-

Posts

10,605 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ccoyle

-

I was going to mention the 1:250 card model published by Paper Shipwright and still available from them as either a printed kit or free download.

-

Welcome aboard!

-

I have resurrected this pathetic, long-dead topic only to share with you what can be done with this very kit by those card modeling wizards over in Poland. Oh, that I should ever possess such skills! Curtiss H-75 P.S. Stumbled across that thread quite by accident while searching for info on an unrelated kit.

-

Very nice! Much sleeker-looking than a typical cutter.

- 57 replies

-

- Trial

- Vanguard Models

-

(and 1 more)

Tagged with:

-

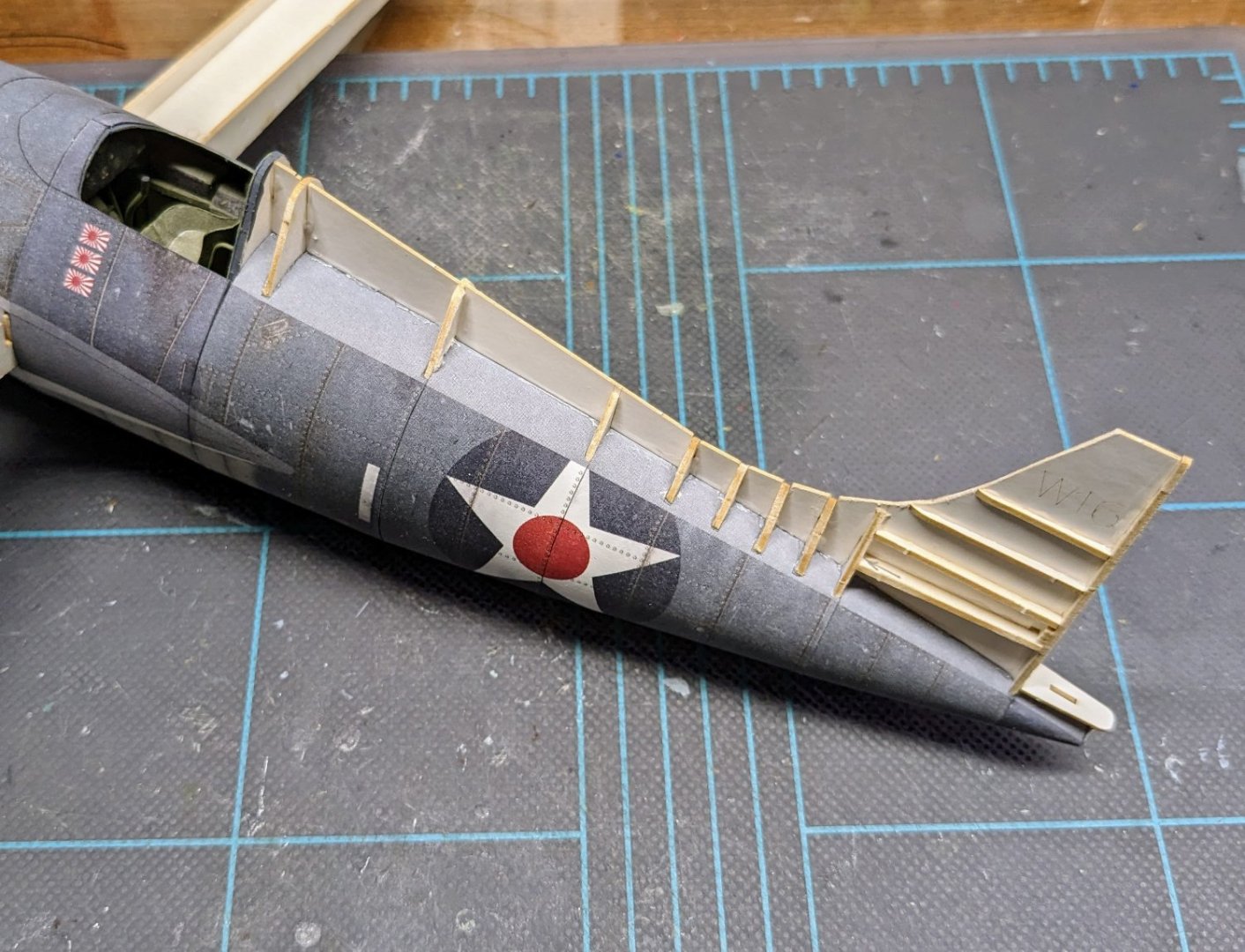

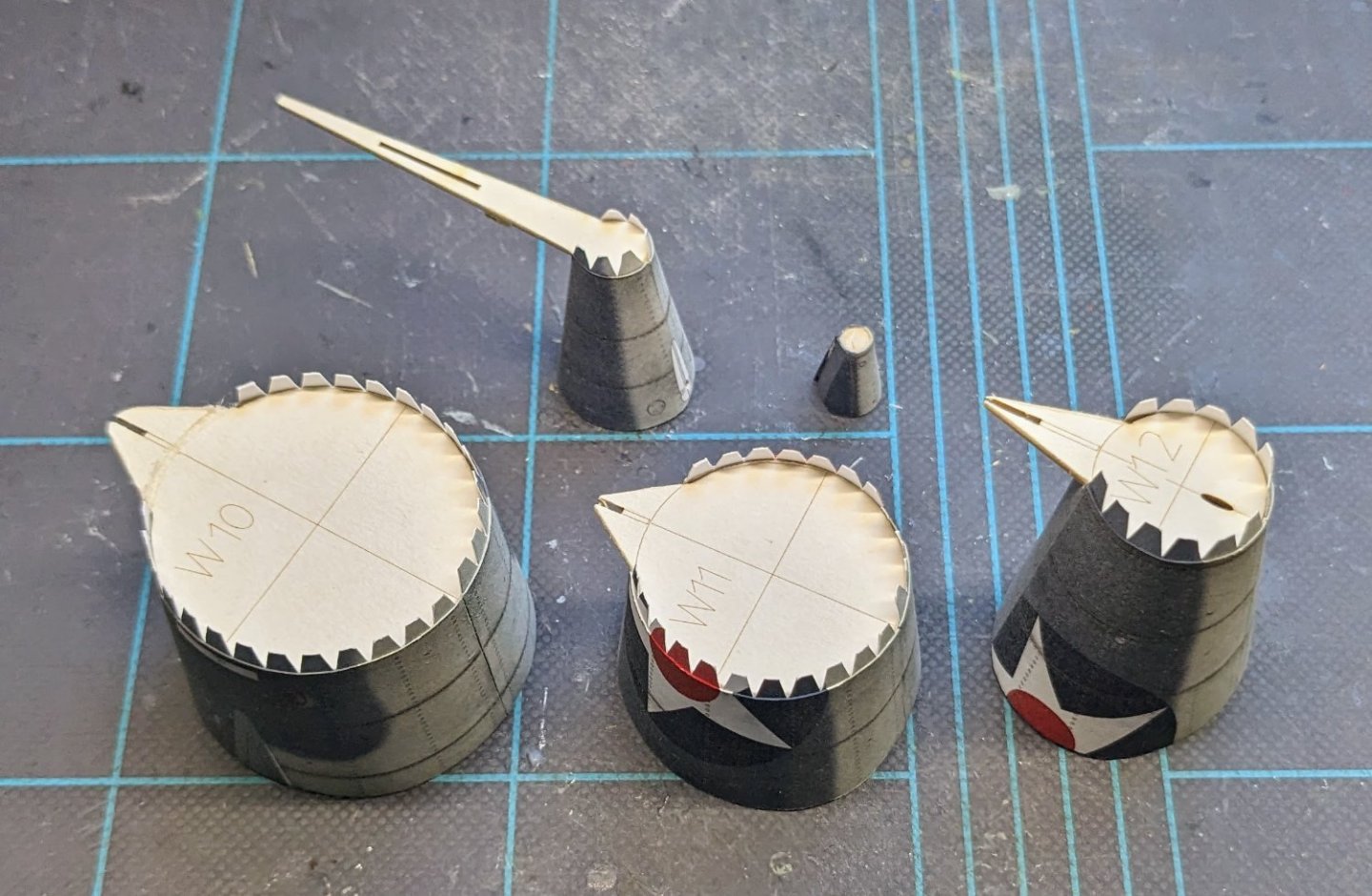

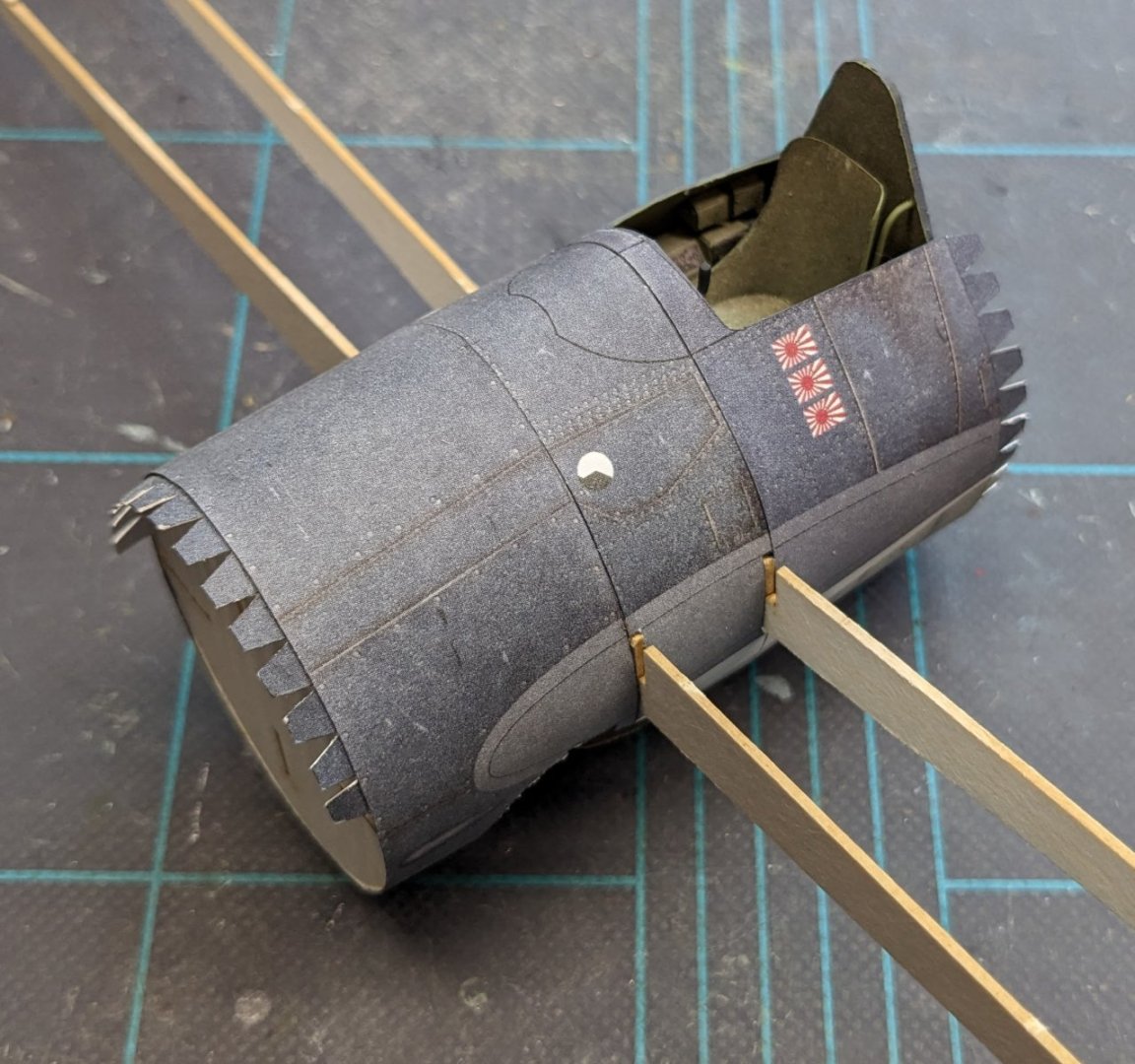

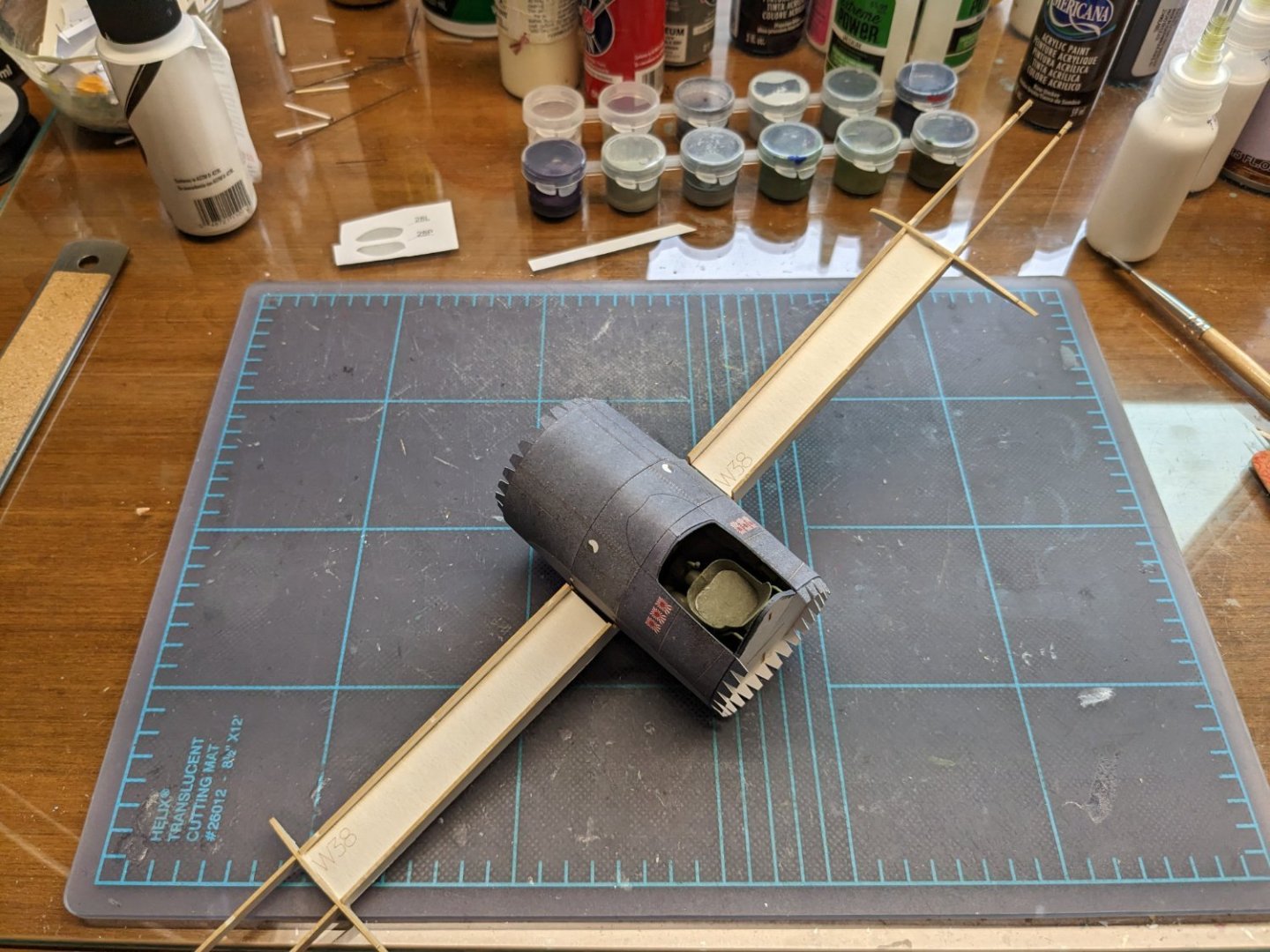

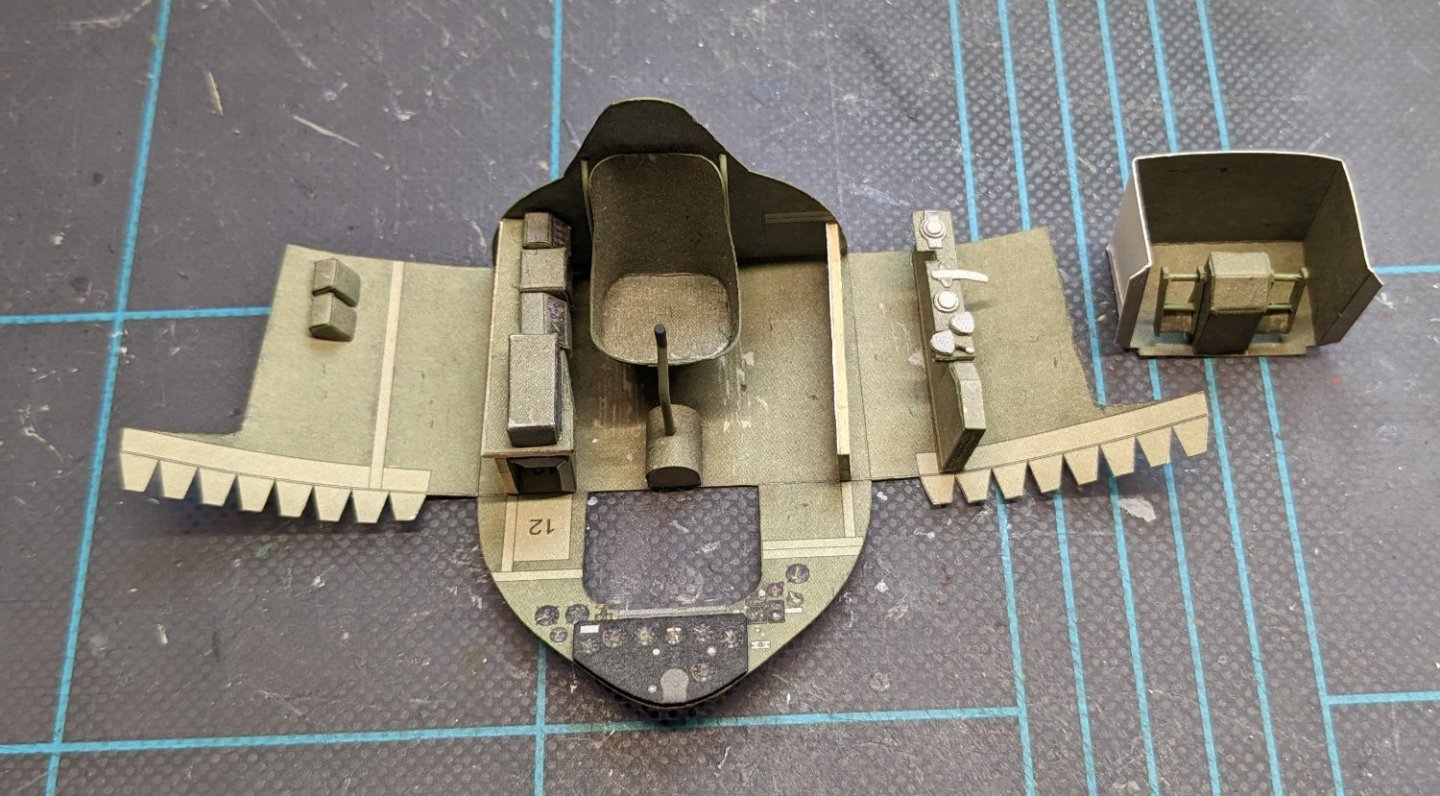

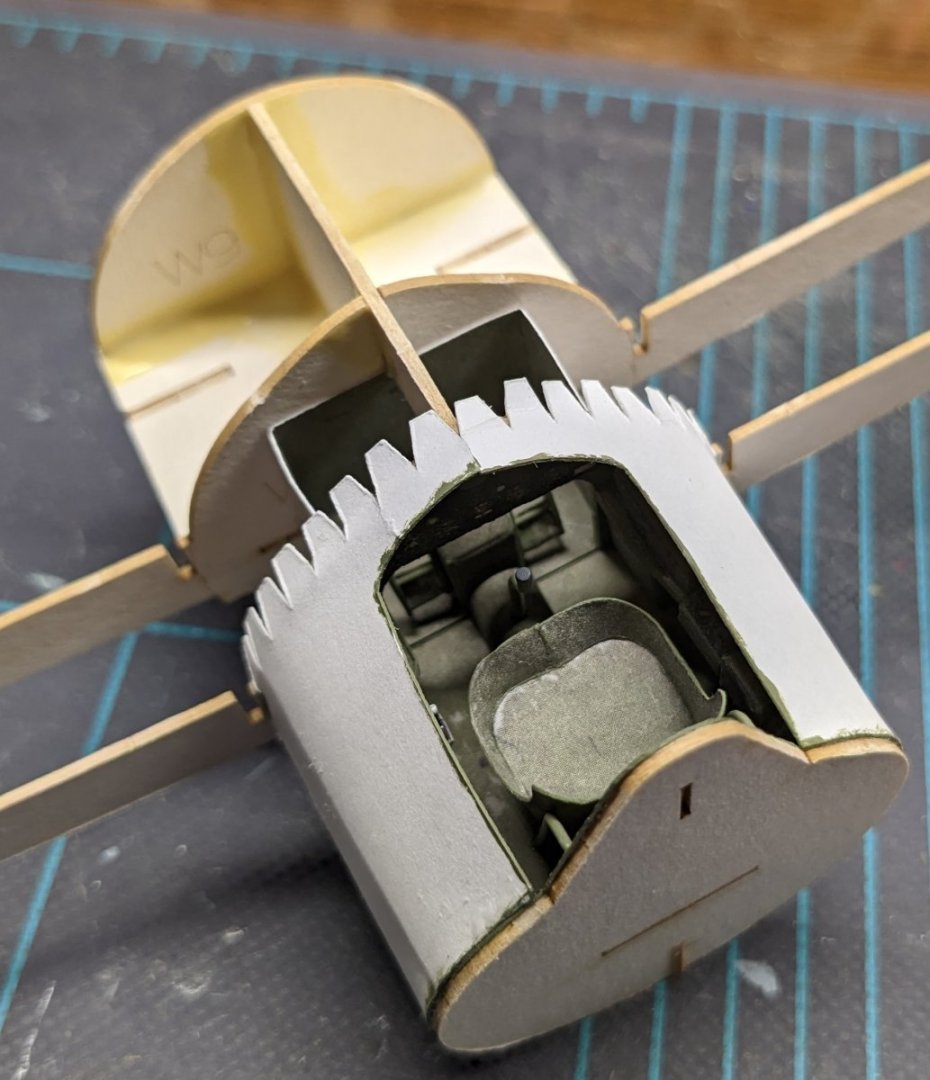

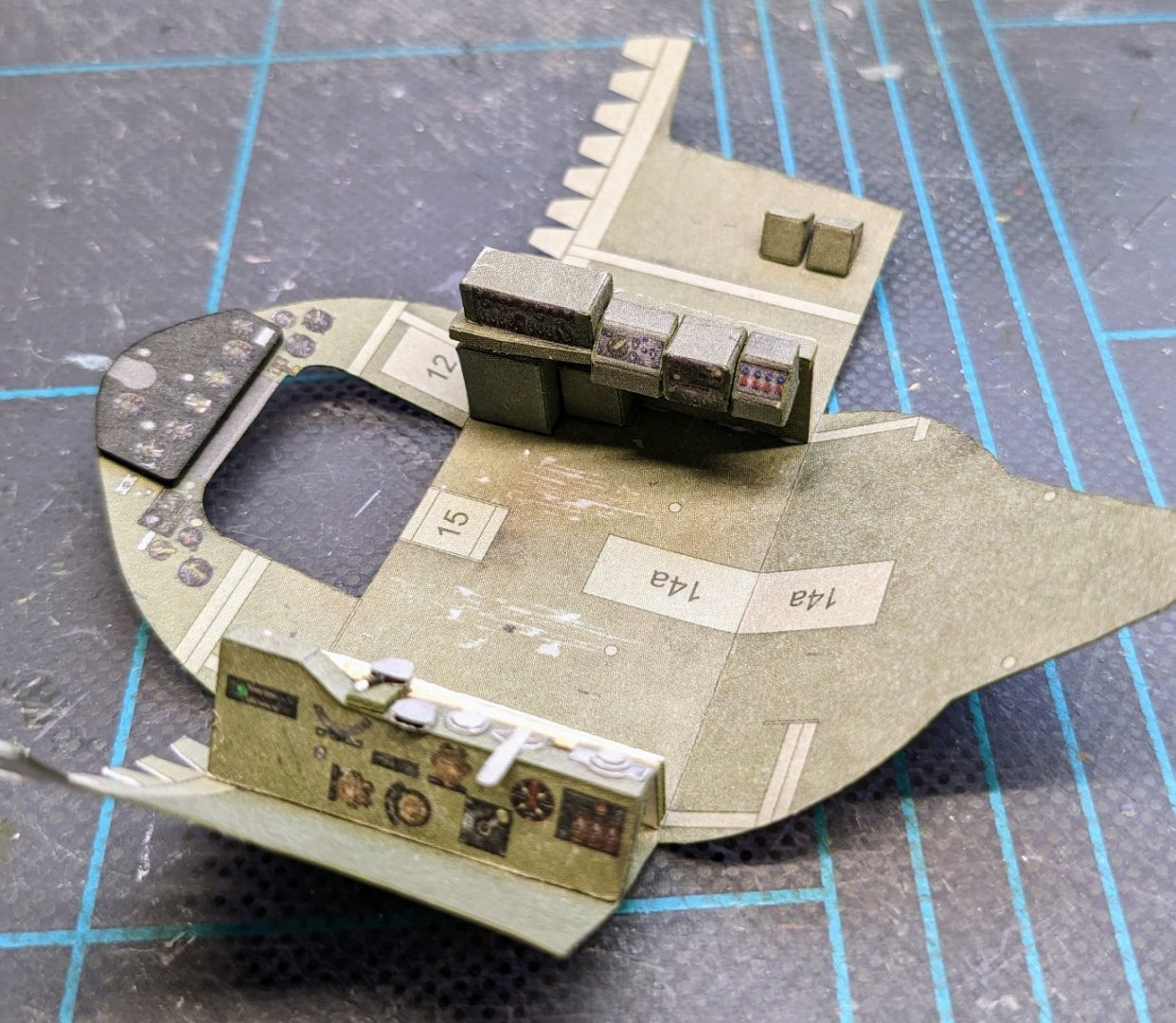

