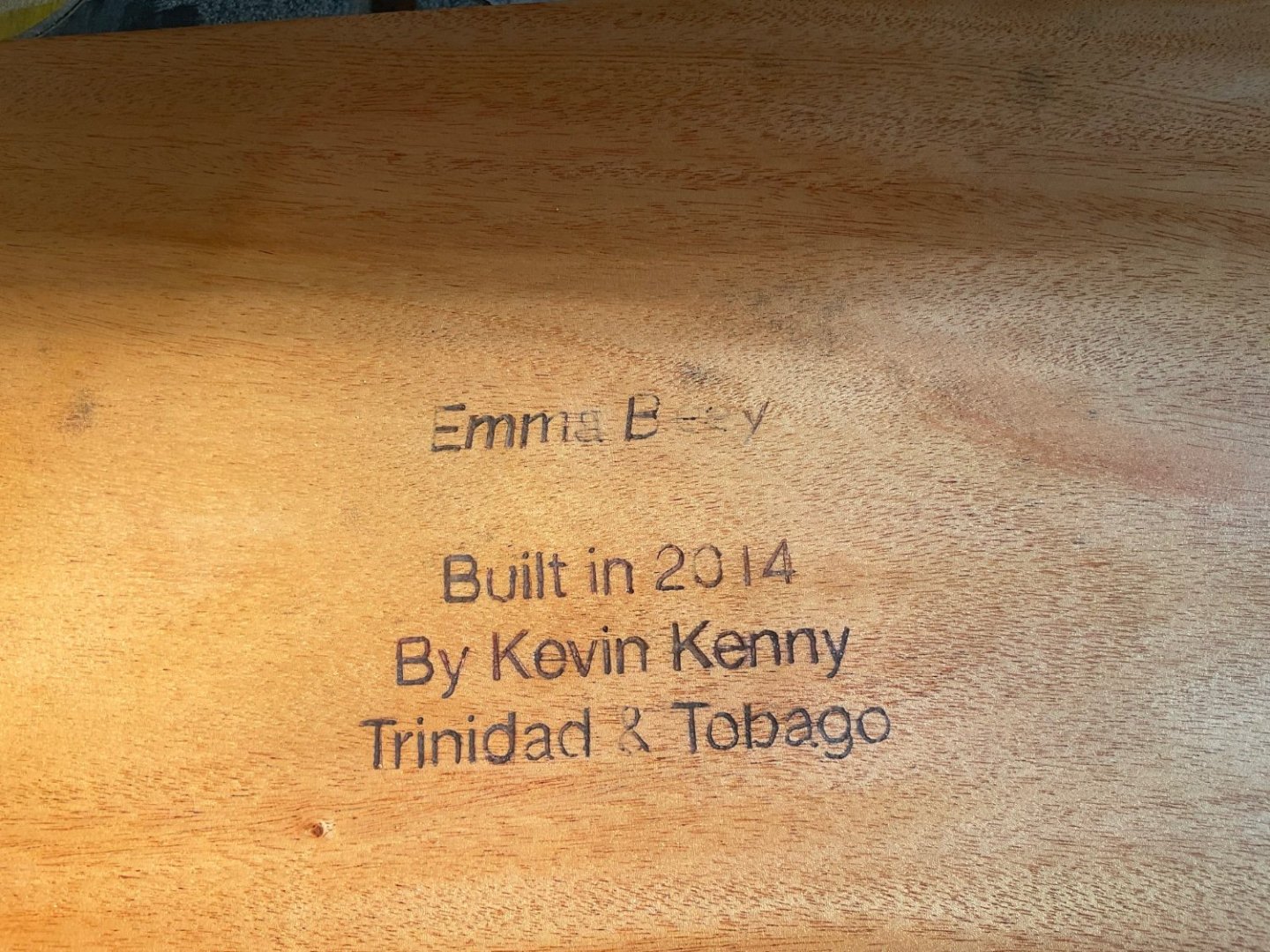

HMS Thorn by Kevin Kenny - Swan class 1:48 scale - David Antscherl practium

in - Build logs for subjects built 1751 - 1800

Posted

Lots of very good questions,

let me say that the process was based on my research. I do not pretend to be an expert in this field,

quenching to soften. It was particularly mentioned that steel that is brought up to a slow heat should not be quenched as it will become brittle. They specifically suggest that it should be left to cool at room temperature. Apparently this is different for gold and silver and specific only for steel.

tempering. There are different opinions about the temperature and the time it should stay at that temperature. The objective here is again to slowly bring the piece up to a low red heat. This temperature is supposed to be around 250 to 300. when this happens and to check that the correct temperature has been reached and you have a magnet check the steel to see if it has lost all its magnetic properties. This is the critical temperature. At this point it is dunked in the oil. The type of oil does not seem to be important except for environmental issues. At 300 degrees there is little chance of fire. Some use cooking oil some use old discarded motor oil. Water is not recommended as it will again make the metal brittle. The time spent in the oven is just to get to temperature slowly back to the 250 to 300 degrees. Once achieved You simply turn off the over and let it cool naturally providing your wife does not come around and want to know what you are doing in her oven. This was my big problem as we were renovating her kitchen at the time hence the use of the toaster oven. The swishing of the steel in the oil is an old holdback from my drinking days as i was a rum salesman.