russ

Members-

Posts

3,086 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by russ

-

Copper Plating Pattern

russ replied to capnharv2's topic in Building, Framing, Planking and plating a ships hull and deck

In the late 18th century, British warships had the plates ending at an angle without the top belt of copper. They used a wooden batten to mark the waterline and the plates butted into the wooden batten at an angle. This has been noted on early coppered models like the Bellona. In the 19th century, it became the custom (and perhaps a rule) to add that top strip of copper plates. How a model should be coppered really depends on the time period and perhaps nationality of the ship in question. Russ -

The doors are looking good so far. I like the idea simulating hinges. If the flattened wire does not work out, you can get very thin brass strip or sheet to make them. You can also use paper or tape painted black to simulate them. The hinges can be made from your wire. Russ

- 773 replies

-

- san francisco ii

- artesania latina

-

(and 1 more)

Tagged with:

-

David: Check my signature for the skiff build. The advice you give about using PVA glue is good stuff. Slow and steady wins the race in modeling. Russ

- 51 replies

-

- sharpie schooner

- finished

-

(and 1 more)

Tagged with:

-

Al: The best advice I can give is to find barrels that are a rough match for the size of the barrels you need. You are looking for a barrel about 2 1/4" long, maybe slightly smaller. That would be about 9 ft long at 1/48 scale. Model Expo and Bluejacket Shipcrafters are two companies I can think of off the top of my head where you can look for different size barrels. They are not going to sell them by scale so much as size. You need to look for the size barrel you need. Russ

-

I am glad your reposting this log. There was a lot of good stuff in it. Russ

- 51 replies

-

- sharpie schooner

- finished

-

(and 1 more)

Tagged with:

-

Sam: Thanks. The transom is, more or less, straight across. For fitting around the stern frames, I did that using trial and error. Mostly error. The steeve is the slight upward angle at which the bowsprit points out beyond the hull. In this case it is governed quite a bit by the sheer (curve) of the deck. The bowsprit wants to continue that graceful curve of the deck's sheer. The catboat restoration continues. I will repost it eventually. Just need to make some time and some progress. Russ

-

Augie: I have just been looking over your build here. The photos with the standing rigging in place are awesome. The entire model is just outstanding. Paintwork, details, nice taut rigging, and some good looking spars so far. Great work indeed. I will be checking in to see how you progress from here. Russ

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Augie: I agree that they were incredible craftsmen. I will add one other item about Martin Fountain. He could not read or write, but according to the family, he could do any math in his head. The story goes that he could look at a table of offsets and tell you whether or not the resulting design would work. That is incredible, especially for people like me who struggle with anything beyond simple math. Russ

-

Augie: Thanks for the kind words. These boats were very graceful for being so shallow. This particular boat is patterned after a schooner called American Girl built by Martin Fountain in 1900. My design is for a slightly smaller boat and the size was necessary for the client. In any case, Fountain was a master designer and builder here in Biloxi so he gets a good deal of the credit for this particular design. Russ

-

Very nice work, especially with that thin veneer. That stuff is not easy to deal with. Russ

- 773 replies

-

- san francisco ii

- artesania latina

-

(and 1 more)

Tagged with:

-

Cap'n Bob: Thanks. No one is more surprised than me. Michael: Thanks for looking in. I am going to add a stanchion at about the midpoint of the scupper opening and then one at each end of the opening and then fill in between them. I will use a plank for a gauge to make sure the opening stays consistent. Once the opening has been dealt with, I will add at the bow and stern. Russ

-

Bob: Nice work on the headrails. You created those very well. I especially like the rudder and the preventer chains. The gudgeons and pintles look great. If you had not said they were paper, I would not have guessed. Likewise on the quarter badges. That is a wonderful job with the kit casing. Looks every bit wood to my eyes. Excellent work. Russ