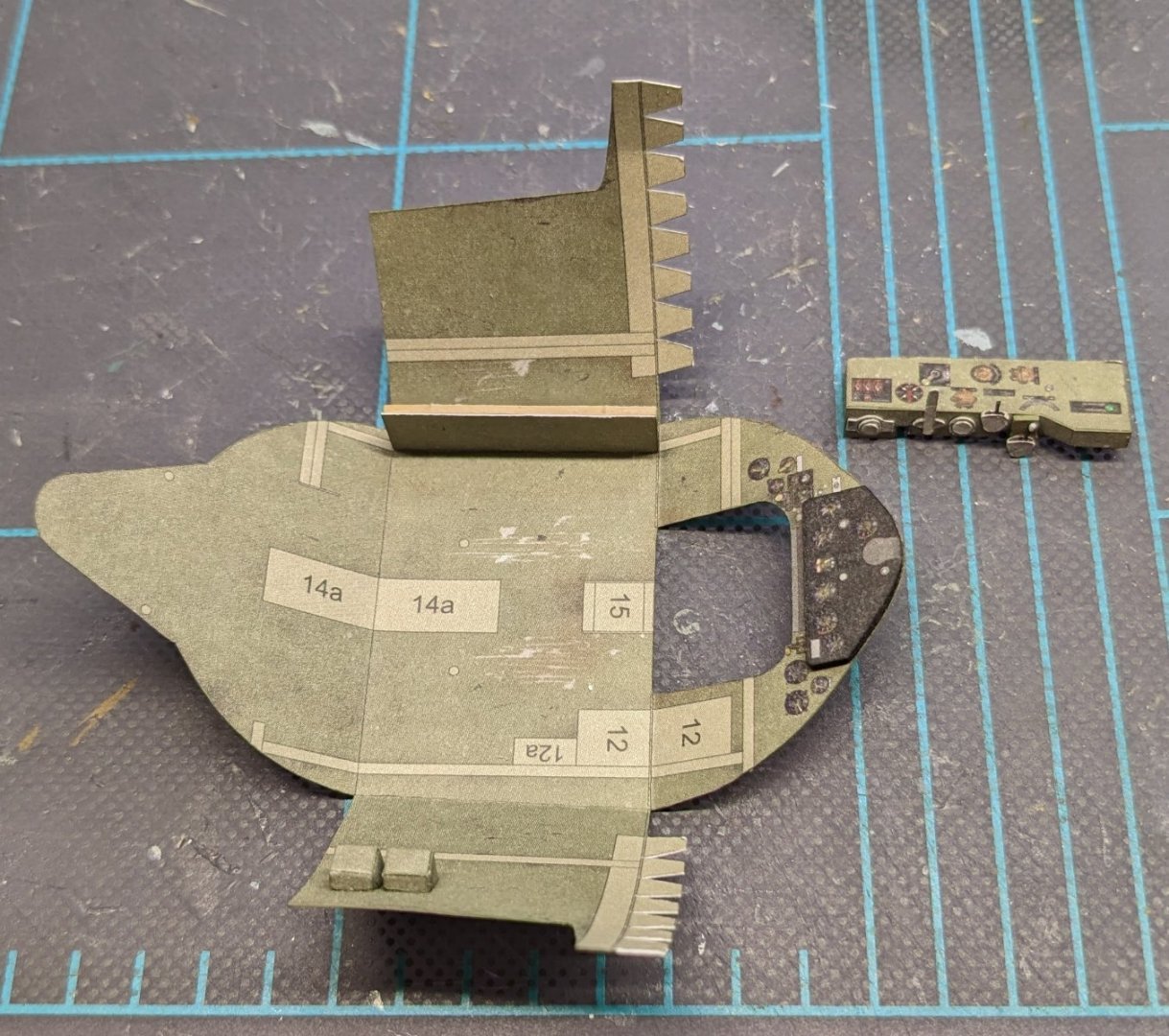

With the cockpit closed up, it's time to start skinning the forward fuselage, beginning with the wheel wells. I'm now committed to eventually building the Wildcat's nightmarish landing gear. 😬 To this point, I've been following the sequence of diagrams pretty closely, but for anyone who decides to build this kit later, it's a good idea to add the flat skins of the wheel wells before gluing the frames together. You can still do