-

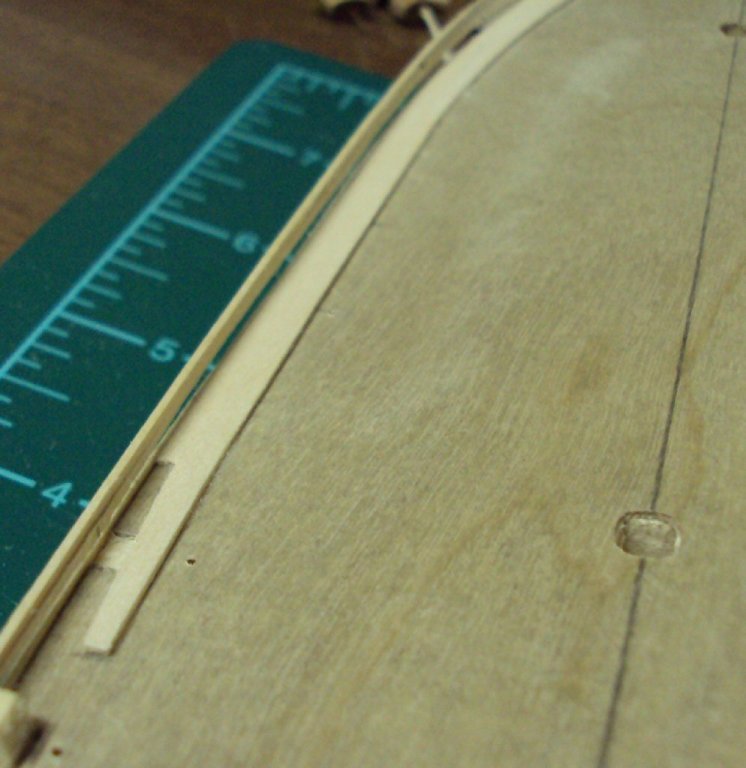

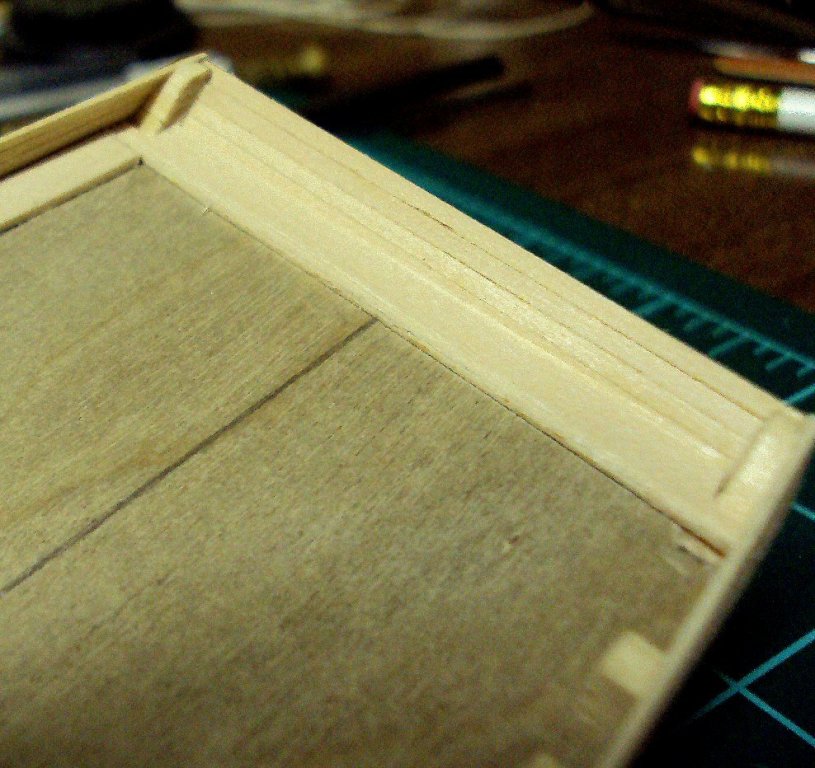

Finally some more progress. I am installing the margin plank on deck. This needs careful handling and I am glad to say I have not made a complete hash of it so far. The first thing is to remove the bulkhead extensions above deck. The bulwarks have already been planked and so they are largely unsupported during the margin plank installation. There are some frightening moments during the fitting of the margin plank. The good news is that the joints are fairly tight. The bad news is you can hardly see my scarph joints. Questions and comments welcomed. Russ

-

Ron: I used to be able to tell you right off the top of my head the thickness of the deadeye, but I cannot recall the source I read it in. However, I "think" (not to be trusted) the deadeye's thickness is half its diameter. Your deadeye jig should be that depth (whatever it is) so that you can cut the deadeye off in the jig and then pop it out afterwards. If someone knows for sure the relative thickness, please correct me here. Russ

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.