it afterwards, but it's a little trickier, because that central girder is part of one of the frames, and it clearly gets in the way. Then we have the first two fuselage skins added. Fit and registration has been good, although there seems to have been a deliberate omission of certain joiner strips. I added homemade ones -- no biggie. There's a very slight color mismatch between the second and third skins, but strangely enough it's only on one side. The parts came from the same sheet, too, so it's kind of weird. But the difference is not as noticeable as it was for the GPM Hellcat kit, so I won't complain. Once again, the fit for this part was very good. I then decided to skip ahead a bit and add some of the wing skeleton parts, just to stiffen up the spindly spars a bit. They were beginning to get uncomfortably wobbly from being jostled around. Interestingly, there are multiple errors in the numbering of these parts between the diagrams and the laser-cut frets. This hasn't been an issue so far because it's pretty obvious which parts are which and where they're supposed to go. That's all for now!

-

Moin moin, Marius! Cala Esmeralda is a beautiful ship -- I'm very fond of topsail schooners. Good luck on your project!

-

Welcome to MSW, Sam!

-

As Allan said, you can certainly spruce up your model however you like. That being said, I would probably shy away from adding ratlines. All of the sails on a small schooner could be raised and lowered from the deck -- there was simply no need for sailors to go aloft, so ratlines would look a bit out of place.

-

Hoping for a speedy recovery, Glenn. Backs are weird -- they can go out for the most seemingly innocuous of reasons.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Looks great! What's the new project?

- 4 replies

-

- San Francisco

- Artesania Latina

-

(and 2 more)

Tagged with:

-

If you want to take your oars up a notch, you can try flattening the blades and slimming the shafts. Fiddly work, but I think you'll like the result.

- 177 replies

-

- Perseverance

- Modellers Shipyard

-

(and 1 more)

Tagged with:

-

Chaz, 1/96 scale for sailing ships is a real challenge in any medium. I think you would find it very helpful to try one of the simpler free models that dot the internet landscape. You can find links in the card modeling tutorial.

- 8 replies

-

- Le Coureur

- Shipyard

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.